Development of a Training Station for the Orientation of Dice Parts with Machine Vision †

Abstract

1. Introduction

2. Analysis of the Suitability of the Part for Automatic Feeding

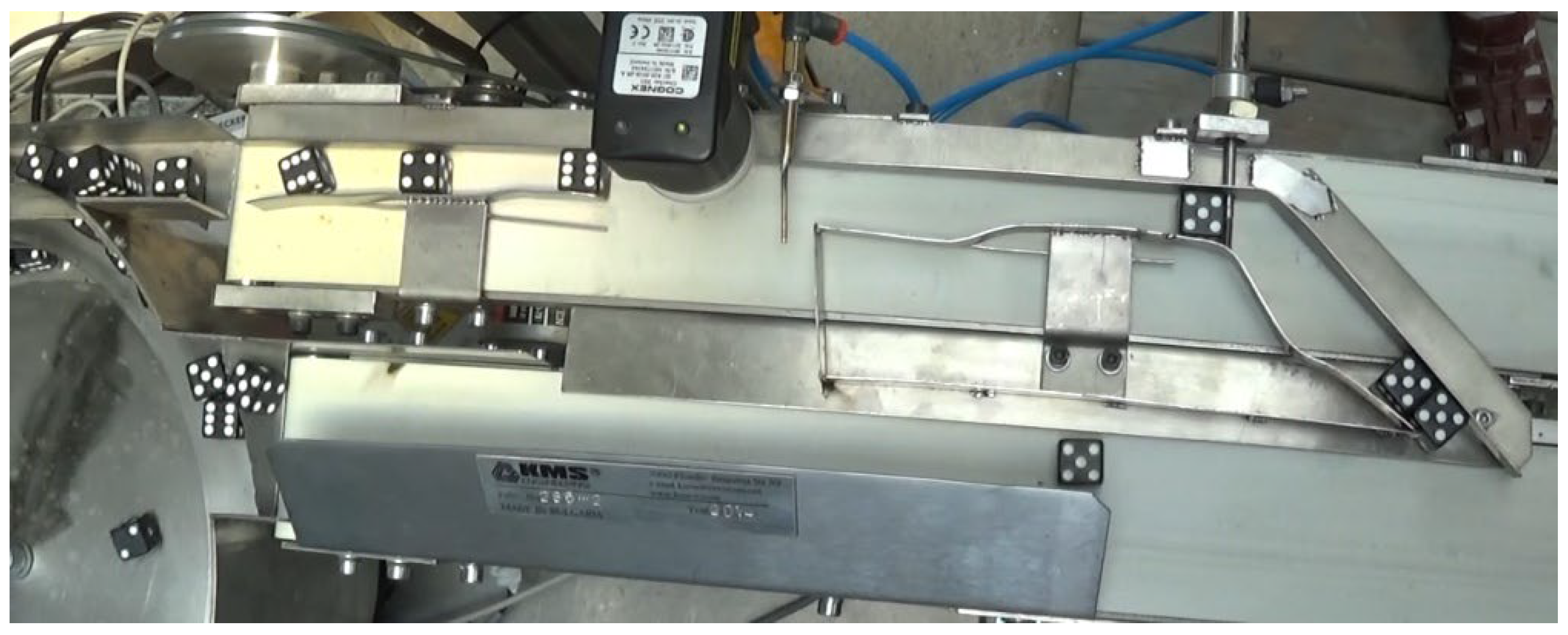

3. Design and Production of the System

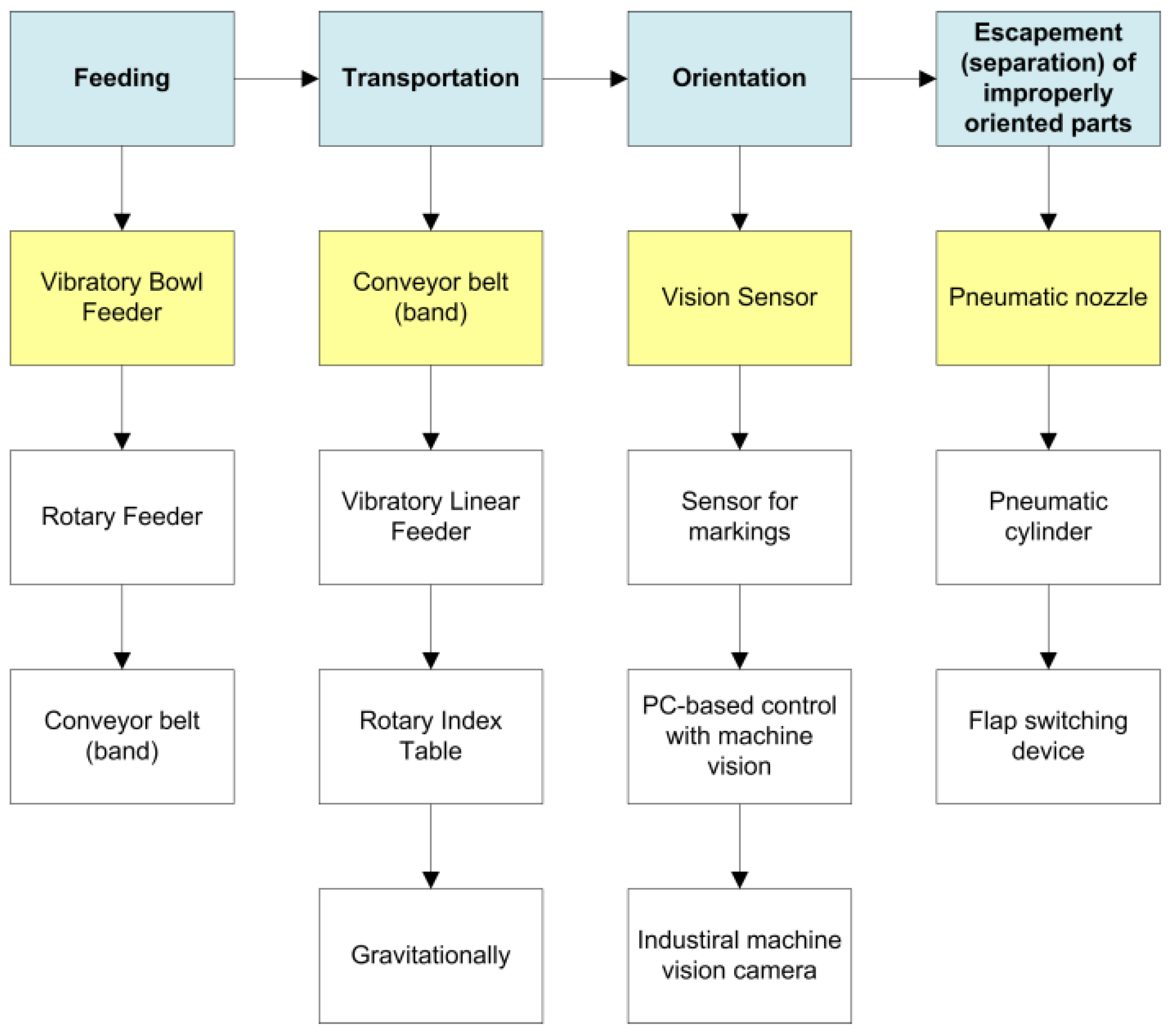

- Feeding—a bowl feeder since the part is easy for pure feeding (without orientation involved). All part orientations are acceptable and considered correct.

- Transportation—a belt conveyor is selected in order to reduce the overall number of vibrations in the area of the camera and keep the final solution as simple as possible.

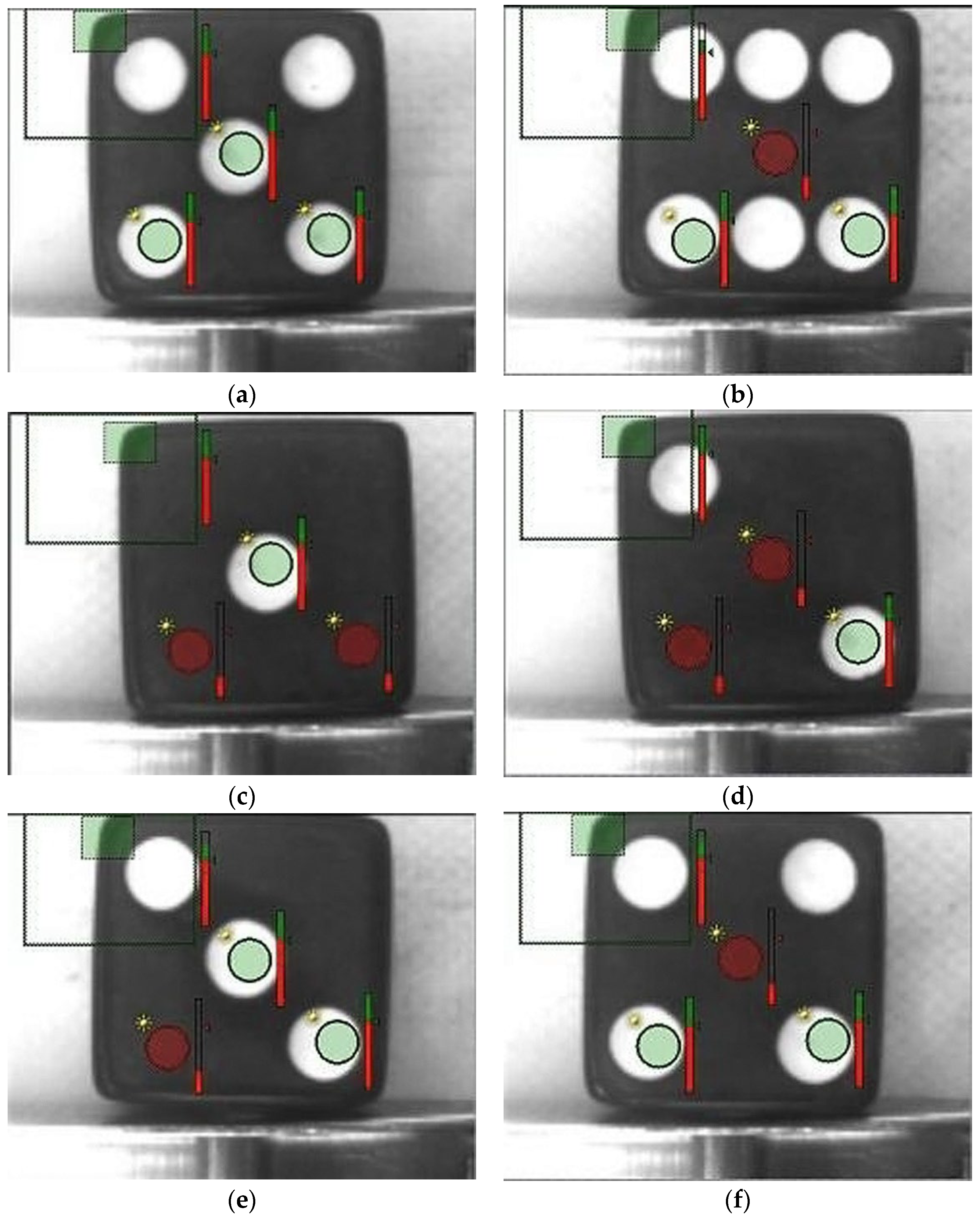

- Orientation—a machine vision sensor is selected due to its versatility and flexibility (it could be reused for other projects in the university labs with a different mechanical system).

- Escapement of incorrectly oriented parts—a pneumatic nozzle is selected due to the ease of use and installation below the camera. There is no mechanical impact that is considered positive because there is no contact with the parts and, thus, no wearing on them.

- At this stage, an additional function is determined—the need for an additional escapement unit (separator) for the correctly oriented parts. When the sequence of five parts is ready, they are released back to a returning conveyor that has an opposite travel direction. A trigger sensor needs to be installed to control the camera picture triggering at the right moment (when a part is passing under the camera).

4. Experimental Research

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mitev, V.; Malakov, I. Analysis of the quality of polymer parts for automatic assembly. AIP Conf. Proc. 2024, 3063, 060012. [Google Scholar] [CrossRef]

- Mitev, P.; Malakov, I. Development of a system for automatic feeding and orientation of cylindrical parts. AIP Conf. Proc. 2024, 3063, 060017. [Google Scholar] [CrossRef]

- 16 mm Dice-Black. Available online: https://kms-e.de/en/blackdice_16mm/ (accessed on 4 September 2024).

- Chakarski, D.; Andonova-Vakarelska, T.; Sarandeva, A. Methodology for design of robotized technological modules for small parts (in Bulgarian). In Proceedings of the NTC for Machine-Building, Sozopol, Bulgaria, 27 June 2000. [Google Scholar]

- Boothroyd, G. Assembly Automation and Product Design; Taylor & Francis Group: Boca Raton, FL, USA, 2005. [Google Scholar]

- Hesse, S. Rationalisation of Small Workpiece Feeding. Orientating, Sorting, Checking and Feeding; Festo AG & Company: Esslingen am Neckar, Germany, 2000. [Google Scholar]

- Bootroyd, G.; Poli, C.R.; Murch, L.E. Handbook of Feeding and Orienting Techniques for Small Parts; Automation Project, Department of Mechanical Engineering, University of Massachusetts: Amherst, MA, USA, 1976. [Google Scholar]

- Akella, S.; Mason, M.T. Parts Orienting with Shape Uncertainty. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Leuven, Belgium, 20–20 May 1998; pp. 565–572. [Google Scholar]

- Klank, U.; Pangercic, D.; Rusu, R.B.; Beetz, M. Real-time cad model matching for mobile manipulation and grasping. In Proceedings of the International Conference on Humanoid Robots, Paris, France, 7–10 December 2009; pp. 290–296. [Google Scholar]

- Agrawal, A.; Sun, Y.; Barnwell, J.; Raskar, R. Vision-guided robot system for picking objects by casting shadows. Int. J. Robot. Res. 2010, 29, 155–173. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Kang, S.; Kim, J.; Lee, J. Vision-based bin picking system for industrial robotics applications. In Proceedings of the 9th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Daejeon, Republic of Korea, 26–28 November 2012; pp. 515–516. [Google Scholar]

- Oh, J.-K.; Lee, S.; Lee, C.-H. Stereo vision based automation for a bin-picking solution. Int. J. Control. Autom. Syst. 2012, 10, 362. [Google Scholar] [CrossRef]

- XD3-16/XD5-16. Available online: https://www.xinje-sps.de/de/produkte/sps/xd3-16-xd5-16/ (accessed on 5 February 2024).

- Dichev, D.; Koev, H.; Bakalova, T.; Louda, P. A Kalman Filter-Based Algorithm for Measuring the Parameters of Moving Objects. Meas. Sci. Rev. 2015, 15, 35–43. [Google Scholar] [CrossRef]

- Malakov, I.; Zaharinov, V. Choosing an Optimal Size Range of the Product “Pipe Clamp”.(Book Chapter). In Recent Advances in Soft Computing and Cybernetics; Matoušek, R., Kůdela, J., Eds.; Springer: Cham, Switzerland, 2021; Volume 403, pp. 197–213. [Google Scholar] [CrossRef]

- Malakov, I.; Georgiev, T.; Zaharinov, V.; Tzokev, A.; Tzenov, V. Demand modeling for the optimization of size ranges. In Proceedings of the 26th DAAAM International Symposium, Vienna, Austria, 18–25 October 2015; pp. 435–444. [Google Scholar] [CrossRef]

| Degree N | Feature | Code |

|---|---|---|

| I | Asymmetry on the external configuration, non-metal part | 2,000,000 |

| II | The parts do NOT join each other mechanically | 000,000 |

| III | Equal dimensions on all sides, non-magnetic | 90,000 |

| IV | Non-round, straight | 3000 |

| V | Three planes of symmetry | 400 |

| VI | No central hole | 50 |

| VII | A hole, lateral to the main axis | 0 |

| Part code number according to the methodology | 2,093,450 |

| # | Parameter | Value | Abbreviation |

|---|---|---|---|

| 1 | Shape | Conical | 2 |

| 2 | Geometry | Fully symmetric | 4 |

| 3 | Material | Plastic | P |

| 4 | Mass | Lightweight | 2 |

| 5 | Number of stable states | - | 6 |

| 6 | Colour | Multi-colour | C |

| 7 | Additional geometrical features | No apparent mechanical features for orientation | 4 |

| 8 | Control features (markings) | Parts with additional graphical information (the dots of the dice) | 1 |

| 9 | Category of application | Others | 8 |

| 10 | Industry | Toys | T |

| 11 | How complex is the part orientation? | Complex orientation | 3 |

| 12 | Design features easing orientation | Without any taken measures at design phase | 1 |

| 13 | Is it possible for the parts to entangle? | The parts do not entangle | 1 |

| 14 | Are the parts with delicate surfaces? | No delicate surfaces | 1 |

| 15 | Is electrostatics an impacting factor? | Normal influence by electrostatics | 2 |

| Trial # | Number of Parts Taking Position “5” as Top |

|---|---|

| 1 | 20 |

| 2 | 4 |

| 3 | 12 |

| 4 | 16 |

| 5 | 20 |

| 6 | 16 |

| 7 | 12 |

| 8 | 8 |

| 9 | 20 |

| 10 | 4 |

| 1 | 20 |

| Average: 13.2 pcs/5 min |

| Orientation: | #1.1 | #1.2 | #1.3 | #1.4 | #1.5 | #1.6 |

| Quantity | 29 | 10 | 16 | 13 | 16 | 25 |

| Probability (p) | 0.2 | 0.1 | 0.16 | 0.13 | 0.16 | 0.25 |

| Orientation: | #2.1 | #2.2 | #2.3 | #2.4 | #2.5 | #2.6 |

| Quantity | 22 | 12 | 16 | 14 | 16 | 20 |

| Probability (p) | 0.22 | 0.12 | 0.16 | 0.14 | 0.16 | 0.2 |

| Orientation: | #3.1 | #3.2 | #3.3 | #3.4 | #3.5 | #3.6 |

| Quantity | 16 | 16 | 13 | 14 | 16 | 25 |

| Probability (p) | 0.16 | 0.16 | 0.13 | 0.14 | 0.16 | 0.25 |

| Orientation: | #4.1 | #4.2 | #4.3 | #4.4 | #4.5 | #4.6 |

| Quantity | 6 | 13 | 8 | 5 | 11 | 7 |

| Probability (p) | 0.06 | 0.13 | 0.08 | 0.05 | 0.11 | 0.07 |

| Orientation: | #5.1 | #5.2 | #5.3 | #5.4 | #5.5 | #5.6 |

| Quantity | 16 | 14 | 18 | 14 | 16 | 22 |

| Probability (p) | 0.16 | 0.14 | 0.18 | 0.14 | 0.16 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitev, P. Development of a Training Station for the Orientation of Dice Parts with Machine Vision. Eng. Proc. 2024, 70, 57. https://doi.org/10.3390/engproc2024070057

Mitev P. Development of a Training Station for the Orientation of Dice Parts with Machine Vision. Engineering Proceedings. 2024; 70(1):57. https://doi.org/10.3390/engproc2024070057

Chicago/Turabian StyleMitev, Penko. 2024. "Development of a Training Station for the Orientation of Dice Parts with Machine Vision" Engineering Proceedings 70, no. 1: 57. https://doi.org/10.3390/engproc2024070057

APA StyleMitev, P. (2024). Development of a Training Station for the Orientation of Dice Parts with Machine Vision. Engineering Proceedings, 70(1), 57. https://doi.org/10.3390/engproc2024070057