Transforming Agricultural Waste into Sustainable Composite Materials: Mechanical Properties of Tamarindus Fruit Fiber (TFF)-Reinforced Polylactic Acid Composites †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

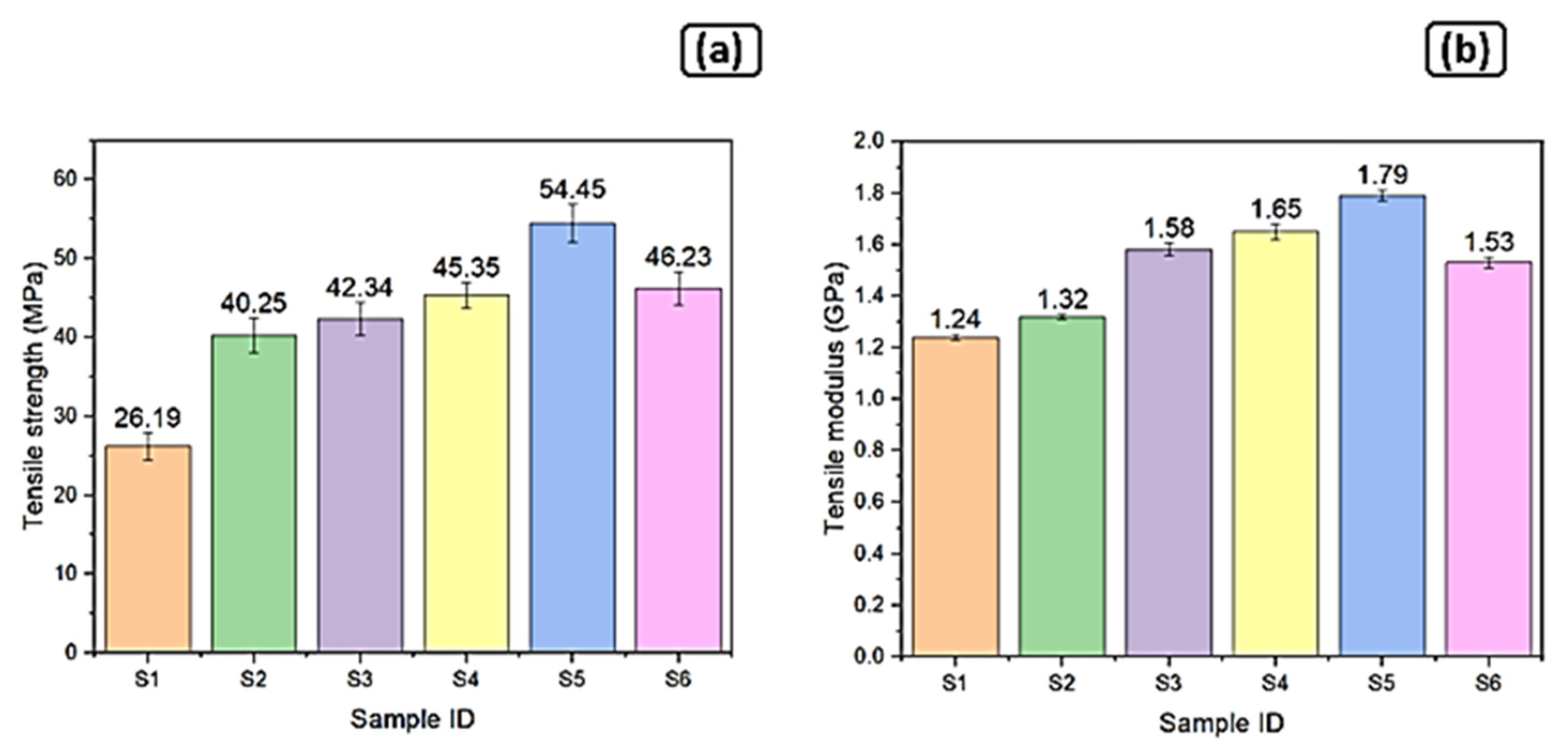

3.1. Performance on Tensile Strength and Modulus

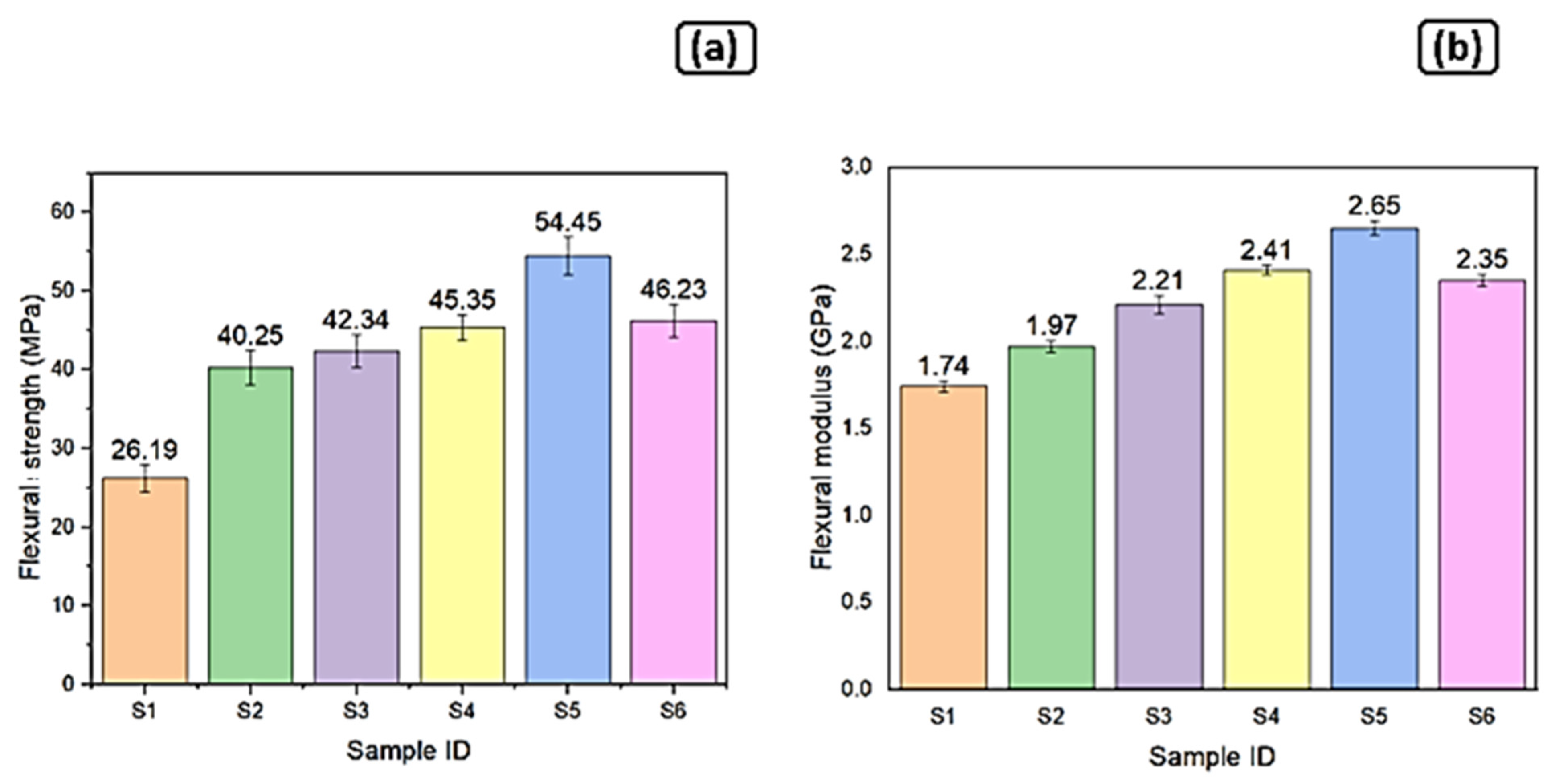

3.2. Performance on Flexural Strength and Modulus

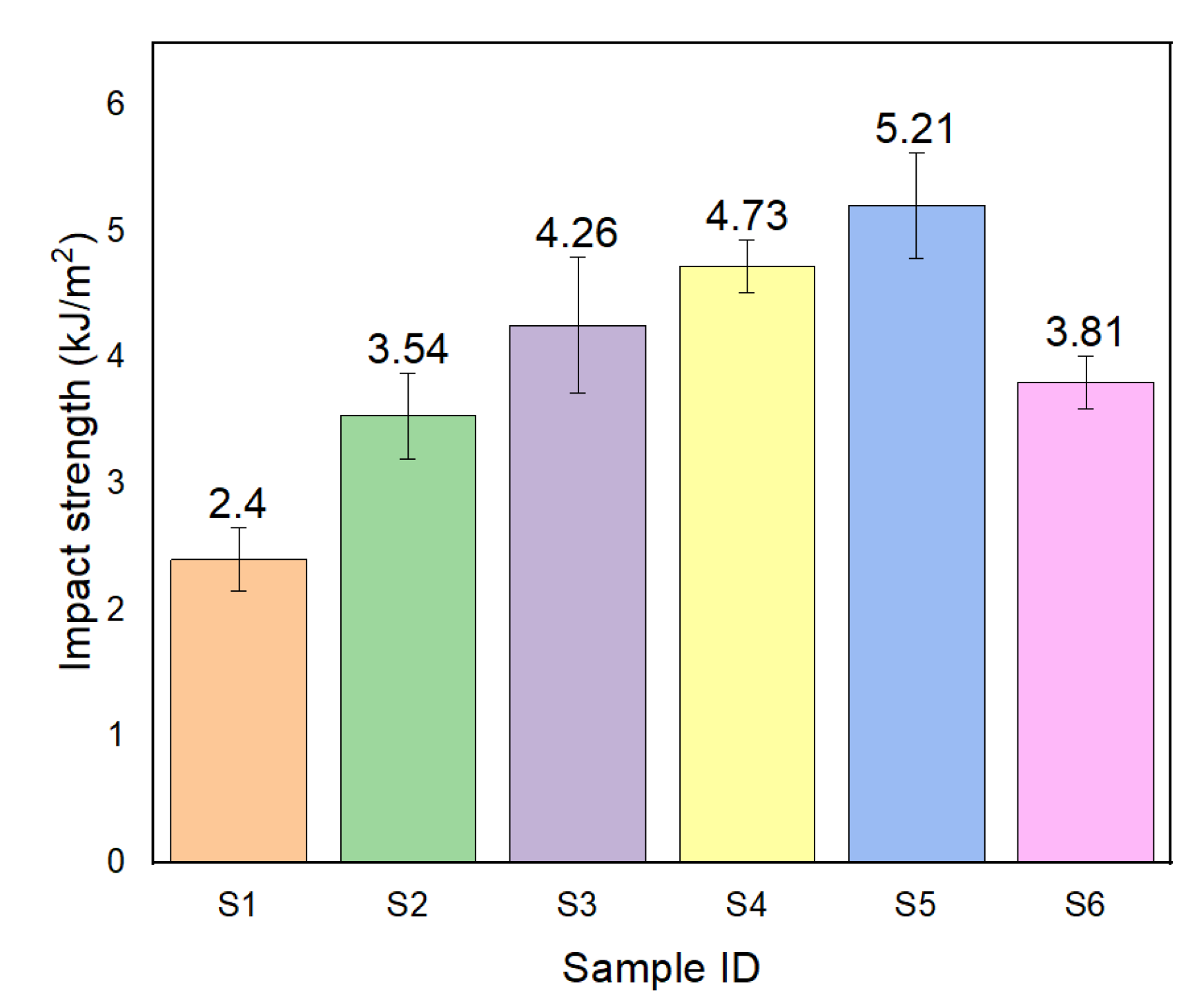

3.3. Impact Strength

3.4. Hardness

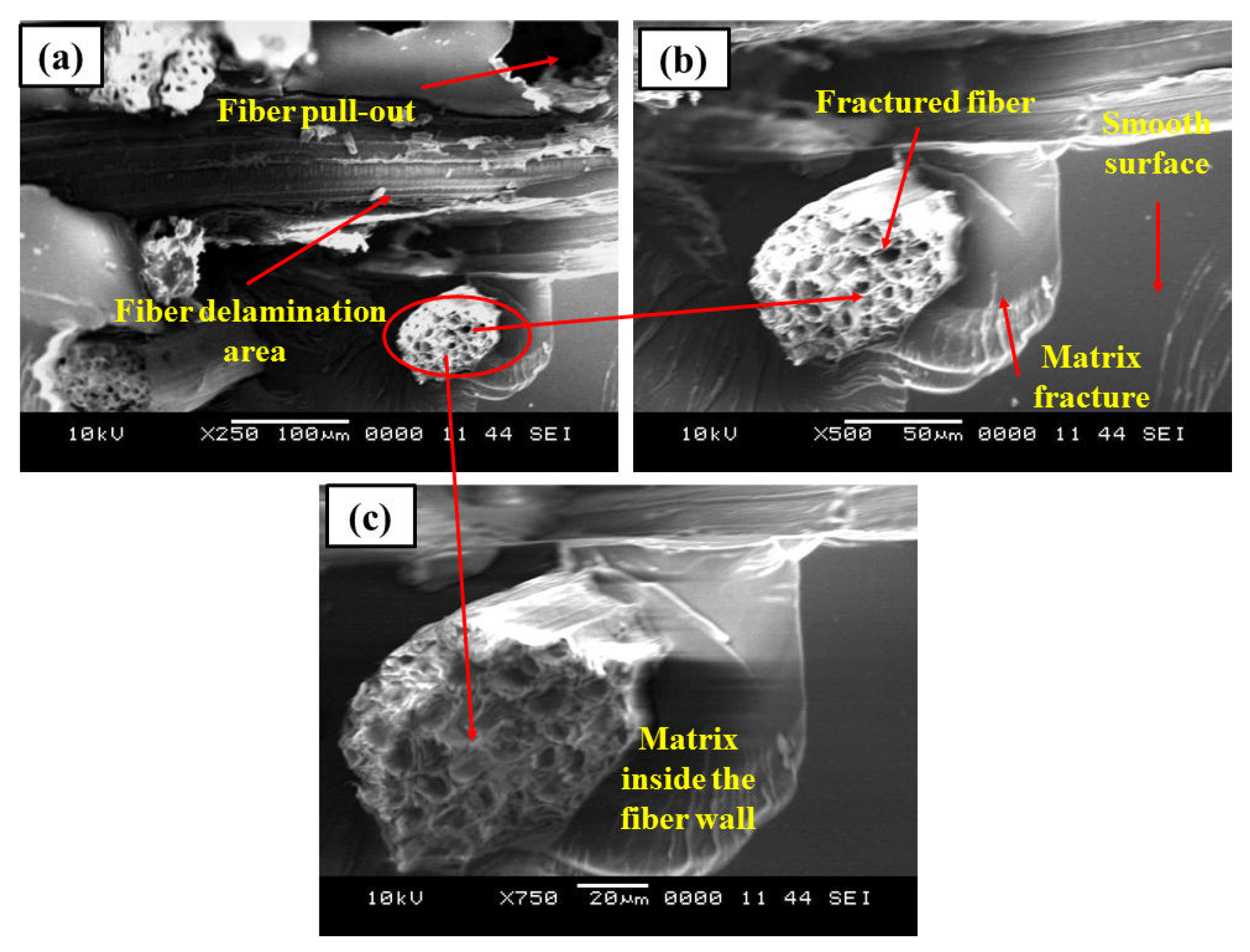

3.5. Morphological Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bhuvaneshwari, S.; Hettiarachchi, H.; Meegoda, J.N. Crop residue burning in India: Policy challenges and potential solutions. Int. J. Environ. Res. Public Health 2019, 16, 832. [Google Scholar] [CrossRef]

- Sahayaraj, A.F.; Muthukrishnan, M.; Ramesh, M.; Rajeshkumar, L. Effect of hybridization on properties of tamarind (Tamarindus indica L.) seed nano-powder incorporated jute-hemp fibers reinforced epoxy composites. Polym. Compos. 2021, 42, 6611–6620. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Rajeshkumar, L.; Tamil Selvan, M.; Balaji, D. Influence of fiber surface treatment on the tribological properties of Calotropis gigantea plant fiber reinforced polymer composites. Polym. Compos. 2021, 42, 4308–4317. [Google Scholar] [CrossRef]

- Iyyadurai, J.; Arockiasamy, F.S.; Manickam, T.; Rajaram, S.; Suyambulingam, I.; Siengchin, S. Experimental Investigation on Mechanical, Thermal, Viscoelastic, Water Absorption, and Biodegradability Behavior of Sansevieria Ehrenbergii Fiber Reinforced Novel Polymeric Composite with the Addition of Coconut Shell Ash Powder. J. Inorg. Organomet. Polym. Mater. 2023, 33, 796–809. [Google Scholar] [CrossRef]

- Kumar, R.P.; Muthukrishnan, M.; Sahayaraj, A.F. Experimental investigation on jute/snake grass/kenaf fiber reinforced novel hybrid composites with annona reticulata seed filler addition. Mater. Res. Express 2022, 9, 095304. [Google Scholar] [CrossRef]

- Jenish, I.; Veeramalai Chinnasamy, S.G.; Basavarajappa, S.; Indran, S.; Divya, D.; Liu, Y.; Sanjay, M.R.; Siengchin, S. Tribo-Mechanical characterization of carbonized coconut shell micro particle reinforced with Cissus quadrangularis stem fiber/epoxy novel composite for structural application. J. Nat. Fibers 2022, 19, 2963–2979. [Google Scholar] [CrossRef]

- Arul Marcel Moshi, A.; Ravindran, D.; Sundara Bharathi, S.R.; Padma, S.R.; Indran, S.; Divya, D. Characterization of natural cellulosic fiber extracted from Grewia damine flowering plant’s stem. Int. J. Biol. Macromol. 2020, 164, 1246–1255. [Google Scholar]

- Hariprasad, P.; Kannan, M.; Ramesh, C.; Felix Sahayaraj, A.; Jenish, I.; Hussain, F.; Ben Khedher, N.; Boudjemline, A.; Suresh, V. Mechanical and morphological studies of Sansevieria trifasciata fiber-reinforced polyester composites with the addition of SiO2 and B4C. Adv. Mater. Sci. Eng. 2022, 2022, 1634670. [Google Scholar] [CrossRef]

- Jenish, I.; Sahayaraj, A.F.; Appadurai, M.; Irudaya Raj, E.F.; Suresh, P. Sea sand abrasive wear of red mud micro particle reinforced Cissus quadrangularis stem fiber/epoxy composite. J. Nat. Fibers 2022, 19, 13216–13231. [Google Scholar] [CrossRef]

- Arockiasamy, F.S. Experimental investigation on the effect of fiber volume fraction of sponge gourd outer skin fiber reinforced epoxy composites. Polym. Compos. 2022, 43, 6932–6942. [Google Scholar] [CrossRef]

- Felix Sahayaraj, A.; Muthukrishnan, M.; Ramesh, M. Experimental investigation on physical, mechanical, and thermal properties of jute and hemp fibers reinforced hybrid polylactic acid composites. Polym. Compos. 2022, 43, 2854–2863. [Google Scholar] [CrossRef]

- Felix Sahayaraj, A.; Jenish, I.; Tamilselvan, M.; Muthukrishnan, M.; Kumar, B.A. Mechanical and morphological characterization of sisal/kenaf/pineapple mat reinforced hybrid composites. Int. Polym. Process. 2022, 37, 581–588. [Google Scholar] [CrossRef]

- Manimekalai, G.; Kavitha, S.; Divya, D.; Indran, S.; Binoj, J.S. Characterization of enzyme treated cellulosic stem fiber from Cissus quadrangularis plant: An exploratory investigation. Curr. Res. Green Sustain. Chem. 2021, 4, 100162. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar]

- Vijay, R.; Singaravelu, D.L.; Vinod, A.; Sanjay, M.R.; Siengchin, S.; Jawaid, M.; Khan, A.; Parameswaranpillai, J. Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int. J. Biol. Macromol. 2019, 125, 99–108. [Google Scholar] [CrossRef]

- Khan, A.; Vijay, R.; Singaravelu, D.L.; Sanjay, M.R.; Siengchin, S.; Verpoort, F.; Alamry, K.A.; Asiri, A.M. Extraction and characterization of natural fiber from Eleusine indica grass as reinforcement of sustainable fiber reinforced polymer composites. J. Nat. Fibers 2021, 18, 1742–1750. [Google Scholar] [CrossRef]

- Felix Sahayaraj, A.; Muthukrishnan, M.; Ramesh, M. Influence of Tamarindus indica seed nano-powder on properties of Luffa cylindrica (L.) fruit waste fiber reinforced polymer composites. Polym. Compos. 2022, 43, 6442–6452. [Google Scholar] [CrossRef]

- Premkumar, R.; Sathish Kumar, K.; Maniraj, J.; Jenish, I.; Hussain, F.; Khedher, N.B.; Aich, W.; Suresh, V. Experimental studies on mechanical and thermal properties of polyester hybrid composites reinforced with Sansevieria trifasciata fibers. Adv. Mater. Sci. Eng. 2022, 2022, 8604234. [Google Scholar] [CrossRef]

- Gandhi, V.S.; Jenish, I.; Indran, S.; Rajan, D.Y. Mechanical and thermal analysis of Cissus quadrangularis stem fiber/epoxy composite with micro-red mud filler composite for structural application. Trans. Indian Inst. Met. 2022, 75, 737–747. [Google Scholar] [CrossRef]

- Sathish, S.; Kumaresan, K.; Prabhu, L.; Gokulkumar, S. Experimental investigation of mechanical and FTIR analysis of flax fiber/epoxy composites incorporating SiC, Al2O3 and graphite. Rev. Romana Mater. 2018, 48, 476. [Google Scholar]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An overview: Natural fiber reinforced hybrid composites, chemical treatments and application areas. Mater. Today Proc. 2020, 27, 2828–2834. [Google Scholar] [CrossRef]

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Supian, A.B.M.; Jawaid, M.; Rashid, B.; Fouad, H.; Saba, N.; Dhakal, H.N.; Khiari, R. Mechanical and physical performance of date palm/bamboo fibre reinforced epoxy hybrid composites. J. Mater. Res. Technol. 2021, 15, 1330–1341. [Google Scholar] [CrossRef]

- Manickam, T.; Iyyadurai, J.; Jaganathan, M.; Babuchellam, A.; Mayakrishnan, M.; Arockiasamy, F.S. Effect of stacking sequence on mechanical, water absorption, and biodegradable properties of novel hybrid composites for structural applications. Int. Polym. Processing. 2022, 38, 88–96. [Google Scholar] [CrossRef]

- Devadiga, D.G.; Bhat, K.S.; Mahesha, G. Sugarcane bagasse fiber reinforced composites: Recent advances and applications. Cogent Eng. 2020, 7, 1823159. [Google Scholar] [CrossRef]

- Maniraj, J.; Arockiasamy, F.S.; Kumar, C.R.; Kumar, D.A.; Jenish, I.; Suyambulingam, I.; Rangappa, S.M.; Siengchin, S. Machine Learning Techniques for the Design and Optimization of Polymer Composites: A Review. E3S Web Conf. 2023, 428, 02013. [Google Scholar] [CrossRef]

- Sahayaraj, A.F.; Dhamotharan, S.; Sandeep, D.; Ramachandran, P.; Jenish, I.; Divakaran, D.; Suyambulingam, I.; Sanjay, M.R.; Siengchin, S. Sustainable Smart Polymer Composite Materials: A Comprehensive Review. E3S Web Conf. 2023, 428, 02014. [Google Scholar] [CrossRef]

- Rajaram, S.; Venkatesan, K.; Jenish, I.; Bhaskar, G.B. Study of mechanical properties on abaca/sisal fibre–reinforced epoxy resin–based hybrid composites. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Gokulkumar, S.; Suyambulingam, I.; Divakaran, D.; Priyadharshini, G.S.; Aravindh, M.; Iyyadurai, J.; Edwards, M.S.; Siengchin, S. Facile exfoliation and physicochemical characterization of biomass-based cellulose derived from Lantana aculeata leaves for sustainable environment. Macromol. Res. 2023, 31, 1163–1178. [Google Scholar] [CrossRef]

- Suyambulingam, I.; Gangadhar, L.; Sana, S.S.; Divakaran, D.; Siengchin, S.; Kurup, L.A.; Iyyadurai, J.; Albert Bernad Noble, K.E. Chitosan Biopolymer and Its Nanocomposites: Emerging Material as Adsorbent in Wastewater Treatment. Adv. Mater. Sci. Eng. 2023, 2023, 9387016. [Google Scholar] [CrossRef]

- Venugopal, J.; Dhanasakkaravarthi, B.; Surakasi, R.; Rinawa, M.L.; Manjunatha, L.H.; Alshgari, R.A.; Wabaidur, S.M.; Islam, A.; Jenish, I. Effect on Compression Molding Parameters in Mechanical Properties of MWCNT/Glass Fiber/Epoxy Composites. Adv. Polym. Technol. 2022, 2022, 9295407. [Google Scholar] [CrossRef]

- Iyyadurai, J.; Arockiasamy, F.S.; Manickam, T.S.; Suyambulingam, I.; Siengchin, S.; Appadurai, M.; Raj, E. Revolutionizing Polymer Composites: Boosting Mechanical Strength, Thermal Stability, Water Resistance, and Sound Absorption of Cissus Quadrangularis Stem Fibers with Nano Silica. Silicon 2023, 15, 6407–6419. [Google Scholar] [CrossRef]

- Venkatesan, K.; Rajaram, S.; Jenish, I.; Bhaskar, G.B. Fatigue and creep behavior of abaca–sisal natural fiber–reinforced polymeric composites. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Vigneshwaran, G.V.; Jenish, I.; Sivasubramanian, R. Design, fabrication and experimental analysis of pandanus fibre reinforced polyester composite. Adv. Mater. Res. 2014, 984, 253–256. [Google Scholar] [CrossRef]

- Prabhu Stalin, J.R.; Jenish, I.; Indran, S. Tribological charecterization of carbon epoxy composite materials with particulate silane treated SiC fillers. Adv. Mater. Res. 2014, 984, 331–335. [Google Scholar] [CrossRef]

- Jenish, I.; Gandhi, V.S.; Raj, R.E.; Basavarajappa, S.; Indran, S.; Divya, D.; Kumaravelan, R. A new study on tribological performance of cissus quadrangularis stem fiber/epoxy with red mud filler composite. J. Nat. Fibers 2022, 19, 3502–3516. [Google Scholar] [CrossRef]

- Sahayaraj, A.F.; Selvan, M.T.; Jenish, I.; Ramesh, M. Extraction and characterization of novel cellulosic fiber from Jatropha integerrima plant stem for potential reinforcement in polymer composites. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Ramesh, M.; Tamil Selvan, M.; Felix Sahayaraj, A.; Jenish, I.; Balakrishnan, P.; Ravanan, A. Investigation of mechanical and viscoelastic properties of Agave cantala fiber-reinforced green composites for structural applications. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023; online ahead of print. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajaram, S.; Subbiah, T.; Arockiasamy, F.S.; Iyyadurai, J. Transforming Agricultural Waste into Sustainable Composite Materials: Mechanical Properties of Tamarindus Fruit Fiber (TFF)-Reinforced Polylactic Acid Composites. Eng. Proc. 2024, 61, 32. https://doi.org/10.3390/engproc2024061032

Rajaram S, Subbiah T, Arockiasamy FS, Iyyadurai J. Transforming Agricultural Waste into Sustainable Composite Materials: Mechanical Properties of Tamarindus Fruit Fiber (TFF)-Reinforced Polylactic Acid Composites. Engineering Proceedings. 2024; 61(1):32. https://doi.org/10.3390/engproc2024061032

Chicago/Turabian StyleRajaram, Srinivasan, Thirugnanam Subbiah, Felix Sahayaraj Arockiasamy, and Jenish Iyyadurai. 2024. "Transforming Agricultural Waste into Sustainable Composite Materials: Mechanical Properties of Tamarindus Fruit Fiber (TFF)-Reinforced Polylactic Acid Composites" Engineering Proceedings 61, no. 1: 32. https://doi.org/10.3390/engproc2024061032

APA StyleRajaram, S., Subbiah, T., Arockiasamy, F. S., & Iyyadurai, J. (2024). Transforming Agricultural Waste into Sustainable Composite Materials: Mechanical Properties of Tamarindus Fruit Fiber (TFF)-Reinforced Polylactic Acid Composites. Engineering Proceedings, 61(1), 32. https://doi.org/10.3390/engproc2024061032