Performance Analysis of Mixed Mode Solar Dryer for Tobacco Leaves †

Abstract

:1. Introduction

2. Material and Methods

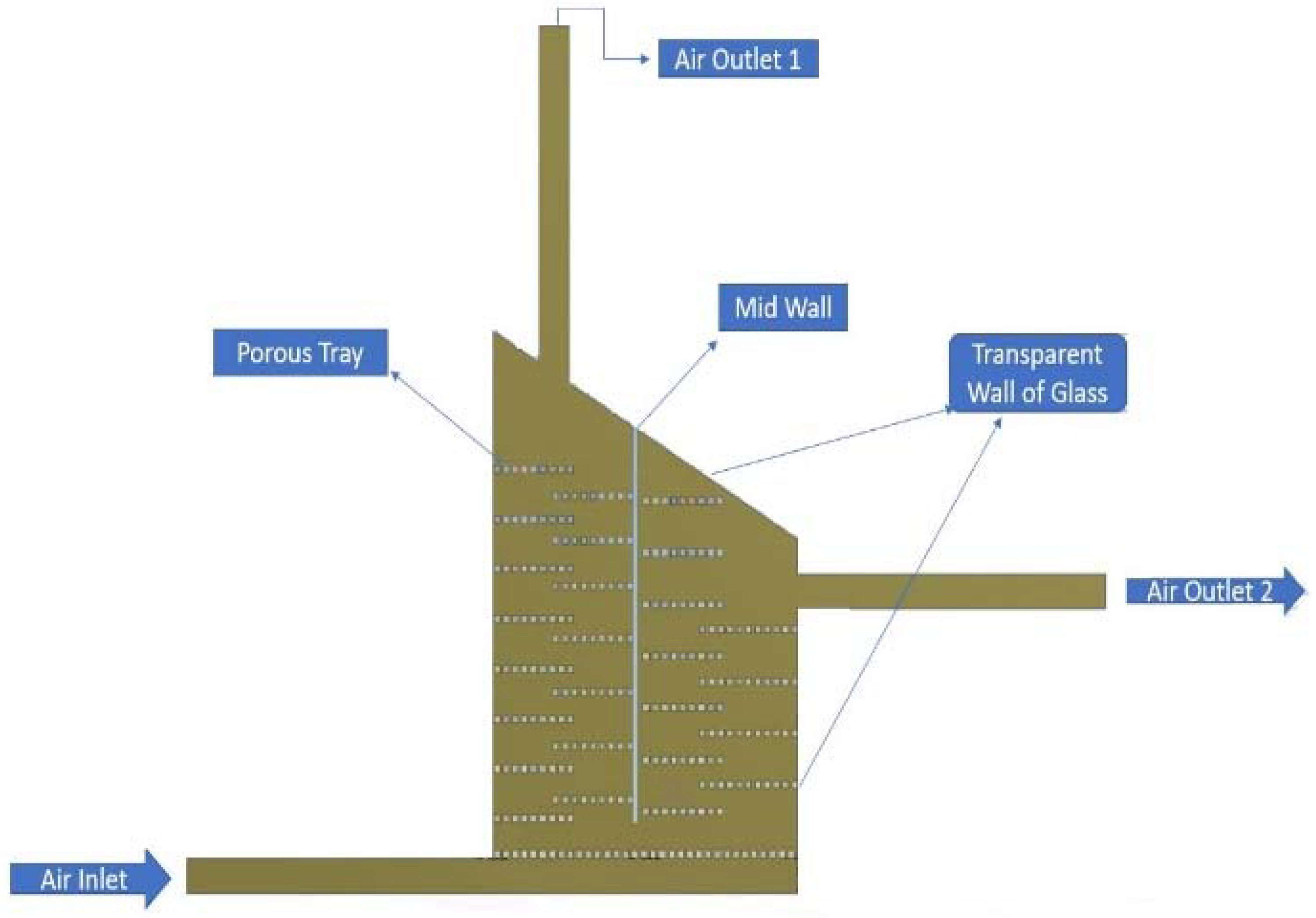

2.1. Design of Solar Dryer

Design Considerations for Solar Dryer

- Temperature—The minimum temperature for drying tobacco leaves was 313 K and the maximum temperature was 348 K, therefore 318 K and above was considered normal for drying tobacco leaves.

- Efficiency of solar dryer—This was defined as the ratio of the useful output of a device to the input of the device.

- Dryer Trays—Aluminum can be used as dryer trays to pass air circulation within the drying chamber. The design of the dryer chamber that made use of wooden wall sides and a glass top (tilted) protects the leaves placed on the trays from direct sunlight.

2.2. Numerical Modeling

Initial and Boundary Condition

2.3. Mesh Independency

3. Result and Discussion

3.1. Effect of Velocity Variation at Dryer Entry

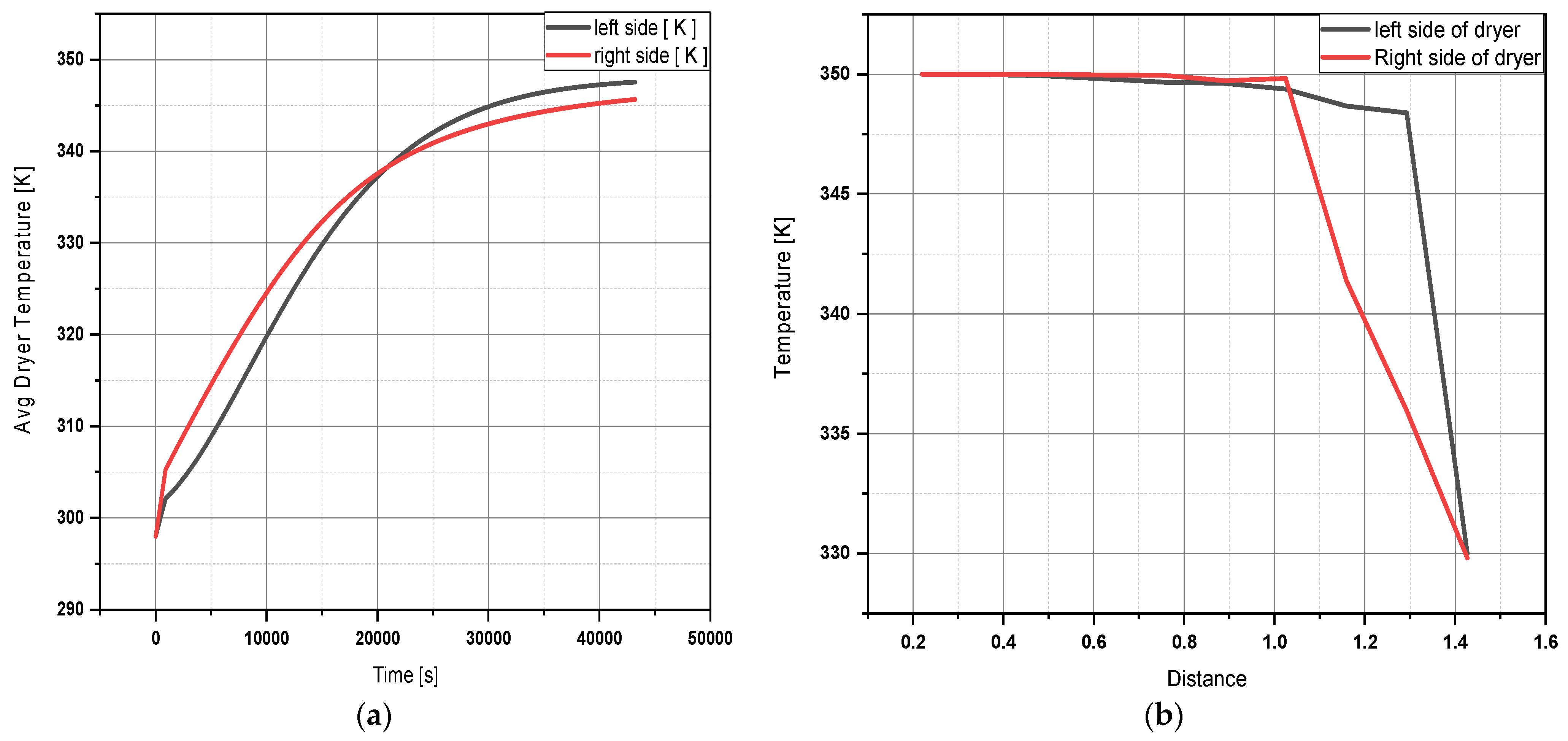

3.2. Performance Analsysis of Left and Right Sections of the Dryer

4. Conclusions

- By increasing the air flow velocity at the entry point of the dryer, the temperature and pressure also increases with the time. If we need to achieve the required drying temperature and best efficiency, we have to use air flow velocity of 0.15 m/s. This way, the tobacco stem and leaves will dry properly and in the required time.

- The left side of the cabinet dryer heated slowly with respect to time, but, at the end, the left side dryer reached a higher temperature compared to right side of the dryer. This result shows that we can place the stem on the side which is more heated (left side) and place the leaves on the right side of dryer.

- Overall results indicated that the proposed design configuration was able to maintain required uniform temperature distribution in separate sections of the single cabinet dryer and, thus, offers promising results to keep the standard quality of the dried tobacco leaves and stems.

Author Contributions

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Waewsak, J.; Chindaruksa, S.; Punlek, C. A mathematical modeling study of hot air drying for some agricultural products. Sci. Technol. Asia 2006, 2006, 14–20. [Google Scholar]

- Mehta, P.; Samaddar, S.; Patel, P.; Markam, B.; Maiti, S. Design and performance analysis of a mixed mode tent-type solar dryer for fish-drying in coastal areas. Sol. Energy 2018, 170, 671–681. [Google Scholar] [CrossRef]

- Mathioulakis, E.; Karathanos, V.T.; Belessiotis, V.G. Belessiotis, Simulation of air movement in a dryer by computational fluid dynamics: Application for the drying of fruits. J. Food Eng. 1998, 36, 183–200. [Google Scholar] [CrossRef]

- Mirade, P.S. Prediction of the air velocity field in modern meat dryers using unsteady computational fluid dynamics (CFD) models. J. Food Eng. 2003, 60, 41–48. [Google Scholar] [CrossRef]

- Margaris, D.P.; Ghiaus, A.G. Ghiaus, Dried product quality improvement by air flow manipulation in tray dryers. J. Food Eng. 2006, 75, 542–550. [Google Scholar] [CrossRef]

- ELkhadraoui, A.; Kooli, S.; Hamdi, I.; Farhat, A. Experimental investigation and economic evaluation of a new mixed-mode solar greenhouse dryer for drying of red pepper and grape. Renew. Energy 2015, 77, 1–8. [Google Scholar] [CrossRef]

| Initial condition | The fluid in the solar cabinet dryer was initially assumed stagnant and at a uniform ambient temperature. At t = 0, Ta,c = 298 K |

| Boundary conditions | Walls: the inclined wall and right-side wall of the solar cabinet dryer were made of glass and fixed because of the mixed mode dryer type. Tinclined wall = Tright side wall = 330 K For the remaining walls, no slip wall condition was used. ΔQwall = 0 |

| Outlet | Outlet pressure was fixed. Poutlet = 105 Pa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdi, S.A.W.; Ahmad, N. Performance Analysis of Mixed Mode Solar Dryer for Tobacco Leaves. Eng. Proc. 2021, 12, 102. https://doi.org/10.3390/engproc2021012102

Abdi SAW, Ahmad N. Performance Analysis of Mixed Mode Solar Dryer for Tobacco Leaves. Engineering Proceedings. 2021; 12(1):102. https://doi.org/10.3390/engproc2021012102

Chicago/Turabian StyleAbdi, Syed Ali Wahaj, and Naveed Ahmad. 2021. "Performance Analysis of Mixed Mode Solar Dryer for Tobacco Leaves" Engineering Proceedings 12, no. 1: 102. https://doi.org/10.3390/engproc2021012102

APA StyleAbdi, S. A. W., & Ahmad, N. (2021). Performance Analysis of Mixed Mode Solar Dryer for Tobacco Leaves. Engineering Proceedings, 12(1), 102. https://doi.org/10.3390/engproc2021012102