Abstract

A solar still is a device that achieves desalination using solar energy in a relatively economical manner. In this paper, a mathematical model has been used to evaluate the performances of single-slope solar stills for different cities in Pakistan (Islamabad, Lahore, Peshawar, and Karachi) on 22 June 2024. The analysis incorporated the ambient, design, and operational parameters, and this study presents the obtained results. From the investigations, the desalinated water rates were found to be 4.32, 3.04, 2.92, and 2.56 L for Karachi, Lahore, Islamabad, and Peshawar, respectively, for the time duration considered from 10 am to 4pm. Meanwhile, the thermal efficiencies were observed to be 37.18%, 33.75%, 27.96%, and 25.71%.

1. Introduction

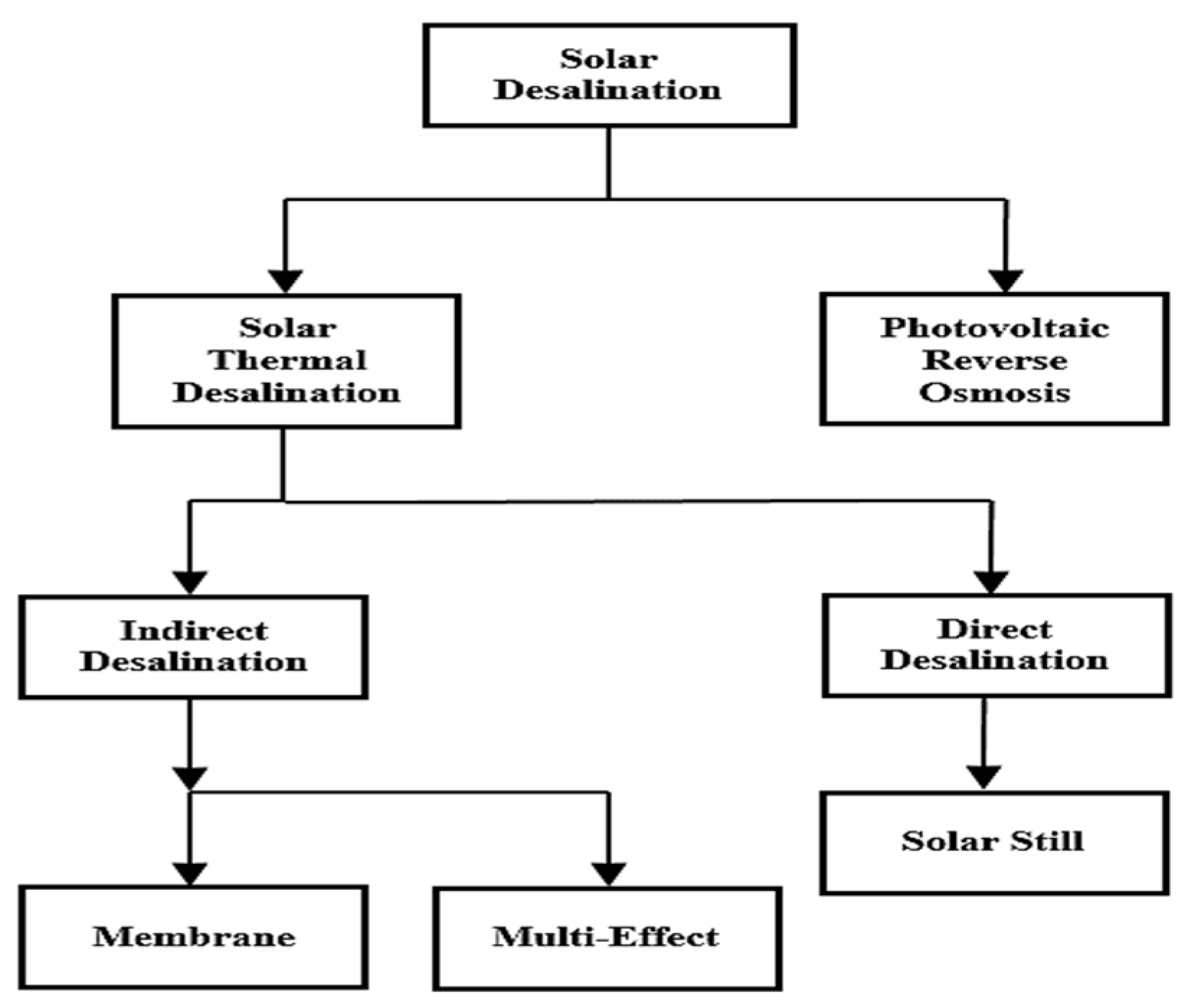

The world is facing a serious dilemma due to water scarcity [1]. Around 97% of the water on earth is brackish and saline in the form of oceans and sea. In the 3% that constitutes clean water, only 0.01% is present in surface water form [2]. To address this issue, water desalination is performed. Water desalination is achieved either by utilizing solar-thermal energy or by using the reverse osmosis technique [3], as shown in Figure 1. The distillation process can be performed by a solar still, which has a basic design. The design can be improved to enhance the distillate output [4].

Figure 1.

Types of solar desalination.

Some of the major advantages of solar still technology include its fuel free operation, as solar energy is the main energy source; its low maintenance cost; its high reliability; and the distilled water obtained being in the required pH range [4]. Major advancements have been made in both passive and active solar still technologies. Passive solar still technology directly uses solar energy, whereas active solar still technology uses devices such as pumps, compressors, and thermoelectric modules to increase the output [5]. Further information regarding this technology can be sought from Lisboa et al. [6], Patek et al. [7], and Panchal et al. [8].

A number of designs of passive solar still technologies have been studied by the researchers, including single-slope, double-slope, tabular, and pyramid-shape varieties. These are also known as convectional solar desalination technologies [9]. The benefits of using these convectional solar stills are that they are eco-friendly, require less initial investment, and have no expense in terms of fuel [10]. Extensive research is being conducted in this area to enhance the solar still efficiency and distillate output [11].

Water resource management and, in particular, drinking water are major concerns in Pakistan [12]; therefore, this study is aimed at predicting the performances of single-slope basin-type solar stills for different cities of Pakistan, including Islamabad, Lahore, Peshawar, and Karachi. The weather conditions of 22 June 2024 are considered, and the time of study is selected to range from 10 am to 4 pm.

2. Factors Affecting Productivity

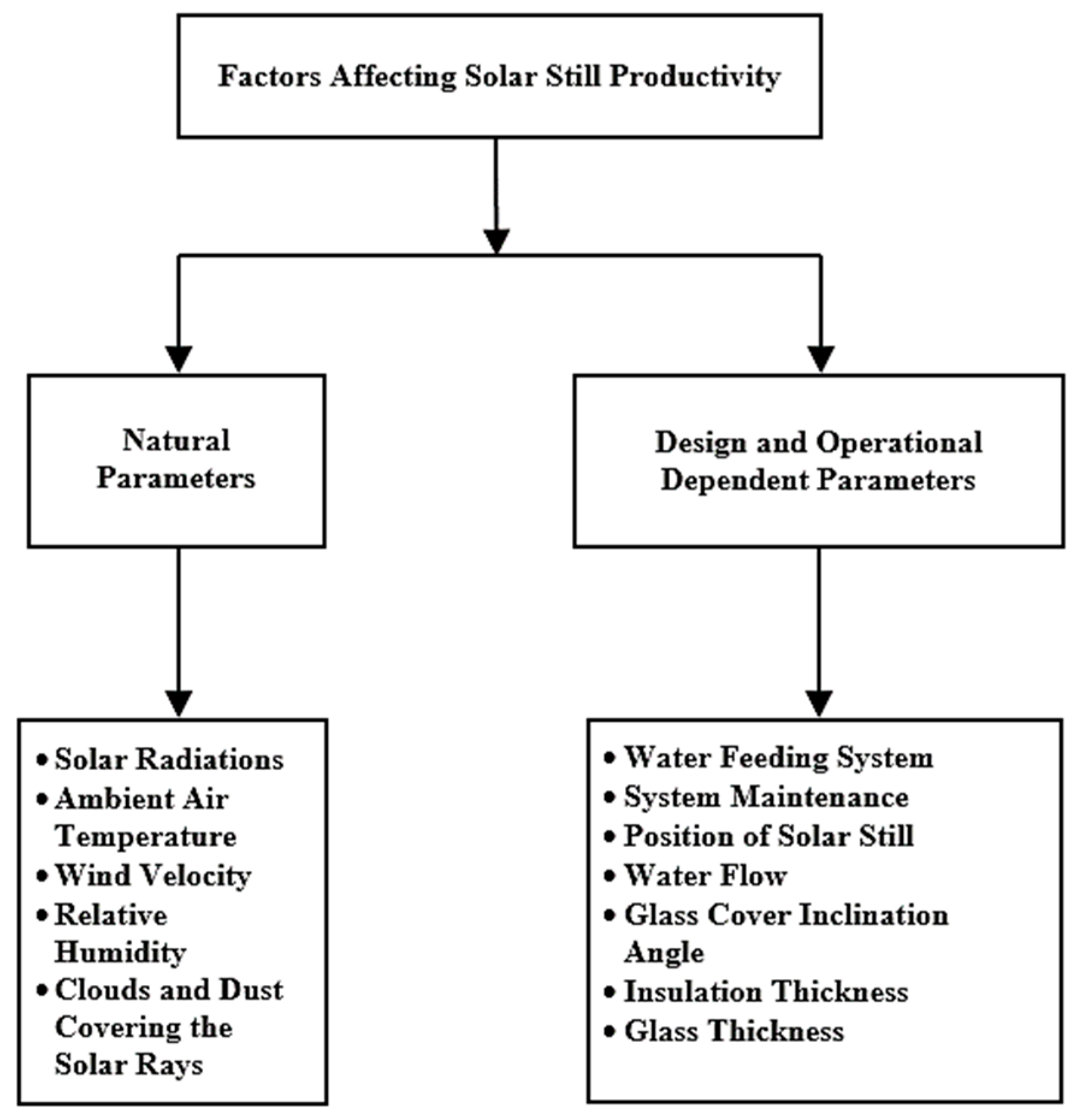

In accordance with the observations from Hammoodi et al. [13], the purification performance of the solar still depends on several parameters, as depicted in Figure 2. Broadly, these parameters can be categorized into two primary domains: (1) natural and (2) design- and operational-dependent parameters.

Figure 2.

Factors affecting solar still productivity.

3. Mathematical Modelling

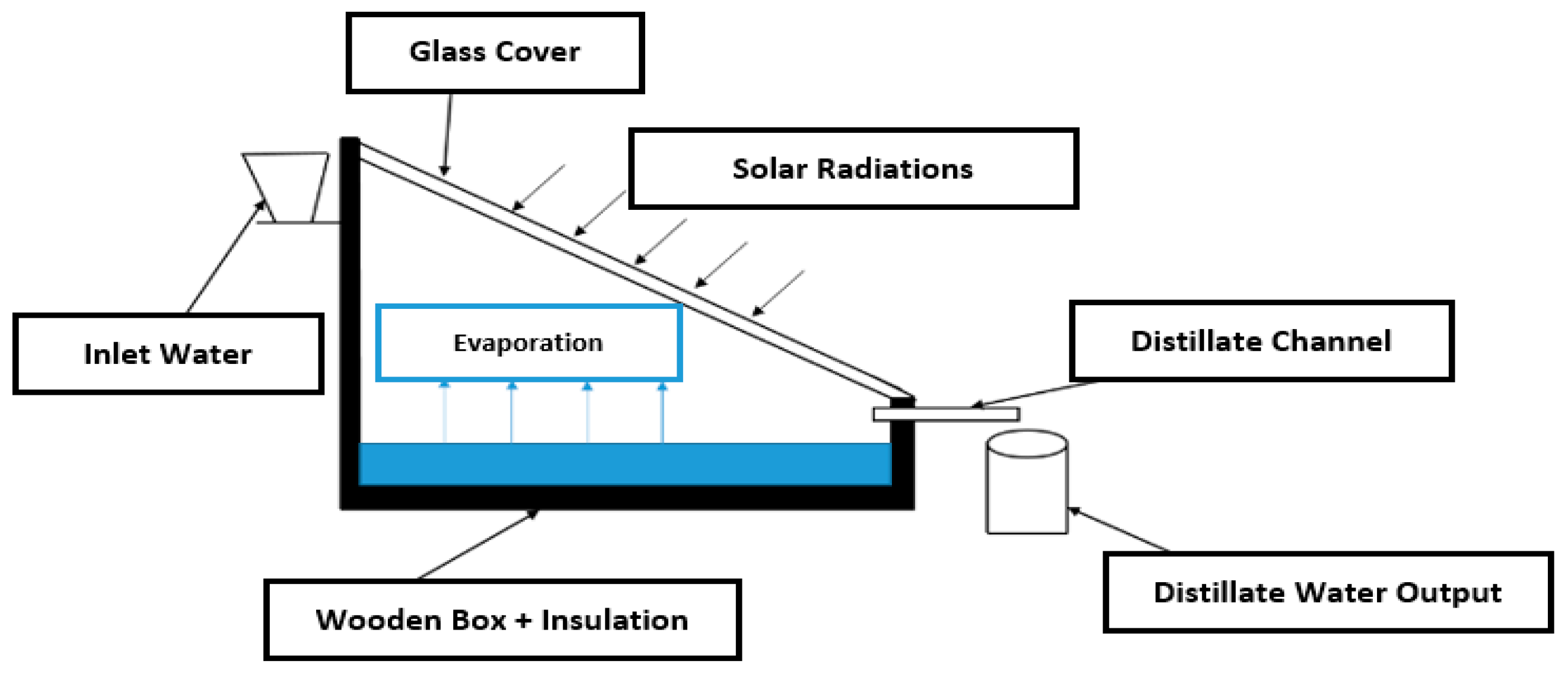

In this section, a mathematical model for a single-slope solar still is presented, in accordance with Figure 3. To perform the calculations, certain assumptions were adopted from Panchal and Shah [14], and these are presented below:

Figure 3.

Single-slope solar still.

- No leakage of the water vapour in the solar still;

- A constant level of water, i.e., 2 cm, was maintained during the entire process;

- Water loss due to evaporation was negligible compared to the amount of water in the basin;

- The temperature gradient was not considered across the glass cover thickness and the depth of the water.

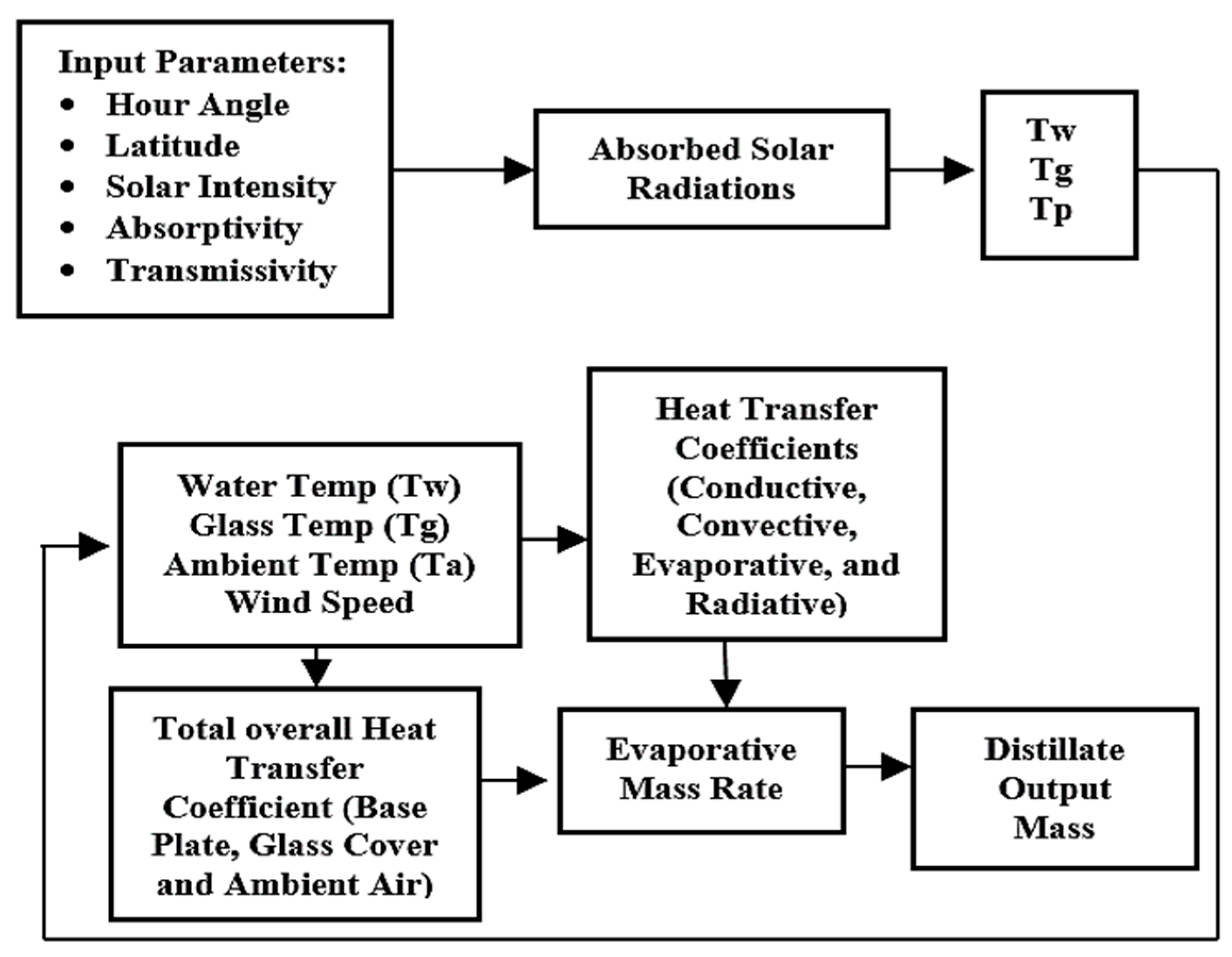

To evaluate the output of distilled water for various cities in Pakistan, the mathematical model developed by Nguyen [15] was implemented. A summary of the methodology is shown in Figure 4.

Figure 4.

Mathematical model diagram of solar still.

To further emphasize, the solar still basin area was kept at 0.4 m2, and the thickness of the glass cover was kept at 4 mm. The water level in the basin of solar still was kept constant during the operation i.e., at 2 cm [16,17]. The walls and basin of solar still was made of a metal body with a thickness of 6 mm. The analysis was conducted in two phases. Firstly, the total solar radiation (beam, reflected, and albedo) falling on the solar still was calculated, and then a numerical heat transfer analysis was carried out to find the value of output distilled water from the solar still. All heat transfer modes (convection, conduction, and radiation) were included to carry out the heat and mass transfer analysis.

3.1. Total Available Radiations on Solar Still

During this first phase of designing a solar still, the total radiation, with diffuse, reflected, and beam radiation as its components, was computed. The mathematical formula to calculate the total available radiations is given below [18]:

Available solar radiation above the surface of earth was given as [19]

For the clearness index (kT), the formula was represented as [18]

The declination angle (ω) in the case of the solar still could be obtained via the following mathematical expression [18]:

In case of tilted surfaces, the sun incident angle (θ) was represented as follows [19]:

θ = cos−1 (cos β sinф sin δ − sin β cos ф cos γ sin δ + cos δ cos β cos ф cos ω + sin ф sin cos γ cos δ cos ω + sin β sin ω cos δ sin γ)

The zenith angle () was evaluated from the following mathematical formula [18]:

Meanwhile, the altitude angle (αs) can be computed from the following expression [20]:

αs = sin−1(sin δ sin ф+ cos ω cos ф cos δ)

The diffuse fraction was calculated by implementing the Orgill and Holland model [18], given as

The beam radiation tilt factor is given as [21]

3.2. Solar Still Heat Transfer Calculations

Heat transfer through convection between water and the solar still glass cover (Qc-g) was represented as [22]

Qc-g = (–Tgi + Tw) hc-gi

Afterwards, these equations were modified, as shown below [22]:

The temperature of glass (Tg) was computed from the following expression [22]:

The temperature of water basin (Tb) could be calculated as [22]

The radiative heat transfer from the glass of the solar still to water (hrgw) was given as [18]

hrgw = (Tw − Tg)Ɛ σ (Tw − Tg)

Meanwhile, the heat transfer through radiation (qrwg) was given as [20]

qrwg = σƐ (Tw4 − Tsky4)

The temperature of the sky (Tsky) was estimated using the following formula [21]:

The evaporative heat transfer coefficient between the water in the basin and the glass cover of the solar still (hewg) could be calculated as [21]

The evaporative transfer of heat from water to the glass (qewg) was given as [22]

Heat loss through convection from the glass to the surrounding area () can be calculated as [22]

The glass-to-water area ratio is given as [22]

Ar = Ag/Aw

The overall heat transfer from glass cover of solar still to the basin water (Uwg) is given as [4]

The overall transfer of heat between the basin plate and solar still glass was represented as [4]

The evaporative transfer of mass in the desalination process from water to glass is given as [23]

Water vaporization was calculated by using the formula given below [24]:

hfg = 3044205.5 − 1679.11Tw − 1.14258

The solar still’s cumulative output could be calculated by using the equation shown below [16]:

The thermal efficiency of the solar thermal water desalination system was given by the following formula [18]:

Hence, the distillate output and efficiency were calculated as a final product from the given set of Equations (1)–(26).

4. Results and Discussions

With regard to applying the mathematical modelling method explained in the above section to our single-slope solar still in different cities within Pakistan, the obtained data are shown in Table 1, Table 2, Table 3 and Table 4. The minimum solar distillate output was found by the solar still in Peshawar. The solar still in Lahore showed a slightly better performance than the one in Islamabad. Despite the high ambient temperature and solar radiation, the performance of the solar still in Peshawar was low due to the low wind speed and high temperature of the glass cover [5], which indicates that to enhance the distillate output of a solar still, the temperature of the glass cover should be low to promote enhancement during the condensation process. Additionally, wind velocity is proportional to the distillate output of a solar still until a certain limit [8].

Table 1.

Solar still performance in Islamabad.

Table 2.

Solar still performance in Lahore.

Table 3.

Solar still performance in Peshawar.

Table 4.

Solar still performance in Karachi.

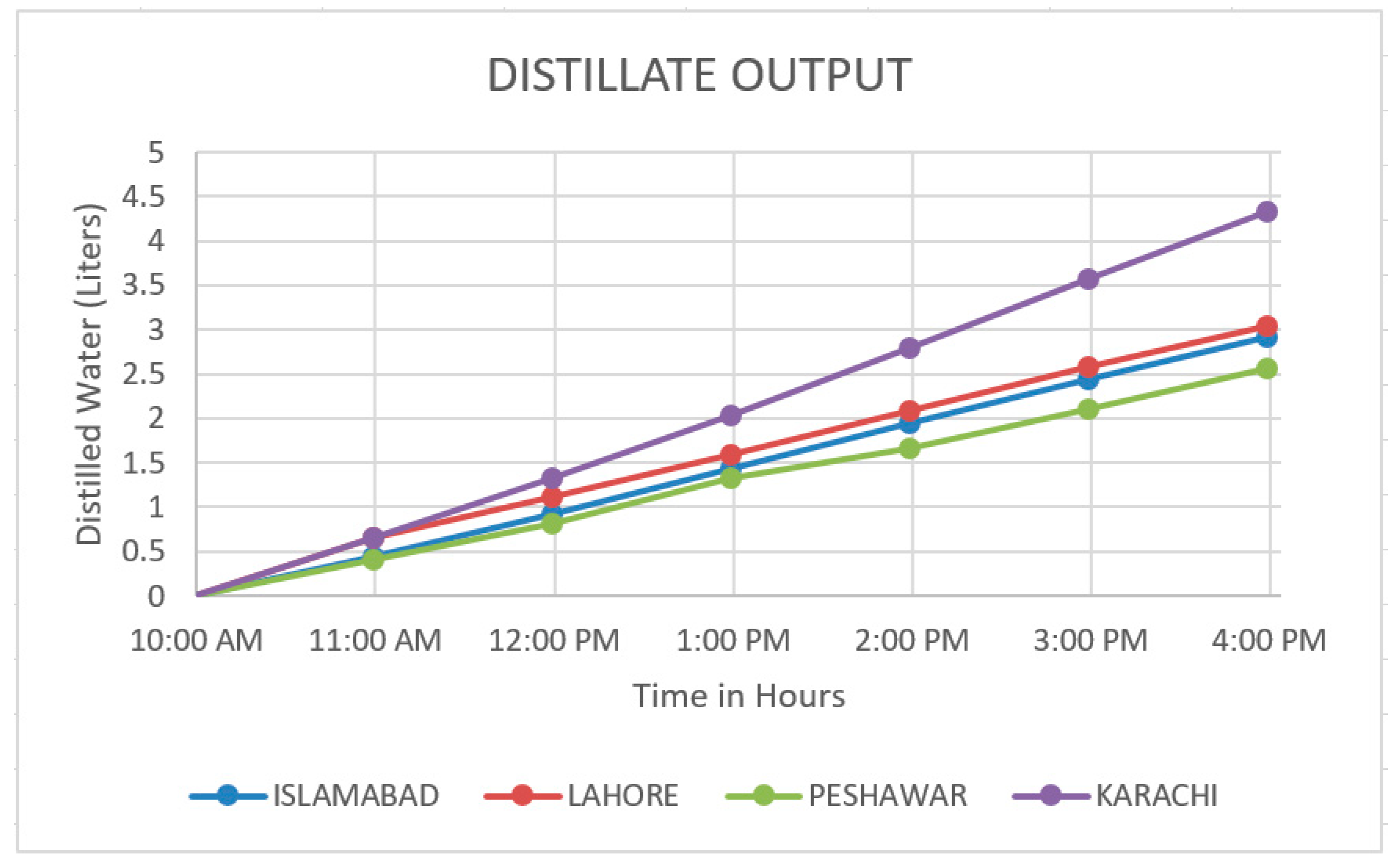

The data are further shown graphically in Figure 5 for better understanding the results.

Figure 5.

Distillate output of solar stills at different locations of Pakistan.

It can be observed that the output from a solar still depends not just on the total available solar radiation and ambient temperature. If that was the only factor, then the solar still placed in Peshawar should perform best. Other factors affecting solar still performance include the temperature of glass cover, wind velocity, and relative humidity. If the glass cover temperature is low, then a large temperature difference would occur between the water evaporating from the basin and the glass cover, thus enhancing the condensation rate and eventually increasing the output of distilled water. Therefore, techniques such as pouring cool water on the glass cover of the solar still or using a fan to lower the glass cover temperature can significantly improve the yield of distilled water in hot areas.

5. Conclusions

The results obtained from the analysis of the solar still for various cities in Pakistan revealed that the maximum distillate output was found in Karachi, while the minimum amount of distilled water was produced in Peshawar. Despite having high solar radiation and an ambient temperature, the solar still in Peshawar produced less output than that in Karachi. The solar still in Lahore showed a slightly better performance than the one in Islamabad. Factors such as wind velocity, relative humidity, and glass cover temperature played a key role in this regard. Keeping the glass cover at a lower temperature would enhance the solar still’s distillate output. Wind velocity is directly proportional to the output of the solar still up to a certain limit, while the solar still performs better with a low humidity level.

In future, research could focus on different ways to cool the glass cover of the solar still. This would enhance the condensation rate and, consequently, the output of the solar still.

Author Contributions

Conceptualization, N.M.M.; methodology, N.M.M. and W.K.; software, N.M.M. and M.T.; validation, N.M.M. and W.K.; formal analysis, N.M.M.; investigation, N.M.M.; data curation, W.K. and M.T.N.; writing—original draft preparation, N.M.M.; writing—review and editing, N.M.M. and M.T.N.; supervision, W.K.; project administration, N.M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| Ag | Glass surface area (m2) |

| σ | Constant of Stephen Boltzmann (Wm−2K−4) |

| Ɛ | Glass emittance |

| Cw | Basin water heat capacity (J/K) |

| hcwg | Glass-to-water heat transfer coefficient due to convection (W/m2K) |

| g | Acceleration due to gravity (m2/s) |

| hb | Heat transfer coefficient from base due to conduction (W/m2K) |

| hcblw | Basin-to-water heat transfer coefficient due to convection (W/m2K) |

| hcga | Glass-to-air heat transfer coefficient due to convection (W/m2K) |

| hewg | Water-to-glass cover heat transfer coefficient due to evaporation (W/m2K) |

| hrga | Glass-to-air heat transfer coefficient due to radiation (W/m2K) |

| hrwg | Water-to-glass cover heat transfer coefficient due to radiation (W/m2K) |

| I | Solar radiations intensity (W/m2) |

| Id | Diffused radiations per month average (W/m2) |

| Gsc | At a particular location global radiations (W/m2) |

| ω | Hour angle (°) |

| γ | Angle of azimuth (°) |

| φ | Angle of latitude (°) |

| δ | Angle of declination (°) |

| β | Incident angle (°) |

| Kt | Measure of clearness of atmosphere |

| L | Water length/depth (m) |

| Pr | Viscosity to thermal conductivity of fluid |

| qcwg | Water-to-glass cover heat transfer rate due to convection (W/m2) |

| qewg | Water-to-glass cover heat transfer rate due to evaporation (W/m2) |

| qrga | Glass-to-air heat transfer rate due to radiation (W/m2) |

| hfg | Water evaporative latent heat (KJ/kg) |

| hw | Coefficient of wind heat transfer (W/m2K) |

| qrwg | Water-to-glass cover heat transfer rate due to radiation (W/m2) |

| r | Glass of solar still length (m) |

| Rbr | Reflector-to-horizontal surface beam radiation ratio |

| Rg | Glass reflectivity |

| Rw | Water reflectivity |

| tb | Bottom insulation thickness (m) |

| kb | Bottom insulation thermal conductivity (W/mK) |

| tp | Base plate thickness (m) |

| kp | Base plate thermal conductivity (W/mK) |

| Ub | Overall heat transfer coefficient from bottom (W/m2K) |

| Uga | Overall heat transfer coefficient from glass cover to ambient (W/m2K) |

| Upa | Overall heat transfer coefficient from base plate to ambient (W/m2K) |

| Upg | Overall heat transfer coefficient from base plate to glass cover (W/m2K) |

| αb | Basin absorptivity |

| αg | Glass absorptivity |

| αw | Water absorptivity |

| λw | Water thermal conductivity (W/mK) |

| P | Water vapour partial pressure (mm of Hg) |

| Tw | Temperature of water (K) |

| Tp | Base plate temperature (K) |

| Ts | Sky temperature of black body (K) |

| Ut | Glass cover and water heat transfer coefficient (W/m2K) |

References

- Musie, W.; Gonfa, G. Fresh water resource, scarcity, water salinity challenges and possible remedies: A review. Heliyon 2023, 9, e18685. [Google Scholar] [CrossRef] [PubMed]

- Alsehli, M.; Essa, F.A.; Omara, Z.; Othman, M.M.; Elsheikh, A.H.; Alwetaishi, M.; Alghamdi, S.; Saleh, B. Improving the performance of a hybrid solar desalination system under various operating conditions. Process. Saf. Environ. Prot. 2022, 162, 706–720. [Google Scholar] [CrossRef]

- Zheng, Y.; Hatzell, K.B. Technoeconomic analysis of solar thermal desalination. Desalination 2020, 474, 114168. [Google Scholar] [CrossRef]

- Saxena, A.; Cuce, E.; Kabeel, A.; Abdelgaied, M.; Goel, V. A thermodynamic review on solar stills. Solar Energy 2022, 237, 377–413. [Google Scholar] [CrossRef]

- Shoeibi, S.; Rahbar, N.; Esfahlani, A.A.; Kargarsharifabad, H. Application of simultaneous thermoelectric cooling and heating to improve the performance of a solar still: An experimental study and exergy analysis. Appl. Energy 2020, 263, 114581. [Google Scholar] [CrossRef]

- Lisboa, A.A.; Segurado, R.; Mendes, M.A. Solar still performance for small-scale and low-cost seawater desalination: Model-based analysis and water yield enhancement techniques. Solar Energy 2022, 238, 341–362. [Google Scholar] [CrossRef]

- Patel, S.K.; Modi, K.V. Techniques to improve the performance of enhanced condensation area solar still: A critical review. J. Clean. Prod. 2020, 268, 122260. [Google Scholar] [CrossRef]

- Panchal, H.N.; Patel, S. An extensive review on different design and climatic parameters to increase distillate output of solar still. Renew. Sustain. Energy Rev. 2017, 69, 750–758. [Google Scholar] [CrossRef]

- Shoeibi, S.; Mirjalily, S.A.A.; Kargarsharifabad, H.; Khiadani, M.; Panchal, H. A comprehensive review on performance improvement of solar desalination with applications of heat pipes. Desalination 2022, 540, 115983. [Google Scholar] [CrossRef]

- Vaithilingam, S.; Gopal, S.T.; Srinivasan, S.K.; Manokar, A.M.; Sathyamurthy, R.; Esakkimuthu, G.S.; Kumar, R.; Sharifpur, M. An extensive review on thermodynamic aspect based solar desalination techniques. J. Therm. Anal. Calorim. 2021, 145, 1103–1119. [Google Scholar] [CrossRef]

- Shoeibi, S.; Rahbar, N.; Esfahlani, A.A.; Kargarsharifabad, H. A review of techniques for simultaneous enhancement of evaporation and condensation rates in solar stills. Solar Energy 2021, 225, 666–693. [Google Scholar] [CrossRef]

- Ahmad, S.; Jia, H.; Ashraf, A.; Yin, D.; Chen, Z.; Xu, C.; Chenyang, W.; Jia, Q.; Xiaoyue, Z.; Israr, M.; et al. Water resources and their management in Pakistan: A critical analysis on challenges and implications. Water-Energy Nexus 2023, 6, 137–150. [Google Scholar] [CrossRef]

- Hammoodi, K.A.; Dhahad, H.A.; Alawee, W.H.; Omara, Z.; Yusaf, T. Pyramid solar distillers: A comprehensive review of recent techniques. Results Eng. 2023, 18, 101157. [Google Scholar] [CrossRef]

- Panchal, H.; Shah, P. Modelling and verification of single slope solar still using ANSYS-CFX. Int. J. Energy Environ. 2011, 2, 985–998. [Google Scholar]

- Bao, N.T. The mathematical model of basin-type solar distillation systems. In Distillation-Modelling, Simulation and Optimization; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Panchal, H. Performance investigation on variations of glass cover thickness on solar still: Experimental and theoretical analysis. Technol. Econ. Smart Grids Sustain. Energy 2016, 1, 1–11. [Google Scholar] [CrossRef]

- Panchal, H.; Mevada, D.; Sathyamurthy, R. The requirement of various methods to improve distillate output of solar still: A review. Int. J. Ambient. Energy 2021, 42, 597–603. [Google Scholar] [CrossRef]

- El-Sebaii, A.; AKhallaf, E.-M. Mathematical modeling and experimental validation for square pyramid solar still. Environ. Sci. Pollut. Res. 2020, 27, 32283–32295. [Google Scholar] [CrossRef]

- Tanaka, H. A theoretical analysis of basin type solar still with flat plate external bottom reflector. Desalination 2011, 279, 243–251. [Google Scholar] [CrossRef]

- Tanaka, H. Tilted wick solar still with flat plate bottom reflector. Desalination 2011, 273, 405–413. [Google Scholar] [CrossRef]

- Yang, Y.; Li, G.; Tang, R. On the estimation of daily beam radiation on tilted surfaces. Energy Procedia 2012, 16, 1570–1578. [Google Scholar] [CrossRef][Green Version]

- Bataineh, K.M.; Abbas, M.A. Performance analysis of solar still integrated with internal reflectors and fins. Solar Energy 2020, 205, 22–36. [Google Scholar] [CrossRef]

- El-Sebaii, A.; Al-Dossari, M. A mathematical model of single basin solar still with an external reflector. Desalination Water Treat. 2011, 26, 250–259. [Google Scholar] [CrossRef]

- Demain, C.; Journée, M.; Bertrand, C. Evaluation of different models to estimate the global solar radiation on inclined surfaces. Renew. Energy 2013, 50, 710–721. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).