Performance Evaluation of Self-Compacting Glass Fiber Concrete Incorporating Silica Fume at Elevated Temperatures

Abstract

:1. Introduction

2. Materials and Methods

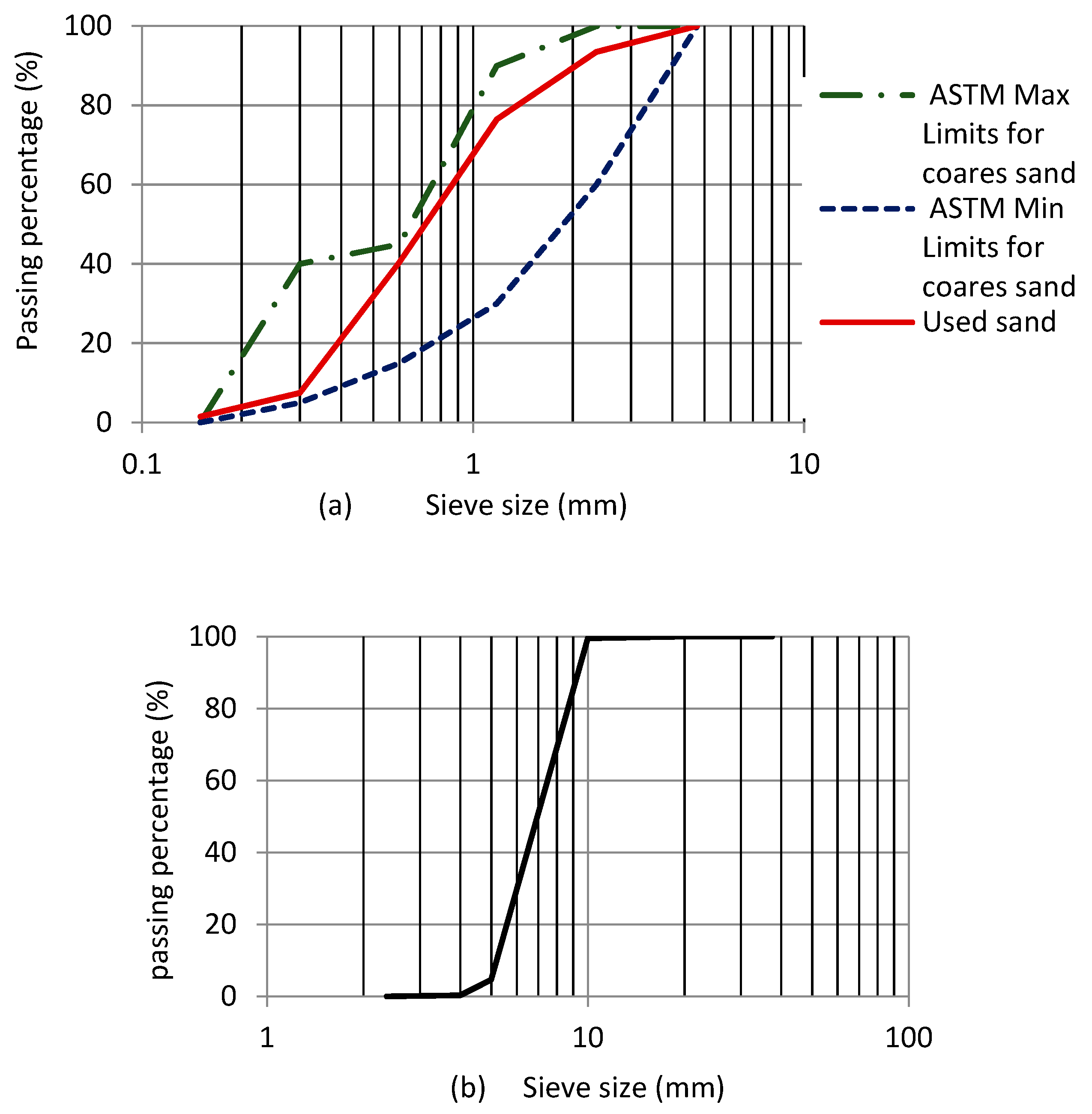

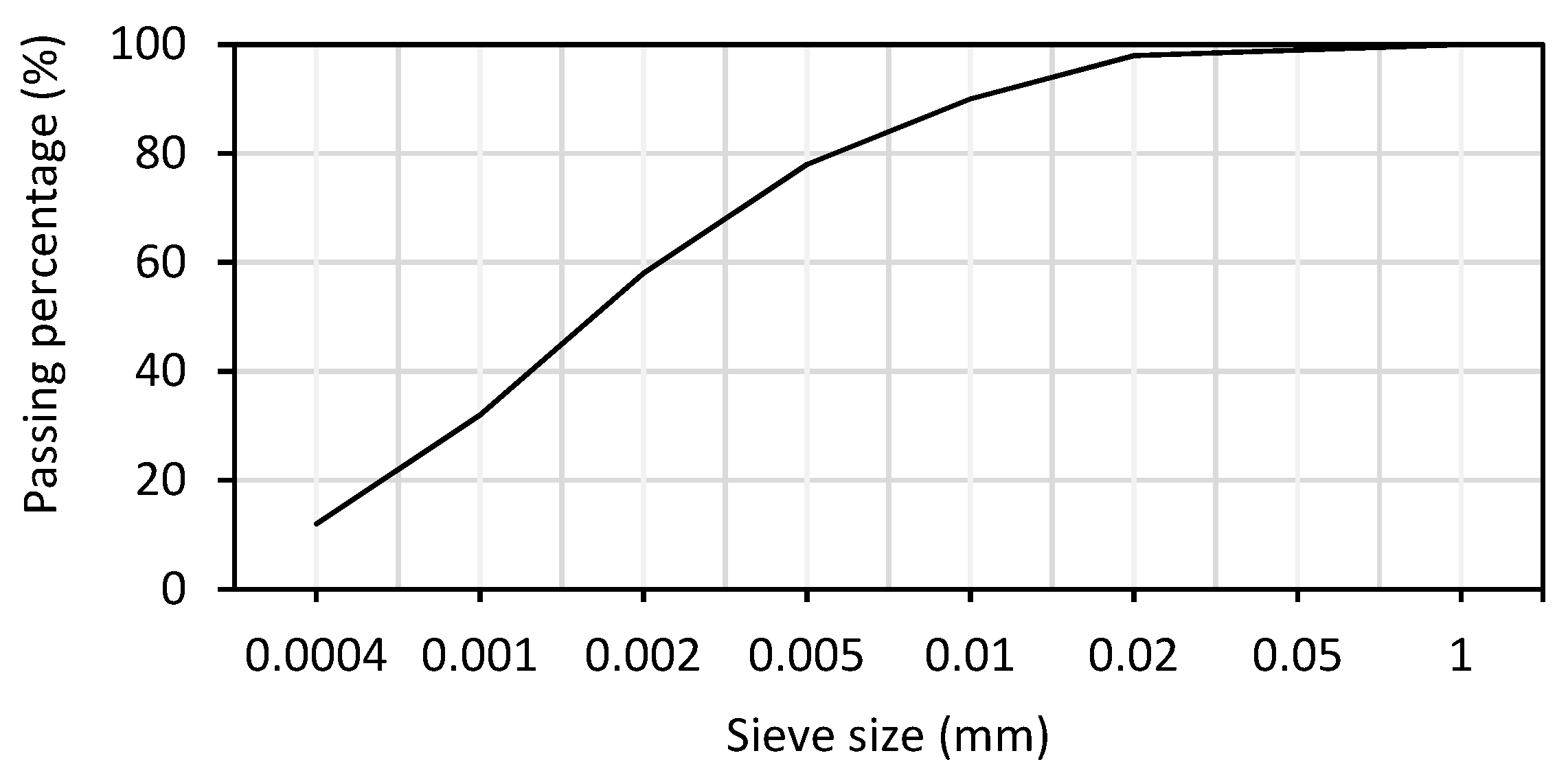

2.1. Raw Materials

2.2. Mixing, Moulding, and Curing

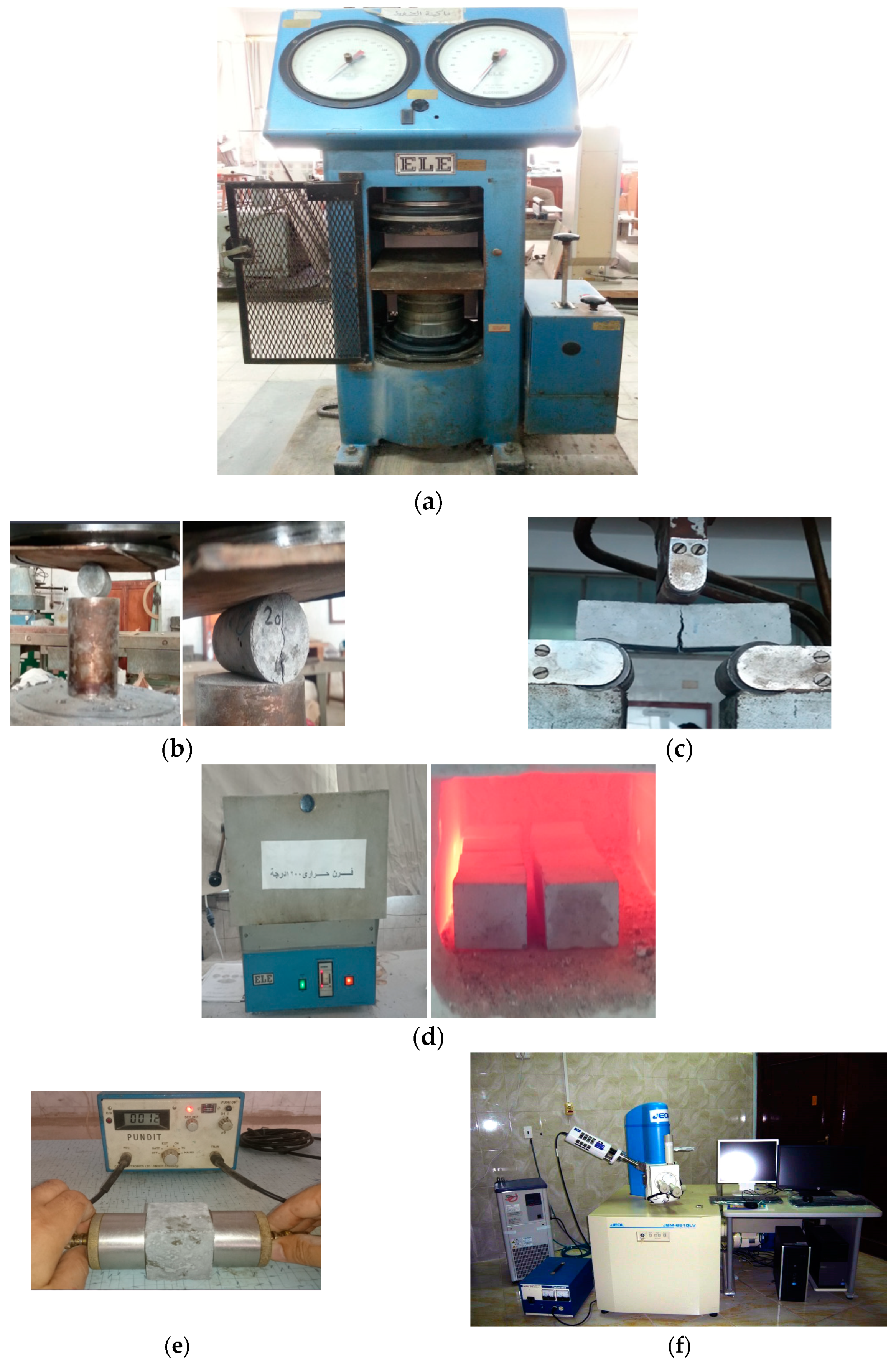

2.3. Tests Procedure

3. Results and Discussion

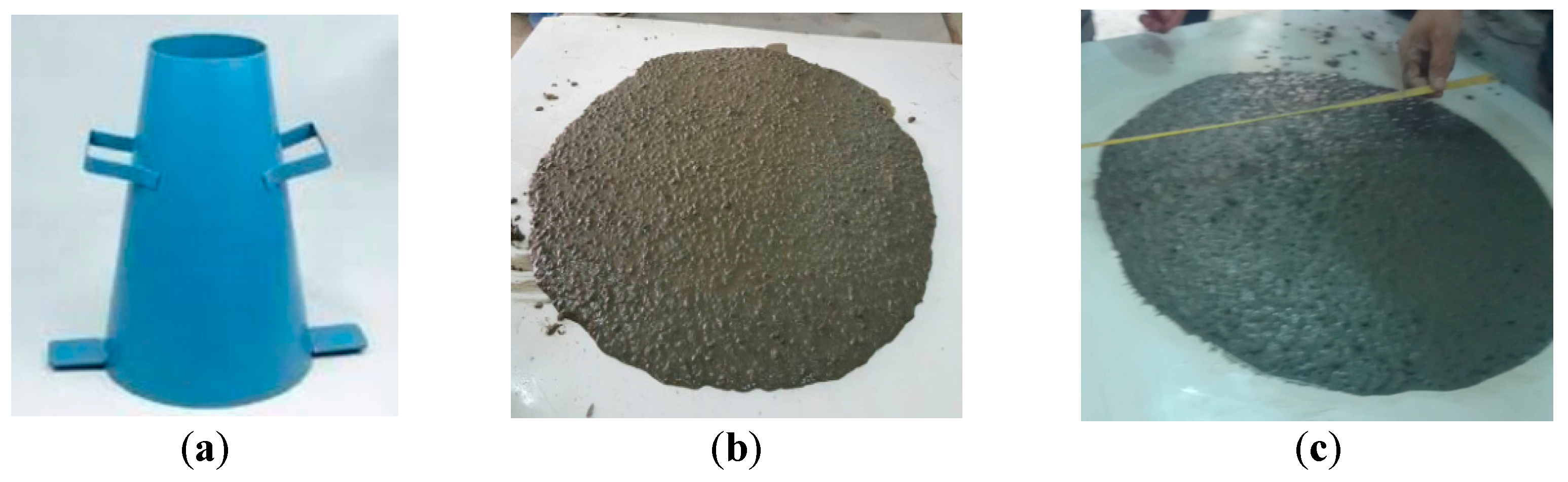

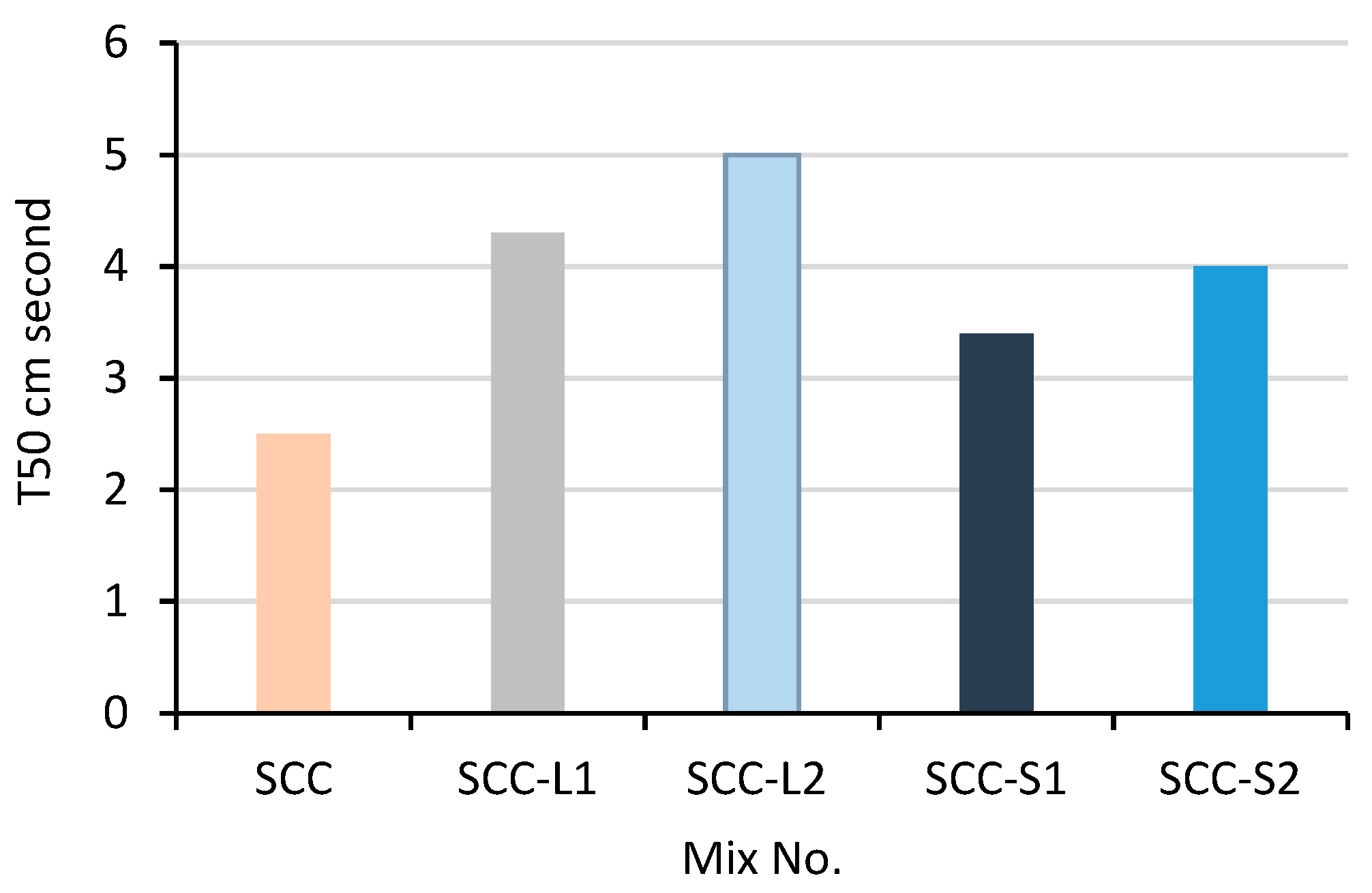

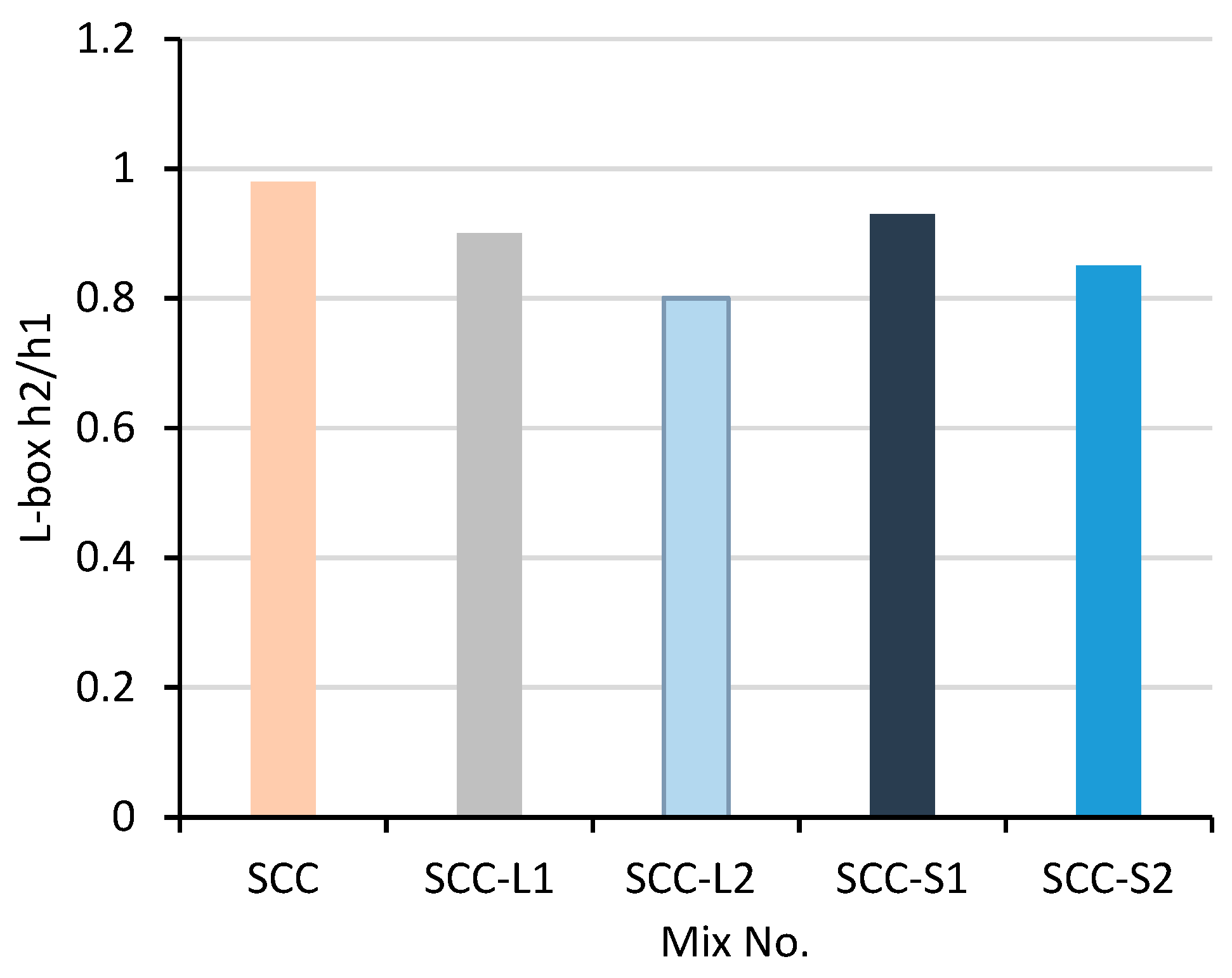

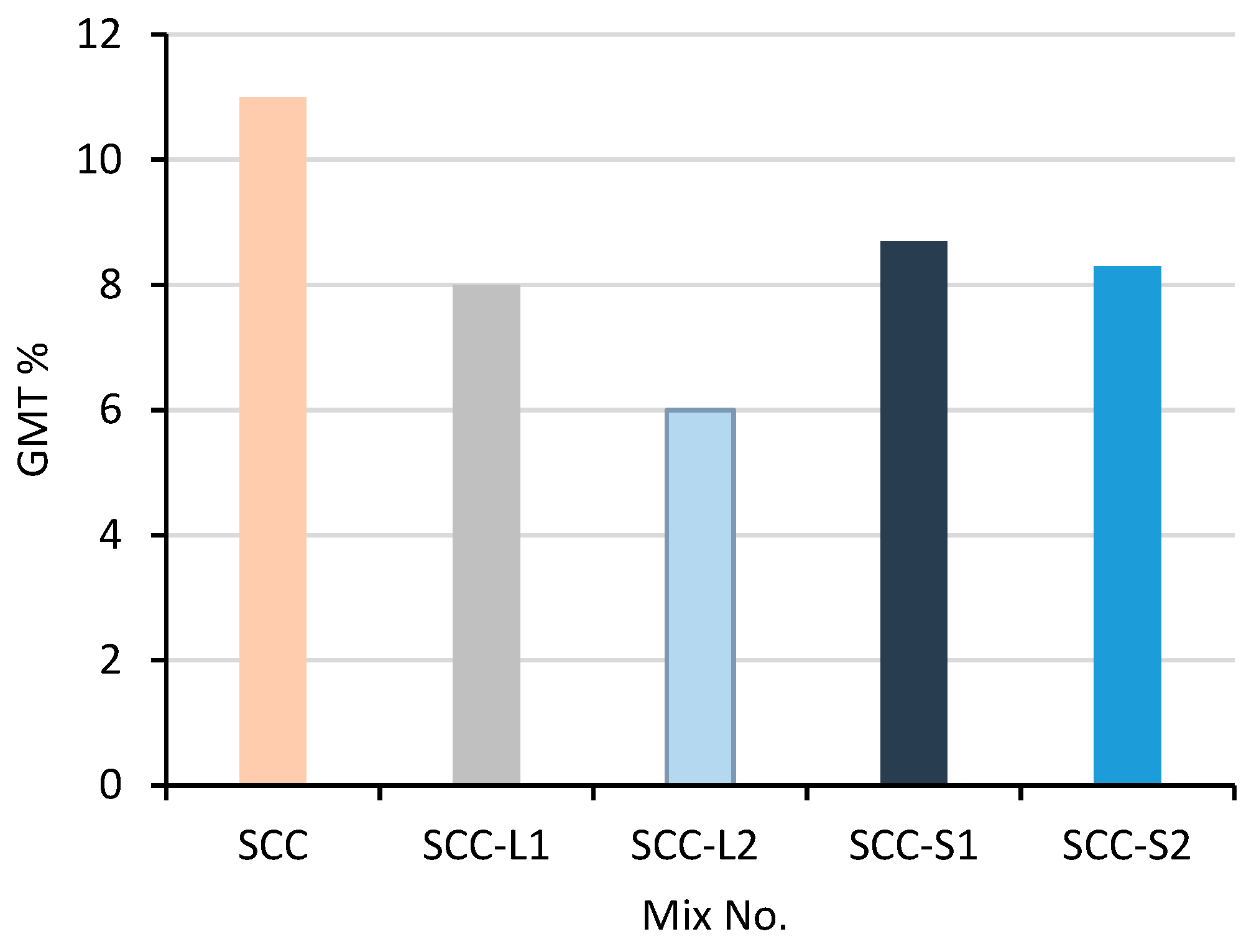

3.1. Properties of Fresh SCC and Fresh SCC with Glass Fibers

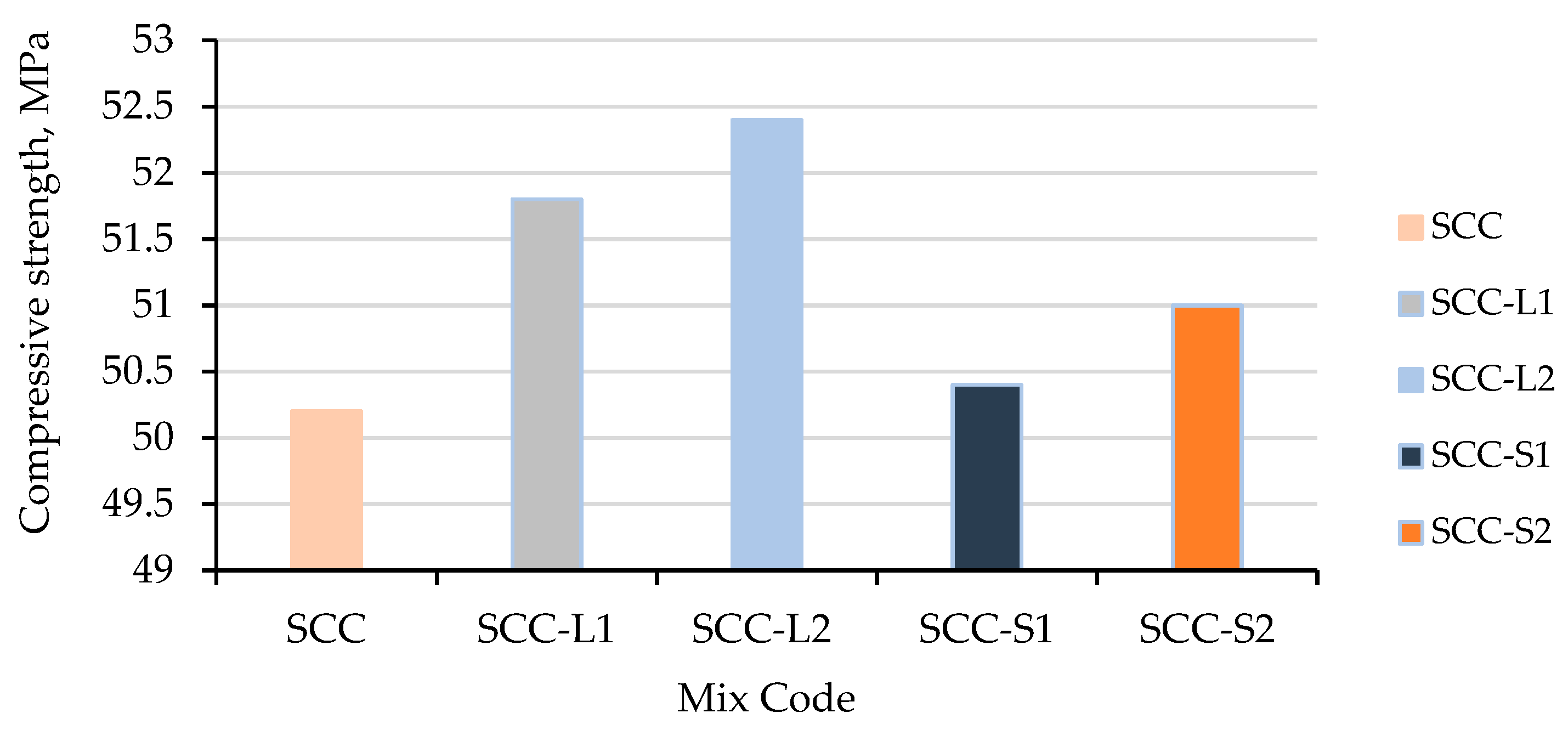

3.2. Compressive Strength

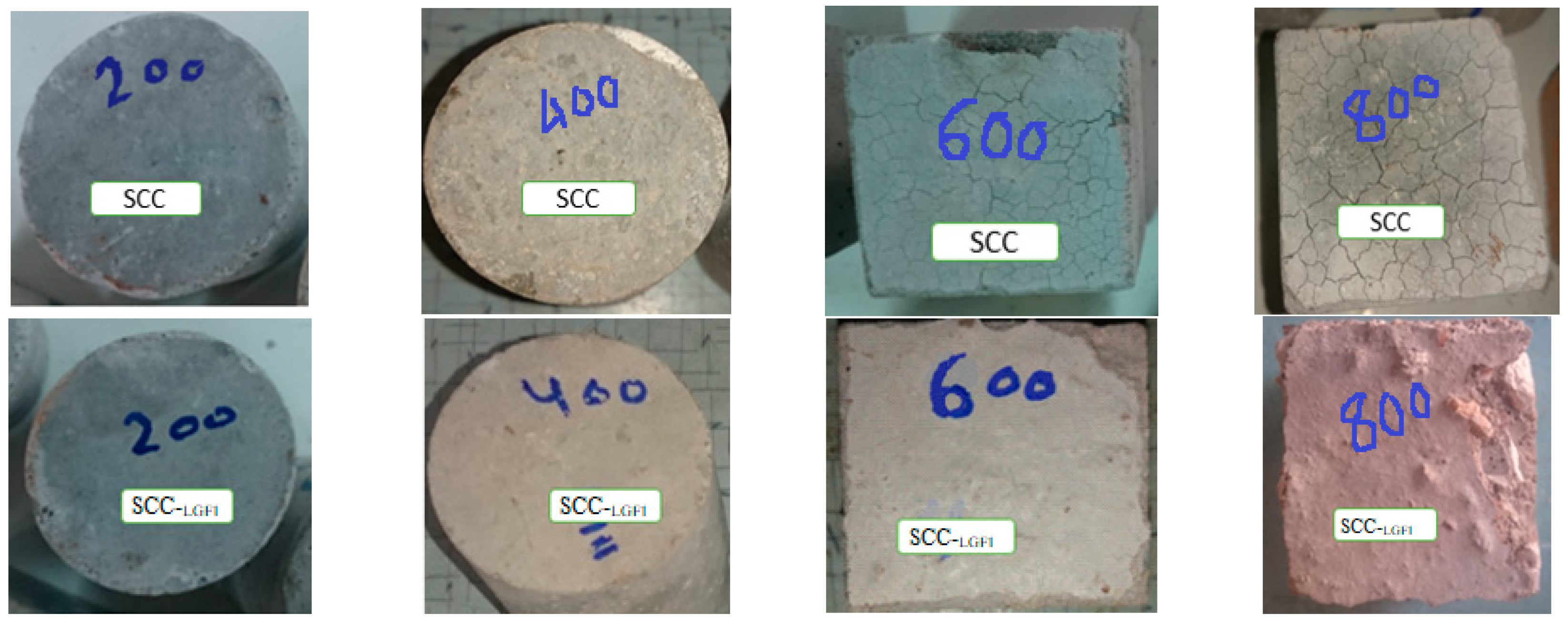

3.3. Spalling

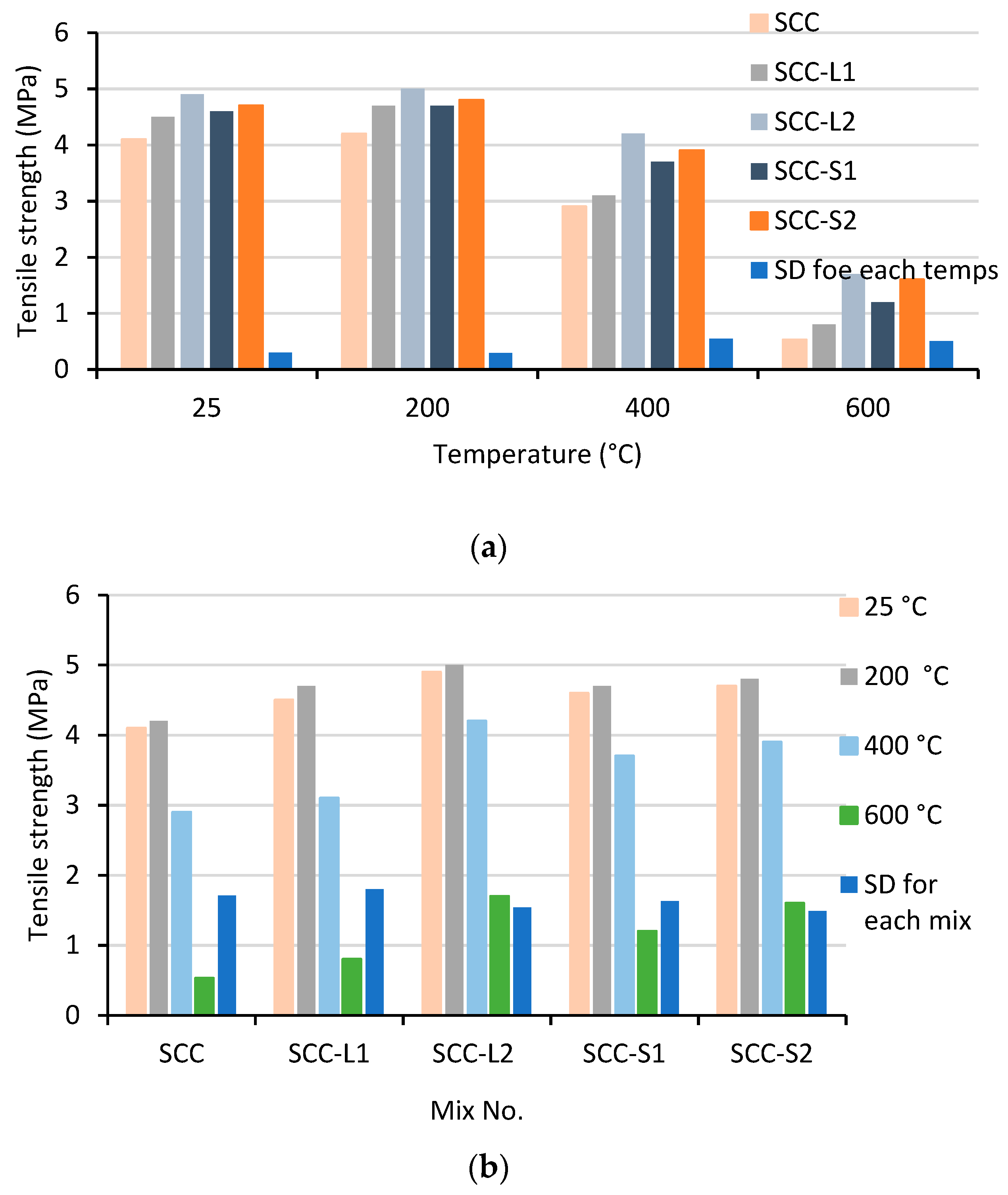

3.4. Splitting Tensile Strength

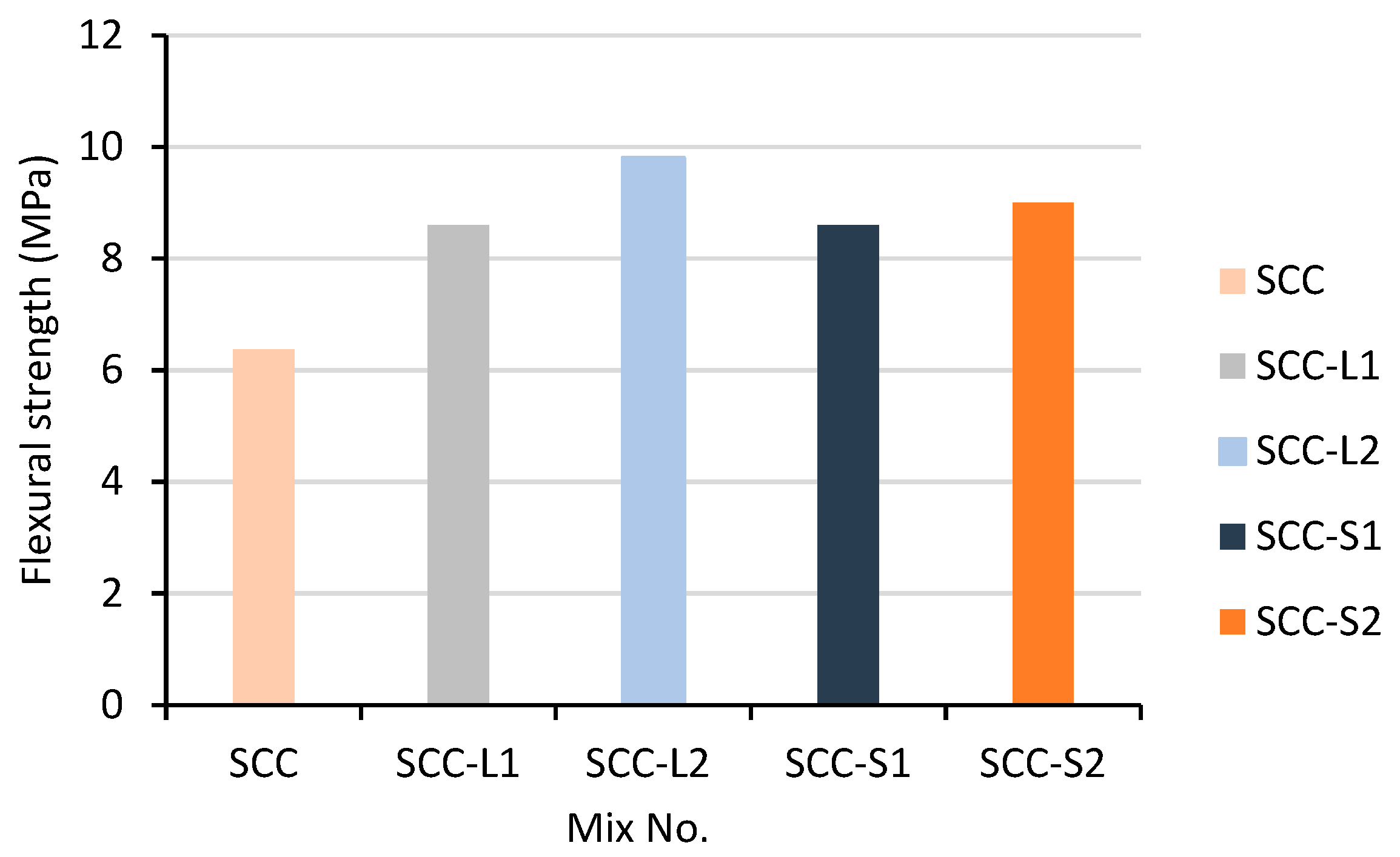

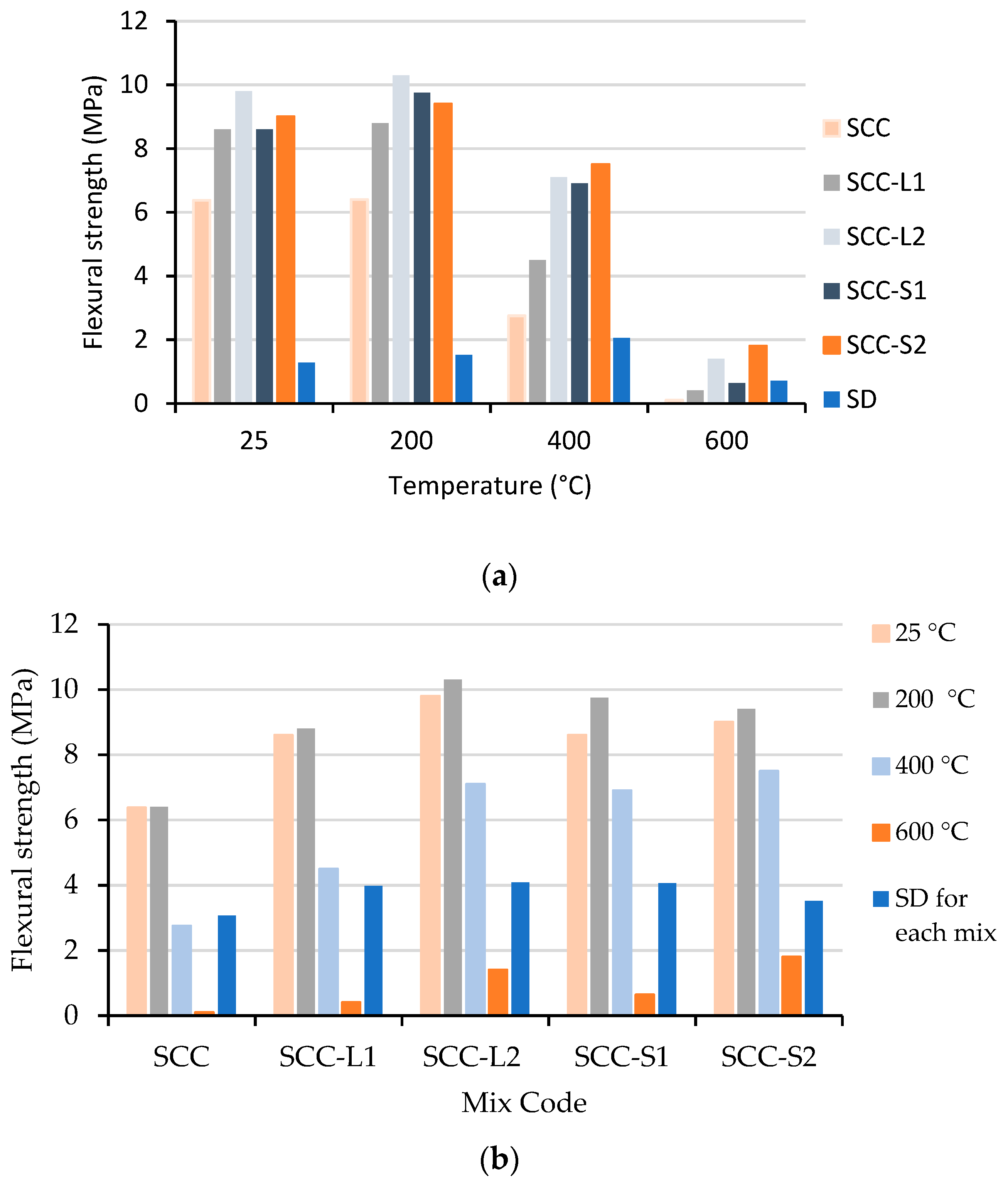

3.5. Flexural Strength

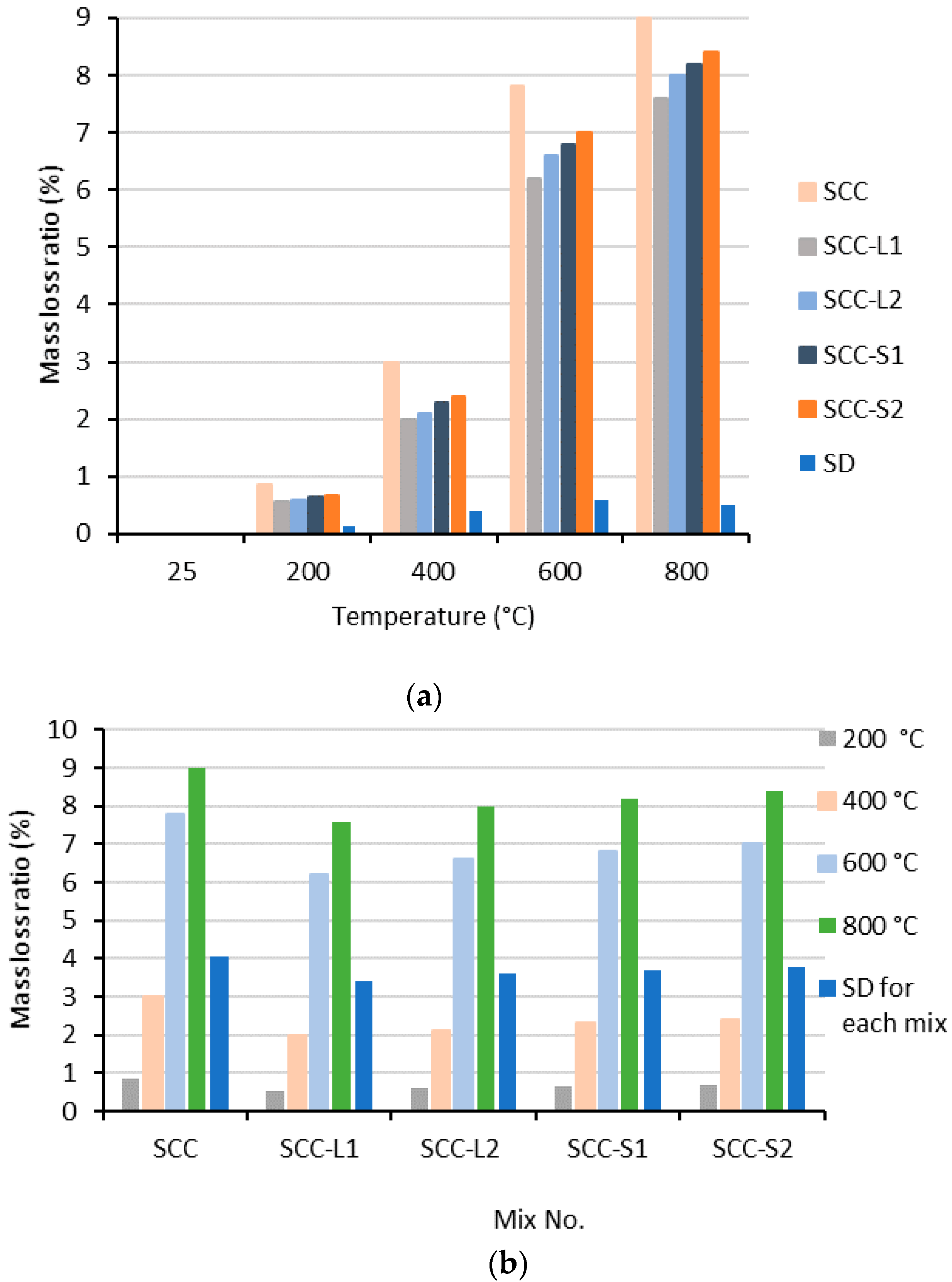

3.6. The Mass Loss Ratio

3.7. Ultrasonic Pulse Velocity (UPV)

4. Effects or Spin-Offs of the Study in Practice

5. Conclusions

- In terms of filling and passing ability, all SCC combinations are regarded as having acceptable consistency and workability. The addition of glass fiber to SCC diminishes workability but it does so within the permissible limit of EFNARC. There is neither bleeding nor segregation while the flow is running or stopped.

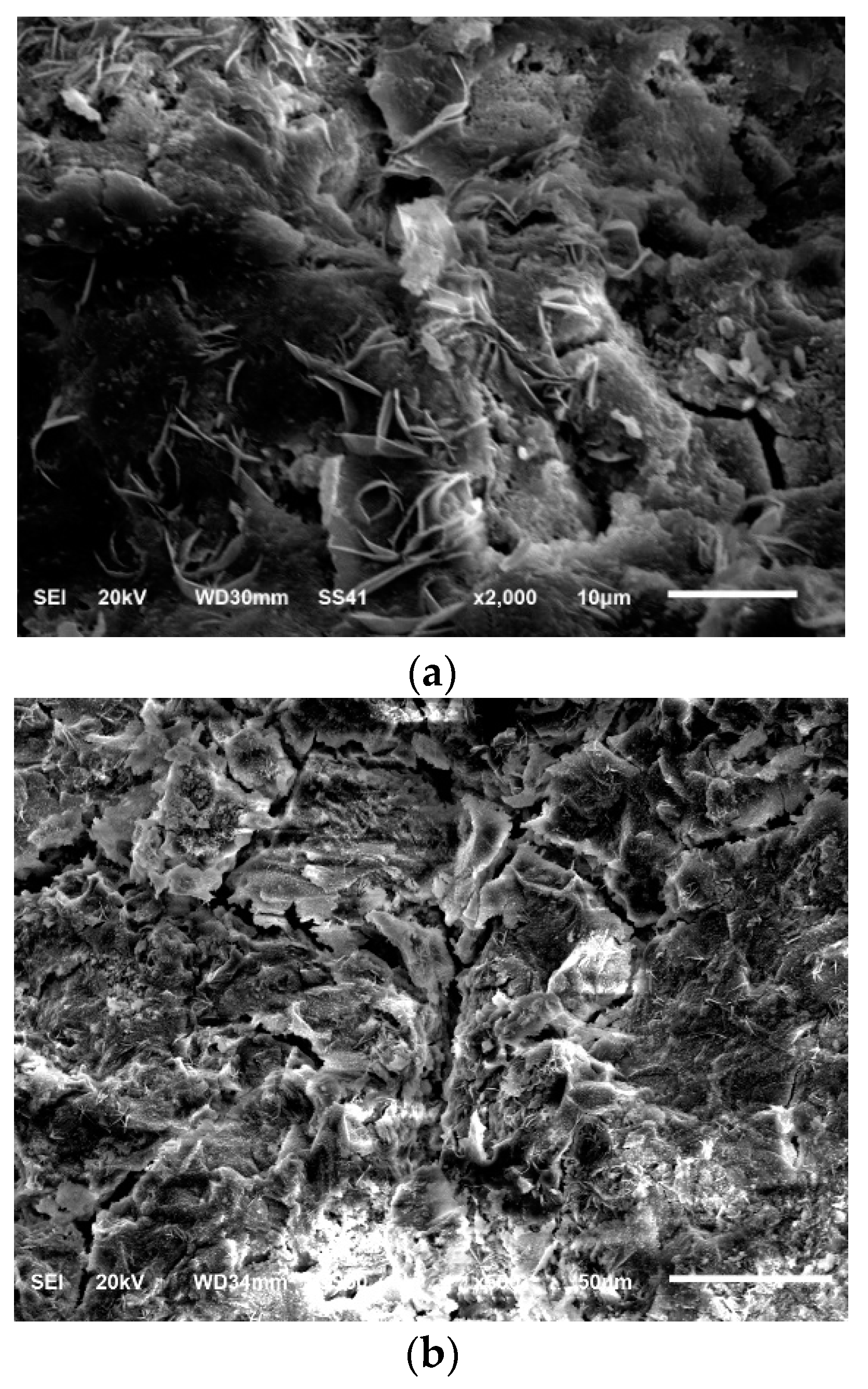

- When glass fibers were added to SCC samples, their mechanical strength rose. This improvement in mechanical properties can be attributed to fiber influence, which successfully inhibits the development of cracks by forming a strong relationship between the fibers and matrix. The SCC’s mechanical strength was increased as a result of the SCC’s improved energy absorption capacity. Additionally, fibers can join micro- and macrofractures, delaying the spread of significant fractures and switching the failure mode from brittle to flexible.

- Glass fibers were added to SCC samples to improve their mechanical strength, and as a result, the improvements in SCC samples with glass fibers are greater than in those samples without fibers. The influence of fibers, which successfully prevent crack development by forming a strong bond between the fibers and matrix, can be attributed to this improvement in mechanical qualities. As a result, the SCC’s capacity to absorb energy was improved, increasing its mechanical strength. Additionally, fibers have the ability to join micro- and macrofractures, delaying the spread of significant fractures and changing the failure mode from brittle to flexible.

- The mechanical properties of specimens containing glass fibers increased at up to 200 °C but then declined at 400 °C, whereas the SCC-L2 mixture exhibited better mechanical properties.

- SCC samples with and without fibers did not break or show any signs of visual cracking at 200 °C. Some SCC samples showed some corner and edge spalling at temperatures of about 400 °C. Above 400 °C, a large number of microcracks started to develop. Between 600 and 800 °C, SCC samples experienced rapid spalling and complete destruction.

- The GFR-SCC specimens cracked between 300 °C and 400 °C, spalled significantly between 400 °C and 600 °C, and were completely destroyed between 600° C and 800°C. According to the results, glass fibers cannot stop RPC from spalling over the course of a fire.

- For the examined SCC specimens, there was no significant mass loss between 200 and 400 °C. At 600 °C, however, there is a rapid rise in mass loss, and this mass loss increased by more than ten times when compared to 200 °C.

- At room temperature, the UPV of SCC samples with glass fibers grew, and SCC-L2 exhibited a somewhat higher UPV than other SCC mixes. The results show that at 200, 400, 600, and 800 °C, SCC samples containing glass fibers exhibit a larger improvement in UPV than SCC samples without fibers. At about 200 °C, the UPV of each SCC sample began to rise, then at roughly 400 °C, it began to fall. When the temperature was increased from 200 to 800 °C, UPV decreased, especially for the control SCC sample.

6. Recommendation for Future Work

- The effects of glass fibers on the mechanical and thermal properties of SCC exposed to varying periods of high temperatures.

- The effect of adding carbon fibers to SCC that has been exposed to high temperatures on mechanical and thermal properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SCC | self-compacting concrete |

| GFR-SCC | glass fiber-reinforced self-compacting concrete |

| SCC-L1 | mixture contains 1% glass fibers of a length of 13 mm |

| SCC-L2 | mixture contains 0.5% glass fibers of a length of 13 mm |

| SCC-S1 | mixture contains 1% glass fibers of a length of 6 mm |

| SCC-S2 | mixture contains 0.5% glass fibers of a length of 6 mm |

References

- Ahmed, G.H.; Ahmed, H.; Ali, B. Alyousef R Assessment of High Performance Self-Consolidating Concrete through an Experimental and Analytical Multi-Parameter Approach. Materials 2021, 14, 985. [Google Scholar] [CrossRef] [PubMed]

- Geiker, M.; Jacobsen, S. Self-compacting concrete (SCC). In Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Mindess, S., Ed.; Woodhead: Vancouver, BC, Canada, 2020; Volume 10, pp. 229–256. [Google Scholar]

- Anıl, N. Mechanical Properties of Steel Fiber Reinforced Self-Compacting Concrete. Int. J. Eng. Technol.-IJET 2018, 4, 2018. [Google Scholar]

- Megid, W.A.; Khayat, K.H. Effect of concrete rheological properties on quality of formed surfaces cast with self-consolidating concrete and superworkable concrete. Cem. Concr. Compos. 2018, 93, 75–84. [Google Scholar] [CrossRef]

- El-Chabib, H.; Syed, A. Properties of self-consolidating concrete made with high volumes of supplementary cementitious materials. J. Mater. Civ. Eng. 2013, 25, 1579–1586. [Google Scholar] [CrossRef]

- Sideris, K.K.; Tassos, C.; Chatzopoulos, A.; Manita, P. Mechanical characteristics and durability of self-compacting concretes produced with ladle furnace slag. Constr. Build. Mater. 2018, 170, 660–667. [Google Scholar] [CrossRef]

- Zinkaah, O.H.; Sultan, H.K.; Al-Rifaie, A.; Alridha, Z. Influence of Strut Geometry on the Size Effect of FRP Reinforced Simply Supported Deep Beams: A Theoretical Analysis. Math. Model. Eng. Probl. 2022, 9, 411–417. [Google Scholar] [CrossRef]

- Aziz, H.Y.; Sultan, H.K.; Abbas, B.J. Simulation and Style Design of Bridge Stability Supported on Large Diameter Piles. Math. Model. Eng. Probl. 2021, 8, 961–966. [Google Scholar] [CrossRef]

- Łázniewska-Piekarczyk, B. Investigations on the relationship between porosity and strength of admixtures modified high performance self-compacting concrete. J. Civ. Eng. Manag. 2016, 22, 520–528. [Google Scholar] [CrossRef]

- Huseien, G.F.; Sam, A.R.M.; Alyousef, R. Texture, morphology and strength performance of self-compacting alkali-activated concrete: Role of fly ash as GBFS replacement. Constr. Build. Mater. 2020, 270, 121368. [Google Scholar] [CrossRef]

- Sultan, H.K. Designing reinforced HSC rectangular beams using optimization techniques. Pollack Period. J. 2023, 18, 20–25. [Google Scholar] [CrossRef]

- Sultan, H.K.; Abbas, B.J.; Al Khuzaie, H.M.A.; Alsheakayree, T.K.Q. Designing High Strength Concrete Grade T-Beams at the Lowest Possible Cost. Math. Model. Eng. Probl. 2023, 10, 1369–1376. [Google Scholar] [CrossRef]

- Hameed, A.A.; Al-Sherrawi, M.H. Influence of Steel Fiber on the Shear Strength of a Concrete Beam. Civ. Eng. J. 2018, 4, 1501–1509. [Google Scholar] [CrossRef]

- Faridmehr, I.; Shariq, M.; Plevris, V.; Aalimahmoody, N. Novel hybrid informational model for predicting the creep and shrinkage deflection of reinforced concrete beams containing GGBFS. Neural Comput. Appl. 2022, 34, 13107–13123. [Google Scholar] [CrossRef]

- Sultan, H.K.; Mohammed, A.T. Assessing of the common strengthening methods for existing RC buildings. Pollack Period. J. 2023, 18, 6–11. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, R.; Gupta, K. Study on Normally Vibrated Concrete to Self-Compacting Concrete. J. Ceram. Concr. Technol. 2016, 1, 1–18. [Google Scholar]

- Sultan, H.K.; Mohammed, A.T.; Qasim, O.D.; Maula, B.H.; Aziz, H.Y. Ductility Factor Evaluation of Concrete Moment Frame Retrofitted by FRP Subjected to Seismic Loads. Int. Rev. Civ. Eng. (I.RE.C.E.) 2020, 11, 275–282. [Google Scholar] [CrossRef]

- Sultan, H.K.; Huseien, G.F. Minimum Shear Reinforcement for Reactive Powder Concrete Beams. ENG 2024, 5, 801–818. [Google Scholar] [CrossRef]

- Alyousef, R.; Benjeddou, O.; Khadimallah, M.A.; Mohamed, A.M.; Soussi, C. Study of the Effects of Marble Powder Amount on the Self-Compacting Concretes Properties by Microstructure Analysis on Cement-Marble Powder Pastes. Adv. Civ. Eng. 2018, 2018, 6018613. [Google Scholar] [CrossRef]

- Domone, P.L. A review of the hardened mechanical properties of self-compacting concrete. Cem. Concr. Compos. 2007, 29, 1–12. [Google Scholar] [CrossRef]

- Foroughi-Asl, A.; Dilmaghani, S.; Famili, H. Bond strength of reinforcement steel in self-compacting concrete. Int. J. Civ. Eng. 2008, 6, 24–33. [Google Scholar]

- Kang, S.-H.; Hong, S.-G.; Moon, J. Shrinkage characteristics of heat-treated ultra-high performance concrete and its mitigation using superabsorbent polymer based internal curing method. Cem. Concr. Compos. 2018, 89, 130–138. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K. Influence of water to cement ratio on the efficiency of internal curing of high-performance concrete. Constr. Build. Mater. 2017, 144, 311–316. [Google Scholar] [CrossRef]

- Alyousef, R.; Khadimallah, M.A.; Soussi, C.; Benjeddou, O.; Jedidi, M. Experimental and Theoretical Study of a New Technique for Mixing Self-Compacting Concrete with Marble Sludge Grout. Adv. Civ. Eng. 2018, 2018, 3283451. [Google Scholar] [CrossRef]

- Alabduljabbar, H.; Alyousef, R.; Alrshoudi, F.; Alaskar, A.; Fathi, A.; Mohamed, A.M. Mechanical effect of steel fiber on the cement replacement materials of self-compacting concrete. Fibers 2019, 7, 36. [Google Scholar] [CrossRef]

- Kannan, V.; Jerin, C.; Murali, D.K. A Review on Self Compacting Concrete. Int. J. Adv. Res. Eng. Manag. 2015, 1, 64–68. [Google Scholar]

- Nadeem, A.; Memon, S.A.; Lo, T.Y. The performance of fly ash and metakaolin concrete at elevated temperatures. Constr. Build. Mater. 2014, 62, 67–76. [Google Scholar] [CrossRef]

- Memon, S.A.; Shah, S.F.A.; Khushnood, R.A.; Baloch, W.L. Durability of sustainable concrete subjected to elevated temperature–A review. Constr. Build. Mater. 2019, 199, 435–455. [Google Scholar] [CrossRef]

- Alyousef, R.; Benjeddou, O.; Soussi, C.; Khadimallah, M.A.; Mohamed, A.M. Effects of Incorporation of Marble Powder Obtained by Recycling Waste Sludge and Limestone Powder on Rheology, Compressive Strength, and Durability of Self-Compacting Concrete. Adv. Mater. Sci. Eng. 2019, 2019, 4609353. [Google Scholar] [CrossRef]

- Ahmad, S.; Umar, A.; Masood, A. Properties of normal concrete, self-compacting concrete and glass fibre-reinforced self-compacting concrete: An experimental study. Procedia Eng. 2017, 173, 807–813. [Google Scholar] [CrossRef]

- Hake, S.L.; Shinde, S.S.; Bhandari, P.K.; Awasarmal, P.R.; Kanawade, B.D. Effect of Glass Fibers on Self-Compacting Concrete. E3S Web Conf. 2020, 170, 6018. [Google Scholar] [CrossRef]

- Bogas, J.; Hawreen, A. Capillary Absorption and Oxygen Permeability of Concrete Reinforced with Carbon Nanotubes. Adv. Civ. Eng. Mater. 2019, 8, 307–326. [Google Scholar]

- Hawreen, A.; Bogas, J.A.; Kurda, R. Mechanical Characterization of Concrete Reinforced with Different Types of Carbon Nanotubes. Arab. J. Sci. Eng. 2019, 44, 8361–8376. [Google Scholar] [CrossRef]

- Abu Maraq, M.A.; Tayeh, B.A.; Ziara, M.M.; Alyousef, R. Flexural behavior of RC beams strengthened with steel wire mesh and self-compacting concrete jacketing—Experimental investigation and test results. J. Mater. Res. Technol. 2020, 10, 1002–1019. [Google Scholar] [CrossRef]

- Li, Y.; Pimienta, P.; Pinoteau, N.; Tan, K.-H. Effect of aggregate size and inclusion of polypropylene and steel fibers on explosive spalling and pore pressure in ultra-high-performance concrete (UHPC) at elevated temperature. Cem. Concr. Compos. 2019, 99, 62–71. [Google Scholar] [CrossRef]

- Ali, S.; Saeed, H.; Behzad, T. Residual Strength and Microstructure of Fiber Reinforced Self-Compacting Concrete Exposed to High Temperatures. Constr. Build. Mater. 2020, 230, 116969. [Google Scholar] [CrossRef]

- Cifuentes, H.C.; Leiva, M.F.; Fernández-Pereira, C. Effects of fibers and rice husk ash on properties of heated high-strength concrete. Mag. Concr. Res. 2012, 64, 457–470. [Google Scholar] [CrossRef]

- Zuhair, M.; Deshmukh, S.K. Effect of different fibers on compressive strength of self-compacting concrete at elevated temperature. IOP Conf. Ser. Mater. Sci. Eng. 2018, 410, 012007. [Google Scholar] [CrossRef]

- Qasim, O.A.; Sultan, H.K. Experimental investigation of effect of steel fiber on concrete construction joints of prism. IOP Conf. Ser. Mater. Sci. Eng. 2020, 745, 012170. [Google Scholar] [CrossRef]

- Sultan, H.K.; Alyaseri, I. Effects of elevated temperatures on mechanical properties of reactive powder concrete elements. Constr. Build. Mater. 2020, 261, 120555. [Google Scholar] [CrossRef]

- Ombres, L.; Mazzuca, P.; Verre, S. Effects of Thermal Conditioning at High Temperatures on the Response of Concrete Elements Confined with a PBO-FRCM Composite System. J. Mater. Civ. Eng. 2021, 34, 04021413. [Google Scholar] [CrossRef]

- Bakhtiyari, S.; Allahverdi, A.; Rais-Ghasemi, M.; Zarrabi, B.A.; Parhizkar, T. Self-compacting concrete containing different powders at elevated temperatures–Mechanical properties and changes in the phase composition of the paste. Thermochim. Acta 2011, 514, 74–81. [Google Scholar] [CrossRef]

- Vanwalleghem, H.; Blontrock, H.; Taerwe, L. Spalling tests on self-compacting concrete. In Proceedings of the International RILEM Symposium on Self-Compacting Concrete, Proceedings PRO, Reykjavik, Iceland, 17–20 August 2003. [Google Scholar]

- Sultan, H.K.; Zinkaah, O.H.; Rasheed, A.A.; Alridha, Z.; Alhawat, M. Producing Sustainable Modified Reactive Powder Concrete Using Locally Available Materials. Innov. Infrastruct. Solut. 2022, 7, 342. [Google Scholar] [CrossRef]

- Noumowé, A.; Carré, H.; Daoud, A.; Toutanji, H. High-strength self-compacting concrete exposed to fire test. J. Mater. Civ. Eng. 2006, 18, 754–758. [Google Scholar] [CrossRef]

- Haddad, R.H.; Odeh, R.A.; Amawi, H.A.; Ababneh, A.N. Thermal performance of self-compacting concrete: Destructive and nondestructive evaluation. Can. J. Civ. Eng. 2013, 40, 1205–1214. [Google Scholar] [CrossRef]

- Persson, B. Fire resistance of self-compacting concrete, SCC. Mater. Struct. 2004, 37, 575–584. [Google Scholar] [CrossRef]

- Subhan, A.; Arshad, U. Fibre-reinforced Self Compacting Concrete: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012117. [Google Scholar] [CrossRef]

- Farhad, A.; Jack, K. Assessment and development of high-performance fibre reinforced lightweight self-compacting concrete including recycled crumb rubber aggregates exposed to elevated temperatures F. Aslani J. Kelin/J. Clean. Prod. 2018, 200, 1009–1025. [Google Scholar]

- Asce, M.; Junbo, S.; Guanqi, H. Mechanical Behavior of Fiber Reinforced Self-Compacting Rubberized Concrete Exposed to Elevated Temperatures. J. Mater. Civ. Eng. 2019, 31, 04019302. [Google Scholar]

- Mahapatra, C.K.; Barai, S.V. Temperature impact on residual properties of self-compacting based hybrid fiber reinforced concrete with fly ash and colloidal nano silica. Constr. Build. Mater. 2019, 198, 120–132. [Google Scholar] [CrossRef]

- Yahy AL-Radi, H.H.; Dejian, S.; Sultan, H.K. Performance of Fiber Self-Compacting Concrete at High Temperatures. Civ. Eng. J. 2021, 7, 2083–2098. [Google Scholar] [CrossRef]

- Venkadachalam, G.; Kumar, M.D. Behaviour of Self Compacted Concrete Produced with Steel Fiber, Glass fiber and Polypropylene Fiber Additives Subjected To High Temperature. IOP Conf. Ser. Mater. Sci. Eng. 2020, 981, 042088. [Google Scholar] [CrossRef]

- Pathak, N.; Siddique, R. Properties of self-compacting-concrete containing fly ash subjected to elevated temperatures. Constr. Build. Mater. 2012, 30, 274–280. [Google Scholar] [CrossRef]

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM C109/C109M-20; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; American Society for Testing and Materials Standard Practice C496. American Society for Testing and Materials: Philadelphia, PA, USA, 2017.

- ASTM C293; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center Point Loading). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C597-16; Standard Test Method for Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- EFNARC. Specification and Guidelines for Self-CompactingConcrete; European Federation for Specialist Construction Chemicals and Concrete: Brussels, Belgium, 2005. [Google Scholar]

- Mezzal, S.K.; Khalid, B.; Najim, K.N.; Al-Azzawi, Z. Residual Mechanical Properties of High Strength Self-Compacting Concrete with Reused Steel Fibers at High Temperatures. J. Green Eng. (JGE) 2020, 10, 14. [Google Scholar]

- Qasim, O.A. Ahmed AS High temperature effect on shear transfer strength of steel fiber reinforced self-compacting concrete. J. Eng. Appl. Sci. 2019, 14, 3158–3174. [Google Scholar] [CrossRef]

- Kumar, S.L.; Manasa, V.; Harish, M. Evaluation of workability characteristics of self-compacting concrete creep behavior of self-compacting concrete. Int. Res. J. Eng. Technol. (IRJET) 2018, 5, 1193–1198. [Google Scholar]

- Umar, A.; Al-Tamimi, A. Acritical study of the effect of viscosity modifying admixture and glass fibers on the properties of self-compacting concrete (SCC). J. Struct. Eng. 2011, 38, 153–1621. [Google Scholar]

- Salami, F.; Shami, N. Self-compacting concrete incorporating steel and polypropylene fibers: Compressive and tensile strengths, moduli of elasticity and rupture, compressive stress—Strain curve, and energy dissipated under compressive. Compos. Part B Eng. 2013, 53, 121–133. [Google Scholar]

- Lim, S.; Mondal, P. Effects of Nanosilica Addition on Increased Thermal Stability of Cement-Based Composite. ACI Mater. J. 2015, 112, 305–315. [Google Scholar] [CrossRef]

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, C.; Zhang, B.; Li, Q.; Shui, Z. Study on the high-temperature behavior and rehydration characteristics of hardened cement paste. Fire Mater. 2015, 39, 741–750. [Google Scholar] [CrossRef]

- Arioz, O. Effects of elevated temperatures on properties of concrete. Fire Saf. J. 2007, 42, 516–522. [Google Scholar] [CrossRef]

- Ezziane, M.; Kadri, T.; Molez, L.; Jauberthie, R.; Belhacen, A. High temperature behaviour of polypropylene fibres reinforced mortars. Fire Saf. J. 2015, 71, 324–331. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L.J. Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures. J. Cem. Concr. Res. 2004, 34, 2215–2222. [Google Scholar] [CrossRef]

- Ali, M.H.; Dinkha, Y.Z.; Haido, J.H. Mechanical properties and spalling at elevated temperature of high performance concrete made with reactive and waste inert powders. Eng. Sci. Technol. Int. J. 2017, 20, 536–541. [Google Scholar] [CrossRef]

- So, H.-S. Spalling Prevention of High Performance Concrete at High Temperatures. In High Performance Concrete Technology and Applications; InTech: London, UK, 2016. [Google Scholar]

- Kanema, M. Influence des Paramètres de Formulation Etmicrostructurauxsur le Comportement à Haute Température des Bétons. Ph.D. Thesis, Université de Cergy-Pontoise, Cergy, France, 2007. [Google Scholar]

- Parka, J.-J.; Yoob, D.-Y.; Kimb, S.; Kima, S.-W. Benefits of synthetic fibers on the residual mechanical performance of UHPFRC after exposure to ISO standard fire. Cem. Concr. Compos. 2019, 104, 103401. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Sikora, P.; Cendrowski, K.; Mijowska, E. The effect of elevated temperature on the properties of cement mortars containing nanosilica and heavyweight aggregates. Constr. Build. Mater. 2017, 137, 420–431. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. An investigation into the hydration and microstructure of cement pastes modified with glass powders. Constr. Build. Mater. 2016, 112, 915–924. [Google Scholar] [CrossRef]

- Behnood, A.; Ghandehari, M. Comparison of compressive and splitting tensile strength of high-strength concrete with and without polypropylene fibers heated to high temperatures. Fire Saf. J. 2009, 44, 1015–1022. [Google Scholar] [CrossRef]

- Rathish, K.; Kumar Srikuth, K. Mechanical Characteristics of Polypropylene Fiber Reinforced Self Compacting Concrete. Asian J. Civ. Eng. (Build. Hous.) 2008, 9, 647–657. [Google Scholar]

- Corinaldesi, V.; Moriconi, G. Characterization of self-compacting concretes prepared with different fibers and mineral additions. Cem. Concr. Compos. 2011, 33, 596–601. [Google Scholar] [CrossRef]

- Düğenci, O.; Haktanir, T.; Altun, F. Experimental research for the effect of high temperature on the mechanical properties of steel fiber-reinforced concrete. Constr. Build. Mater. 2015, 75, 82–88. [Google Scholar] [CrossRef]

- Yüksel, I.; Siddique, R.; Özkan, Ö. Influence of high temperature on the properties of concretes made with industrial by-products as fine aggregate replacement. Constr. Build. Mater. 2011, 25, 967–972. [Google Scholar] [CrossRef]

- Gencel, O. Effect of elevated temperatures on mechanical properties of high-strength concrete containing varying proportions of hematite. Fire Mater. 2012, 36, 217–230. [Google Scholar] [CrossRef]

- IS 13311-1; Method of Non-Destructive Testing of Concrete, Part 1: Ultrasonic Pulse Velocity [CED 2: Cement and Concrete]. Bureau of Indian Standards: New Delhi, India, 1992.

| Mix No. | Cement | Silica Fume | Aggregate | Water | Super-Plasticizer | Glass Fibers | ||

|---|---|---|---|---|---|---|---|---|

| Coarse | Fine | 6 mm | 13 mm | |||||

| SCC | 420 | 105 | 810.5 | 810.5 | 189 | 4.2 | 0 | 0 |

| SCC-L1 | 420 | 105 | 779.1 | 779.1 | 189 | 4.2 | 0 | 9 |

| SCC-L2 | 420 | 105 | 793.5 | 793.5 | 189 | 4.2 | 0 | 4.5 |

| SCC-S1 | 420 | 105 | 779.1 | 779.1 | 189 | 4.2 | 9 | 0 |

| SCC-S2 | 420 | 105 | 793.5 | 793.5 | 189 | 4.2 | 4.5 | 0 |

| Mix No. | Slump-Flow mm | T50 cm s | L-Box (H2/H1) | GTM (%) |

|---|---|---|---|---|

| SCC | 790 | 2.5 | 0.98 | 11 |

| SCC-L1 | 750 | 4.3 | 0.9 | 8 |

| SCC-L2 | 650 | 5 | 0.8 | 6 |

| SCC-S1 | 760 | 3.4 | 0.93 | 8.7 |

| SCC-S2 | 670 | 4 | 0.85 | 8.3 |

| Limit of EFNARC (2005) [60] | 650–800 | 2–5 | 0.8–1.0 | ≤15 |

| Mix No. | Compressive Strength at High Temp (MPa) | SD | COV | ||||

|---|---|---|---|---|---|---|---|

| 25 °C | 200 °C | 400 °C | 600 °C | 800 °C | |||

| SCC | 50.2 (1) | 50.5 | 30.6 | 17 | 4.6 | 20.255 | 410.282 |

| SCC-L1 | 51.8 (1) | 52.3 | 37.3 | 18 | 6.4 | 20.475 | 419.213 |

| SCC-L2 | 52.4 (1) | 56.5 | 45 | 19.4 | 7.2 | 21.652 | 468.79 |

| SCC-S1 | 50.4 (1) | 51.1 | 36.6 | 19.3 | 6.2 | 19.678 | 387.217 |

| SCC-S2 | 51.0 (1) | 54 | 41.5 | 19 | 5.8 | 21.007 | 441.288 |

| SD | 0.932 | 2.425 | 5.437 | 1.024 | 0.953 | ||

| COV | 0.868 | 5.882 | 29.565 | 1.048 | 0.908 | ||

| Mix | Tensile Strength at Elevated Temp (MPa) | SD | COV | |||

|---|---|---|---|---|---|---|

| 25 °C | 200 °C | 400 °C | 600 °C | |||

| SCC | 4.1 | 4.20 | 2.90 | 0.53 | 1.707 | 2.914 |

| SCC-L1 | 4.5 | 4.70 | 3.1 | 0.80 | 1.797 | 3.229 |

| SCC-L2 | 4.9 | 5.00 | 4.20 | 1.7 | 1.542 | 2.377 |

| SCC-S1 | 4.60 | 4.70 | 3.7 | 1.2 | 1.630 | 2.657 |

| SCC-S2 | 4.7 | 4.8 | 3.9 | 1.6 | 1.489 | 2.217 |

| SD | 0.297 | 0.295 | 0.546 | 0.503 | ||

| COV | 0.088 | 0.087 | 0.298 | 0.253 | ||

| Mix | At Higher Temps, Relative Flexural Strength (MPa) | SD | COV | |||

|---|---|---|---|---|---|---|

| 25 °C | 200 °C | 400 °C | 600 °C | |||

| SCC | 6.375 | 6.4 | 2.75 | 0.10 | 3.063 | 9.379 |

| SCC-L1 | 8.60 | 8.8 | 4.5 | 0.40 | 3.979 | 15.829 |

| SCC-L2 | 9.8 | 10.3 | 7.1 | 1.40 | 4.083 | 16.670 |

| SCC-S1 | 8.6 | 9.75 | 6.9 | 0.64 | 4.061 | 16.490 |

| SCC-S2 | 9.0 | 9.4 | 7.5 | 1.8 | 3.513 | 12.343 |

| SD | 1.272 | 1.516 | 2.048 | 0.709 | ||

| COV | 1.618 | 2.297 | 4.193 | 0.503 | ||

| Pulse Velocity (km/s) | Concrete Quality Grading |

|---|---|

| Above 4.5 | Excellent |

| 3.5–4.5 | Good |

| 3.0–3.5 | Medium |

| Below 3.0 | Doubtful |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sultan, H.K.; Noor, A.A.A.; Huseien, G.F. Performance Evaluation of Self-Compacting Glass Fiber Concrete Incorporating Silica Fume at Elevated Temperatures. Eng 2024, 5, 1043-1066. https://doi.org/10.3390/eng5020057

Sultan HK, Noor AAA, Huseien GF. Performance Evaluation of Self-Compacting Glass Fiber Concrete Incorporating Silica Fume at Elevated Temperatures. Eng. 2024; 5(2):1043-1066. https://doi.org/10.3390/eng5020057

Chicago/Turabian StyleSultan, Hussein Kareem, Abbas Abdulhssein Abd Noor, and Ghasan Fahim Huseien. 2024. "Performance Evaluation of Self-Compacting Glass Fiber Concrete Incorporating Silica Fume at Elevated Temperatures" Eng 5, no. 2: 1043-1066. https://doi.org/10.3390/eng5020057