Abstract

Cores were recovered from the right wheel path and between wheel paths at 8 locations US 34 in Mills and Wapello Counties. The cores were cut into discs to isolate the pavement layers and the discs were fabricated into semicircular bending test specimens. Asphalt contents among CIR cores varied significantly and that CIR specimens with higher asphalt binder contents exhibited higher flexibility index values. From the output of these tests, the CIR pavement layers were found to be more flexible in comparison to the HMA layers, that CIR layers have higher flexibility that allow them to serve as a stress relieving layer and mitigate reflective cracking.

1. Introduction

Cold in-place recycling (CIR) involves cold milling 3 to 4 in of a deteriorated asphalt pavement; processing and stabilizing the millings; and relaying, compacting, curing, and covering with a hot-mix asphalt (HMA) overlay or a bituminous surface treatment. A mix design procedure was previously developed and validated [1,2]. The long-term field performance of the CIR pavements constructed in Iowa was evaluated [3,4,5,6], and the impacts of moisture content in the CIR layer prior to an overlay were identified [7,8]. This paper discusses an analysis of cores collected from CIR/HMA overlay sections in Iowa. It was confirmed that the higher binder contents in the cores produced higher Flexibility Index values based on the Semi-Circular Bending (SCB) test. HMA samples seemed to have aged more than CIR samples, resulting in lower flexibility index values with a brittle behavior.

2. Analysis of HMA/CIR Cores

To investigate the underlying characteristics of CIR, field cores were collected from CIR/HMA overlay sections on US 34 in Mills and Wapello Counties, Iowa, on 16 November 2021. The cores were evaluated to determine the cracking resistance, binder contents, and gradations of both the CIR and HMA layers. A total of 16 cores with 6 in diameters were collected from eight locations at one-mile intervals along US 34. Two cores were collected at each location, one in the wheel path and one between wheel paths.

The HMA and CIR layers were distinguished by a difference in color, with the CIR layer being darker than the HMA layer. The thicknesses of both the HMA and CIR layers were measured from each core and are summarized in Table 1. Cores were labeled with the milepost number followed by either “RWP”, which indicates that the core was collected from the pavement’s right wheel path, or “¼ pt”, which indicates that the core was collected from between the pavement’s wheel paths.

Table 1.

Thicknesses of HMA and CIR cores from US 34.

3. Semicircular Bending Test Results

Semicircular bending (SCB) tests have been used to evaluate both fatigue cracking and low-temperature cracking. The flexibility index (FI) resulting from this test has been reported to have the capability to capture some of the critical changes in mixture variables. Lower FI values indicate that the asphalt mixture is more brittle and has a higher crack growth rate.

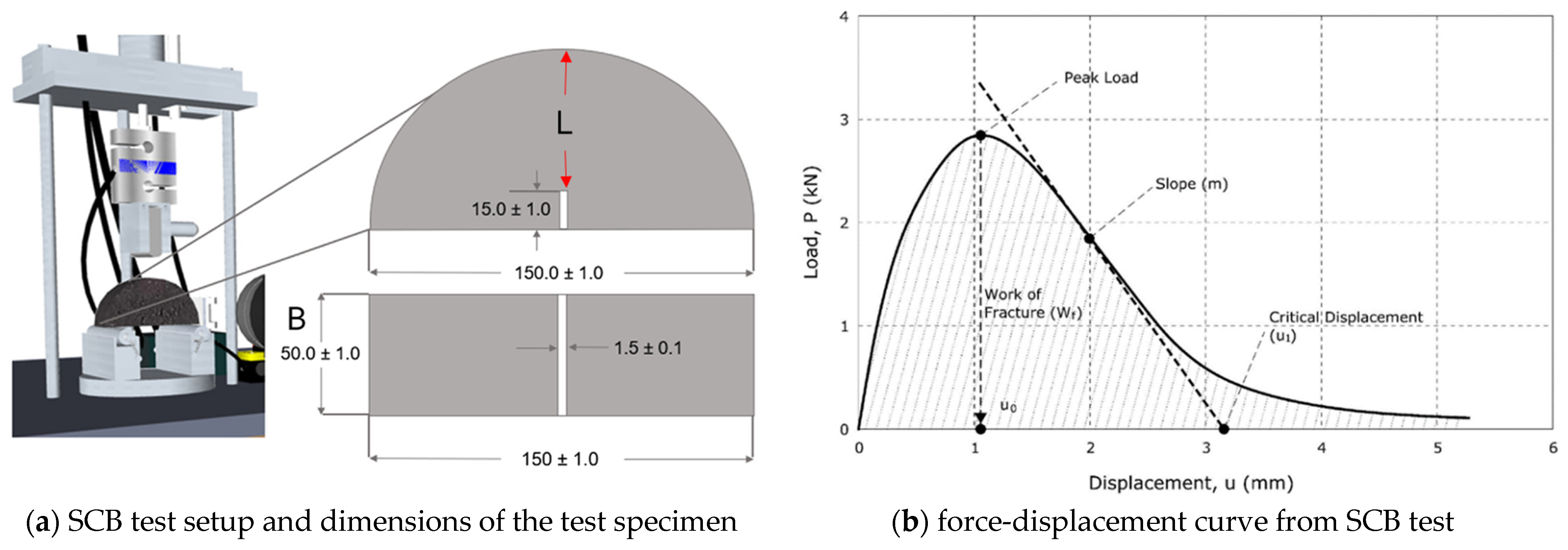

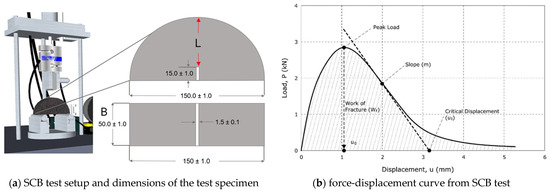

SCB tests were performed according to AASHTO TP 124 on the cores taken from US 34. As shown in Figure 1, samples for SCB testing were prepared by cutting the cores into semicircular specimens, each with a diameter of 150 mm and a maximum thickness of 50 mm (with some samples being thinner because field core samples have various thicknesses). A notch 15 mm long and 1.5 mm wide was made on the flat side of each semicircular specimen to induce cracking. All specimens were conditioned at 25 °C for 2 h before SCB testing was performed.

Figure 1.

Cuts made along the red lines to prepare a semicircular specimen with a thickness of 50 mm.

The SCB test setup and the dimensions of the test specimens are illustrated in Figure 2a. To induce cracking in the middle of the specimens, a 15 mm notch was created in each.

Figure 2.

SCB test setup, dimensions, and force–displacement curve.

A typical force–displacement curve from an SCB test is illustrated in Figure 2b, which shows the work of fracture (WF) as the area under the curve and the post-peak slope (m) at the inflection point after the peak point. These parameters were used to calculate the fracture energy (GF) and Flexibility Index (FI).

Fracture energy (GF) can be calculated using the equation below:

where WF is the work of fracture, B is the specimen thickness, and L is the ligament length.

FI can be calculated using the equation below:

where GF is the fracture energy calculated by dividing the work of fracture by the ligament area, m is the post-peak slope at the inflection point after the peak point, and A is a unit conversion from field to laboratory (0.01).

4. Test Results

Based on the burn-off and sieve test results for the cores from all eight MP locations, the asphalt contents in the CIR layers were higher than those in the HMA layers and the aggregates of the CIR layers were finer than those of the HMA layers, as expected. However, there was no statistically significant difference in aggregate gradations or AC contents between the cores obtained from the right wheel path (RWP) and the cores obtained from between the wheel paths (¼ pt).

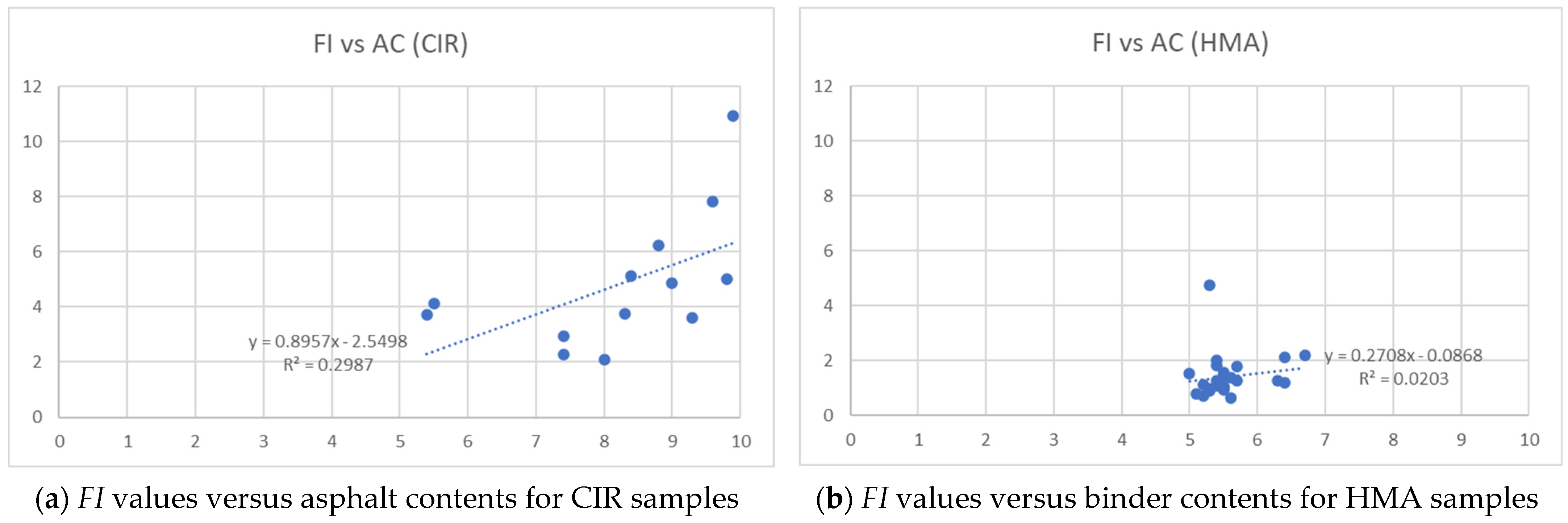

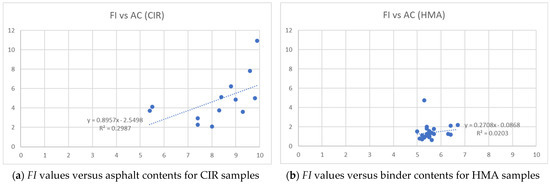

The FI values of both the CIR and HMA samples are plotted against binder contents in Figure 3. Based on the SCB test results of the CIR and HMA samples, increased binder contents produced higher FI values for both the CIR and HMA samples. However, the FI values of the CIR samples were significantly higher than those of the HMA samples. The average FI value of the CIR samples was 4.808, whereas that of the HMA samples was 1.422. It can be postulated that the HMA samples were aged for longer than the CIR samples, resulting in lower FI values, and that, therefore, relative brittleness was observed in the HMA samples.

Figure 3.

Plots of FI values versus binder contents for (a) CIR and (b) HMA samples.

5. Summary and Conclusions

Laboratory testing was conducted on cores extracted from US 34 in Mills and Wapello Counties, Iowa. These cores were cut to isolate the HMA and CIR layers, and the resulting samples were fabricated into specimens for the semicircular bending test. The output of the test was a load versus displacement curve that could be processed to calculate the work of fracture; further calculations were conducted to provide the flexibility index for each specimen. A higher flexibility index was expected to be associated with specimens that are more flexible and less likely to crack. When the HMA and CIR layers of the cores were compared, the HMA layers were found to have lower flexibility index values versus the CIR layers. This would suggest that, for CIR projects with an HMA overlay, a more brittle HMA overlay layer would cover a more flexible CIR layer. It was found that the asphalt contents among CIR cores varied noticeably and that CIR specimens with higher asphalt binder contents exhibited higher flexibility index values.

Asphalt binder contents may vary significantly across a pavement’s width due to a limited number of spraying nozzles and subsequent mixing operations for CIR with foamed asphalt. Therefore, adding the correct amount of asphalt is important. Too much asphalt will the reduce air void content in the CIR layer, which will facilitate shearing of the pavement layer under heavy traffic loading. Too much asphalt will also reduce the aggregate-to-aggregate interlock, allowing aggregate particles to move past each other as they are separated by asphalt that shears under load. Too little foamed asphalt will increase the air void content in the CIR layer, which will cause wheel path cracking in the HMA overlay as compaction rutting of the CIR layer develops under heavy traffic loading. The CIR layers are more flexible than the HMA overlay layers. For CIR using foamed asphalt, it is recommended that asphalt binder be more evenly distributed and mixed across the width of the pavement to ensure a more consistent asphalt binder content.

Author Contributions

Conceptualization and methodology, H.L.; validation, A.B. and C.T.J.; investigation, B.M.; writing—original draft preparation, H.L. and B.M.; writing—review and editing, A.B. and C.T.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Iowa Department of Transportation (DOT) and the Iowa Highway Research Board (IHRB), grant number IHRB Project TR-774.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank the Iowa Department of Transportation (DOT) and the Iowa Highway Research Board (IHRB) for sponsoring this research, as well as the Technical Advisory Committee members.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Kim, Y.; Lee, H.D. Development of mix design procedure for cold in-place recycling with foamed asphalt. J. Mater. Civ. Eng. 2006, 18, 116–124. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, H.D.; Heitzman, M. Validation of new mix design procedure for cold in-place recycling with foamed asphalt. J. Mater. Civ. Eng. 2007, 19, 1000–1010. [Google Scholar] [CrossRef]

- Diefenderfer, B.K.; Bowers, B.F.; Apeagyei, A.K. Initial Performance of Virginia’s Interstate 81 In-Place Pavement Recycling Project. Transp. Res. Rec. J. Transp. Res. Board 2015, 2524, 152–159. [Google Scholar] [CrossRef]

- Kim, J.J.; Lee, H.D.; Jahren, C.T.; Heitzman, M.; Chen, D. Long-term field performance of cold in-place recycled roads in Iowa. J. Perform. Constr. Facil. 2010, 24, 265–274. [Google Scholar] [CrossRef]

- In-Place and Central-Plant Recycling of Asphalt Pavements in Virginia. Available online: https://www.fhwa.dot.gov/pavement/sustainability/case_studies/hif19078.pdf (accessed on 4 August 2023).

- Buss, A.; Mercado, M.G.; Schram, S. Long-term evaluation of cold-in-place recycling and factors influencing performance. J. Perform. Constr. Facil. 2017, 31, 04016111. [Google Scholar] [CrossRef]

- Kim, Y.; Im, S.; Lee, H.D. Impacts of curing time and moisture content on engineering properties of cold in-place recycling mixtures using foamed or emulsified asphalt. J. Mater. Civ. Eng. 2011, 23, 542–553. [Google Scholar] [CrossRef]

- Al-Qadi, I.; Cao, Q.; Abufares, L.; Wang, S.; Ali, U.M.; Renshaw, G. Moisture Content and In-Place Density of Cold-Recycling Treatments. Available online: https://apps.ict.illinois.edu/projects/getfile.asp?id=10152 (accessed on 4 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).