Effect of Volume Fraction of Epoxy Matrix Coconut Shell Composite on Tensile and Impact Loads †

Abstract

:1. Introduction

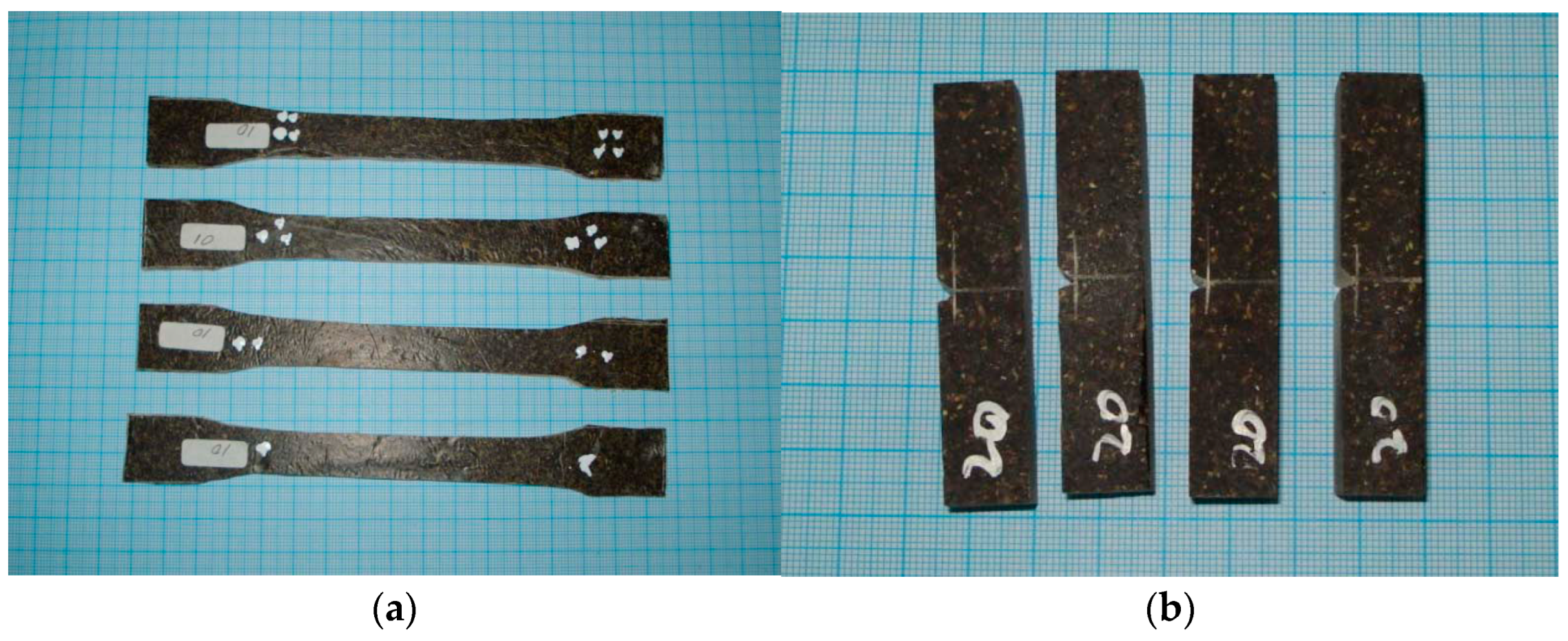

2. Research Method

3. Research and Discussion

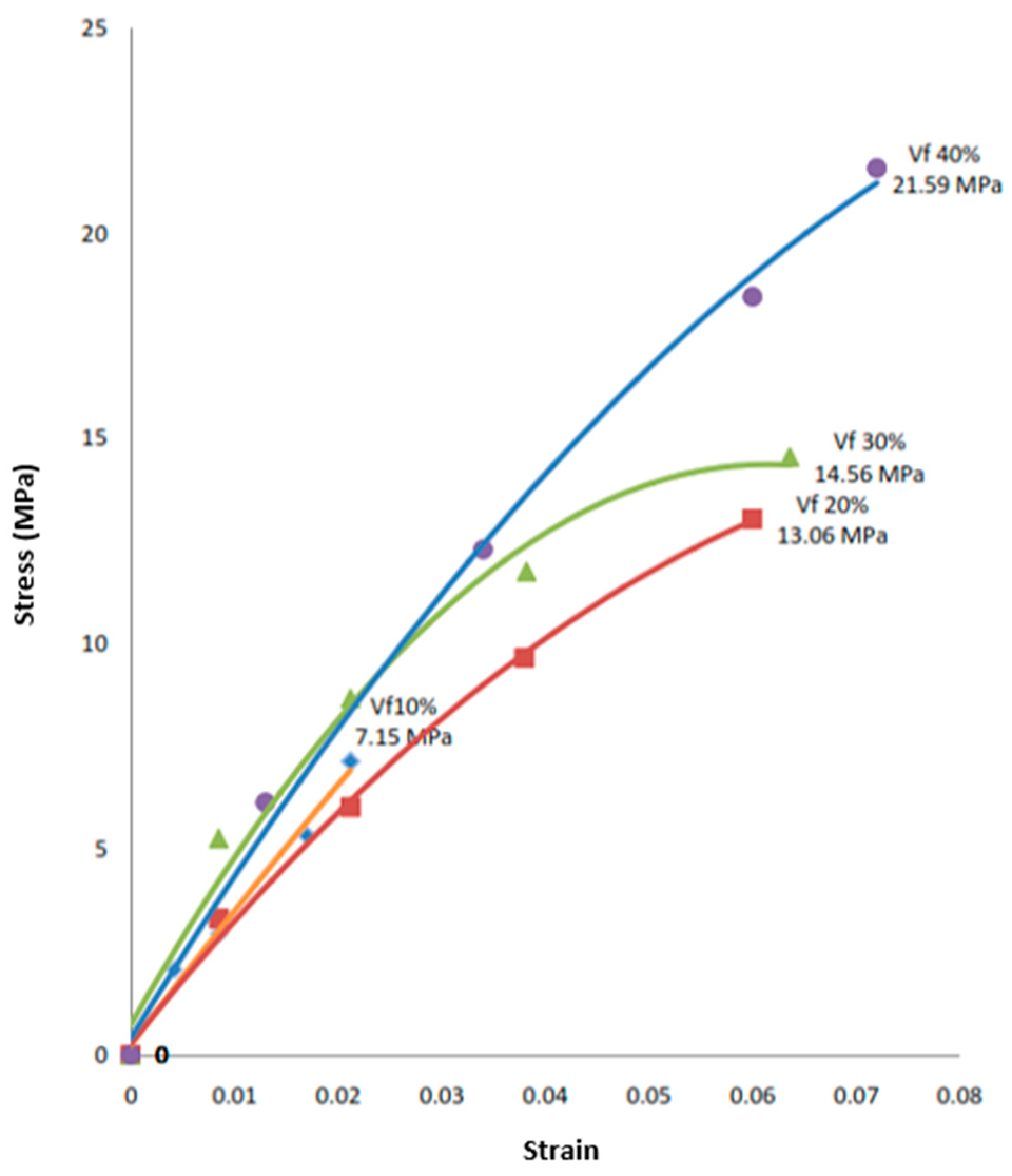

3.1. Tensile Test Results

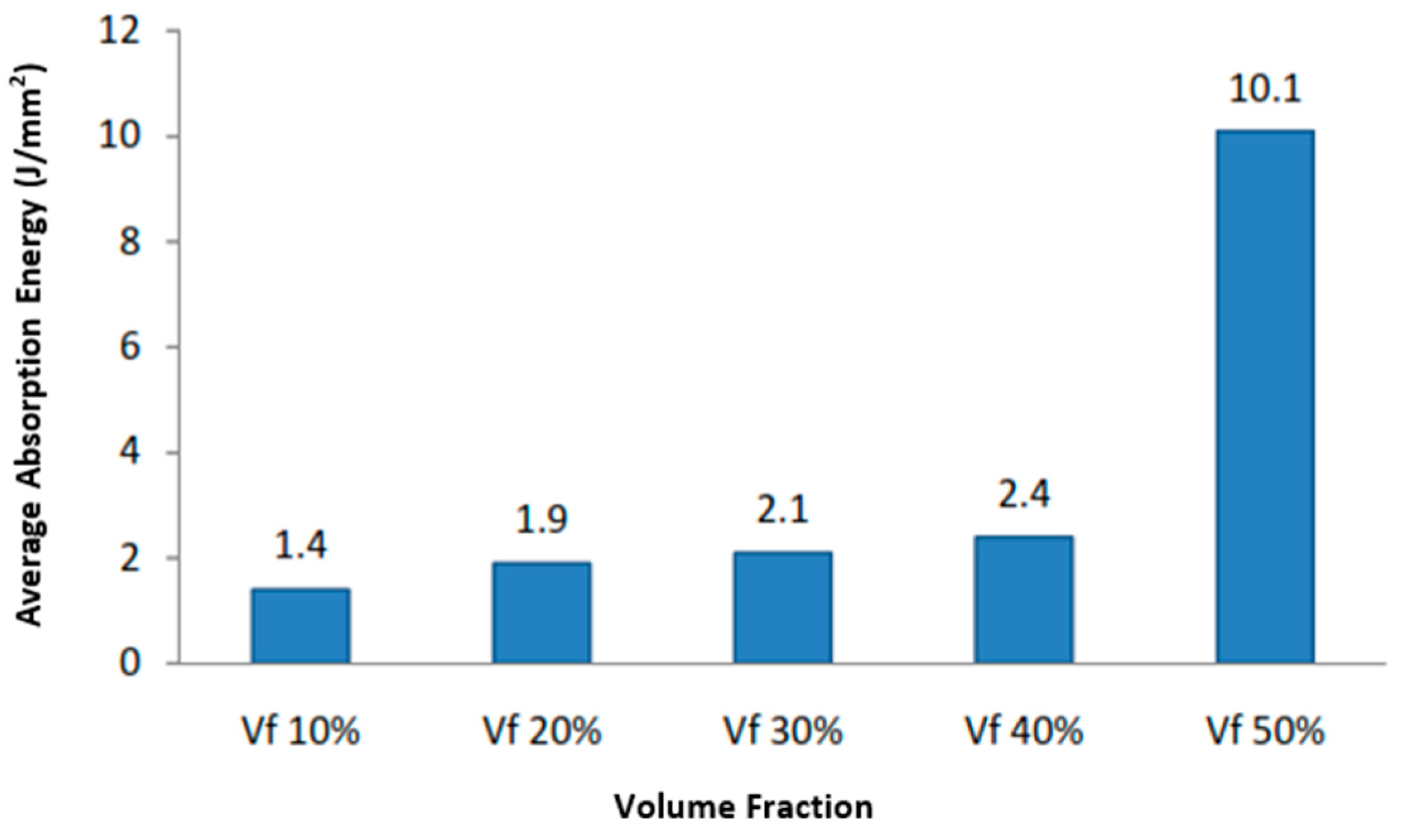

3.2. Impact Test Results

3.3. Composite Density Test Results

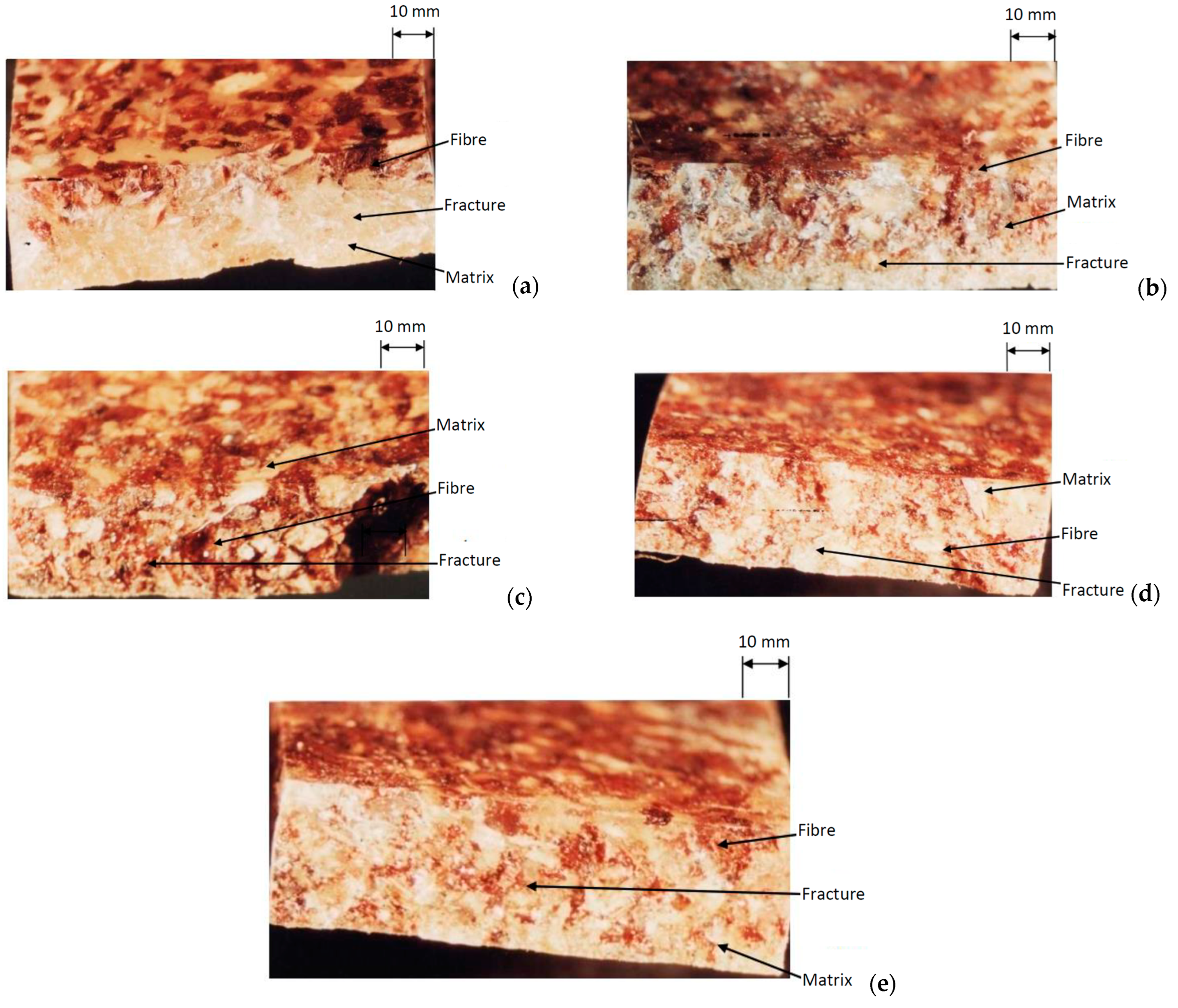

3.4. Macrostructure Testing

4. Conclusions

- On the basis of data from tensile testing results, it is known that as the volume fraction increases, the tensile strength becomes greater. The highest tensile strength at a volume fraction of 40% was 21.59 MPa, and the lowest at a volume fraction of 10% was 7.15 MPa. The highest strain at a volume fraction of 40% was 8.1%, and the lowest at a volume fraction of 10% was 2.8%.

- On the basis of data from impact testing results, it is known that as the volume fraction increases, the impact price increases. The highest average impact value is for the composite with a volume fraction of 50%, amounting to 0.074 J/mm2, and the lowest with a volume fraction of 10%, amounting to 0.010 J/mm2.

- The highest composite density at a volume fraction of 50% was 1.067 gr/cm3, and the lowest was at a volume fraction of 10%, at 1.014 gr/cm3.

- In observing the fracture after tensile and impact testing, a brittle fracture can be noted, with the direction of crack propagation being perpendicular to the direction of the acting tensile stress, producing a relatively flat fracture surface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dar, B.N.; Pérez-Akaki, P.; Muñoz, R.C.; Wilder, J.; Sossa, Z. Innovations and trends in the coconut agroindustrysupply chain: A technological surveillance and foresight analysis. Front. Sustain. Food Syst. 2023, 7, 1048450. [Google Scholar]

- Aklis, N.; Program, M.; Doktor, S.; Mesin, T.; Rohmat, T.A.; Saptoadi, H. The effect of thermal wall on hydrodynamics and syngas characteristics in dual fluidized bed gasifier made of coconut shell using cpfd based simulation. Media Mesin Maj. Tek. Mesin 2021, 22, 49–63. [Google Scholar] [CrossRef]

- Kairupan, A.N.; Kindangen, J.G.; Joseph, G.H.; Hutapea, R.T.P.; Malia, I.E.; Paat, P.C.; Polakitan, D.; Polakitan, A.; Rawung, J.B.M.; Lintang, M. Value Chain Implementation in Rural-Scale Integrated Coconut Farming System in North Sulawesi Province, Indonesia. In Agricultural Value Chains; Stanton, J., Caiazza, R., Eds.; IntechOpen: Rijeka, Croatia, 2023; Chapter 7. [Google Scholar] [CrossRef]

- Kabir Ahmad, R.; Sulaiman, S.A.; Yusup, S.; Dol, S.S.; Inayat, M.; Umar, H.A. Exploring the potential of coconut shell biomass for charcoal production. Ain Shams Eng. J. 2022, 13, 101499. [Google Scholar] [CrossRef]

- Keppetipola, N.M.; Dissanayake, M.; Dissanayake, P.; Karunarathne, B.; Dourges, M.A.; Talaga, D.; Servant, L.; Olivier, C.; Toupance, T.; Uchida, S.; et al. Graphite-type activated carbon from coconut shell: A natural source for eco-friendly non-volatile storage devices. RSC Adv. 2021, 11, 2854–2865. [Google Scholar] [CrossRef] [PubMed]

- Nadzri, S.N.I.H.A.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A.; Abu Talib, A.R.; Jawaid, M.; Basri, A.A. A comprehensive review of coconut shell powder composites: Preparation, processing, and characterization. J. Thermoplast. Compos. Mater. 2020, 35, 2641–2664. [Google Scholar] [CrossRef]

- Kumar, A.; Nirala, A.; Singh, V.; Sahoo, B.K.; Singh, R.; Chaudhary, R.; Dewangan, A.K.; Gaurav, G.K.; Klemeš, J.J.; Liu, X. The utilisation of coconut shell ash in production of hybrid composite: Microstructural characterisation and performance analysis. J. Clean. Prod. 2023, 398, 136494. [Google Scholar] [CrossRef]

- Sarki, J.; Hassan, S.B.; Aigbodion, V.S.; Oghenevweta, J.E. Potential of using coconut shell particle fillers in eco-composite materials. J. Alloys Compd. 2011, 509, 2381–2385. [Google Scholar] [CrossRef]

- Daramola, O.O.; Akinwande, A.A.; Adediran, A.A.; Balogun, O.A.; Olajide, J.L.; Adedoyin, K.J.; Adewuyi, B.O.; Jen, T.C. Optimization of the mechanical properties of polyester/coconut shell ash (CSA) composite for light-weight engineering applications. Sci. Rep. 2023, 13, 1066. [Google Scholar] [CrossRef] [PubMed]

- Purboputro, P.I.; Awaluddin, D. Variation of mesh size (Al-Si) and coconut shell carbon using BQTN 157 polyester on hardness testing value. Media Mesin Maj. Tek. Mesin 2018, 19, 84–89. [Google Scholar] [CrossRef]

- Livingston, T.; Athijayamani, A.; Alavudeen, A. Evaluation of mechanical properties of coconut shell particle/vinyl ester composite based on the untreated and treated conditions. Mater. Res. Express 2021, 8, 035309. [Google Scholar] [CrossRef]

- Sujiono, E.H.; Saputra, A.; Muchlis; Usman, B.; Fadilah, N.; Zurnansyah; Zabrian, D.; Azizah, N. Coconut shell waste-derived graphene oxide composite with neodymium oxide (Nd2O3) for advanced applications. Results Mater. 2023, 20, 100480. [Google Scholar] [CrossRef]

- Darmawan, A.S.; Hariyanto, A.; Purboputro, P.I.; Ihwanudin, H.A.; Pamungkas, M.I. The effect of heat treatment and pressing at 400 °C with coconut shell charcoal media on the hardness, microstructure, and density of al-si alloys. J. Media Mesin 2022, 23, 2. [Google Scholar]

- Standard Test Method for Tensile Properties of Plastics. Available online: https://www.astm.org/d0638-02.html (accessed on 8 June 2022).

- Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. Available online: https://www.astm.org/standards/d256 (accessed on 8 June 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hariyanto, A.; Anggono, A.D.; Pratiwi, D.A.; Amali, A.B.; Melaty, S.; Adi, Z.K.; Ngafwan; Supriyono; Kultsum, U. Effect of Volume Fraction of Epoxy Matrix Coconut Shell Composite on Tensile and Impact Loads. Eng. Proc. 2024, 63, 14. https://doi.org/10.3390/engproc2024063014

Hariyanto A, Anggono AD, Pratiwi DA, Amali AB, Melaty S, Adi ZK, Ngafwan, Supriyono, Kultsum U. Effect of Volume Fraction of Epoxy Matrix Coconut Shell Composite on Tensile and Impact Loads. Engineering Proceedings. 2024; 63(1):14. https://doi.org/10.3390/engproc2024063014

Chicago/Turabian StyleHariyanto, Agus, Agus Dwi Anggono, Dessy Ade Pratiwi, Anas Bariquddin Amali, Sekar Melaty, Zanuar Kusuma Adi, Ngafwan, Supriyono, and Ummi Kultsum. 2024. "Effect of Volume Fraction of Epoxy Matrix Coconut Shell Composite on Tensile and Impact Loads" Engineering Proceedings 63, no. 1: 14. https://doi.org/10.3390/engproc2024063014

APA StyleHariyanto, A., Anggono, A. D., Pratiwi, D. A., Amali, A. B., Melaty, S., Adi, Z. K., Ngafwan, Supriyono, & Kultsum, U. (2024). Effect of Volume Fraction of Epoxy Matrix Coconut Shell Composite on Tensile and Impact Loads. Engineering Proceedings, 63(1), 14. https://doi.org/10.3390/engproc2024063014