Determination of the Mechanical Properties of Parsley Stems Related to the Design of Processing Machines †

Abstract

:1. Introduction

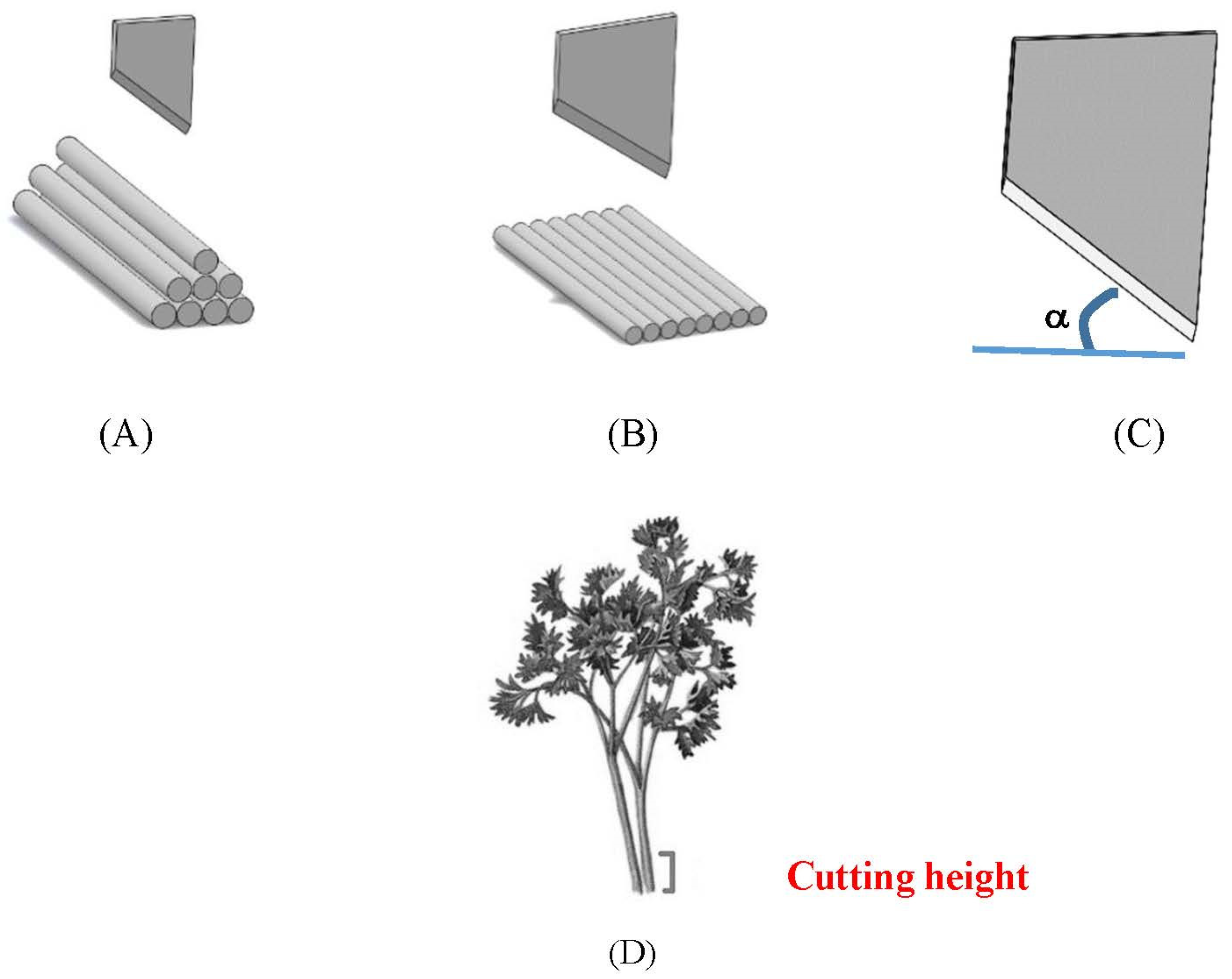

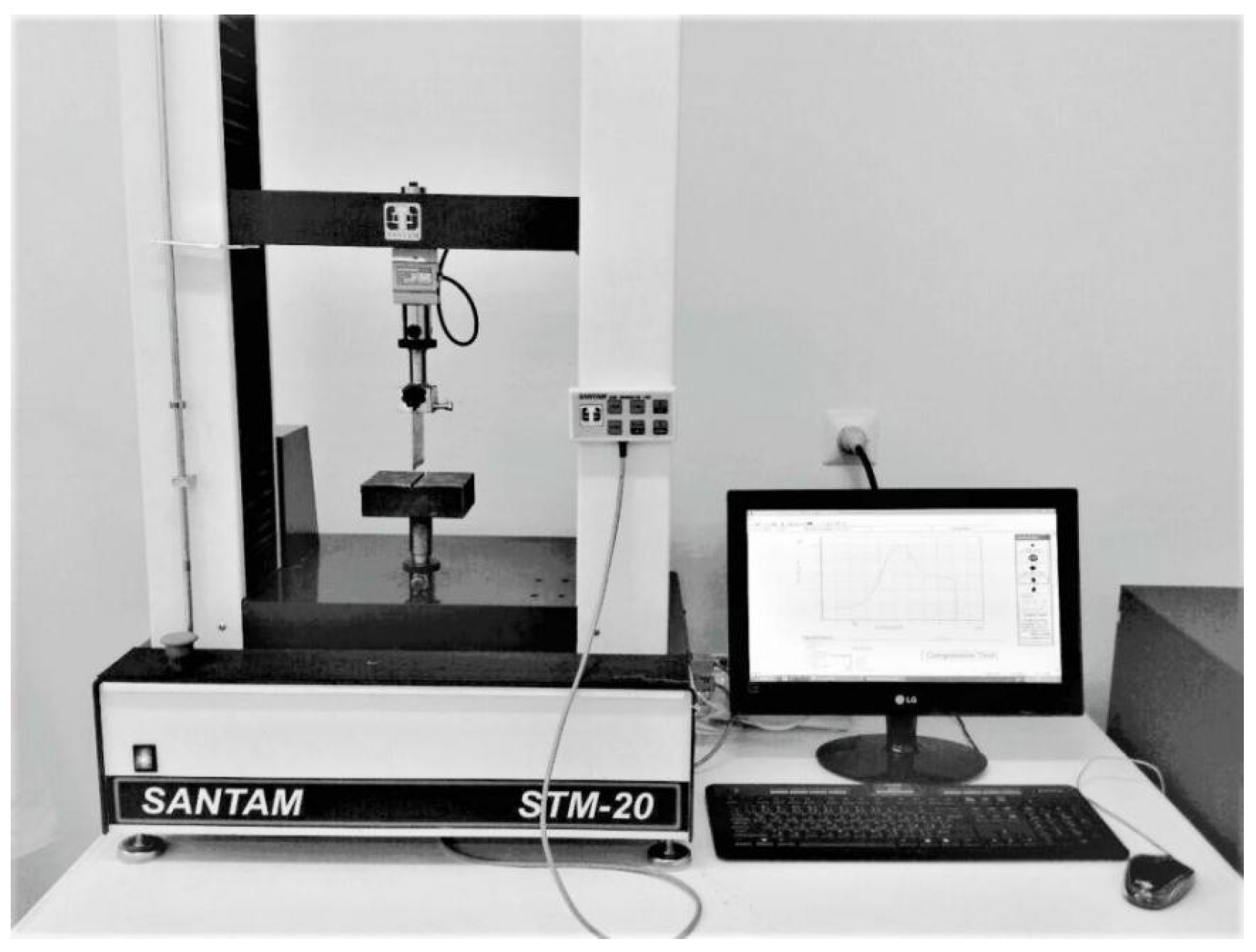

2. Materials and Methods

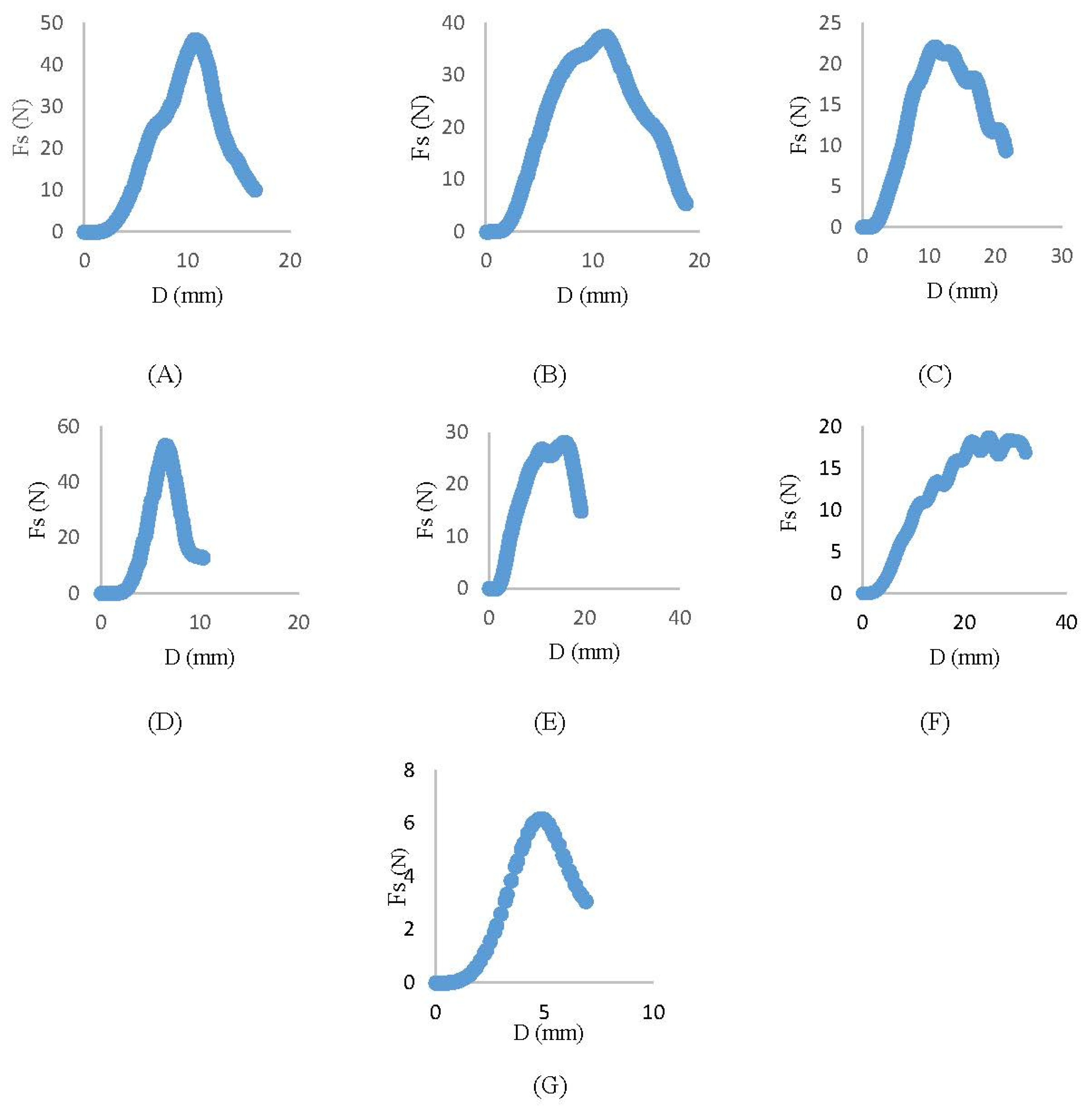

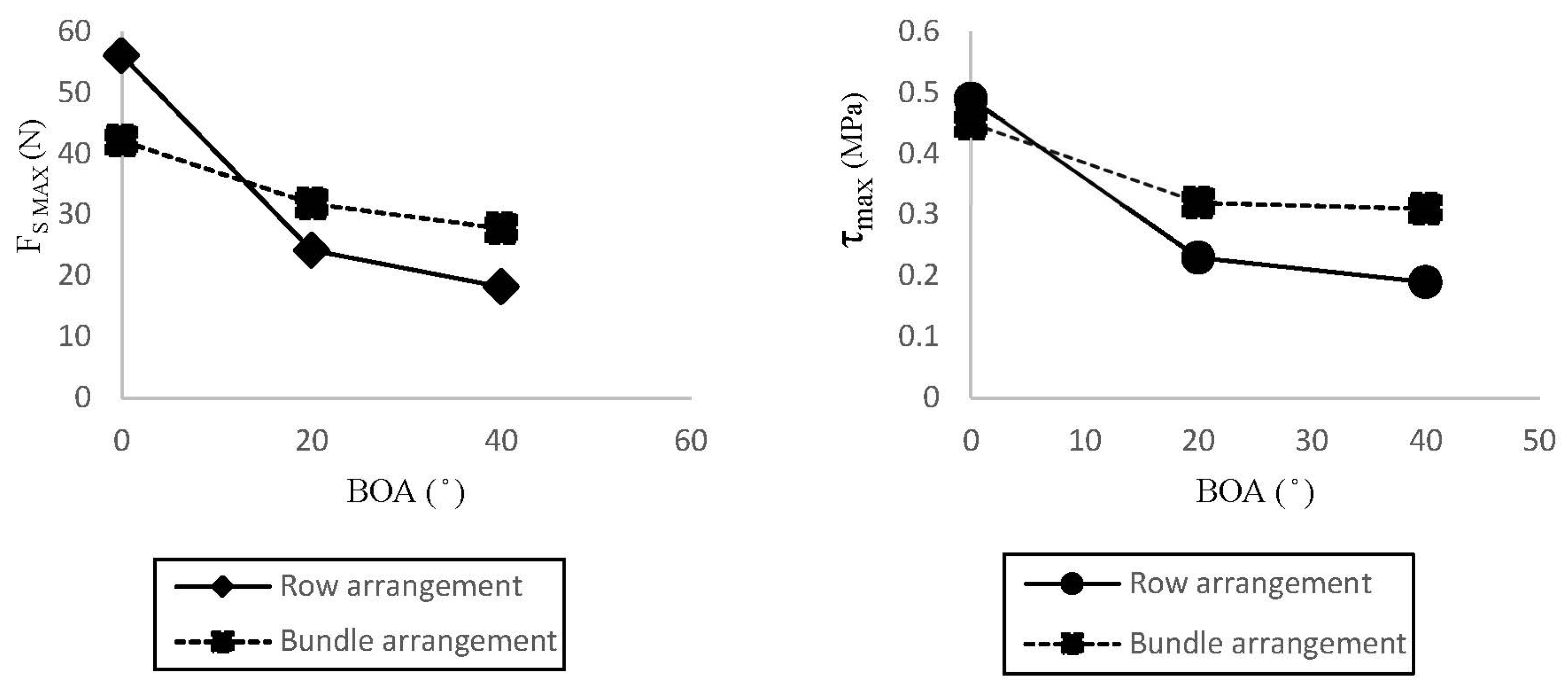

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclatures

| BOA | blade oblique angle |

| A | stem cross sectional area, m2 |

| d | stem diameter, mm |

| D | deformation, mm |

| Fs | shear force, N |

| Fs max | maximum shear force, N |

| τmax | shear strength, MPa |

| ES | shear energy, J |

| ESC | specific cutting energy, mJ mm−2 |

References

- Ahangarnezhad, N.; Najafi, G.; Jahanbakhshi, A. Determination of the physical and mechanical properties of a potato (the Agria variety) in order to mechanise the harvesting and post-harvesting operations. Res. Agric. Eng. 2019, 65, 33–39. [Google Scholar] [CrossRef]

- Bako, T.; Garba, A.J. Engineering properties of acha (Digitaria exilis) grains in relation to the design of grain processing machines. Agric. Eng. Int. CIGR J. 2020, 22, 159–170. [Google Scholar]

- Li, Z.; Li, P.; Liu, J. Physical and mechanical properties of tomato fruits as related to robot’s harvesting. J. Food Eng. 2011, 103, 170–178. [Google Scholar] [CrossRef]

- Azmi, Y.; Khairunnisa, H.; Tajudeen, A.I.; Hadi, S. Physical and mechanical properties of Jatropha curcas l. Fruits from different planting densities. J. Appl. Sci. 2013, 13, 1004–1012. [Google Scholar]

- Chattopadhyay, P.S.; Pandey, K.P. Mechanical properties of sorghum stalk in relation to quasi-static deformation. J. Agric. Eng. Res. 1999, 73, 199–206. [Google Scholar] [CrossRef]

- Sitkei, G. Mechanics of Agricultural Materials; Elsevier: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Li, X.; Wang, S.; Du, G.; Wu, Z.; Meng, Y. Variation in physical and mechanical properties of hemp stalk fibers along height of stem. Ind. Crop. Prod. 2013, 42, 344–348. [Google Scholar] [CrossRef]

- O’dogherty, M.J.; Huber, J.A.; Dyson, J.; Marshall, C.J. A study of the physical and mechanical properties of wheat straw. J. Agric. Eng. Res. 1995, 62, 133–142. [Google Scholar] [CrossRef]

- Azadbakht, M.; Esmaeilzadeh, E.; Esmaeili-Shayan, M. Energy consumption during impact cutting of canola stalk as a function of moisture content and cutting height. J. Saudi Soc. Agric. Sci. 2015, 14, 147–152. [Google Scholar] [CrossRef] [Green Version]

- Esehaghbeygi, A.; Hoseinzadeh, B.; Khazaei, M.; Masoumi, A. Bending and shearing properties of wheat stem of alvand variety. World Appl. Sci. J. 2009, 6, 1028–1032. [Google Scholar]

- Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Effect of blade oblique angle and cutting speed on cutting energy for energycane stems. Biosyst. Eng. 2015, 133, 64–70. [Google Scholar] [CrossRef]

- McRandal, D.M.; McNulty, P.B. Mechanical and physical properties of grasses. Trans. ASAE 1980, 23, 816–0821. [Google Scholar] [CrossRef]

- Galedar, M.N.; Jafari, A.; Mohtasebi, S.S.; Tabatabaeefar, A.; Sharifi, A.; O’Dogherty, M.J.; Rafiee, S.; Richard, G. Effects of moisture content and level in the crop on the engineering properties of alfalfa stems. Biosyst. Eng. 2008, 101, 199–208. [Google Scholar] [CrossRef]

- İnce, A.H.M.E.T.; Uğurluay, S.; Güzel, E.; Özcan, M.T. Bending and shearing characteristics of sunflower stalk residue. Biosyst. Eng. 2005, 92, 175–181. [Google Scholar] [CrossRef]

- Aydın, İ.; Arslan, S.J.I.C. Mechanical properties of cotton shoots for topping. Ind. Crop. Prod. 2018, 112, 396–401. [Google Scholar] [CrossRef]

- Boydaş, M.G.; Comakli, M.; Sayinci, B.; Kara, M. Effects of moisture content, internode region, and oblique angle on the mechanical properties of sainfoin stem. Turk. J. Agric. For. 2019, 43, 254–263. [Google Scholar] [CrossRef] [Green Version]

- Yore, M.W.; Jenkins, B.M.; Summers, M.D. Cutting properties of rice straw. In Proceedings of the 2002 ASAE Annual Meeting, Chicago, IL, USA, 28–31 July 2002; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2002. [Google Scholar]

- Allameh, A.; Alizadeh, M.R. Specific cutting energy variations under different rice stem cultivars and blade parameters. Idesia 2016, 34, 11–17. [Google Scholar] [CrossRef]

- Ghahraei, O.; Ahmad, D.; Khalina, A.; Suryanto, H.; Othman, J. Cutting tests of kenaf stems. Trans. ASABE 2011, 54, 51–56. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, D.; Zhao, J. Study of the Cutting Mechanism of Oil Tree Peony Stem. Forests 2020, 11, 760. [Google Scholar] [CrossRef]

- Johnson, P.C.; Clementson, C.L.; Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Cutting energy characteristics of Miscanthus x giganteus stems with varying oblique angle and cutting speed. Biosyst. Eng. 2012, 112, 42–48. [Google Scholar] [CrossRef]

- Maughan, J.D.; Mathanker, S.K.; Fehrenbacher, B.M.; Grift, T.E.; Hansen, A.C. Impact of Cutting Speed, Blade Type, and Blade Angle on Miscanthus Harvesting Energy Requirement. In Proceedings of the American Society of Agricultural and Biological Engineers, Dallas, TX, USA, 29 July–1 August 2012; p. 1. [Google Scholar]

- Eliçin, A.K.; Sessiz, A.; Pekitkan, F.G. Effect of Various Knife Type, Cutting Angle and Speed on Cutting Force and Energy of Grape Cane. Avrupa Bilim Teknol. Derg. 2019, 15, 519–525. [Google Scholar] [CrossRef]

- Vu, V.D.; Ngo, Q.H.; Nguyen, T.T.; Nguyen, H.C.; Nguyen, Q.T.; Nguyen, V.D. Multi-objective optimisation of cutting force and cutting power in chopping agricultural residues. Biosyst. Eng. 2020, 191, 107–115. [Google Scholar] [CrossRef]

| Independent Variables | Levels |

|---|---|

| Blade oblique angle | 0°, 20° and 40° |

| Stem arrangement | Row and bundle |

| Average cross Sectional Area | Average Diameter | Stem Moisture Content | Cutting Height |

|---|---|---|---|

| 13.1 mm2 | 4.1 mm | 92% (Wet basis) | 4–8 cm |

| Source of Variation | Dependent Variable | df | SS | MS | F Value |

|---|---|---|---|---|---|

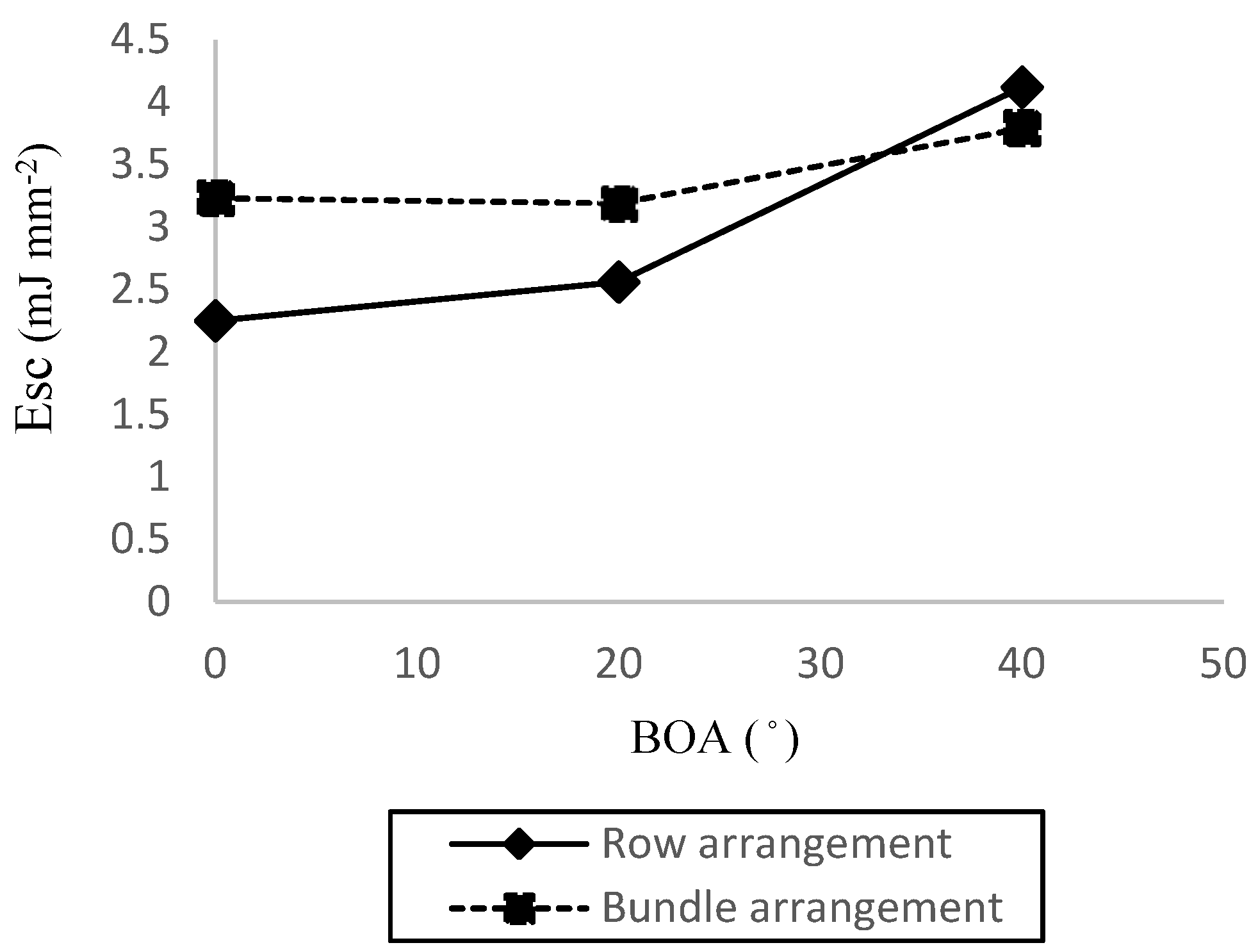

| BOA | ESC | 2 | 10.58 | 5.29 | 28.6 ** |

| τmax | 2 | 0.34 | 0.17 | 127.24 ** | |

| Stem arrangement | ESC | 1 | 1.64 | 1.64 | 8.9 * |

| τmax | 1 | 0.02 | 0.02 | 21.25 ** | |

| BOA × Stem arrangement | ESC | 2 | 2.76 | 1.38 | 7.47 * |

| τmax | 2 | 0.04 | 0.02 | 15.43 ** | |

| Error | ESC | 30 | 5.55 | 0.185 | |

| τmax | 30 | 0.04 | 0.001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hosseinpour-Zarnaq, M.; Minaei, S.; Bazyar, P. Determination of the Mechanical Properties of Parsley Stems Related to the Design of Processing Machines. Chem. Proc. 2022, 10, 16. https://doi.org/10.3390/IOCAG2022-12338

Hosseinpour-Zarnaq M, Minaei S, Bazyar P. Determination of the Mechanical Properties of Parsley Stems Related to the Design of Processing Machines. Chemistry Proceedings. 2022; 10(1):16. https://doi.org/10.3390/IOCAG2022-12338

Chicago/Turabian StyleHosseinpour-Zarnaq, Mohammad, Saeid Minaei, and Pourya Bazyar. 2022. "Determination of the Mechanical Properties of Parsley Stems Related to the Design of Processing Machines" Chemistry Proceedings 10, no. 1: 16. https://doi.org/10.3390/IOCAG2022-12338

APA StyleHosseinpour-Zarnaq, M., Minaei, S., & Bazyar, P. (2022). Determination of the Mechanical Properties of Parsley Stems Related to the Design of Processing Machines. Chemistry Proceedings, 10(1), 16. https://doi.org/10.3390/IOCAG2022-12338