1. Introduction

The assembly process is an indispensable link in the entire product life cycle, and the assembly workload of the product accounts for 20% to 70% of the entire product manufacturing workload [

1]. It is of great significance to improve the intelligence level of the assembly link. Product assembly involves multiple processes such as the sequence of assembly parts and path planning, making it difficult to automatically generate assembly sequences. In recent years, with the application and development of knowledge-based engineering technologies such as knowledge mining and knowledge acquisition, the generation of product assembly sequences is changing from manual and empirical to automated and intelligent [

2].

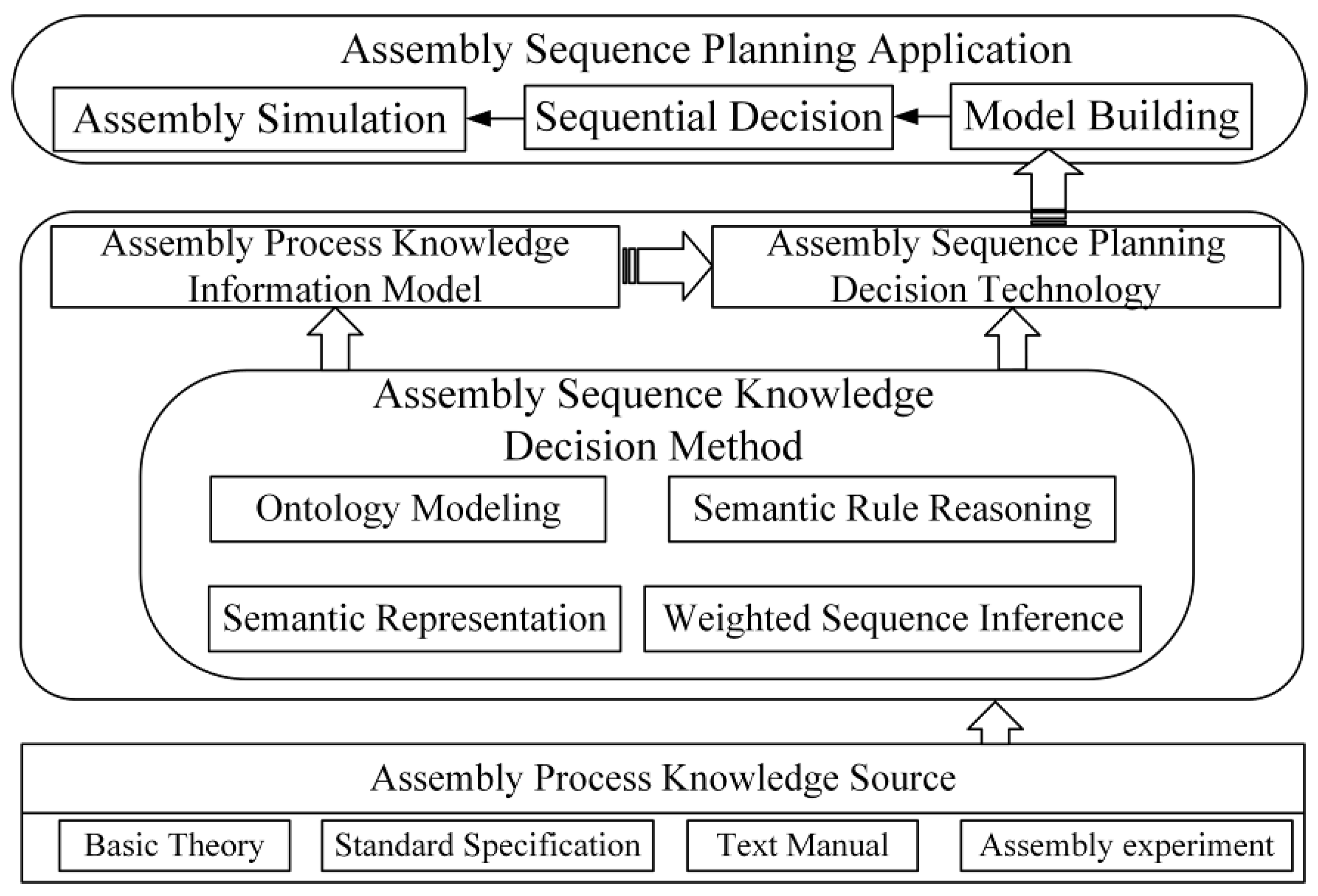

Therefore, this paper first establishes an ontology-based assembly semantic process knowledge model and proposes an assembly semantic process knowledge information model covering sub-assembly-level semantic information. Second, the assembly sequence planning ontology model was constructed in Protégé, and based on the part assembly constraint rules, feature coordination constraint rules and assembly priority rules, an iterative revision assembly sequence process based on semantic rules was designed. Finally, the application and verification of the construction method of the assembly semantic process knowledge information model and the assembly sequence planning decision technology based on the semantic process knowledge were carried out. The product assembly sequence planning process based on semantic process knowledge proposed in this paper is shown in

Figure 1.

2. Semantic Modeling of an Assembly Process Based on Ontology

The generation method of the product assembly sequence needs to build an assembly information model first and then design an assembly sequence generation method based on the assembly information model. Finally, a feasible assembly sequence is obtained [

3]. The construction of the assembly semantic process information model is the primary premise of research on product assembly sequence planning. The semantic modeling of assembly process knowledge based on ontology in this paper is used to describe the assembly semantic information of sub-assembly required for the automatic generation of the assembly sequence [

4].

The subassembly semantic information is used to represent the assembly semantic information of the assembly process, including the assembly operation

, the assembly relationship

and the assembly constraint

. According to the above analysis, the semantic information of subassembly assembly can be defined as follows:

Meanwhile, in order to express the engineering assembly experience and knowledge contained in the assembly process of the construction machinery drive axle, this paper uses the Web Ontology Language (Web Ontology Language) and the Semantic Web Rule Language (Semantic Web Rule Language) to construct the assembly sequence planning rule base [

5]. The rule base mainly includes assembly constraint rules, coordination constraint rules and special connection relationship rules. Through these three types of rules, decision-making inferences are made for different stages of construction machinery drive axle sequence planning.

According to the seven-step method of ontology construction that defines the assembly sequence planning ontology object attributes and data attributes, the model in Protégé is shown in

Figure 2.

3. Assembly Sequence Planning and Verification Based on Knowledge Reasoning

Figure 3 shows the sequence planning process of atypical structural subassembly. The atypical structure of the drive axle of construction machinery subassembly sequence planning involves two important technical steps.

Considering the geometric attribute information and physical attribute information of the sub-assembly and the weight priority of the parts in the assembly process, an attribute weight table is established, and the weight sequence is generated.

- 2.

Generation of correction sequences.

The weight sequence essentially belongs to the initial sequence in the statistical concept, and the assembly sequence finally used to guide the assembly site depends on the determined connection and matching relationship between the parts and the specific assembly operation [

6]. Therefore, by considering the semantic rules in the assembly semantic information (

,

and

) of the subassembly during the assembly process, the assembly sequence is revised and reasoned many times to ensure the rationality of the assembly sequence.

3.1. Generation of a Weight Sequence

After obtaining the atypical structural assembly set, access the data information of the atypical structural part model file; then, read the assembly component attribute information [

7], including the geometry of the part attributes, physical attributes, non-geometric attribute values and part assembly process factor values. The above values are quantified into six types of eigenvalues: mass

(

), size

(

), quantity

(

), constraint form

(

), fit form

(

) and assembly operation

(

). Finally, the comprehensive average eigenvalues of the components are calculated, the size is sorted and the weight sequence is generated.

According to the mass, size, quantity, constraint form, fit form and assembly operation mode of similar parts, different eigenvalues are obtained. The average eigenvalues of non-geometric properties

, assembly process average eigenvalues

and comprehensive mean eigenvalues

can be expressed as:

The calculated average eigenvalues of non-geometric properties, assembly process average eigenvalues and comprehensive mean eigenvalues are summarized into the weight table, and a preliminary sequence is generated according to the size of the values.

3.2. Generation of Correction Sequences

In order to obtain a reasonable assembly sequence, it is necessary to perform multiple revision and reasoning on the weight sequence based on the actual assembly operation experience and design knowledge [

8]. First, it is judged whether the first part in the weight sequence can be used as the reference part in the assembly process. If the first part is not the reference part, the part that is the reference part in the sequence can be adjusted to the first position of the sequence to update the sequence. Then, the constraint state of the part is inferred from Rule 1—whether it has a constraint relationship with the part in the non-sequence. If the sequence does not contain the corresponding part, insert the part with the constraint state after the current part position. Then, update the sequence. Sort the spatial position coordinates of the parts in the sequence and the sequence in a certain direction; then, update the sequence again. Where the part and the adjacent parts have mating surfaces can be inferred from Rule 2–Rule 7. If there are no adjacent parts in the feature constraint style, insert the part with the feature constraint of the mating surface into the immediate position of the part, and then update the sequence. Otherwise, maintain the sequence. Whether the part has a special assembly relationship with the parts not in this assembly group can be inferred from Rule 8. If so, adjust the position of the part and update the sequence according to the characteristics of the assembly relationship. Finally, check if part P is the last part of the sequence or not. Otherwise, go back to check the constraint status of the part.

3.3. A Typical Structural Subassembly Sequence Generation of a Machinery Drive Axle

Figure 4 shows the weight sequence inference correction process of the atypical structure sub-assembly main reducer of the drive axle of construction machinery. Among them, part ➀ shows the summary table of the weight sequence of each part of the main reducer. Part ➁ shows that it is checked that part P50 is a shafting part, which can be used as a reference part to maintain the original weight sequence. Part ➂ shows the status bar in the table. There is a constraint relationship between the middle parts inferred from Rule 1 in the inference engine. P39 and P38 have a constraint relationship, and sequence 1 does not contain P39, inserting P39 into the current sequence to generate sequence 2. Part ➃ shows the spatial position coordinates of each part of the main reducer assembly group, and sequence 3 is generated. Part ➄ shows that it is checked whether the adjacent parts have the assembly matching feature style in the red frame line. The adjacent relationship between the parts is obtained by reasoning. Sequence 4 is the new sequence after adjustment. Part ➅ shows that it is checked that the part P51-driven spur bevel gear and the parts not in this assembly group have a preferential fixed installation relationship. The inference engine has a fixed installation relationship. The special assembly relationship of P51 is obtained by inference in Rule 8, and P51 is adjusted to the first position of the sequence to generate sequence 5.

4. Conclusions

This paper explores knowledge representation modeling and knowledge reasoning techniques in the assembly sequence planning process. The research method of product assembly sequence planning based on semantic process knowledge is studied. An assembly semantic process knowledge information model based on semantic information is proposed. An assembly sequence planning ontology and assembly semantic rules for sequence knowledge reasoning are constructed. A method of amending and inferring subassembly sequences of atypical structures many times is proposed. Finally, this paper realizes the rational application of assembly semantic process knowledge in assembly sequence planning decisions.

At present, the transformation of semantic process knowledge in the assembly process is still in the primary application stage. The introduction of intelligent algorithms into the decision-making process in the assembly process can better realize the intelligent planning and decision making of assembly sequences. Therefore, combining intelligent algorithms with knowledge to study assembly sequence planning decisions is the focus of future research.

Author Contributions

Conceptualization, G.W.; methodology, G.W.; software, T.L. and D.Z.; formal analysis, T.L. and D.Z.; writing—original draft preparation, T.L.; funding acquisition, G.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the Natural Science Basic Research Project of Shaanxi Province, China (Grant No. 2019JM-073) and the China Postdoctoral Science Foundation (Grant No. 2018M633439).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, J.H.; Sun, Q.C.; Cheng, H.; Liu, X.K.; Ding, X.Y.; Liu, S.L.; Xiong, H. The State-of-the-art, Connotation and Developing Trends of the Products Assembly Technology. J. Mech. Eng. 2018, 54, 2–28. [Google Scholar] [CrossRef]

- Liu, S.M.; Sun, X.M.; Lu, Y.Q.; Wang, B.C.; Bao, J.S.; Guo, G.Q. A Knowledge-Driven Digital Twin Modeling Method for Machining Products Based on Biomimicry. J. Mech. Eng. 2021, 57, 182–194. [Google Scholar]

- Shi, X.L.; Tian, X.T.; Wang, G.F.; Zhao, D.P.; Zhang, M. Semantic-based subassembly identification considering non-geometric structure attributes and assembly process factors. Int. J. Adv. Manuf. Technol. 2020, 110, 439–455. [Google Scholar] [CrossRef]

- Chen, S.L.; Yi, J.J.; Jiang, H.; Zhu, X.M. Ontology and CBR based automated decision-making method for the disassembly of mechanical products. Adv. Eng. Inform. 2016, 30, 564–584. [Google Scholar] [CrossRef]

- Wang, T.L.; Chen, Y.; Liu, M.F. Modeling and Application of Complex Process Knowledge for Determining Parameters. J. Shanghai Jiaotong Univ. 2021, 55, 1237–1245. [Google Scholar]

- Liu, Y.; Li, S.Q.; Wang, J.F.; Zeng, H.M.; Lu, M.S. Interactive disassembly approach for assembly sequence planning based on product hierarchical-classification. Comput. Integr. Manuf. Syst. 2014, 20, 785–792. [Google Scholar]

- Xia, P.J.; Yao, Y.X.; Liu, J.S.; Li, J.G. Generating Optimized Assembly Sequence by Virtual Reality and Bionic Algorithm. Chin. J. Mech. Eng. 2007, 43, 44–52. [Google Scholar] [CrossRef]

- Cui, J.J. Product Intelligent Assembly Sequence Planning Based on Spatio-Temporal Engineering Semantic Knowledge. Master’s Thesis, Shandong Jianzhu University, Jinan, China, 2018. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).