Abstract

The demolishing of concrete structures such as bridges, tunnels, buildings, and pavements has become a common activity due to reasons such as renovation, rehabilitation, retrofitting, or simply ending the service life of these structures. This upsurge has brought major challenges in managing construction demolition waste (CDW). Traditional demolition techniques are often characterized by high environmental impacts, inefficiency in waste management, and safety concerns. This paper critically reviews traditional and emerging concrete structure demolition technologies in terms of efficiency, safety, environmental impact, waste minimization, and material recyclability. A detailed review of manual demolition, mechanical demolition, implosion, and relatively new techniques such as static blasting, diamond wire sawing, soundless chemical demolition agents, hydro demolition, electrical discharge technology, demolition robots, and microwave heating is conducted. The key findings of this paper are that various alternative technologies have significant advantages over their traditional counterparts by offering minimum environmental pollution, improvements in on-site safety, and a possibility for materials to be reused and recycled. For instance, hydro demolition and diamond wire sawing are very efficient and accurate, meaning that actual waste management is highly improved. This paper underlines that the choice of demolition methods adapted to project needs is crucial for the development of sustainable CDW management. Such findings are useful to practitioners and policymakers who have to make fully informed decisions to promote environmental sustainability and resource conservation goals.

1. Introduction

It has been widely reported that the construction industry is responsible for approximately 6 billion tons of CO2 emissions annually worldwide [1]. Raw materials used as aggregates in concrete had a demand of about 2.7 billion tons and 900 million tons annually in European Union (EU) countries [2] and the USA [3], respectively. Construction and demolition waste (CDW) materials such as concrete, tiles, ceramics, plastic, wood, glass, bituminous mixtures, metals, and soil are generated from the construction, demolition, and maintenance of buildings. Villoria et al. [4] reported that approximately 36% of the total waste globally is related to CDW. The volume of discarded CDW has dramatically increased, rising from 50 million tons in 1980 to 548 million tons in 2015 in the USA [5]. Additionally, this number exceeds 1.5 billion tons each year in China and surpasses 850 million tons in EU countries, accounting for 31% of total generated waste [6]. An effective alternative is recycling and reusing CDW; however, the overall recycled CDW volume is only 30% in Europe and the USA [7]. Some other countries have even lower recycled CDW volumes, such as 5% and 9% for China and Portugal, respectively [1,6,8]. Interestingly, countries such as Japan have a recycled CDW volume of about 85% due to limited natural resources and landfill space [9].

Many factors, such as excessively ordered supplies or the mishandling of materials by unskilled laborers, can result in excessive waste generation. Demolition techniques are extremely essential and functional for the development of megacities, where space is limited and renovation is required for buildings nearing the end of their lifespan [10]. Time and cost-effectiveness are known to be key advantages of demolition. CDW can also be produced in large amounts due to natural disasters, leading to complications such as transportation issues, storage limitations, and disposal challenges at landfill sites [10]. The main challenge in CDW management is its chemical nature, which prevents processing through conventional waste management techniques. Therefore, shifting towards other waste management strategies, such as minimization, reuse, and recycling, is vital to address the shortage of landfill space and rising transportation costs.

There have been a number of investigations assessing the materials reused in the deconstruction of buildings, confirming their benefits [11,12,13]. However, the adoption of this technology still faces significant barriers, such as budget concerns and time-consuming processes. Recycling is considered a promising option for managing this waste stream, as materials such as steel, concrete, glass, wood, ceramic, and bricks can be recycled. These newly generated recycled materials can be integrated into new building materials and used for other purposes. Concrete, which shows composition differences depending on the country and application, is reported to be the most rapidly increasing component of the CDW family. Therefore, developing proper guidelines for the application of these materials is crucial [14].

Millions of tons of concrete waste are generated from buildings and structures nearing the end of their useful lifespan. Additionally, large quantities of construction materials are rejected for failing to meet specifications, and marble deposits yield aggregates of varying sizes from fragmentation operations and extensive stone sawing [15,16]. The U.S. Environmental Protection Agency (EPA) [5] strongly supports a Sustainable Material Management (SMM) approach, viewing specific CDW materials as valuable commodities that reduce the need for virgin materials and mitigate the cost and environmental burden of waste [15]. New buildings, roads, bridge projects, and other infrastructure can be constructed using these recycled materials. CDW materials can be effectively recycled, reduced, and reused following SMM plan guidance. Concrete engineers have shown appreciation for and achieved desired results in treating and utilizing CDW in fresh concrete, particularly for low-demand applications [17].

Notably, Recycled Concrete Aggregate (RCA) produced from recycled clean concrete waste offers a reasonable alternative to concrete made with virgin aggregate [18]. Effective management of CDW requires a comprehensive approach that covers all stages of its lifecycle, including preparation, end-of-life management, sorting and separation, and reprocessing [19].

Both minimizing waste generation and ensuring efficient material use are classified as the preparation phase [20], while the systematic dismantling or demolition of structures to facilitate material recovery is the main focus of end-of-life management [21]. Subsequently, sorting and separation are critical for segregating different types of waste to enhance recycling efficiency [22]. Reprocessing transforms recovered materials into usable products, closing the loop in the waste management cycle [23]. By addressing each of these key components, a sustainable and efficient system for managing CDW can be established, resulting in reduced environmental impacts and conserved natural resources.

Demolition directly influences the quantity and quality of generated waste, playing a crucial role in CDW management. Effective demolition practices can significantly enhance material recovery and recycling, thereby reducing the environmental footprint of construction activities [19]. Advanced demolition technologies can minimize waste production, improve sorting and separation processes, and increase the reuse and recycling rates of materials, particularly concrete. As the demand for sustainable construction practices grows, the importance of efficient demolition methods in CDW management also increases [24].

Urban redevelopment, building lifecycle management, and structural modifications necessitate the demolition of concrete structures, employing a combination of mechanized tools, explosives, and manual techniques to minimize the impact on the surrounding area. Traditional demolition methods span from piecemeal or manual demolition, utilizing hand tools for detailed work, to a suite of mechanical methods encompassing excavators, bulldozers, wrecking balls, pusher arm techniques, and grapples, which have been criticized for environmental unsustainability, inefficiency, safety risks, causing considerable noise, dust, and vibrations, risking workers’ and nearby communities’ health, and damaging regional ecosystems [25,26]. Additionally, the lack of accuracy in these methods often leads to unnecessary damage to neighboring infrastructure, excessive waste production, and a high carbon footprint due to inadequate resource and energy use [10]. High-reach excavators prove essential in safely bringing down tall structures, while cutting and lifting methods enable the targeted removal and disposal of specific building segments. For projects demanding minimal or partial disruption to preserve the integrity of nearby or targeted establishments, traditional techniques are being replaced with advanced methods to avoid side effects such as unwanted hairline cracks in targeted structures that negatively affect safety and noise, vibration, and dust in the area. Additionally, in projects requiring a quieter approach, particularly in sensitive or densely populated areas, non-explosive demolition presents a viable alternative to conventional techniques, ensuring a controlled demolition process, mainly when dealing with historically significant structures [27,28].

Technological advancements in equipment and methodologies have significantly transformed the demolition industry in recent years. These innovations have enhanced safety, efficiency, and sustainability in demolition projects [29]. Notable advancements include the development of robotic systems, high-reach excavators, and controlled implosion techniques, which allow for precise operations while minimizing risks and environmental impacts. Additionally, the integration of tools such as sensors, drones, and Building Information Modeling (BIM) has improved the planning, monitoring, and execution of demolition activities, thereby streamlining processes and reducing inefficiencies [30].

This paper provides a comprehensive review of demolition techniques for concrete structures, synthesizing academic papers and professional documents from reputable sources such as the American Society of Civil Engineers (ASCE), Construction Research Congress (CRC), ASCE Computing in Civil Engineering (i3CE), the Transportation Research Board (TRB), and various international conferences. The selected resources focus on advancements in demolition technologies, their effectiveness in waste reduction, and their implications for sustainable CDW management.

Articles for this paper were selected using defined eligibility criteria. These criteria included a publication timeframe of 1990 to 2024 to capture both historical trends and recent innovations, prioritization of peer-reviewed sources for quality assurance, and a specific focus on demolition techniques. A keyword-based search in the Scopus database using terms such as “demolition methods”, “concrete structures”, “CDW management”, and “waste reduction” identified an initial pool of 151 articles. After reviewing titles and abstracts against the eligibility criteria, the selection was narrowed to 75 articles.

The goal of this review is to highlight recent advancements in demolition technologies, evaluate their effectiveness in waste reduction, and explore their implications for sustainability and resource conservation in the construction industry. Through this analysis, the authors seek to contribute to a deeper and broader understanding of how innovative demolition practices can support environmental sustainability and resource conservation in the construction industry.

2. Demolition Methods

There are various end-of-life management strategies available; nevertheless, they can be broadly categorized into three main groups: demolition, adaptive reuse, and deconstruction [21]. Within the scope of this study, demolition is often considered a subset of “construction work” as defined by local regulations [24]. Specifically, demolition may involve dismantling a structure or load-bearing components critical to maintaining the physical integrity of the building. This definition excludes the dismantling of elements that provide support, access, or containment, as well as the removal of power, lighting, or telecommunications poles, as these elements are essential for continuing work on the project after demolition. The dismantling of such elements will be carried out in conjunction with the demolition of the structure(s) to which they are connected, ensuring the avoidance of any safety-related hazards during the process.

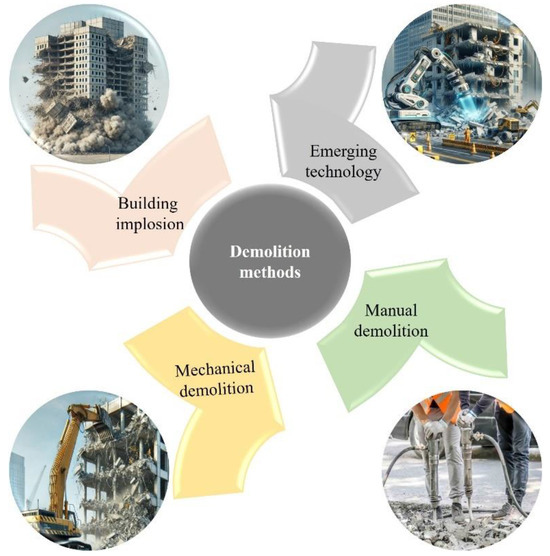

There are several demolition methods that can be grouped into four primary types: manual demolition, mechanical demolition, building implosion, and emerging technologies [19], as shown in Figure 1. The selection of an appropriate demolition method depends on several factors, including the type of construction, site conditions, associated costs, and relevant regulations [19]. Structures are typically dismantled sequentially, in reverse order of their original construction. This is to ensure the safety and health of workers and the public.

Figure 1.

Four primary types of demolition methods.

2.1. Manual Demolition

Manual demolition is a process in which contractors utilize portable tools such as sledgehammers, drills, and jackhammers to dismantle a building or structure floor by floor, from top to bottom [31]. This method typically starts from the roof and progresses downward to the floor, although the specific sequence may vary based on site conditions and the layout of the structure [32]. For this method, the safety and stability of the structure during manual demolition are vital to prevent unexpected collapse [31], therefore requiring additional time and labor. Nevertheless, the additional time and labor required in manual demolition minimize damage to sounding and increase the quantity of reusable materials, contributing to sustainable construction practices. These advantages make this method particularly suitable for dismantling small structures in urban areas, where minimizing the impact of demolition activities is crucial. In addition, it is also ideal for projects requiring the selective removal of parts of a structure, such as floor slabs using jackhammers [19]. This labor intensity, combined with precision and control, underscores the method’s applicability, especially in cases where adjacent structures or specific structures need to be preserved. In addition, this method produces less dust and noise compared to mechanical methods, making it a preferable option in densely populated or environmentally sensitive areas.

Manual demolition requires a highly skilled workforce in order to manage complex demolitions. The complexity is associated with various structural designs and materials. This requires proper training and adherence to safety procedures and protocols to safeguard workers and the public. It can be concluded that even though manual demolition is labor-intensive and time-consuming, it provides advantages in terms of safety, material preservation, and reduced environmental impact. Therefore, it is preferable for specific demolition scenarios. As urban areas continue to develop, demand for sustainable practices increases, and the role of manual demolition in the construction industry remains vital.

2.2. Mechanical Demolition

Mechanical demolition involves using motorized and heavy types of machinery in order to dismantle structures. Common machinery used for small- and medium-sized structures include bulldozers, wrecking balls, cranes, and excavators [27]. Figure 2 shows typical mechanical demolition utilizing heavy machinery equipment. The wrecking ball method is employed for larger structures, utilizing the weight, inertia, and gravity of wrecking balls to bring down buildings. Despite its cost- and time-efficiency, it is seldom used in urban areas due to environmental concerns [25,33].

Figure 2.

Mechanical demolition utilizing heavy machinery equipment.

Mechanical demolition, similar to manual demolition, follows a top-to-bottom and layer-by-layer sequence [26,28]. Large-scale equipment in this method significantly accelerates the process and reduces the risk of on-site injuries. However, this method can lead to increased contamination of recycled CDW due to the extensive mixing of materials. Additionally, mechanical demolition necessitates highly trained operators to ensure safe and efficient execution.

2.3. Implosion

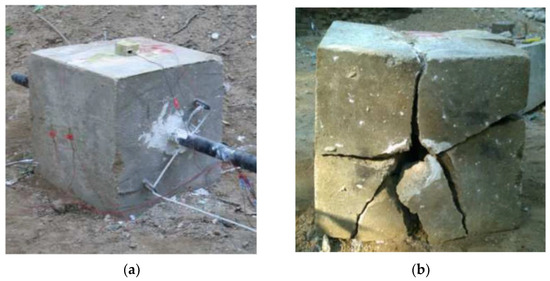

Implosion is another advanced technique for the demolition of large or high-rise structures, particularly in urban areas. Explosive materials or high air pressure (as shown in Figure 3 [34]) are installed in predetermined locations. Then, with the precise timing of detonation, it ensures that the structure collapses in a controlled manner. In general, there are two approaches to implosion: (1) placing explosives at the pillars to direct the collapse in a specific direction where space permits, and (2) placing explosives at the structure’s supports and middle sections to cause an inward collapse in confined spaces [35]. Implosion is generally utilized for robust or high-rise structures due to its ability to bring down buildings within tight urban environments efficiently. In some cases, demolition experts use 3D computer models to simulate implosion plans in advance, ensuring precision and safety [35,36,37]. However, similar to mechanical demolition, implosion can cause significant physical damage to the structural integrity of buildings, making material recovery and recycling more challenging.

Figure 3.

Concrete specimen (a) before blasting and (b) after blasting with high air pressure. Ref. [34] reproduced with permission. Ref. [34], 2016, Elsevier.

For large-scale projects, mechanical demolition and implosion are appropriate candidates, particularly due to their efficiency in handling large-scale projects. Operators should be professionally trained to ensure demolition is conducted in a safe and effective manner.

Due to the effectiveness of implosion for large-scale demolition projects, this method is likely to be a preferable method in the future. The ongoing development of innovative materials, practices, and technologies will offer safer and more environmentally friendly techniques to enhance their viability and contribution to sustainable construction practices.

2.4. Emerging Demolition Technologies

Emerging demolition technologies are gaining attention due to the fact that they revolutionize the way structures, particularly concrete buildings, are dismantled or demolished. There are a number of emerging demolition methods such as static blasting, diamond wire saws, soundless chemical demolition agents (SCDAs), hydro demolition, electrical discharge technology (EDT), demolition robots, and microwave heating.

2.4.1. Static Blasting

Static blasting or static expansion refers to the use of a static expansion agent, typically installed in medium boreholes, to fracture and demolish materials such as concrete. Static blasting does not rely on the use of explosives; therefore, it is safer and quieter than implosion. It is effective for the silent crushing and demolition of concrete structures, building foundations, or specific blocks, and provides a controlled means of material breakdown without the associated risks of explosive detonation.

Static blasting is preferable, particularly for structures where the use of explosives is restricted or impractical [38]. In comparison to conventional methods, static blasting minimizes the risk of flying debris and reduces noise pollution. This relatively convenient and quiet method is desirable in urban settings or sensitive areas where minimal disruption is essential. The process of static blasting involves drilling boreholes into the structure, into which the expansion agent is inserted. As the agent reacts, it expands, generating sufficient pressure to cause fracturing and eventual disintegration of the material. This method also allows for precise targeting of specific areas within a structure, enhancing control over the demolition process and improving safety and efficiency [38]. The expansion agent relies on hydration reactions to produce sufficient pressure to break rock or concrete. Experiments showed that the pressure generated ranged between 30–40 MPa, effectively meeting the 10–20 MPa required for rupturing soft rock and concrete [38].

2.4.2. Diamond Wire Sawing

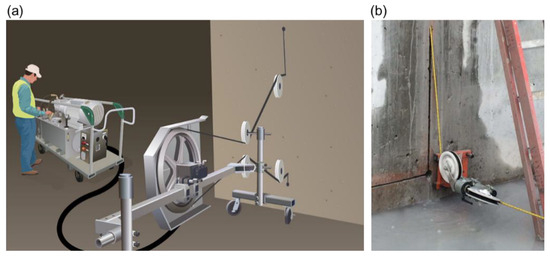

Diamond wire sawing technology is considered a highly efficient and safe method for cutting and separating large reinforced concrete structures. The method involves the use of a diamond wire saw to grind through concrete at high speeds, as shown in Figure 4. The wire, which is embedded with industrial-grade diamond, cuts through the materials, producing a smooth and precise separation [39]. The high efficiency of diamond wire sawing makes it particularly suitable for complex demolition tasks where precision is paramount. Diamond wire sawing is often employed in scenarios where traditional demolition methods may pose a risk to surrounding structures or when high precision is required. It significantly reduces the amount of dust and noise generated during the demolition process, therefore enhancing safety and minimizing environmental impacts. In addition, this method is highly adaptable and capable of being used in confined spaces and underwater, further broadening its applicability [39].

Figure 4.

Diamond wire sawing technology for concrete demolition. (a) Operator and diamond wire saw machine, (b) real-world implementation.

Experimental results indicated that the maximum cutting rate occurs with a bead diameter of 1 cm, with efficiency decreasing as the bead diameter increases. A multivariate regression analysis established a relationship between cutting rate and influencing parameters, achieving a correlation coefficient of 0.98 [40].

2.4.3. Soundless Chemical Demolition Agents (SCDAs)

Soundless chemical demolition agents (SCDAs) offer an environmentally friendly and efficient alternative to traditional demolition methods such as explosives and heavy machinery. These non-explosive chemicals are designed to break down concrete and rock safely and quietly without generating noise, vibration, or dust. This makes them ideal for use in sensitive areas such as urban centers, historical sites, or near hospitals [27]. SCDA works by being inserted into pre-drilled holes in the structure. Upon reacting with water, these agents expand, applying massive pressure internally within the concrete, leading to controlled cracking and breaking [39], as illustrated in Figure 5.

Figure 5.

The SCDA technique for concrete demolition: (a) Drill holes to the desired depth, (b) Mix the SCDA chemical material, (c) Pour the mixed SCDA into the holes, (d) Crack into the concrete as a result of the chemical reaction of the SCDA, (e) Cut steel rebars, (f) Remove concrete pieces.

The use of SCDA minimizes the impact on surrounding structures and reduces safety hazards, facilitating more manageable debris handling and disposal. Additionally, the method enhances the overall efficiency and sustainability of demolition projects by reducing the environmental impact and improving safety [41].

While static blasting and SCDA share similarities, such as both being non-explosive demolition methods that involve the insertion of agents into drilled boreholes to generate expansion and pressure for fracturing, key differences exist between the two technologies that justify their distinction. The static blasting method is more closely related to traditional blasting techniques in terms of the speed of reaction and the resulting fracture mechanism [38]. However, this method generates a more intense and quicker expansion force, which can result in a sudden fracture of the material, although still without the shockwaves or vibrations associated with conventional explosives [20]. This makes static blasting more suited for applications where rapid demolition is required but without the safety concerns associated with high-energy explosives [42]. On the other hand, SCDA works through a much slower chemical reaction. The agent, usually composed of calcium oxide- or magnesium oxide-based compounds, is mixed with water and poured into the boreholes, where it gradually expands over several hours or even days [39]. The pressure buildup in SCDA is much more gradual and controlled, leading to more predictable and less disruptive fracturing. This slower process significantly reduces the risk of unintended damage to surrounding structures and minimizes vibration, making SCDA particularly useful in sensitive environments, such as near hospitals, historical sites, or densely populated urban areas [41]. Additionally, SCDA does not produce noise or dust, whereas static blasting may cause some minimal noise or disruption due to the speed of its reaction [43].

Thus, while both methods rely on expansive pressure for fracturing, the primary differences lie in the speed, force, and environmental impact of the demolition process. Static blasting offers faster results but may be less suitable for delicate environments, while SCDA provides a slower, quieter, and more controlled demolition process, making it ideal for more sensitive applications.

2.4.4. Water Jet Machining (WJM)

Water jet machining is an advanced machine technique that has a history of more than 40 years and is used in a wide range of industrial and manufacturing applications [44]. In water jet cutting technology, a pump is used to pressurize water to about 4000 bars depending upon application. Later, the technology is modified by adding solid particles or abrasives to the high-pressure water jet to improve the process efficiency. The modified process is known as abrasive water jet machining (AWJM). Water jet machining is particularly effective for removing deteriorated concrete or preparing surfaces for repairs. By using water jets, hydro demolition ensures minimal damage to the remaining structure and preserves its integrity, making it an ideal choice for repair and renovation projects [45]. One of the significant advantages of hydro demolition is its environmental friendliness. The method produces no dust and significantly reduces noise levels compared to mechanical demolition, making it suitable for use in urban and residential areas. Additionally, the use of water jets allows for precise targeting of specific areas within the structure, improving control over the demolition process and enhancing safety and efficiency [45]. Trials conducted on 15 concrete specimens demonstrated that water pressure, cutting time, and concrete compressive strength influence the cutting depth. Statistical analyses produced a multi-regression model for predicting and optimizing hydro demolition performance parameters [45].

2.4.5. Electro-Discharge Technology (EDT)

Electrical discharge machining (EDT) is a controlled metal remover process that uses an electric spark as the cutting tool to cut the workpiece [46]. It operates by using high-voltage electrical discharges to create plasma channels and shockwaves within the concrete. This precise method allows for targeted destruction, minimizing collateral damage to neighboring structures, making EDT suitable for sensitive or densely populated areas. The technology produces significantly less dust, noise, and vibrations compared to conventional methods [47,48]. EDT works by generating electrical discharges that create localized high temperatures and pressures, leading to the formation of plasma channels within the concrete. These channels generate shockwaves that cause the concrete to fracture and disintegrate.

The precision of EDT allows for the targeted removal of specific areas within a structure, enhancing control over the demolition process and improving safety and efficiency. Despite the high equipment cost and need for specialized training, EDT offers significant advantages in terms of safety, environmental impact, and precision [47,48].

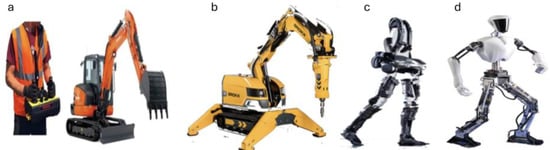

2.4.6. Robots

Demolition robots are becoming more popular as they are equipped with various tools such as hammers, crushers, and shears, representing an innovative approach to demolition. These robots are operated remotely and can function in hazardous conditions and confined spaces that are unsafe for workers. Figure 6 shows human collaborative robots for demolition construction [49]. Demolition robots offer high working efficiency and safety, performing demolition tasks autonomously under human supervision [50]. The success of demolition robots lies in their advanced perceptual capabilities, which enable them to accurately identify structures to be dismantled and avoid obstacles [51]. Robots are designed to carry out tasks that require human oversight, especially in areas where autonomous decision-making is challenging. Demolition robots are designed to operate in harsh conditions involving heat, dust, and noise, making them suitable for heavy demolition and renovation work [50,52]. Despite their many benefits, demolition robots need to be adapted and tested in various working environments to ensure efficiency. Their use in the industry is expected to increase as technology advances, making them a valuable asset for safe and efficient demolition [50,52].

Figure 6.

Collaborative robots for demolition construction: (a) human-assisted robot, (b) demolition robot, (c) exoskeleton, and (d) humanoid robot. Ref. [49] reproduced with permission. Ref. [49], 2016, Elsevier.

2.4.7. Microwave Heating

Microwave heating is based on the dissipation of internal energy due to the excitation of molecular dipoles when exposed to an electromagnetic field [53]. Microwaves cause water within the cement paste, present in various forms such as free water, capillary water, gel water, and chemically combined water, to rapidly heat and vaporize, creating high steam pressure [54]. The heterogeneous nature of concrete, with differing microwave-absorbing capacities among its components, leads to selective heating and thermal gradients under microwave treatment. This results in considerable deterioration in cement-based materials [55,56]. Since the 1960s, microwave-assisted crushing of concrete structures has been studied for applications such as concrete decontamination, coarse aggregate recovery, and slotting or drilling [57]. For instance, Buttress et al. [58] used microwave irradiation to thermally scabble concrete surfaces, separating the polluted layer from the main structure. White et al. [59,60] conducted extensive research on microwave decontamination of radionuclide-contaminated concrete, involving equipment development, optimization, working condition selection, and removal efficiency evaluation. Lagos et al. (1995) [61] applied finite element methods to calculate temperature distribution during microwave decontamination, assessed the influence of steel bars on microwave field distribution, and compared microwave frequencies. Regarding microwave-assisted aggregate recycling, Tsujino et al. [62] used an aggregate coating technique to improve recovery and quality. Jerby et al. [63,64] and Meir et al. [65] developed and refined a microwave drill capable of drilling holes in building materials such as cement and concrete by exploiting the thermal runaway phenomenon during microwave heating.

Previous studies have primarily focused on demolishing and recycling concrete structures, with less attention given to cement and mortar materials. Investigating the thermal response of cement and mortar under microwave radiation is crucial for understanding the failure mechanisms of concrete materials, particularly the vapor pressure theory. The damage to cementitious materials under microwave irradiation is primarily thermal, and factors such as the mixture ratio, moisture content, and microwave parameters significantly affect heating and damage. However, due to the lack of real-time monitoring methods, previous studies have struggled to accurately describe the physical and chemical changes occurring in materials during microwave irradiation. Further research is necessary to elucidate the various influencing factors and the mechanisms underlying the microwave heating characteristics of materials. Testing on five steel-reinforced concrete specimens verified the feasibility of microwave heating for demolition. Under experimental conditions, concrete and steel were separated within approximately 15 min, with a critical expansion difference of approximately 1.85 mm [66].

3. Discussion

The construction industry’s ongoing challenges in managing CDW have led to the development and application of various demolition techniques. Each method offers distinct advantages and limitations based on efficiency, cost, safety, and environmental impact. This discussion aims to compare several concrete demolition techniques, including manual demolition, mechanical demolition, building implosion, static blasting, diamond wire saws, SCDAs, hydro demolition, EDT, demolition robots, and microwave heating. Table 1 provides a comprehensive comparison using a five-point Likert scale [37], ranging from: “Extremely high” = 5; “High” = 4; “Moderate” = 3; “Low” = 2; and “Extremely low” = 1, which will serve as a foundation for this analysis.

Table 1.

Comparison of Concrete Demolition Methods.

The key indicators for selecting the appropriate range for each method are established as follows:

- Demolition Time/Rate: This indicator measures the speed at which a demolition method can complete a given task. Faster methods, such as building implosions or mechanical demolitions, are rated higher, whereas slower methods such as manual demolition score lower. Efficiency is essential for time-sensitive projects, especially in urban environments where downtime must be minimized.

- Cost: This factor evaluates the economic feasibility of the demolition method. Methods with lower operational and equipment costs, such as manual demolition, are rated as being more affordable, whereas advanced technologies such as hydro demolition or diamond wire saws, which require specialized equipment and higher energy consumption, have higher associated costs.

- Need for Skilled Operators: This indicator assesses the level of expertise required to operate a particular method effectively. For example, technologies such as diamond wire saws or demolition robots require specialized training and experience, while manual and mechanical demolition can be performed with basic training.

- Safety: Safety evaluates the risk to workers and surrounding structures during demolition. Methods such as implosion, while efficient, carry significant safety risks if not executed properly. In contrast, controlled techniques such as hydro demolition or demolition robots are rated higher due to their enhanced precision and the lower risk of accidents.

- Environmental Pollution: This measures the environmental impact, including dust, noise, and emissions generated during demolition. Environmentally friendly methods such as hydro demolition and SCDA score higher as they produce minimal noise and airborne particles, whereas implosions and mechanical demolitions are rated lower due to their higher environmental disruption.

- Waste Reduction: This indicator evaluates the amount of demolition waste generated and the potential to minimize it. Advanced methods such as hydro demolition or EDT are rated higher as they reduce waste through controlled processes, while conventional techniques such as manual or mechanical demolition may result in higher volumes of debris.

- Recyclability of Materials: This assesses how effectively materials from the demolition process can be reused or recycled. Methods such as diamond wire saws and hydro demolition are rated highly for their ability to preserve material integrity, facilitating recycling, whereas techniques such as implosions may result in mixed or contaminated debris that is harder to recycle.

3.1. Conventional Demolition Technologies

Conventional demolition technologies, such as manual demolition, mechanical demolition, and building implosion, have been widely used due to their proven effectiveness and reliability. The traditional manual demolition method involves the use of portable tools such as sledgehammers, drillers, and jackhammers. It is labor-intensive, allowing for meticulous dismantling, which minimizes damage to building components and increases the potential for material reuse. However, manual demolition is time-consuming (rated 2 in Table 1) and costly (rated 3) due to high labor requirements. Skilled operators are essential to ensure safety (rated 3), and the environmental impact is relatively low (rated 3) since heavy machinery and emissions are absent. This method is particularly suitable for small structures in urban areas where the effects of demolition must be minimized. In addition, the manual demolition method provides a moderate level of “waste reduction” (rated 3), as the careful dismantling process minimizes damage to the building components. This selectivity allows for a higher level of “recyclability of materials” (rated 4) since many elements, such as bricks, wood, and metal, remain intact and suitable for reuse. However, this method’s slower pace and labor-intensive nature often increase costs and time, making it more appropriate for projects where maximizing material salvage is a priority rather than rapid completion.

Mechanical demolition is based on the utilization of heavy machinery such as bulldozers, cranes, and excavators. Mechanical demolition significantly accelerates the demolition process (rated 4) and reduces labor costs (rated 4). However, highly trained operators (rated 4) are required to handle the equipment safely. While effective in expediting demolition and reducing onsite injuries, mechanical demolition increases the mixing levels of CDW, reducing material recyclability (rated 4 in cost). The environmental impact is moderate (rated 3) due to noise and dust generation, although it is more efficient for larger structures compared to manual methods. Furthermore, mechanical demolition, while efficient in terms of speed, offers only a moderate degree of “waste reduction” (rated 3). The use of heavy machinery can result in mixed and sometimes damaged debris, limiting the ability to separate materials effectively for reuse. Consequently, the “recyclability of materials” is also moderate (rated 3), with steel and other durable materials typically being recoverable, while concrete and fragile components are often too damaged to be reused. This method’s advantages in time and labor savings come at the cost of reduced potential for material recovery.

The implosion method involves strategically placing explosives to collapse a structure inwardly, making it highly efficient (rated 5 in skilled operators) and time-efficient (rated 5). It is generally cost-effective (rated 2) for large, robust, or high-rise structures in urban areas but demands highly skilled operators (rated 5) to ensure precision and safety. Environmental concerns include dust, vibrations, and noise (rated 4), making implosion less suitable for densely populated areas. Although extremely fast and efficient for large structures, the implosion method results in low “waste reduction” (rated 2). The violent nature of this technique produces a significant amount of mixed and shattered debris, making material recovery difficult. As a result, the “recyclability of materials” is also rated low (2), particularly for components such as concrete and glass, which are heavily fragmented during the process. The speed and cost-efficiency of implosion make it ideal for large, high-rise buildings, but its impact on waste generation and material salvage is a notable drawback.

3.2. Analysis Emerging Demolition Technologies

The construction and demolition industry is experiencing advancement with emerging demolition technologies such as static blasting, diamond wire saws, soundless chemical demolition agents (SCDAs), hydro demolition, electrical discharge technology (EDT), demolition robots, and microwave heating. These emerging technologies often offer innovative solutions with significant advantages in terms of safety and environmental impact. Based on Table 1, the technologies are rated as follows:

- Static blasting: This technology breaks down concrete structures silently using non-explosive agents. This technique provides a moderate demolition rate (rated 3) and costs (rated 3) and requires skilled operators (rated 4) for precise applications (Table 1). The high level of safety (rated 4) with minimal environmental pollution (rated 4) makes this technique appropriate for sensitive areas. Regarding CDW management factors, static blasting offers moderate “waste reduction (rated 3), as it involves the controlled fracturing of concrete and other materials. However, the precision of this method is still lower than that of more selective technologies (e.g., hydro demolition), resulting in some mixed waste. “recyclability of materials” is also moderate (rated 3) since fractured materials can be recovered; however, separating reusable components such as steel and concrete may require significant processing.

- Dimond wire saws: For cutting large reinforced concrete structures, this technology provides efficiency (rated 4) and safety (rated 4). The costs are moderate (rated 3); however, it requires skilled operators (rated 4) due to the technical nature of the equipment. In addition, this method produces minimal dust and noise (rated 2), which enhances its environmental profile. In addition, it excels in “waste reduction” (rated 5), as this method allows for the precise cutting of concrete and other materials, minimizing unnecessary breakage. This high level of control results in a significant increase in “recyclability of materials” (rated 5), as intact concrete sections, steel reinforcements, and other components can be easily recovered and repurposed. The method’s ability to preserve the integrity of materials makes it an excellent choice for projects prioritizing sustainability and material reuse, though it comes with higher costs and the need for skilled operators.

- SCDA: This method uses chemicals that expand within predrilled holes to fracture concrete. It is an environmentally friendly alternative for concrete demolition. The method offers a moderate demolition rate (rated 3) and costs (rated 3), with a high safety level (rated 5). This high safety level is due to the absence of explosive risks. The environmental impact is low (rated 2) and ideal for urban and sensitive areas. SCDA provides a high level of “waste reduction” (rated 4), as its controlled expansion causes minimal disturbance to surrounding materials. This selective cracking reduces the risk of mixing waste and helps preserve materials for reuse. “recyclability of materials” is also high (rated 4), as the relatively clean fracturing process allows for easier separation of materials such as concrete and steel. SCDA is especially useful in sensitive environments where noise and vibrations must be minimized, further enhancing its value in sustainable demolition practices.

- High-pressure water jets (hydro): This method is ideal for removing concrete without damaging reinforcement bars. It produces no dust and lower noise levels (rated 2), making it environmentally friendly and suitable for surface preparation and selective concrete removal. It provides efficiency (rated 4) and safety (rated 5). The cost is moderate (rated 3) and it requires skilled operators (rated 4). This method is highly effective in “waste reduction” (rated 5), using high-pressure water jets to selectively remove concrete while preserving other materials. This precision leads to high “recyclability of materials” (rated 5), as reinforcing steel and other components remain intact and ready for reuse. This method is particularly beneficial in situations requiring the careful removal of damaged concrete while maintaining the structural integrity of the remaining elements, making it ideal for repair projects and minimizing environmental impact.

- EDT: This method uses high-voltage electrical discharges to create shockwaves within the concrete, causing it to fracture. It is highly safe (rated 5), with a moderate demolition rate (rated 4) and cost (rated 3). This method requires specialized training (rated 5) and produces minimal dust, noise, and vibrations (rated 2), making it suitable for densely populated and sensitive areas. Additionally, EDT achieves a high level of “waste reduction” (rated 4) due to its controlled method of breaking down materials, which minimizes unnecessary debris. This precision ensures that waste is kept to a minimum, making it a more environmentally conscious option. However, “recyclability of materials” is moderate (rated 3) because the resulting material fragments can sometimes be harder to separate, especially when dealing with mixed materials such as reinforced concrete.

- Robots: Robots with tools such as hammers and crushers and demolition robots offer operation in hazardous environments. Their efficiency, demolition rate, and safety are high (all rated 4). The cost is moderate (rated 3) due to the initial investment in technology. Skilled operators (rated 4) are required to supervise and control the robots. The environmental impact is moderate (rated 3) due to reduced human risk and precise demolition capabilities. Moreover, robots offer high waste reduction (rated 4), as their programmable nature enables precise, controlled demolition. This minimizes the unnecessary breakage of materials, allowing for easier waste separation. Recyclability of materials is rated highly (4) as well, as intact concrete sections, steel, and other materials can be salvaged more effectively.

- Microwave heating: This method induces cracks through selective heating and offers moderate efficiency (rated 3) and cost (rated 3). It requires skilled operators (rated 4) and a high safety level (rated 5), with minimal environmental impact (rated 5) due to the absence of noise and dust. It is a suitable candidate for specialized demolition tasks. This method provides a high level of “waste reduction” (rated 4), as it weakens concrete at a molecular level without causing extensive damage to surrounding materials. This localized, controlled approach helps reduce unnecessary waste generation during the demolition process. “Recyclability of materials” is also high (rated 4), as the concrete and reinforcing steel typically remain intact and separable after the process, making it easier to recover and reuse these materials. While microwave heating is still an emerging technology, its ability to balance waste reduction and material recyclability makes it a promising option for sustainable demolition, particularly in applications requiring minimal environmental disturbance.

3.3. Future Directions

Based on the findings of this study, several recommendations and future directions are proposed to advance sustainable demolition practices and improve CDW management. Emerging technologies such as hydro demolition, diamond wire sawing, and microwave heating should be prioritized for further research and implementation due to their potential to enhance safety, reduce environmental impact, and increase material recyclability. Developing comprehensive guidelines for selecting demolition methods tailored to specific project requirements, including structural type and environmental sensitivity, is essential to support decision-making. Additionally, investments in skill development and training programs for operators of advanced technologies will ensure precision and safety in their application. Enhancing recycling and material recovery processes through innovations in separation technologies and chemical treatments should be a key focus to maximize the reuse of materials such as concrete and steel. Incorporating automation and digital tools, such as demolition robots and AI-driven decision-making systems, can further improve precision, efficiency, and safety. Lastly, integrating detailed environmental impact assessments for each method will help quantify emissions, energy consumption, and waste generation, providing a holistic perspective on sustainability. These efforts, combined with continued research and industry collaboration, will drive the adoption of environmentally responsible and efficient demolition practices.

4. Conclusions

The comparison of various concrete demolition techniques highlights the need for a tailored approach based on specific project requirements. Manual demolition is suited for small-scale projects where precision and material reuse are priorities. Mechanical demolition and building implosion are efficient for large-scale demolitions but come with environmental concerns. Emerging technologies such as SCDA, hydro demolition, EDT, and microwave heating offer promising alternatives with higher safety and lower environmental impacts, albeit with a need for skilled operators. Ultimately, the choice of demolition method should balance efficiency, cost, safety, and environmental considerations to achieve sustainable CDW management.

This comprehensive review underscores the necessity of selecting methods that align with project-specific demands, focusing on factors such as efficiency, cost, safety, environmental impact, and waste management.

Demolition Time/Rate: The speed of demolition is crucial for project timelines. Traditional mechanical demolition offers a significant advantage in efficiency for medium- and large-scale structures but falls short when precision is required. Implosion stands out for large structures, providing the fastest demolition rate; however, its applicability is limited to environments that can safely accommodate the associated disruptions. Emerging methods, such as hydro demolition, strike a balance between speed and control, proving effective for projects where structural integrity must be preserved.

Cost: The actual cost is one of the major determining factors in the selection of demolition methods. Manual demolition is very labor-intensive and thus expensive; however, it has the advantage of being very precise for selective deconstruction. In projects where the area is bigger, the mechanical demolition method presents a relatively more economically feasible option, which is nonetheless costly, especially when mitigation to environmental concerns is considered. Advanced technologies such as SCDA and microwave heating are possibly very costly in terms of initial investments but most often present long-term benefits through efficiency improvements and reductions in waste management costs.

Safety: Safety remains a critical concern, particularly in urban and densely populated areas. Traditional methods, such as mechanical demolition, require skilled operators to mitigate risks, and implosion techniques demand meticulous planning to prevent accidents. Emerging methods such as EDT and demolition robots have revolutionized safety standards by minimizing human exposure to hazardous conditions. SCDA and hydro demolition further contribute to worker safety by eliminating explosive risks and reducing airborne contaminants.

Environmental Pollution: The environmental impacts of demolition methods vary significantly. Conventional techniques generate considerable noise, dust, and vibrations, posing risks to both the environment and public health. In contrast, hydro demolition and microwave heating are highly favorable, as they produce minimal pollutants and are more compatible with environmentally sensitive areas. SCDA also stands out for its low environmental footprint, providing a quieter and less disruptive alternative.

Waste Reduction and Recyclability: Effective CDW management is increasingly vital in promoting sustainability. Methods that prioritize material preservation, such as diamond wire sawing and hydro demolition, enable high rates of recyclability, ensuring that valuable resources are reused. Manual demolition, while slower, allows for meticulous material separation, enhancing recycling potential. Conversely, methods such as implosion result in heavily mixed and fragmented debris, complicating recycling efforts and often leading to more waste.

Concluding Remarks: The ongoing development of innovative demolition technologies presents promising opportunities to improve efficiency, enhance safety, and minimize environmental impact. The strategic integration of these methods into construction practices is crucial for sustainable CDW management. Although these emerging techniques require preliminary investment and qualified manpower, the accruing advantages in terms of safety, environmental protection, and recovery of materials make them indispensable tools for the future of construction. It is expected that the contribution of such advanced techniques applied in this dynamic construction industry will be significant in minimizing environmental impacts while conserving natural resources in development.

Author Contributions

The authors confirm contribution to the paper as follows: study conception and design: M.M., G.R.L. and S.A.; data collection: M.M., S.M.M., M.R. and S.A.; analysis and interpretation of results: M.M. and S.A.; draft manuscript preparation: M.M. and S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed during this study are included in the published paper.

Conflicts of Interest

Author Mohsen Mohammadi was employed by the Schnabel Engineering LLC, Saman Mostafa Mohammad was employed by the Kirmanj Construction. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Huang, L.; Krigsvoll, G.; Johansen, F.; Liu, Y.; Zhang, X. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- EAA. A Sustainable Industry for a Sustainable Europe—Annual Review 2017–2018; UEPG: Brussels, Belgium, 2017; Available online: https://www.scribd.com/document/517521433/uepg-annual-review-2017-2018-003 (accessed on 28 October 2024).

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Sáez, P.V.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. Advancing Sustainable Materials Management: 2014 Fact Sheet Assessing Trends in Material Generation, Recycling, Composting, Combustion with Energy Recovery and Landfilling in the United States; US Environmental Protection Agency: Washinton, DC, USA, 2014. [Google Scholar]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Böhmer, S.; Moser, G.; Neubauer, C.; Peltoniemi, M.; Schachermayer, E.; Tesar, M.; Winter, B. Aggregates Case Study, Final Report; Umwelt Bundesamt: Vienna, Austria, 2008. [Google Scholar]

- Coelho, A.; de Brito, J. Economic viability analysis of a construction and demolition waste recycling plant in Portugal—Part I: Location, materials, technology and economic analysis. J. Clean. Prod. 2013, 39, 338–352. [Google Scholar] [CrossRef]

- Movassaghi, R. Durability of Reinforced Concrete Incorporating Recycled Concrete as Aggregate (RCA); UWSpace: Waterloo, ON, Canada, 2006. [Google Scholar]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Saghafi, M.D.; Teshnizi, Z.A.H. Building Deconstruction and Material Recovery in Iran: An Analysis of Major Determinants. Procedia Eng. 2011, 21, 853–863. [Google Scholar] [CrossRef]

- Chau, C.; Xu, J.; Leung, T.; Ng, W. Evaluation of the impacts of end-of-life management strategies for deconstruction of a high-rise concrete framed office building. Appl. Energy 2017, 185, 1595–1603. [Google Scholar] [CrossRef]

- Höglmeier, K.; Weber-Blaschke, G.; Richter, K. Potentials for cascading of recovered wood from building deconstruction—A case study for south-east Germany. Resour. Conserv. Recycl. 2017, 117, 304–314. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Smith, A.; Volz, J.S.; Khayat, K.H. An experimental study on flexural strength of reinforced concrete beams with 100% recycled concrete aggregate. Eng. Struct. 2015, 88, 154–162. [Google Scholar] [CrossRef]

- Osmani, M. Construction Waste. In Waste; Elsevier: Amsterdam, The Netherlands, 2011; pp. 207–218. [Google Scholar] [CrossRef]

- Ibrahim, M.; Alimi, W.; Assaggaf, R.; Salami, B.A.; Oladapo, E.A. An overview of factors influencing the properties of concrete incorporating construction and demolition wastes. Constr. Build. Mater. 2023, 367, 130307. [Google Scholar] [CrossRef]

- Shahidan, S.; Azmi, M.A.M.; Kupusamy, K.; Zuki, S.S.M.; Ali, N. Utilizing Construction and Demolition (C&D) Waste as Recycled Aggregates (RA) in Concrete. Procedia Eng. 2017, 174, 1028–1035. [Google Scholar] [CrossRef]

- Marinković, S.; Carević, V. Comparative studies of the life cycle analysis between conventional and recycled aggregate concrete. In New Trends in Eco-Efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 257–291. [Google Scholar] [CrossRef]

- Jiang, J.; Chu, C.; Song, L.; Gao, X.; Huang, B.; Zhang, Y.; Zhang, Y.; Liu, Y.; Hou, L.; Ju, M.; et al. From prospecting to mining: A review of enabling technologies, LCAs, and LCCAs for improved construction and demolition waste management. Waste Manag. 2023, 159, 12–26. [Google Scholar] [CrossRef] [PubMed]

- EU Construction & Demolition Waste Management Protocol. Available online: https://ec.europa.eu/docsroom/documents/20509/ (accessed on 28 October 2024).

- Chan, J.; Bachmann, C.; Haas, C. Potential economic and energy impacts of substituting adaptive reuse for new building construction: A case study of Ontario. J. Clean. Prod. 2020, 259, 120939. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. Off-site sorting of construction waste: What can we learn from Hong Kong? Resour. Conserv. Recycl. 2012, 69, 100–108. [Google Scholar] [CrossRef]

- Xiao, J. Recycled Aggregate Concrete Structures; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- WHSQ. “Demolition work Code of Practice,” 2021. Available online: https://www.worksafe.qld.gov.au/__data/assets/pdf_file/0026/72629/demolition-work-cop-2021.pdf (accessed on 28 October 2024).

- Hoang, N.H.; Ishigaki, T.; Watari, T.; Yamada, M.; Kawamoto, K. Current state of building demolition and potential for selective dismantling in Vietnam. Waste Manag. 2022, 149, 218–227. [Google Scholar] [CrossRef]

- Rajan, D.; Kumar, M.K.; Ramesh, S. Optimization of Material Recovery Strategies in the Demolition Phase of Buildings–A Case Study. Int. J. Eng. Manag. Res. 2021, 11, 103–108. [Google Scholar] [CrossRef]

- Zhong, Z.; Zhang, H.; Hu, Y.; Lou, R.; Tao, P.; Liu, J. Experimental and numerical explorations on the optimized applications of SCDA in cracking concrete blocks. Measurement 2023, 206, 112335. [Google Scholar] [CrossRef]

- Ascanio Sánchez, E. Development of El Veril (Batch 1) Study and Comparison of Demolition Methodologies and Practical Application; Theseus: Standford, CA, USA, 2023. [Google Scholar]

- Shedge, V.R.; Oak, A. Technological Innovations in Demolition Equipment and Methods. Int. J. Res. Eng. Sci. Manag. 2024, 7, 35–39. [Google Scholar]

- Li, Y.; Liu, C. Applications of multirotor drone technologies in construction management. Int. J. Constr. Manag. 2019, 19, 401–412. [Google Scholar] [CrossRef]

- Rathi, S.O.; Khandve, P. Demolition of Buildings-An Overview. Int. J. Adv. Eng. Res. Dev. (IJAERD) 2014, 1, 2348–4470. Available online: https://www.researchgate.net/publication/292695529 (accessed on 28 October 2024).

- Pranav, P.; Pitroda, J.; Bhavsar, J.J. Demolition: Methods and Comparison. In Proceedings of the International Conference on: “Engineering: Issues, Opportunities and Challenges for Development”, Bardoli, India, 11 April 2015; Available online: https://www.researchgate.net/publication/281174903 (accessed on 28 October 2024).

- Wenzhong, Z.; Zhiming, S.; Wei, Z. Progress and prospect on demolition technology of masonry structures. J. Harbin Inst. Technol. 2019, 51, 13. [Google Scholar] [CrossRef]

- Zhu, W.; Gai, D.; Wei, C.; Li, S. High-pressure air blasting experiments on concrete and implications for enhanced coal gas drainage. J. Nat. Gas Sci. Eng. 2016, 36, 1253–1263. [Google Scholar] [CrossRef]

- Li, X.L.; Yang, Y.; Luan, L.F. Implosion Method of Numerical Simulation and Local Component Failure Analysis. Adv. Mater. Res. 2013, 671–674, 2103–2110. [Google Scholar] [CrossRef]

- Michaloudis, G.; Mattern, S.; Schweizerhof, K. Computer Simulation for Building Implosion Using LS-DYNA. In High Performance Computing in Science and Engineering 2010–Transactions of the High Performance Computing Center, Stuttgart, HLRS 2010; Nagel, W., Kröner, D., Resch, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 519–528. [Google Scholar] [CrossRef]

- Assaad, R.H.; Mohammadi, M.; Chang, A. An IoT-Enabled Sensing Device to Quantify the Reliability of Shared Economy Systems Using Intelligent Sensor Fusion Building Technologies. Buildings 2023, 13, 2182. [Google Scholar] [CrossRef]

- Zhou, H.; Xie, X.; Feng, Y. Rock breaking methods to replace blasting. IOP Conf. Ser. Mater. Sci. Eng. 2018, 322, 022014. [Google Scholar] [CrossRef]

- Park, J.H.; Chu, B. An Experimental Verification on the Development of an Innovative Diamond Wire Saw Cutting Technology. J. Korean Soc. Manuf. Process Eng. 2018, 17, 83–90. [Google Scholar] [CrossRef]

- Amirsharafi, A.; Noroozi, M.; Sereshki, F. Investigation of Cutting Rate of Diamond Wire Saw Machine Using Numerical Modeling. Rock Mech. Rock Eng. 2023, 56, 7301–7314. [Google Scholar] [CrossRef]

- Zhong, Z.; Tao, P.; Jin, H.; Lou, R.; Cui, Y.; Liu, J. A quantitative investigation on the fragmentation performance of SCDA in cracking steel fiber reinforced concrete. Constr. Build. Mater. 2023, 403, 133133. [Google Scholar] [CrossRef]

- Zhou, J.; Shu, P.; Zhang, B.; Deng, B.; Wu, Y. A Finite Element Analysis of Tunnel Lining Demolition by Blasting for Subway Tunnel Expansion. Appl. Sci. 2022, 12, 9564. [Google Scholar] [CrossRef]

- Zhong, Z.; Tao, P.; Zhang, H.; Jin, H.; Lou, R.; Cui, Y.; Huang, Q.; Liu, J. Research progress and future prospective of soundless chemical demolition agents (SCDAs) and associated applications. Constr. Build. Mater. 2023, 409, 134209. [Google Scholar] [CrossRef]

- Mardi, K.B.; Dixit, A.R.; Pramanik, A.; Basak, A.K. Tribology in (abrasive) water jet machining: A review. In Machining and Tribology: Processes, Surfaces, Coolants, and Modeling; Elsevier: Amsterdam, The Netherlands, 2021; pp. 113–125. [Google Scholar] [CrossRef]

- Abu Shanab, I.; Sorensen, A.D. Experimental and Statistical Study of High-Pressure Water Jet ‘Hydro-Demolition Technique’ on Concrete for Partial-Depth Concrete Bridge Deck Repair Applications. Transp. Res. Rec. 2023, 2677, 479–489. [Google Scholar] [CrossRef]

- Mahto, D.G.; Singh, N. Experimental Study of Process Parameters through Dissimilar Form of Electrodes in EDM Machining. SSRN Electron. J. 2017. [Google Scholar] [CrossRef]

- Ushakov, V.Y.; Vajov, V.F.; Zinoviev, N.T. Electro-Discharge Technology for Drilling Wells and Concrete Destruction; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Wang, X.; Li, N.; Wang, W. Experimental study on crushing of concrete slabs by high-voltage pulse discharge. Constr. Build. Mater. 2023, 401, 132951. [Google Scholar] [CrossRef]

- Ohueri, C.C.; Masrom, A.N.; Noguchi, M. Human-robot collaboration for building deconstruction in the context of construction 5.0. Autom. Constr. 2024, 167, 105723. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Zhang, K.; Wang, Z.; Lu, J. Design and analysis of demolition robot arm based on finite element method. Adv. Mech. Eng. 2019, 11. [Google Scholar] [CrossRef]

- Corucci, F.; Ruffaldi, E. Toward Autonomous Robots for Demolitions in Unstructured Environments. In Intelligent Autonomous Systems 13. Advances in Intelligent Systems and Computing; Menegatti, E., Michael, N., Berns, K., Yamaguchi, H., Eds.; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Derlukiewicz, D.; Ptak, M.; KozioŁEk, S. Proactive failure prevention by human-machine interface in remote-controlled demolition robots. In Advances in Intelligent Systems and Computing; Springer: Berlin/Heidelberg, Germany, 2016; pp. 711–720. [Google Scholar] [CrossRef]

- Mangat, P.S.; Grigoriadis, K.; Abubakri, S. Microwave curing parameters of in-situ concrete repairs. Constr. Build. Mater. 2016, 112, 856–866. [Google Scholar] [CrossRef]

- Hover, K.C. The influence of water on the performance of concrete. Constr. Build. Mater. 2011, 25, 3003–3013. [Google Scholar] [CrossRef]

- Ahn, J. Microwave dielectric heating to disassemble a modified cementitious joint. Mater. Struct. 2013, 46, 2077–2090. [Google Scholar] [CrossRef]

- Buttress, A.; Jones, A.; Kingman, S. Microwave processing of cement and concrete materials–Towards an industrial reality? Cem. Concr. Res. 2015, 68, 112–123. [Google Scholar] [CrossRef]

- Zheng, Y.; Su, Z.; Fu, H.; Zhang, Q.; Li, J. Thermal behaviors of cement and mortar under microwave treatment and the influencing factors: An experimental study. Constr. Build. Mater. 2024, 411, 134191. [Google Scholar] [CrossRef]

- Buttress, A.; Jones, D.; Dodds, C.; Dimitrakis, G.; Campbell, C.; Dawson, A.; Kingman, S. Understanding the scabbling of concrete using microwave energy. Cem. Concr. Res. 2015, 75, 75–90. [Google Scholar] [CrossRef]

- White, T.L.; Grubb, R.G.; Pugh, L.P.; Foster, D.; Box, W.D. Removal of Contaminated Concrete Surfaces by Microwave Heating-Phase I Results; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1992. [Google Scholar]

- White, T.L.; Foster, D.; Thomas Wilson, C.; Schaich, C.R.; Ridge, O. Phase 2 Microwave Concrete Decontamination Results; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1995. [Google Scholar]

- Lagos, L.E.; Li, W.; Ebadian, M.A.; White, T.L.; Grubb, R.G.; Foster, D. Heat transfer within a concrete slab with a finite microwave heating source. Int. J. Heat Mass Transf. 1995, 38, 887–897. [Google Scholar] [CrossRef]

- Tsujino, M.; Noguchi, T.; Kitagaki, R.; Nagai, H. Completely Recyclable Concrete Of Aggregate-Recovery Type By Using Microwave Heating. J. Struct. Constr. Eng. (Trans. AIJ) 2011, 76, 223–229. [Google Scholar] [CrossRef]

- Jerby, E.; Dikhtyar, V.; Aktushev, O.; Grosglick, U. The Microwave Drill. Science 2002, 298, 587–589. [Google Scholar] [CrossRef]

- Jerby, E.; Nerovny, Y.; Meir, Y.; Korin, O.; Peleg, R.; Shamir, Y. A Silent Microwave Drill for Deep Holes in Concrete. IEEE Trans. Microw. Theory Tech. 2018, 66, 522–529. [Google Scholar] [CrossRef]

- Meir, Y.; Jerby, E. Localized Rapid Heating by Low-Power Solid-State Microwave Drill. IEEE Trans. Microw. Theory Tech. 2012, 60, 2665–2672. [Google Scholar] [CrossRef]

- Xu, C.; Zheng, W.; Wang, Y.; Zhou, X.; Li, Z. Green and recyclable demolition of steel reinforced concrete: Application and calculation model of induction heating demolition technology. J. Build. Eng. 2022, 61, 105304. [Google Scholar] [CrossRef]

- Menon, A.H.; Jayaraj, G.K. Comparative Study of Demolition Methods. Int. J. Adv. Sci. Res. 2017, 2, 26–31. [Google Scholar]

- Awad, A. Guidelines for Civil Structures Demolition Method Selection to Enhance Environmental Protection. Int. J. Emerg. Trends Eng. Res. 2020, 8, 307–313. [Google Scholar] [CrossRef]

- Huynh, M.-P.; Laefer, D.F. Expansive cements and soundless chemical demolition agents: State of technology review. In Proceedings of the 11th Conference on Science and Technology, Ho Chi Minh, Vietnam, 21–23 October 2009; Available online: http://hdl.handle.net/10197/2285 (accessed on 28 October 2024).

- Habib, K.-M.; Shnorhokian, S.; Mitri, H. Evaluating the Application of Rock Breakage without Explosives in Underground Construction—A Critical Review of Chemical Demolition Agents. Minerals 2022, 12, 220. [Google Scholar] [CrossRef]

- Tazowar, M.; Siddique, A.F.A. Concrete Cutting and Structural Demolition Techniques: A Review. In Proceedings of the 5th Annual Paper Meet and 2nd Civil Engineering Congress, Dhaka, Bangladesh, 29–30 July 2022. [Google Scholar]

- Shalenny, V. Safe technologies for cutting reinforced concrete structures by means of diamond tools. E3S Web Conf. 2019, 97, 03009. [Google Scholar] [CrossRef]

- Bazanov, V. Application of environmentally friendly concrete demolition techniques in the repair of shipping locks. E3S Web Conf. 2019, 91, 07020. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).