Some Studies on the Mechanism of Chip Formation during Machining of Chromium Manganese Austenitic Stainless Steel †

Abstract

:1. Introduction

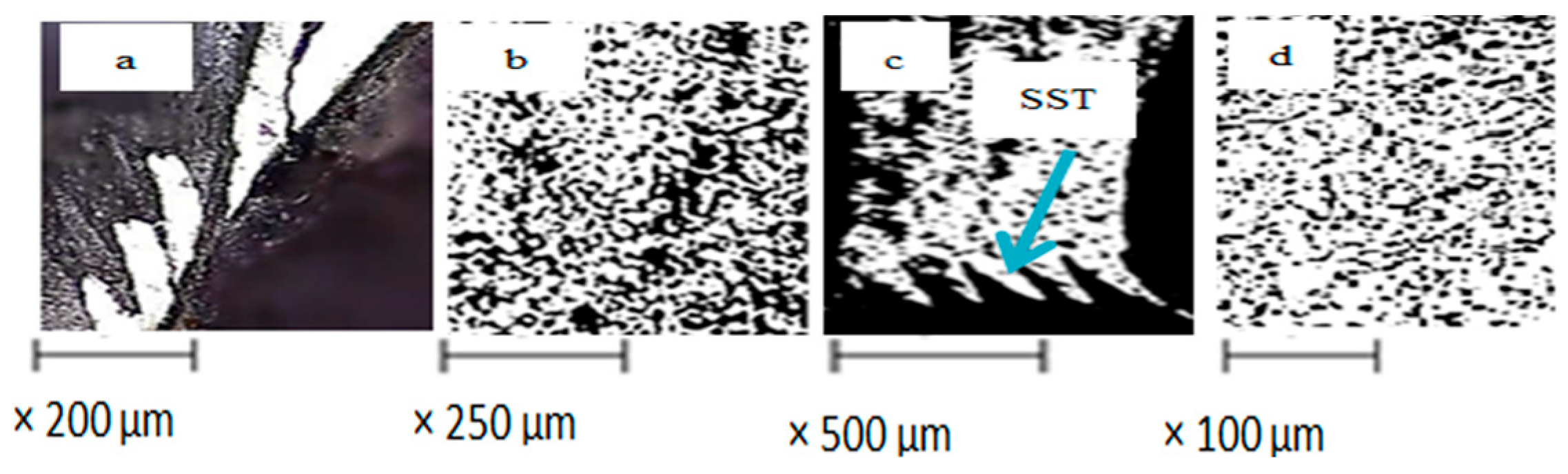

2. Experimental Procedure

- (i)

- Plastic mounting of the formed chips;

- (ii)

- Polishing;

- (iii)

- Etching.

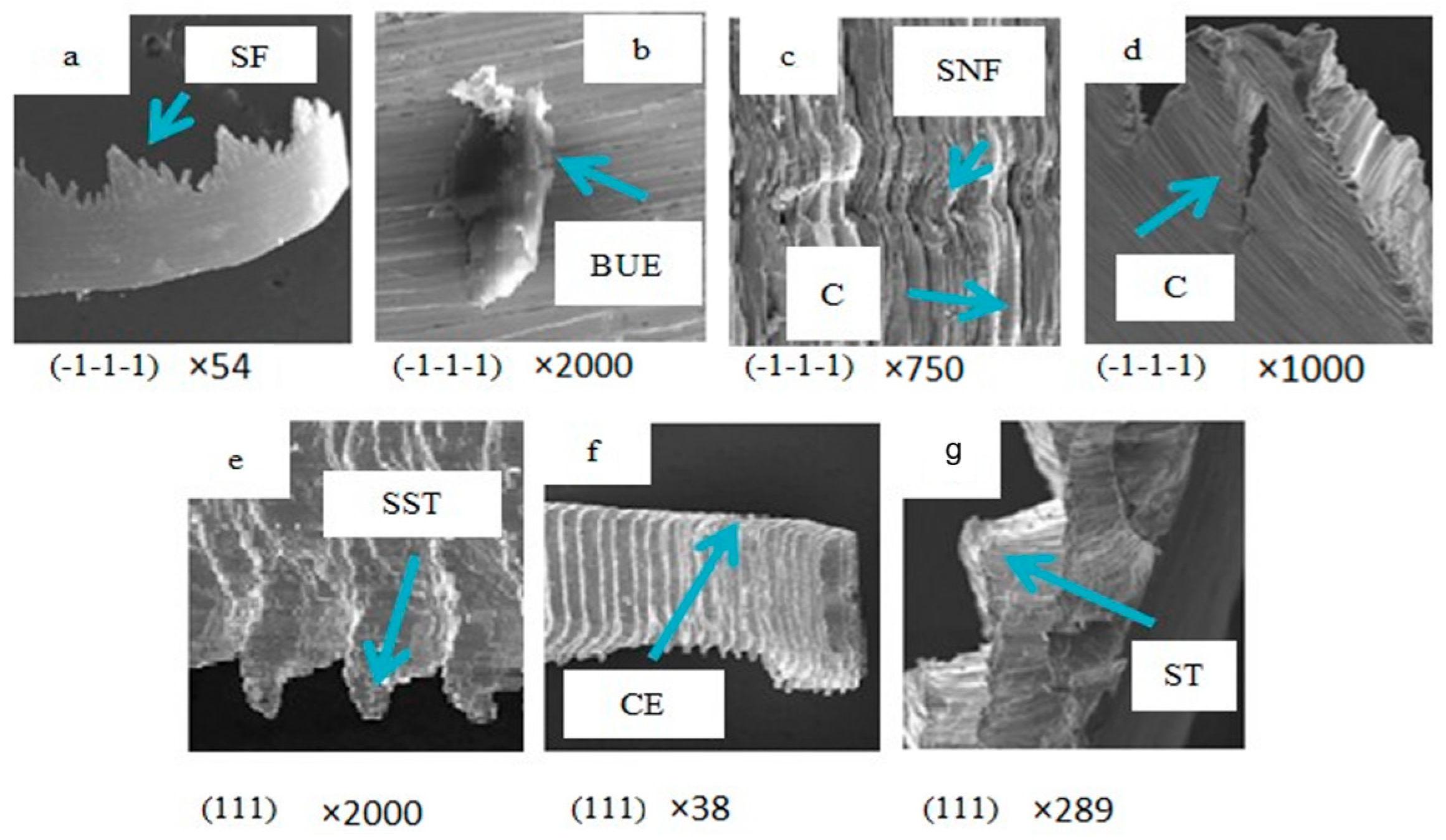

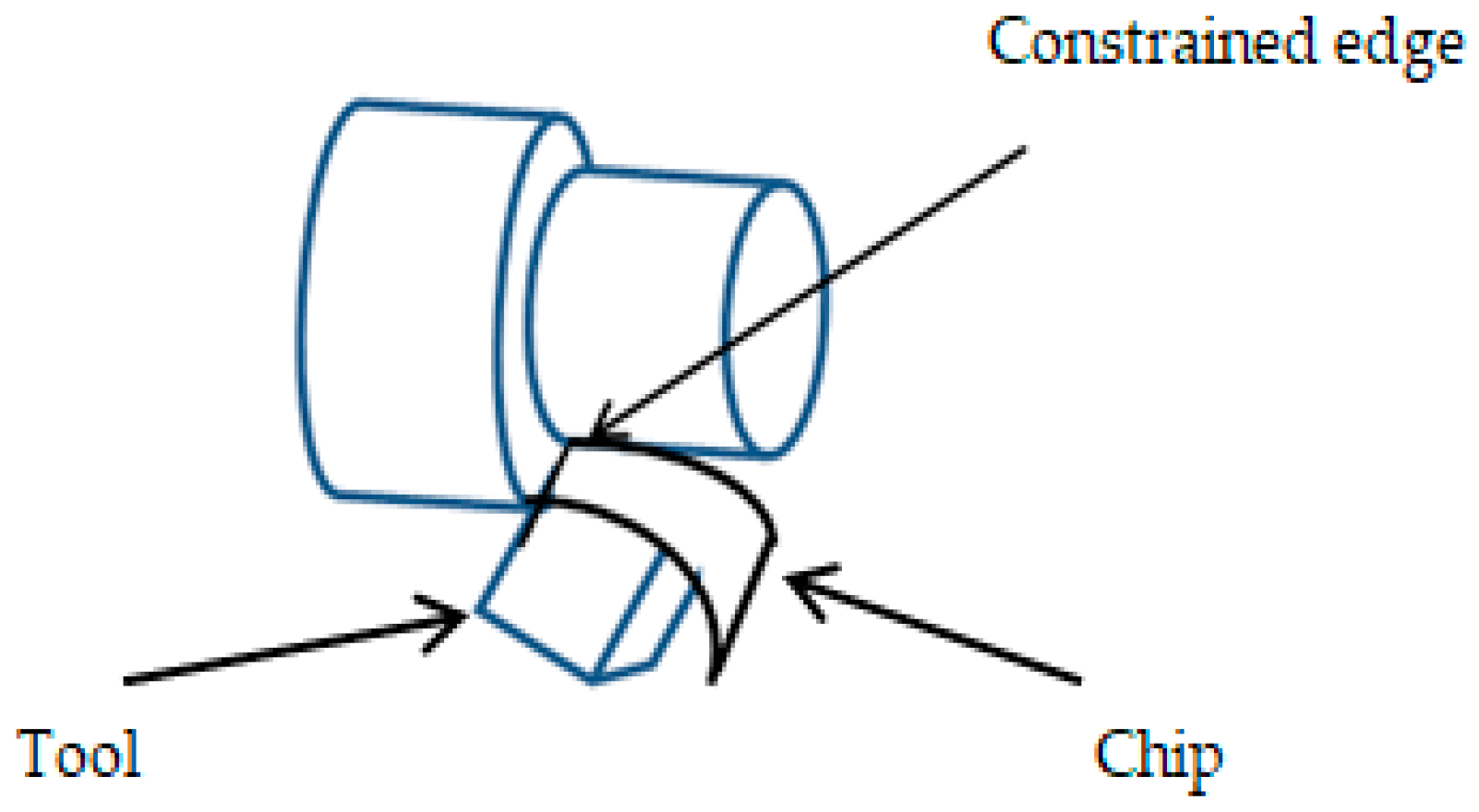

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suman, K.; Bikash, C. CNC Machinability study of AISI 316L & Optimization of Machining parameters using TLBO algorithm. Mater. Today Proc. 2022, 62, 1218–1225. [Google Scholar]

- Kaladhar, M. Process parameters optimisation and coatings influence on the surface quality during turning of AISI 202 austenitic stainless steel. Int. J. Mach. Mach. Mater. 2012, 11, 371. [Google Scholar] [CrossRef]

- Ahmad, H.; Ahmed, A.B. An optimization method of the machining parameters in high-speed machining of stainless steel using coated carbide tool for best surface finish. Int. J. Adv. Manuf. Technol. 2012, 58, 81–91. [Google Scholar]

- Friedrich, B.; Daniel, F.; Anton, S. Machining of difficult to cut materials. In Proceedings of the 27th DAAM International Symposium on Intelligent Manufacturing and Automation, Mostar, Bosnia and Herzegovina, 26–29 October 2016. [Google Scholar]

- Dureja, J.; Ranjit, S.; Talwinder, S. Performance Evaluation of Coated Carbide Tool in Machining of Stainless Steel (AISI 202) under Minimum Quantity Lubrication (MQL). Int. J. Precis. Eng. Manuf. Green Technol. 2015, 2, 123–129. [Google Scholar] [CrossRef]

- Smita, P.; Anshuman, D.; Aniket, S.; Thakkar, R. Level of Thesis, Sustainability Assessment and Machinability Investigation of Austenitic Stainless Steel in Finish Turning with Advanced Ultra-Hard SiAlON Ceramic Tool under Different Cutting Environments. Silicon 2021, 13, 119–147. [Google Scholar]

- Hea, Q.; Paivaa, J.M.; Kohlscheenc, J.; Beaked, B.D.; Veldhuisa, S.C. An integrative approach to coating/carbide substrate design of CVD and PVD coated cutting tools during the machining of austenitic stainless steel. Ceram. Int. 2020, 46, 5149–5158. [Google Scholar] [CrossRef]

- Deng, J.; Zhou, J.; Zhang, H.; Yan, P. Wear mechanisms of cemented carbide tools in dry cutting of precipitation hardening semi-austenitic stainless steels. Wear 2011, 270, 520–527. [Google Scholar]

- Girish, K.; Kuldip, S.S. Prediction and optimization of machining parameters for minimizing power consumption and surface roughness in machining. J. Clean. Prod. 2014, 36, 151–164. [Google Scholar]

- Wagh, S.S.; Kulkarni, A.P.; Sargade, V.G. Machinability studies of austenitic stainless steel (AISI 304) using PVD cathodic arc evaporation (CAE) system deposited AlCrN/TiAlN coated carbide inserts. Procedia Eng. 2013, 64, 907–914. [Google Scholar] [CrossRef]

- Munoz, E.; Shokrani, P.A.; Newman, S.T. Influence of cutting environments on surface integrity and power consumption of austenitic stainless steel. Integr. Manuf. 2015, 36, 60–69. [Google Scholar] [CrossRef]

- He, Q.; DePaiva, J.M.; Kohlscheen, J.; Veldhuis, S.C. Analysis of the performance of PVD AlTiN coating with five different Al/Ti ratios during the high-speed turning of stainless steel 304 under dry and wet cooling conditions. Wear 2022, 492–493, 204213. [Google Scholar] [CrossRef]

- De Oliveira Junior, C.A.; Diniz, A.E.; Bertazzoli, R. Correlating tool wear, surface roughness and corrosion resistance in the turning process of super duplex stainless steel. J. Braz. Soc. Mech. Sci. Eng. 2014, 36, 775–785. [Google Scholar] [CrossRef]

- Umbrello, D.; Saoubt, R.M.; Outeiro, J.C. The influence of Johnson–Cook material constants on finite element simulation of machining of AISI 316L steel. Int. J. Mach. Tools Manuf. 2007, 47, 462–470. [Google Scholar] [CrossRef]

- Rabiae, A.; Guillaume, F.; Frederic, R. Mechanical study in drilling of heat resistant austenitic stainless steel. Procedia CIRP 2018, 77, 425–428. [Google Scholar]

- Jastrzebski, Z.D. The Nature and Properties of Engineering Materials, 3rd ed.; John Willey and Sons: Hoboken, NJ, USA, 1987. [Google Scholar]

- Astakhov, V.P. Tribology of Metal Cutting; Briscoe, B.J., Ed.; Tribology and Interface Engineering Series; Elsevier: Amsterdam, The Netherlands, 2006; No. 52. [Google Scholar]

- De, S.; Chakraborty, K. The machining parameter optimisation during the machining of the Cr-Mn austenitic stainless steel by the topsis method. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

| %C | %Si | %Mn | %S | %P | %Ni | %Cr | %Cu |

|---|---|---|---|---|---|---|---|

| 0.225 | 0.465 | 7.48 | 0.0098 | 0.024 | 0.87 | 13.64 | 1.15 |

| Parameter Levels | Expt. No. (Levels) | ||

|---|---|---|---|

| 1 (Low) | 2 (Medium) | 3 (High) | |

| Speed, m/min | 40 | 70 | 100 |

| Feed, mm/rev. | 0.06 | 0.10 | 0.16 |

| DOC, mm | 0.5 | 1 | 1.5 |

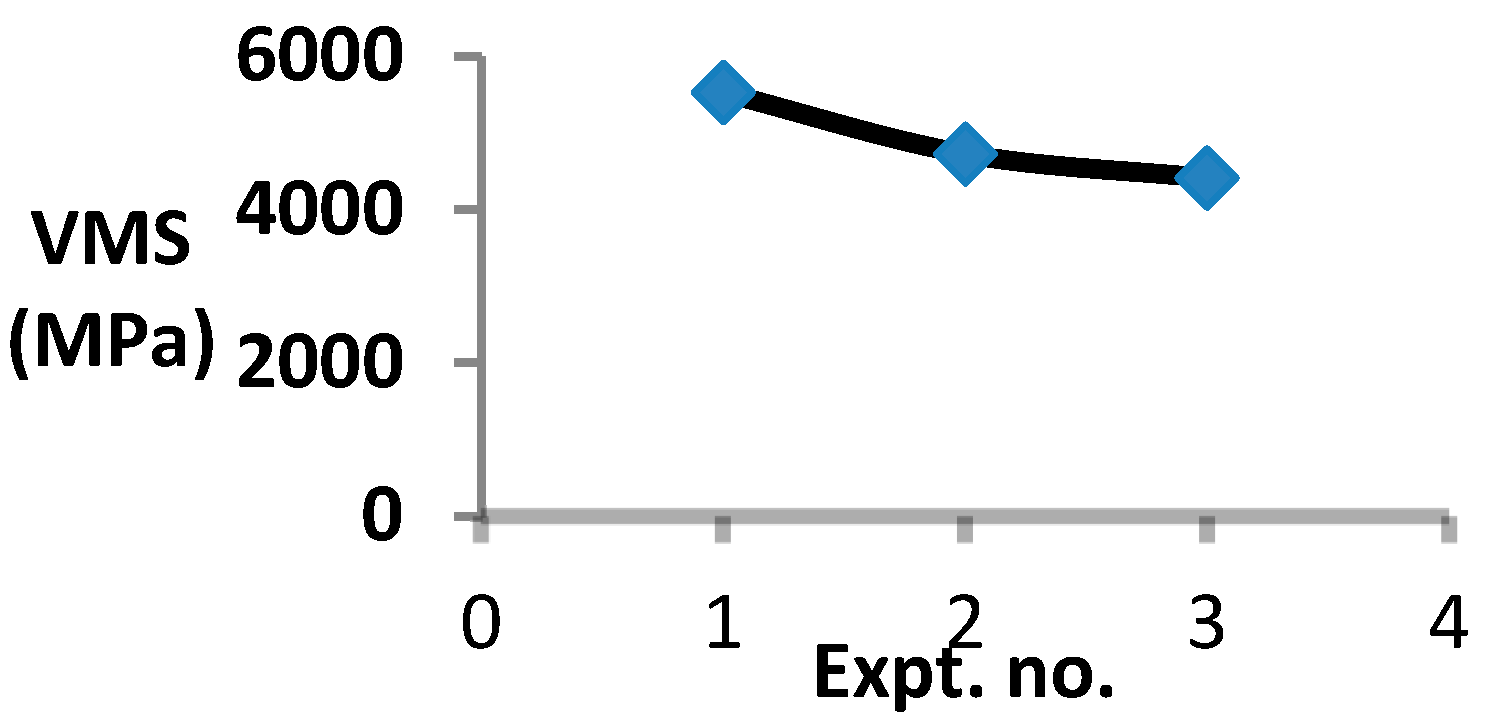

| Expt. No. | CRC | VMS |

|---|---|---|

| 1 | 3.784 | 5532.84 |

| 2 | 2.549 | 4729.83 |

| 3 | 2.230 | 4416.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De, S.; Chakraborty, K. Some Studies on the Mechanism of Chip Formation during Machining of Chromium Manganese Austenitic Stainless Steel. Eng. Proc. 2024, 66, 32. https://doi.org/10.3390/engproc2024066032

De S, Chakraborty K. Some Studies on the Mechanism of Chip Formation during Machining of Chromium Manganese Austenitic Stainless Steel. Engineering Proceedings. 2024; 66(1):32. https://doi.org/10.3390/engproc2024066032

Chicago/Turabian StyleDe, Swarup, and Kalyan Chakraborty. 2024. "Some Studies on the Mechanism of Chip Formation during Machining of Chromium Manganese Austenitic Stainless Steel" Engineering Proceedings 66, no. 1: 32. https://doi.org/10.3390/engproc2024066032

APA StyleDe, S., & Chakraborty, K. (2024). Some Studies on the Mechanism of Chip Formation during Machining of Chromium Manganese Austenitic Stainless Steel. Engineering Proceedings, 66(1), 32. https://doi.org/10.3390/engproc2024066032