Additive Manufacturing in Construction—Implementing Powder-Bed Fusion of Metals Using a Laser (PBF-LB/M) and Shape Optimization in the Construction Design Process †

Abstract

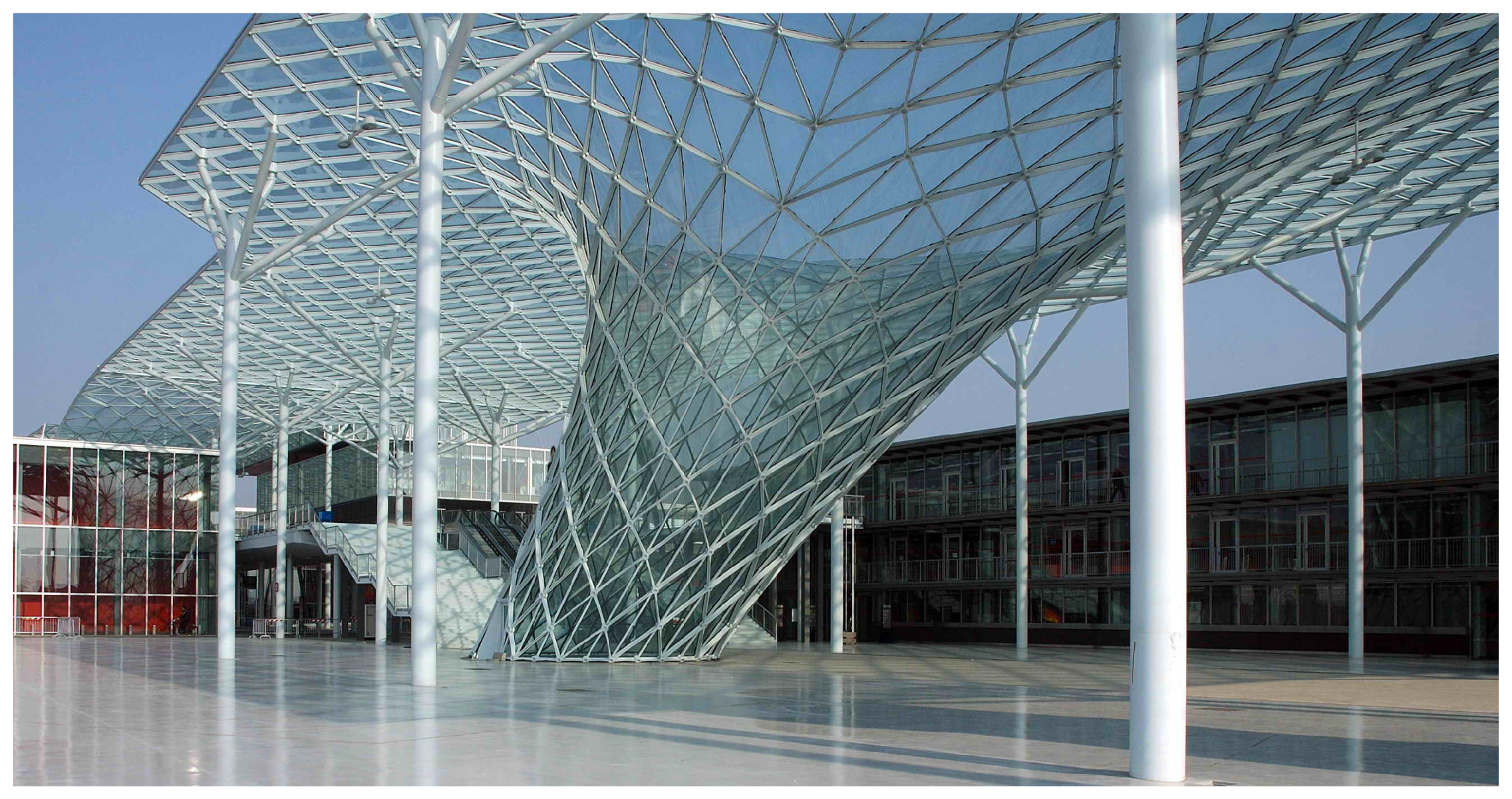

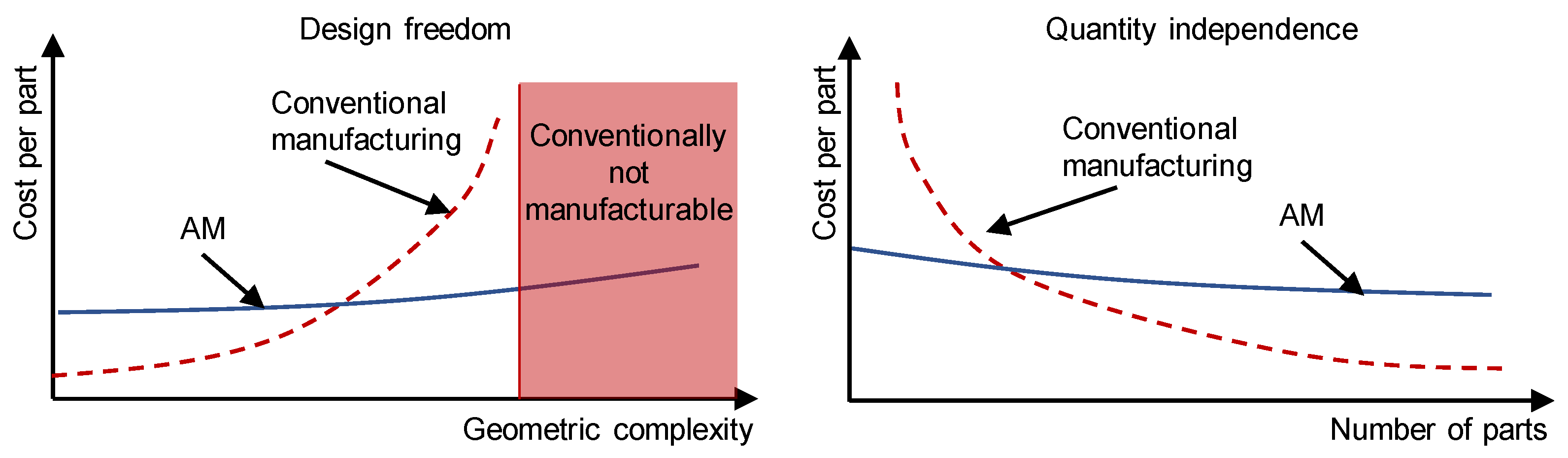

:1. Introduction

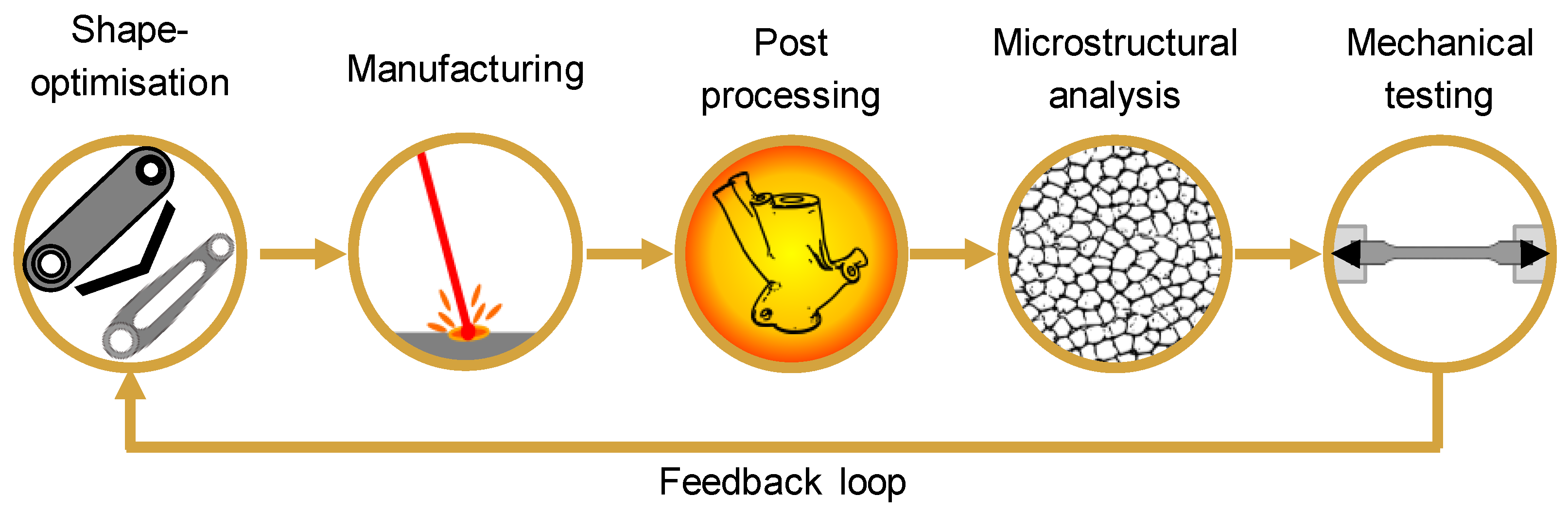

2. Materials and Methods

2.1. Design

2.2. Manufacturing and Post-Processing

2.3. Mechanical Testing and Microstructural Investigation

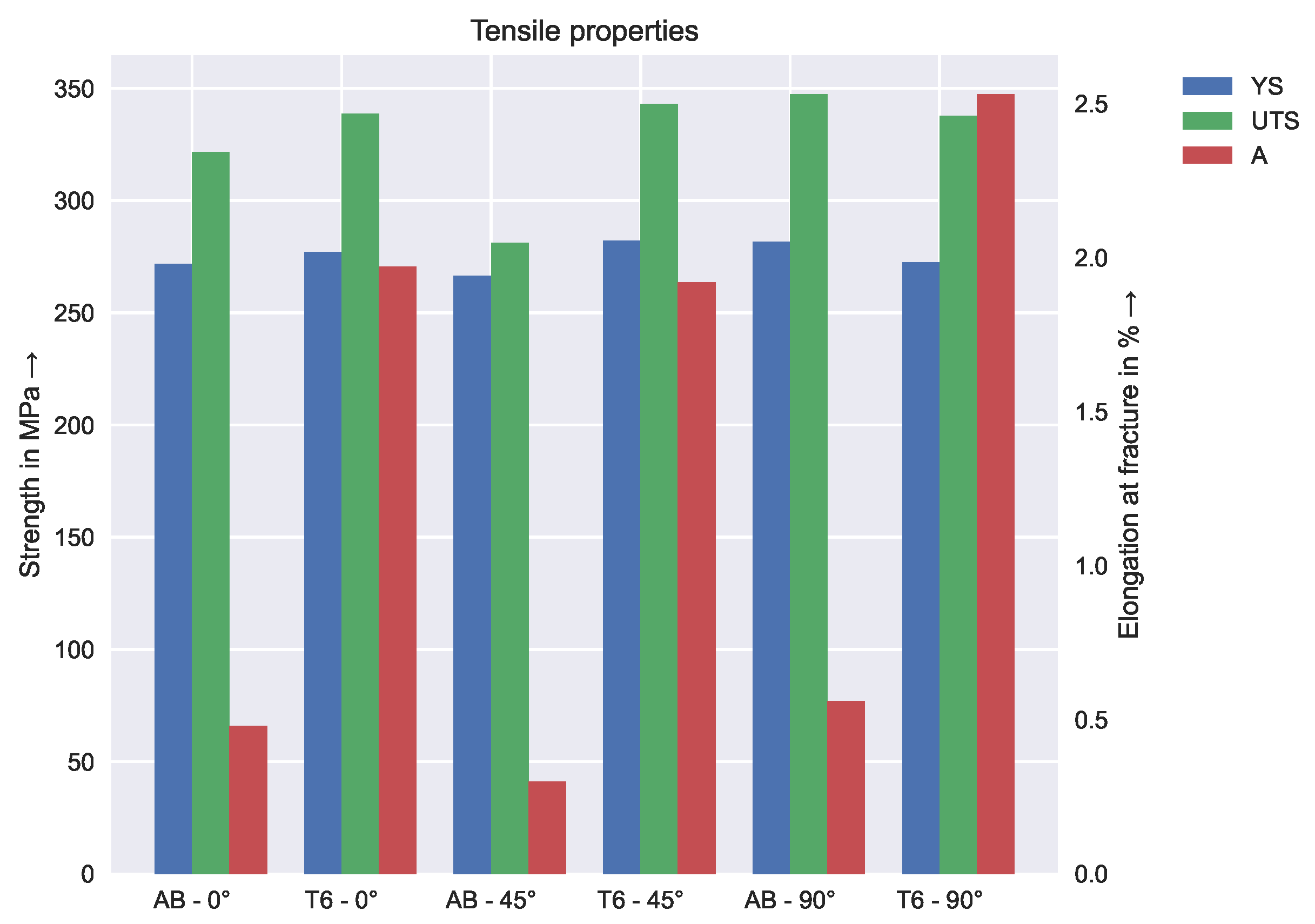

3. Results

3.1. Static Mechanical Properties

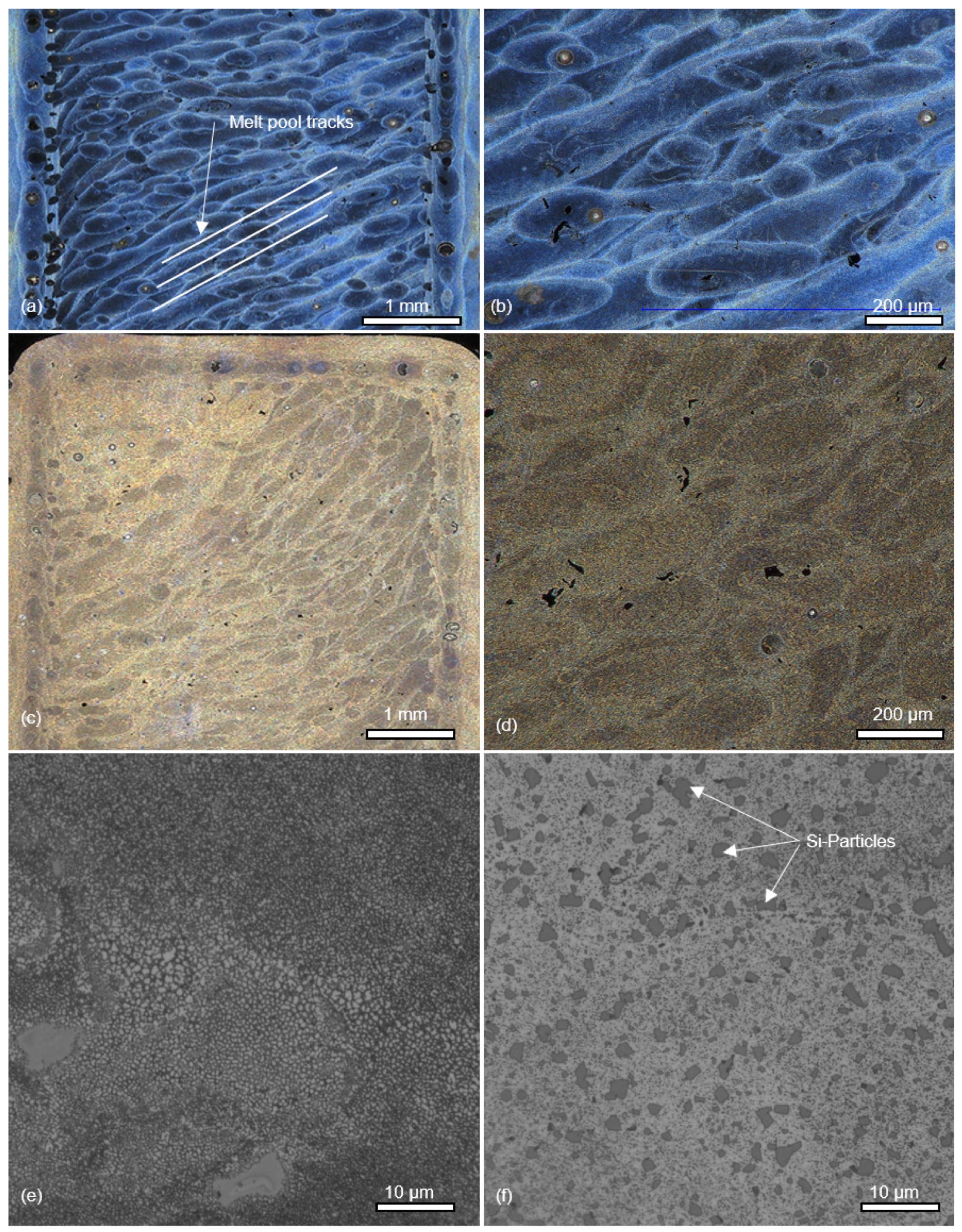

3.2. Microstructure

3.3. Fatigue

4. Discussion

5. Conclusions and Outlook

- The PBF-LB/M process was successfully integrated into the construction design process.

- A design and manufacturing route was proposed to safely implement the PBF-LB/M process into the construction design and manufacturing process.

- Shape optimization can be used to optimize the force flow in the part and reduce mass for faster production.

- A qualification method for PBF-LB/M machines for the construction sector is necessary, which is comparable to qualification methods of welding processes.

- Design restrictions should be implemented into the shape optimization process to reduce the danger of internal defects occurring.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schober, H.; Kürschner, K.; Jungjohann, H. Neue Messe Mailand–Netzstruktur und Tragverhalten einer Freiformfläche. Stahlbau 2004, 73, 541–551. [Google Scholar] [CrossRef]

- Klahn, C.; Meboldt, M.; Fontana, F.F.; Leutenecker-Twelsiek, B.; Jansen, J. Entwicklung und Konstruktion für die Additive Fertigung: Grundlagen und Methoden für den Einsatz in Industriellen Endkundenprodukten; Vogel Business Media: Wuerzburg, Germany, 2021. [Google Scholar]

- Hojjat, M.; Stavropoulou, E.; Bletzinger, K.U. The Vertex Morphing method for node-based shape optimization. Comput. Methods Appl. Mech. Eng. 2014, 268, 494–513. [Google Scholar] [CrossRef]

- Yu, Z.; Dai, H.; Shi, Z. Structural form-finding of bending components in buildings by using parametric tools and principal stress lines. Front. Archit. Res. 2022, 11, 561–573. [Google Scholar] [CrossRef]

- Diller, J.; Rier, L.; Siebert, D.; Radlbeck, C.; Krafft, F.; Mensinger, M. Cyclic plastic material behavior of 316L manufactured by laser powder bed fusion (PBF-LB/M). Mater. Charact. 2022, 191, 112153. [Google Scholar] [CrossRef]

- Ghantasala, A.; Diller, J.; Geiser, A.; Wenzler, D.; Siebert, D.; Radlbeck, C.; Wüchner, R.; Mensinger, M.; Bletzinger, K.U. Node-based shape optimization and mechanical test validation of complex metal components and support structures, manufactured by laser powder bed fusion. In Advances in Manufacturing, Production Management and Process Control; Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2021; pp. 10–17. [Google Scholar]

- Asl, R.N.; Shayegan, S.; Geiser, A.; Hojjat, M.; Bletzinger, K.U. A consistent formulation for imposing packaging constraints in shape optimization using Vertex Morphing parametrization. Struct. Multidiscip. Optim. 2017, 56, 1507–1519. [Google Scholar] [CrossRef]

- Ingenieure, V.D. Additive Manufacturing Processes-Powder Bed Fusion of Metal with Laser Beam (PBF-LB/M)-Material Data Sheet Aluminium Alloy AlSi10Mg, 2nd ed.; Verband Deutscher Ingenieure: Bonn, Germany, 2020; Available online: https://www.beuth.de/en/technical-rule/vdi-3405-blatt-2-1/326385793 (accessed on 15 May 2023).

- Padovano, E.; Badini, C.; Pantarelli, A.; Gili, F.; D’Aiuto, F. A comparative study of the effects of thermal treatments on AlSi10Mg produced by laser powder bed fusion. J. Alloys Compd. 2020, 831, 154822. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, C.C.; Dhillon, J.S.; Kwon, S.Y.; Hudon, P.; Brochu, M. Precipitation behavior of an Al7SiMg alloy processed by laser powder bed fusion during non-isothermal and isothermal heat treatments. Materialia 2023, 28, 101751. [Google Scholar] [CrossRef]

- Schneider, M.; Bettge, D.; Binder, M.; Dollmeier, K.; Dreyer, M.; Hilgenberg, K.; Klöden, B.; Schlingmann, T.; Schmidt, J. Reproducibility and Scattering in Additive Manufacturing: Results from a Round Robin on PBF-LB/M AlSi10Mg Alloy. Pract. Metallogr. 2022, 59, 580–614. [Google Scholar] [CrossRef]

- Kan, W.H.; Nadot, Y.; Foley, M.; Ridosz, L.; Proust, G.; Cairney, J.M. Factors that affect the properties of additively-manufactured AlSi10Mg: Porosity versus microstructure. Addit. Manuf. 2019, 29, 100805. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

| Element | Al | Si | Mg | Fe | Ti | Zn | Mn | Cu | Cr |

|---|---|---|---|---|---|---|---|---|---|

| wt.-% | Bal. | 9–11 | 0.20–0.45 | ≤0.55 | ≤0.15 | ≤0.10 | ≤0.45 | ≤0.05 | ≤0.05 |

| Laser Parameter | Energy Density | Laser Power | Laser Speed | Hatch Distance | Layer Thickness |

|---|---|---|---|---|---|

| Value | 80 J/mm3 | 400 W | 1000 mm/s | 0.1 mm | 0.05 mm |

| Step | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Grinding disk | MD Molto 220 | MD Largo | MD Dac | MD Nap |

| Duration | 4 min | 4 min | 4 min | 3 min |

| Rev./min | 150 | 150 | 150 | 150 |

| Pressure | 30 N | 30 N | 30 N | 30 N |

| Lubricant | Water | 6 μm | 3 μm | 1 μm |

| Specimen | (kN) | Min. F (kN) | Max. F (kN) | Stress Ratio | No. of Cycles |

|---|---|---|---|---|---|

| 1 | 1.5 | 6 | 7.5 | 0.8 | |

| 2 | 1.5 | 15 | 16.5 | 0.9 | |

| 3 | 3.0 | 15 | 18 | 0.83 | |

| 4 | 3.0 | 15 | 18 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diller, J.; Radlbeck, C.; Siebert, D.; Blankenhagen, J.; Gubetini, D.; Oberhaidinger, F.; Mensinger, M. Additive Manufacturing in Construction—Implementing Powder-Bed Fusion of Metals Using a Laser (PBF-LB/M) and Shape Optimization in the Construction Design Process. Eng. Proc. 2023, 43, 10. https://doi.org/10.3390/engproc2023043010

Diller J, Radlbeck C, Siebert D, Blankenhagen J, Gubetini D, Oberhaidinger F, Mensinger M. Additive Manufacturing in Construction—Implementing Powder-Bed Fusion of Metals Using a Laser (PBF-LB/M) and Shape Optimization in the Construction Design Process. Engineering Proceedings. 2023; 43(1):10. https://doi.org/10.3390/engproc2023043010

Chicago/Turabian StyleDiller, Johannes, Christina Radlbeck, Dorina Siebert, Jakob Blankenhagen, Drilon Gubetini, Florian Oberhaidinger, and Martin Mensinger. 2023. "Additive Manufacturing in Construction—Implementing Powder-Bed Fusion of Metals Using a Laser (PBF-LB/M) and Shape Optimization in the Construction Design Process" Engineering Proceedings 43, no. 1: 10. https://doi.org/10.3390/engproc2023043010

APA StyleDiller, J., Radlbeck, C., Siebert, D., Blankenhagen, J., Gubetini, D., Oberhaidinger, F., & Mensinger, M. (2023). Additive Manufacturing in Construction—Implementing Powder-Bed Fusion of Metals Using a Laser (PBF-LB/M) and Shape Optimization in the Construction Design Process. Engineering Proceedings, 43(1), 10. https://doi.org/10.3390/engproc2023043010