Cold Plasma Technology for Tomato Processing By-Product Valorization: The Case of Tomato Peeling and Peel Drying

Abstract

1. Introduction

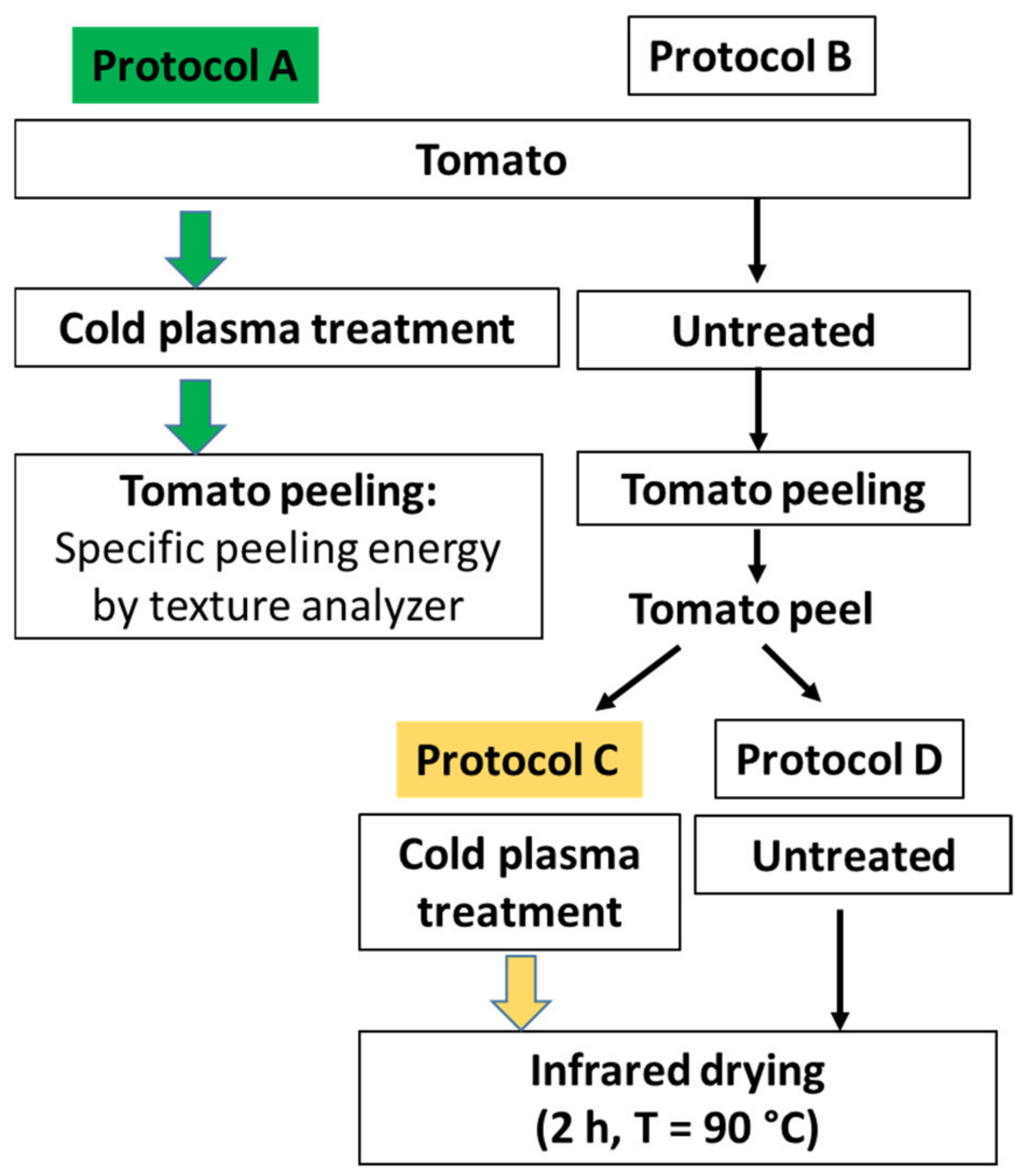

2. Materials and Methods

2.1. Materials

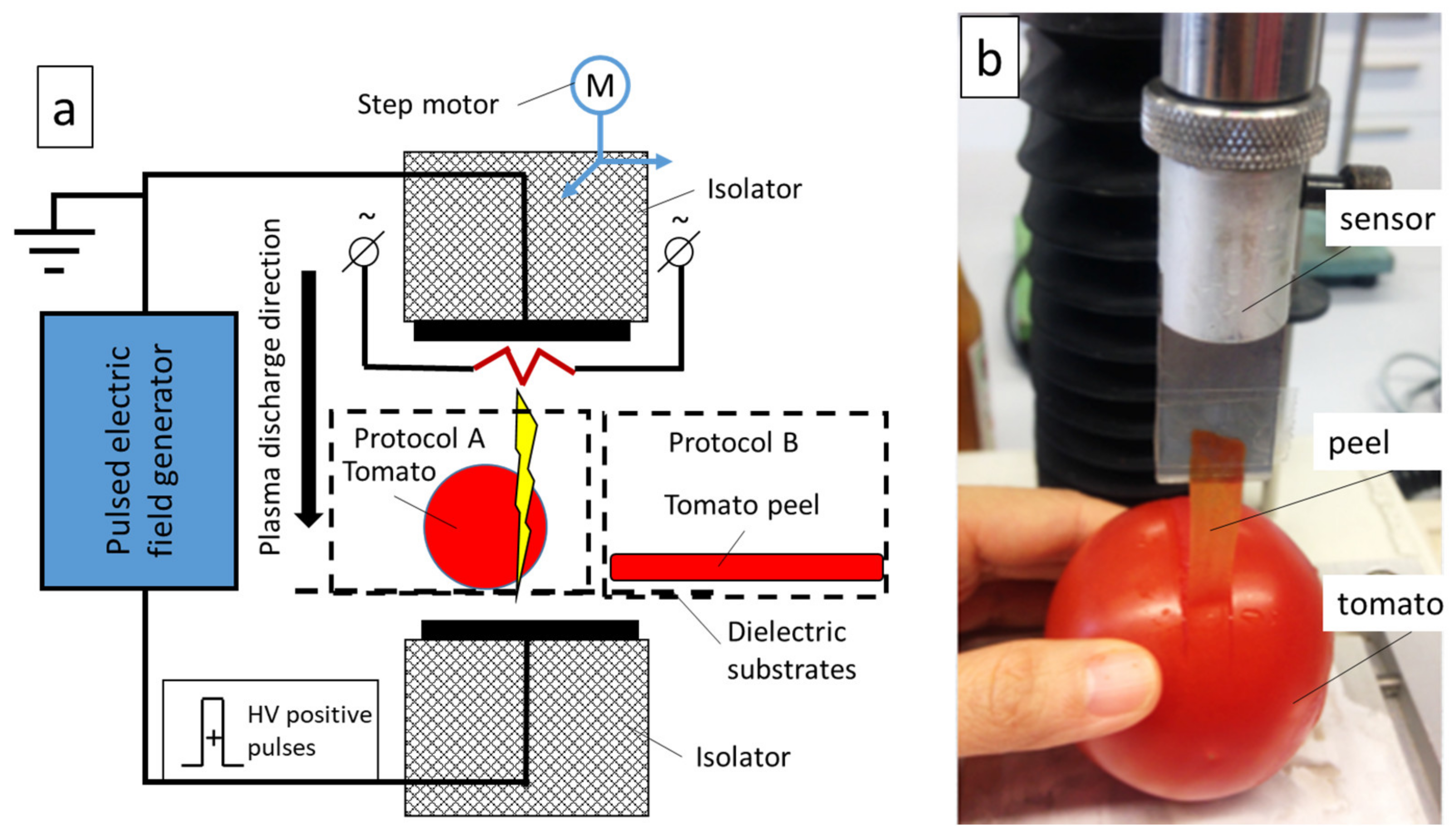

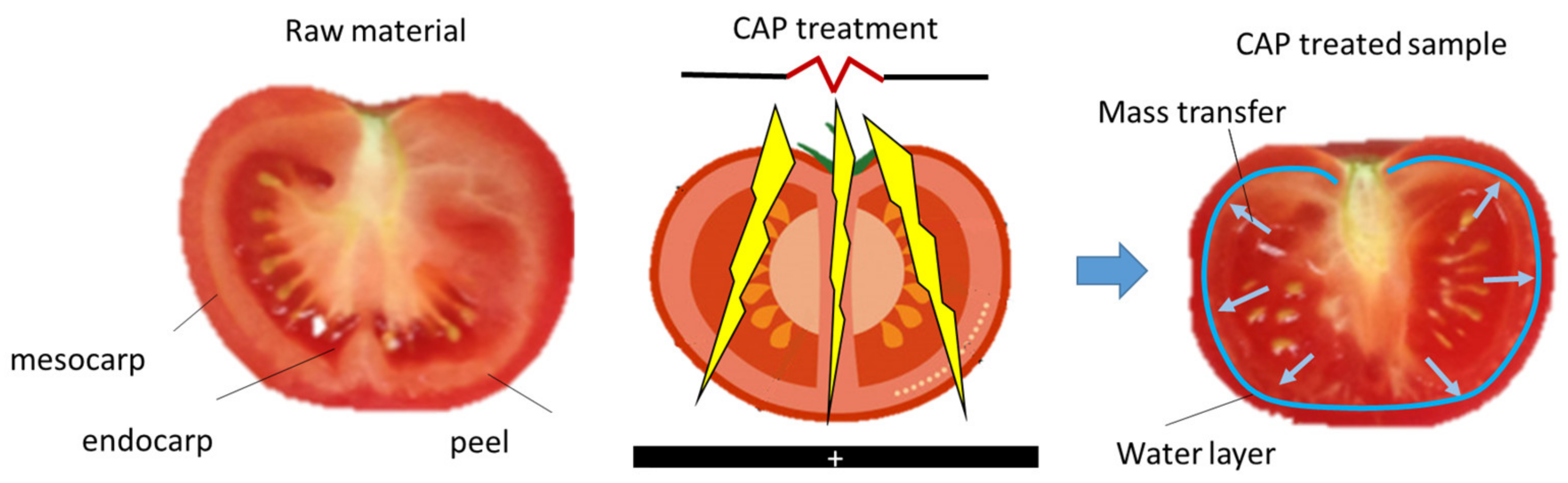

2.2. Cold Plasma Treatment

2.3. Skin Removal

2.4. Peel Drying

2.5. Extraction and Quantification of Total Carotenoids and Total Phenolic Compounds

2.6. Energy Aspects of CAP Treatment and Drying

2.7. Statistical Analysis

3. Results and Discussion

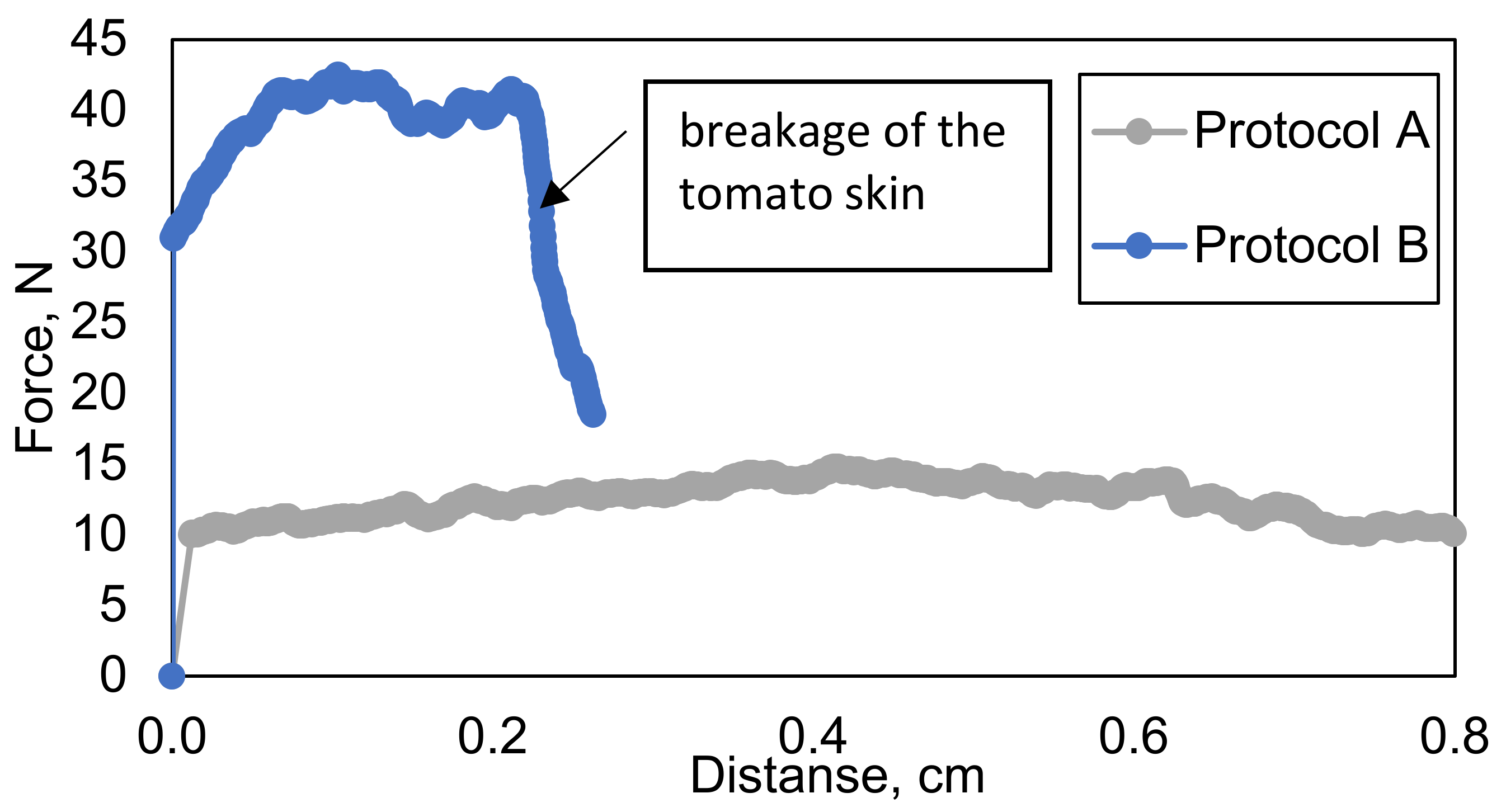

3.1. Improvement in Peeling of Whole Tomato

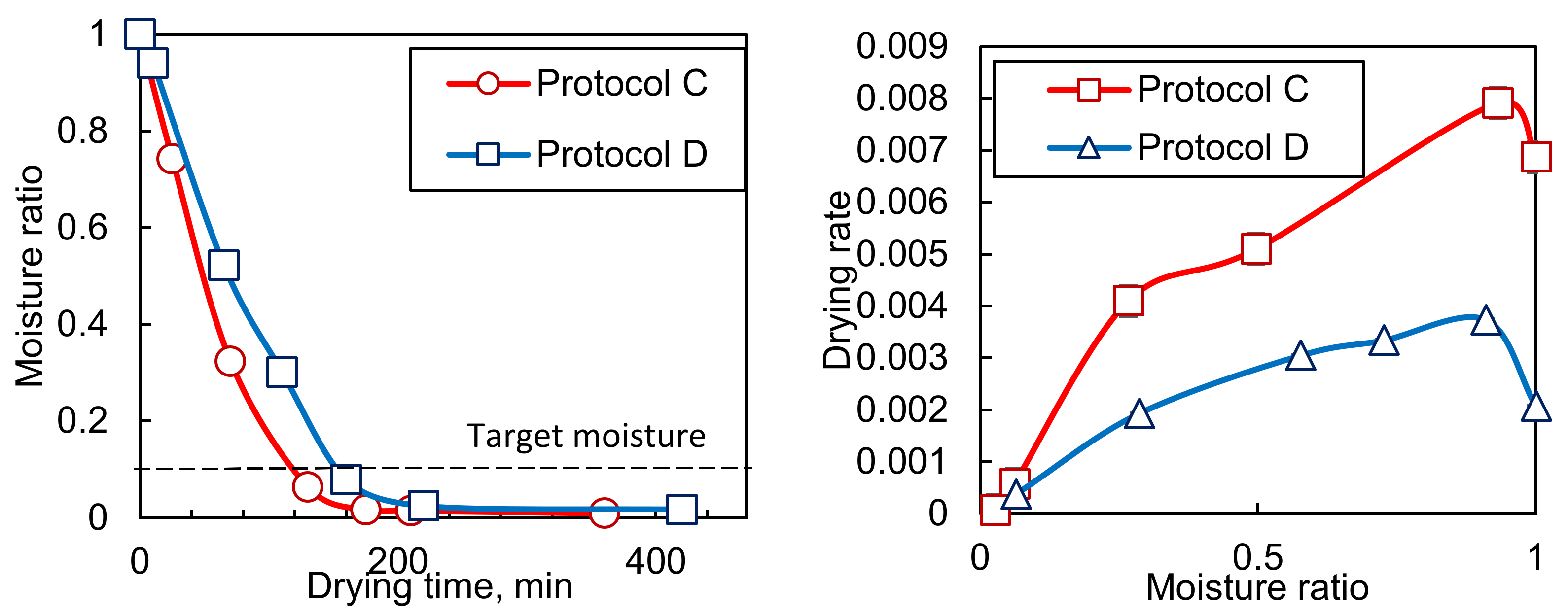

3.2. Improvement in Tomato Peel Drying

3.3. Improvement in Quality Characteristics

3.4. Improvement in Energy Consumption

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eslami, E.; Carpentieri, S.; Pataro, G.; Ferrari, G. A Comprehensive Overview of Tomato Processing By-Product Valorization by Conventional Methods versus Emerging Technologies. Foods 2023, 12, 166. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.F.B.; Tushar, S.R.; Zaman, S.M.; Gonzalez, E.D.R.S.; Bari, A.B.M.M.; Karmaker, C.L. Analysis of the drivers of Agriculture 4.0 implementation in the emerging economies: Implications towards sustainability and food security. Green Technol. Sustain. 2023, 1, 100021. [Google Scholar] [CrossRef]

- Gharibzahedi, S.M.T.; Smith, B.; Guo, Y. Pectin extraction from common fig skin by different methods: The physicochemical, rheological, functional, and structural evaluations. Int. J. Biol. Macromol. 2019, 136, 275–283. [Google Scholar] [CrossRef] [PubMed]

- Nawaz, A.; Ali, S.W.; Irshad, S.; Irshad, F.; Ahmed, A.; Sharmeen, Z.; Khan, I. Effect of peeling and unpeeling on yield, chemical structure, morphology and pasting properties of starch extracted from three diverse potato cultivars of Pakistan. Int. J. Food Sci. Technol. 2020, 55, 2344–2351. [Google Scholar] [CrossRef]

- Wu, X.; Yu, L.; Pehrsson, P.R. Are processed tomato products as nutritious as fresh tomatoes? Scoping review on the effects of industrial processing on nutrients and bioactive compounds in tomatoes. Adv. Nutr. 2022, 13, 138–151. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, J.; Gao, R.; Ye, F.; Zhao, G. Sustainable valorisation of tomato pomace: A comprehensive review. Trends Food Sci. Technol. 2019, 86, 172–187. [Google Scholar] [CrossRef]

- Grassino, A.N.; Brnčić, M.; Vikić-Topić, D.; Roca, S.; Dent, M.; Brnčić, S.R. Ultrasound assisted extraction and characterization of pectin from tomato waste. Food Chem. 2016, 198, 93–100. [Google Scholar] [CrossRef]

- Sengar, A.S.; Rawson, A.; Muthiah, M.; Kalakandan, S.K. Comparison of different ultrasound assisted extraction techniques for pectin from tomato processing waste. Ultrason. Sonochem. 2020, 61, 104812. [Google Scholar] [CrossRef]

- Vidyarthi, S.K.; El Mashad, H.M.; Khir, R.; Zhang, R.; Tiwari, R.; Pan, Z. Quasi-static mechanical properties of tomato peels produced from catalytic infrared and lye peeling. J. Food Eng. 2019, 254, 10–16. [Google Scholar] [CrossRef]

- Koch, Y.; Witt, J.; Lammerskitten, A.; Siemer, C.; Toepfl, S. The influence of Pulsed Electric Fields (PEF) on the peeling ability of different fruits and vegetables. J. Food Eng. 2022, 322, 110938. [Google Scholar] [CrossRef]

- Gavahian, M.; Sastry, S.K. Ohmic-assisted peeling of fruits: Understanding the mechanisms involved, effective parameters, and prospective applications in the food industry. Trends Food Sci. Technol. 2020, 106, 345–354. [Google Scholar] [CrossRef]

- Grassino, A.N.; Pedisić, S.; Dragović-Uzelac, V.; Karlović, S.; Ježek, D.; Bosiljkov, T. Insight into high-hydrostatic pressure extraction of polyphenols from tomato peel waste. Plant Foods Hum. Nutr. 2020, 75, 427–433. [Google Scholar] [CrossRef]

- Shorstkii, I. Application of cold filamentary microplasma pretreatment assisted by thermionic emission for potato drying. Innov. Food Sci. Emerg. Technol. 2020, 66, 102540. [Google Scholar] [CrossRef]

- Bassey, E.J.; Cheng, J.H.; Sun, D.W. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci. Technol. 2021, 112, 137–148. [Google Scholar] [CrossRef]

- Du, Y.; Yang, F.; Yu, H.; Xie, Y.; Yao, W. Improving food drying performance by cold plasma pretreatment: A systematic review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 4402–4421. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Karim, N.; Bao, T.; Gowd, V.; Ding, T.; Sun, C.; Chen, W. Cold plasma pretreatment–A novel approach to improve the hot air drying characteristics, kinetic parameters, and nutritional attributes of shiitake mushroom. Dry. Technol. 2020, 38, 2134–2150. [Google Scholar] [CrossRef]

- Chizoba Ekezie, F.-G.; Sun, D.-W.; Cheng, J.-H. A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends Food Sci. Technol. 2017, 69, 46–58. [Google Scholar] [CrossRef]

- Bao, Y.; Reddivari, L.; Huang, J.-Y. Development of cold plasma pretreatment for improving phenolics extractability from tomato pomace. Innov. Food Sci. Emerg. Technol. 2020, 65, 102445. [Google Scholar] [CrossRef]

- De Araújo Bezerra, J.; Lamarão, C.V.; Sanches, E.A.; Rodrigues, S.; Fernandes, F.A.N.; Ramos, G.L.P.A.; Esmerino, E.A.; Cruz, A.G.; Campelo, P.H. Cold plasma as a pre-treatment for processing improvement in food: A review. Food Res. Int. 2023, 167, 112663. [Google Scholar] [CrossRef] [PubMed]

- Shorstkii, I.; Koshevoi, E. Drying Technology Assisted by Nonthermal Pulsed Filamentary Microplasma Treatment: Theory and Practice. ChemEngineering 2019, 3, 91. [Google Scholar] [CrossRef]

- Andreou, V.; Dimopoulos, G.; Dermesonlouoglou, E.; Taoukis, P. Application of pulsed electric fields to improve product yield and waste valorization in industrial tomato processing. J. Food Eng. 2020, 270, 109778. [Google Scholar] [CrossRef]

- Tappi, S.; Berardinelli, A.; Ragni, L.; Dalla Rosa, M.; Guarnieri, A.; Rocculi, P. Atmospheric gas plasma treatment of fresh-cut apples. Innov. Food Sci. Emerg. Technol. 2014, 21, 114–122. [Google Scholar] [CrossRef]

- Chaple, S.; Sarangapani, C.; Jones, J.; Carey, E.; Causeret, L.; Genson, A.; Duffy, B.; Bourke, P. Effect of atmospheric cold plasma on the functional properties of whole wheat (Triticum aestivum L.) grain and wheat flour. Innov. Food Sci. Emerg. Technol. 2020, 66, 102529. [Google Scholar] [CrossRef]

- Bao, T.; Hao, X.; Shishir, M.R.I.; Karim, N.; Chen, W. Cold plasma: An emerging pretreatment technology for the drying of jujube slices. Food Chem. 2021, 337, 127783. [Google Scholar] [CrossRef] [PubMed]

- Sakudo, A.; Misawa, T.; Yagyu, Y. Equipment design for cold plasma disinfection of food products. In Advances in Cold Plasma Applications for Food Safety and Preservation; Elsevier: Amsterdam, The Netherlands, 2020; pp. 289–307. [Google Scholar]

- Shorstkii, I.; Stuehmeier-Niehe, C.; Sosnin, M.; Mounassar, E.H.A.; Comiotto-Alles, M.; Siemer, C.; Toepfl, S. Pulsed Electric Field Treatment Application to Improve Product Yield and Efficiency of Bioactive Compounds through Extraction from Peels in Kiwifruit Processing. J. Food Process. Preserv. 2023, 2023, 8172255. [Google Scholar] [CrossRef]

- Li, X.; Pan, Z.; Atungulu, G.G.; Zheng, X.; Wood, D.; Delwiche, M.; McHugh, T.H. Peeling of tomatoes using novel infrared radiation heating technology. Innov. Food Sci. Emerg. Technol. 2014, 21, 123–130. [Google Scholar] [CrossRef]

- Krishnamurthy, K.; Khurana, H.K.; Soojin, J.; Irudayaraj, J.; Demirci, A. An overview on ultrafiltration in food processing. Compr. Rev. Food Sci. Food Saf. 2008, 7, 2–13. [Google Scholar] [CrossRef]

- Liu, Z.; Song, Y.; Guo, Y.; Wang, H.; Wu, Z. Influence of Pulsed Electric Field Pretreatment on Vacuum Freeze-dried Apples and Process Parameter Optimization. Adv. J. Food Sci. Technol. 2017, 13, 224–235. [Google Scholar] [CrossRef]

- Velioglu, Y.S.; Mazza, G.; Gao, L.; Oomah, B.D. Antioxidant Activity and Total Phenolics in Selected Fruits, Vegetables, and Grain Products. J. Agric. Food Chem. 1998, 46, 4113–4117. [Google Scholar] [CrossRef]

- Khudyakov, D.; Sosnin, M.; Munassar, E.M.A.; Techakanon, C.; Siemer, C.; Toepfl, S.; Shorstkii, I. Pulsed Electric Field Processing as an Effective Tomato Peeling Method. Food Process. Tech. Technol. 2022, 1748, 189–198. [Google Scholar] [CrossRef]

- Zhang, X.; Zhong, C.; Mujumdar, A.S.; Yang, X. Full title: Cold plasma pretreatment enhances drying kinetics and quality attributes of chili pepper (Capsicum annuum L.). J. Food Eng. 2019, 241, 51–57. [Google Scholar] [CrossRef]

- Zhou, Y.H.; Vidyarthi, S.K.; Zhong, C.S.; Zheng, Z.A.; An, Y.; Wang, J.; Wei, Q.; Xiao, H.W. Cold plasma enhances drying and color, rehydration ratio and polyphenols of wolfberry via microstructure and ultrastructure alteration. Lwt 2020, 134, 110173. [Google Scholar] [CrossRef]

- Koulouris, A.; Kotelida, I. Simulation-based reactive scheduling in tomato processing plant with raw material uncertainty. In 21st European Symposium on Computer Aided Process Engineering; Pistikopoulos, E.N., Georgiadis, M.C., Kokossis, A.C., Eds.; Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2011; Volume 29, pp. 1020–1024. [Google Scholar]

- Santos, N.C.; Almeida, R.L.J.; de Oliveira Brito, A.C.; de Alcantara Silva, V.M.; Albuquerque, J.C.; Saraiva, M.M.T.; Santos, R.M.S.; de Sousa, F.M.; de Alcantara Ribeiro, V.H.; de Oliveira Carvalho, R.; et al. Effect of pulse electric field (PEF) intensity combined with drying temperature on mass transfer, functional properties, and in vitro digestibility of dehydrated mango peels. J. Food Meas. Charact. 2023. [Google Scholar] [CrossRef]

| Sample | Specific Peeling Force, N/cm | Peelability, cm2/g | Energy Consumption of Peeling Procedure Wpeeling, W/kg |

|---|---|---|---|

| Protocol A | 18.3 ± 3.35 | 0.2 ± 0.03 | 0.065 ± 0.009 |

| Protocol B | 52.8 ± 1.12 | 0.18 ± 0.03 | 0.170 ± 0.012 |

| Sample | Total Carotenoids (mg Carotenoids/100 g Tomato Peels) | Total Phenolic Compounds (mg of Gallic Acid/kg Tomato Peels) | The Drying Specific Energy Consumption WDSEC, kW/kg |

|---|---|---|---|

| Protocol C | 14.29 ± 3.18 | 24.43 ± 3.18 | 3.7 ± 0.21 |

| Protocol D | 18.78 ± 2.76 | 29.51 ± 3.08 | 4.5 ± 0.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sosnin, M.; Berestenko, E.; Mounassar, E.H.A.; Shorstkii, I. Cold Plasma Technology for Tomato Processing By-Product Valorization: The Case of Tomato Peeling and Peel Drying. Eng 2023, 4, 2167-2177. https://doi.org/10.3390/eng4030124

Sosnin M, Berestenko E, Mounassar EHA, Shorstkii I. Cold Plasma Technology for Tomato Processing By-Product Valorization: The Case of Tomato Peeling and Peel Drying. Eng. 2023; 4(3):2167-2177. https://doi.org/10.3390/eng4030124

Chicago/Turabian StyleSosnin, Maxim, Egor Berestenko, Emad H. A. Mounassar, and Ivan Shorstkii. 2023. "Cold Plasma Technology for Tomato Processing By-Product Valorization: The Case of Tomato Peeling and Peel Drying" Eng 4, no. 3: 2167-2177. https://doi.org/10.3390/eng4030124

APA StyleSosnin, M., Berestenko, E., Mounassar, E. H. A., & Shorstkii, I. (2023). Cold Plasma Technology for Tomato Processing By-Product Valorization: The Case of Tomato Peeling and Peel Drying. Eng, 4(3), 2167-2177. https://doi.org/10.3390/eng4030124