Abstract

Rising carbon emissions are worsening global climatic conditions, posing a grave threat to the environment. Analysing and reducing carbon footprints are vital for combating climate change. A carbon footprint analysis categorises emissions into three scopes, aiming to identify re- duction areas and promote sustainable practices, such as energy efficiency, renewable energy use, and eco-friendly choices in consumption. The current study’s purpose is to track and analyse the carbon emissions in the inbound and outbound logistics of a process industry belonging to Micro Small and Medium Enterprises using life cycle analysis. Ultimately, this study recommends mitigation strategies to bring down the carbon footprint.

1. Introduction

The persistent escalation of global carbon dioxide (CO2) emissions has substantially heightened the risk of severe climate change consequences. The recent Paris Agreement, forged in collaboration with the Intergovernmental Panel on Climate Change (IPCC), has introduced a fresh objective: to restrict the temperature increase to 2 °C, aiming to mitigate the looming climate crisis [1].

Jackfruit production is rapidly increasing year by year, as it is considered a substitute for meat for vegans. India is the leading jackfruit producer, producing 1.4 million metric tons annually [2]. At 263 thousand metric tons a year, Kerala is the second largest producer of jackfruit in India [3]. There is currently no available research that discusses carbon footprint analysis and life cycle inventory (LCI) specifically within the jackfruit processing industry.

The authors of this study have conducted a carbon footprint analysis and GHG emissions assessment for the jackfruit production in Micro Small Medium Enterprises (MSMEs) located in the southern part of India. The food system accounts for approximately 21–37% of total greenhouse gas (GHG) emissions. It is important to note that within this estimate, approximately 5–10% of these emissions result from supply chain activities [4]. This study aims to evaluate GHG emissions within a specific boundary for one ton of processed jackfruit products.

This research stands out by combining carbon footprint analysis with the context of a jackfruit processing plant, offering a novel approach distinct from previous studies.

This paper starts with a literature review of previous works in this field. A description of the methodology we chose for calculating GHG emissions is given in Section 3. The results and discussions of the CO2 emissions and carbon footprint analyses are presented in Section 4. Lastly, the conclusions and recommendations to reduce emissions are provided in Section 5.

2. Literature Review

The environmental footprints of 33 U.S. food manufacturing sectors were calculated using the Economic Input–Output Life Cycle Assessment (EIO-LCA) model in this study. The food manufacturing industry’s supply chains bear a significant portion of the blame for the effects, accounting for over 80% of the energy, water, and carbon footprint, as well as the fisheries and grazing categories. Murphya et al. [5] performed a GHG and energy-based LCA of the Irish wood processing industry that analysed energy, material inputs, and GHG emissions in timber product production. GHG emissions and energy demand are calculated using SimaPro through an LCA, and it was found that electricity consumption is the primary contributor to GHG emissions in wood processing.

Denham et al. [6] studied GHG emissions in Western Australian finfish supply chains from harvest to retail using a streamlined LCA. Electricity was the major emissions source, potentially mitigated through clean solar energy production, assessed through Life Cycle Inventory (LCI) and emission factors. In an Indonesian coffee processing facility, Suryaningrat and Novita [7] adopted a green supply chain management strategy for a sustainable agroindustry. The total emissions in the processing unit was determined using the IPCC’s emission factors. They discovered a growing interest in sustainable agriculture and food production systems worldwide after analysing research trends in life cycle assessments (LCAs) on food crops.

3. Methodology

To assess the environmental effects of the jackfruit processing industry, we adopted a Life Cycle Inventory (LCI) methodology. This methodology includes defining the boundary and scope of the processing unit, performing a life cycle inventory analysis using certain inputs, modelling CO2 emissions using emissions factors, and calculating the carbon footprint.

3.1. Boundary and Scope

Research data were gathered and refined through surveys conducted with company representatives. These collected data were then employed to create a comprehensive life cycle inventory (LCI) model for a food processing plant.

The system boundaries for the present analysis include the warehouse of suppliers, the processing plant, and the transhipment hub. These boundaries include the transportation of raw materials from the supplier to the processing plant over a distance of approximately 300 km by truck and the processing of the raw materials, which includes emissions from processing machines, other appliances such as fans, lights, and computers, and fuel consumed by the boiler, which are then sent to the nearby trans-shipment hub, which is 60 km from the plant by truck.

3.2. Life Cycle Inventory

This phase compiles data like energy inputs, outputs, and emissions based on the source of emissions and the scope of emissions. The obtained results were then quantified in terms of the appropriate unit of analysis.

Modelling CO2 Emissions

CO2 emissions for different processes, emissions from processing machines, and the usage of electricity and fuel consumption by freight vehicles were calculated using emission factors obtained from certain sources as 0.919 per KWh for electricity [8], 2.676 per L for diesel [9], and 1.747 per kg for firewood and sawdust [9].

The CO2 emissions from energy inputs are as follows:

Production weighted average per tonne of output (Pwa) = amount of input consumed to produce one tonne of output

kg CO2 equivalent for producing one tonne output = Electricity consumed (KWh) × 0.919

CO2 emissions from boilers:

Firewood:

kg CO2 equivalent for producing one tonne output = Pwa × 1.747

Sawdust:

kg CO2 equivalent for producing one tonne output = Pwa × 1.747

CO2 emissions from transportation:

kg CO2 equivalent for producing one tonne output = Pwa × 2.676

CO2 emissions from other appliances:

kg CO2 equivalent for producing one tonne of output = Electricity consumed (KWh) × 0.919

4. Results and Discussions

The results obtained from the Life Cycle Inventory (LCI) analysis serve as inputs to estimate the carbon footprint for one functional unit of jackfruit produced. The details of this are mentioned in the following sections.

4.1. Life Cycle Inventory Results

The energy input per tonne of processed goods is reported to be approximately 679 MJ, and the amount of fuel consumed to process one tonne of goods is approximately 1934 L, which includes both tender and ripened jackfruit.

4.2. Results of CO2 Emissions

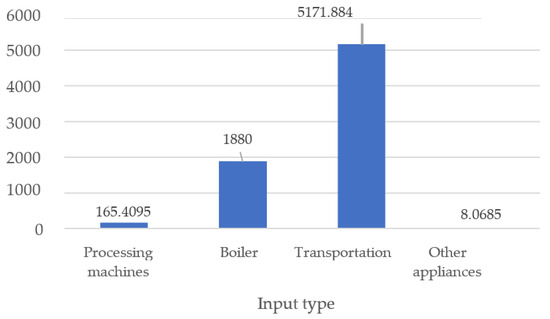

The CO2 emissions for producing one tonne of output are calculated as the total GHG emissions for different inputs, constituting 7226.663 kg CO2 eq per tonne of jackfruit processed goods. Transportation is the major contributor to GHG emissions and accounts for 72% (1800 kg CO2) of emissions, while boilers account for 26% of emissions (5171.884 kg CO2), and the remaining 2% (173.478 kg CO2) is contributed to by processing machines and other appliances. The carbon footprint details are shown in Figure 1. These data represent the production of 650 kg of tender jackfruit and 350 kg of ripened jackfruit.

Figure 1.

Carbon footprint (kg CO2-eq/ton) for processed jackfruit. “Other appliances” refers to fans, lights, and computers.

5. Conclusions and Future Scope

This paper presents the results of an LCI study, including all the processes within the system boundaries and the results of CO2 emissions for one ton of products produced. In order to achieve this goal, GHG emissions were calculated for four different types of input processing machines in the plant, boilers in the plant, transportation across boundaries, and other inputs (fans, lights, and computers). It was found that emissions from processing machines and other appliances have little to no effect on overall emissions, and transportation accounts for a major part of emissions, followed by emissions from boilers.

Overall, future research in this area should seek to do the following: (i) apply the LCA analysis to the entire supply chain from the production of raw materials to the last mile of delivery; (ii) identify mitigation strategies to curb CO2 emissions in MSME supply chains (iii); perform a cost–benefit analysis to estimate the cost associated with making the supply chain a green supply chain, the and benefits in adopting these methods.

Author Contributions

Conceptualization, G.C.C.K., C.R.K., C.S., G.H.G.C., and F.N.; methodology, G.C.C.K.; formal analysis, G.C.C.K., C.R.K., and C.S.; investigation, G.C.C.K.; resources, C.R.K.; writing—original draft preparation, G.C.C.K., C.R.K., and C.S.; writing—review and editing, F.N. and V.V.P.; visualization, C.S.; supervision, V.V.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within this article.

Acknowledgments

We express our gratitude to the National Institute of Technology Calicut for their support in this research. Additionally, we extend our thanks to Rathnakaran for generously providing the raw data essential for the Life Cycle Inventory (LCI) analysis.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- IPCC Special Report: Special Report on Climate Change and Land. Available online: https://www.ipcc.ch/srccl/chapter/chapter-5/ (accessed on 29 October 2023).

- World Atlas. Available online: https://www.worldatlas.com/articles/world-leaders-in-jackfruit-production.html (accessed on 29 October 2023).

- Tractor Junction. Available online: https://www.tractorjunction.com/web-stories/top-jackfruit-producing-states-in-india/ (accessed on 29 October 2023).

- Mbow, C.; Rosenzweig, C.; Barioni, L.G.; Benton, T.G.; Herrero, M.; Krishnapillai, M.; Liwenga, E.; Pradhan, P.; Rivera-Ferre, M.G.; Sapkota, T.; et al. Food Security. In Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Murphya, F.; Devlinb, G.; McDonnellc, K. Greenhouse gas and energy-based life cycle analysis of products from the Irish wood processing industry. J. Clean. Prod. 2015, 92, 134–141. [Google Scholar] [CrossRef]

- Denham, F.C.; Biswas, W.K.; Solah, V.A.; Howieson, J.R. Greenhouse gas emissions from a Western Australian finfish supply chain. J. Clean. Prod. 2016, 112, 2079–2087. [Google Scholar] [CrossRef]

- Suryaningrat, I.B.; Novita, E. Implementation of green supply chain management for sustainable agroindustry in coffee processing unit, a case of Indonesia. Coffee Sci. 2022, 17, e172042. [Google Scholar] [CrossRef]

- Life Cycle Strategies Pty Ltd., Australasian LCI Database Version 2012.7. Life Cycle Strategies Pty Ltd., Melbourne. Available online: https://www.lifecycles.com.au/life-cycle-assessment-databases (accessed on 29 October 2023).

- Bendu, H.; Deepak BB, V.L.; Murugan, S. Application of GRNN for the prediction of performance and exhaust emissions in HCCI engine using ethanol. Energy Convers. Manag. 2016, 122, 165–173. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).