Decarbonizing Pakistan’s Cement Sector: The Role of Carbon Capture and Storage (CCS) Technologies †

Abstract

1. Introduction

Significance of CCS in Decarbonizing Pakistan’s Cement Industry

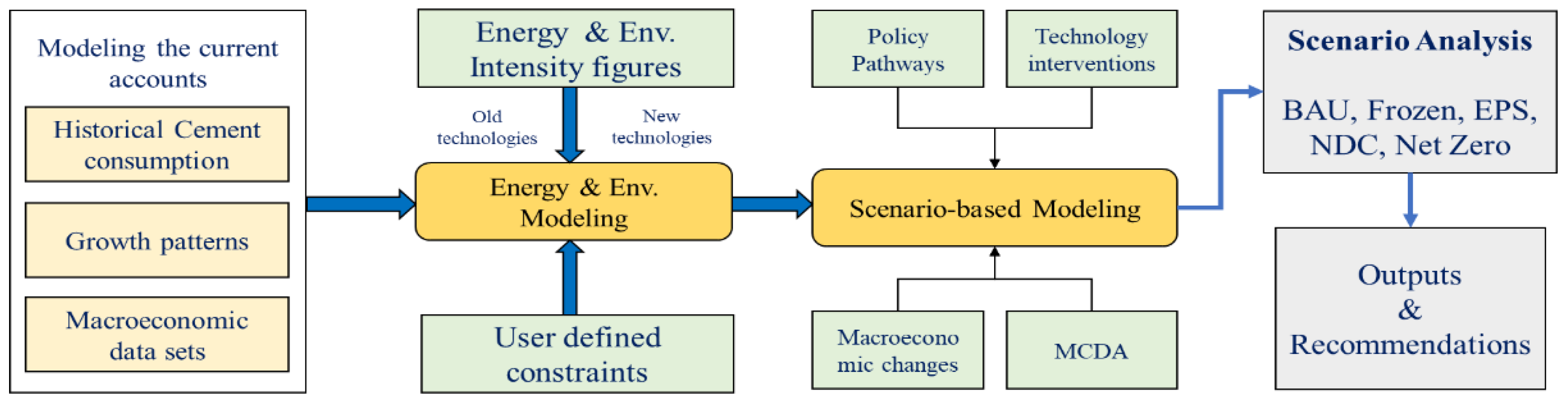

2. Methodology

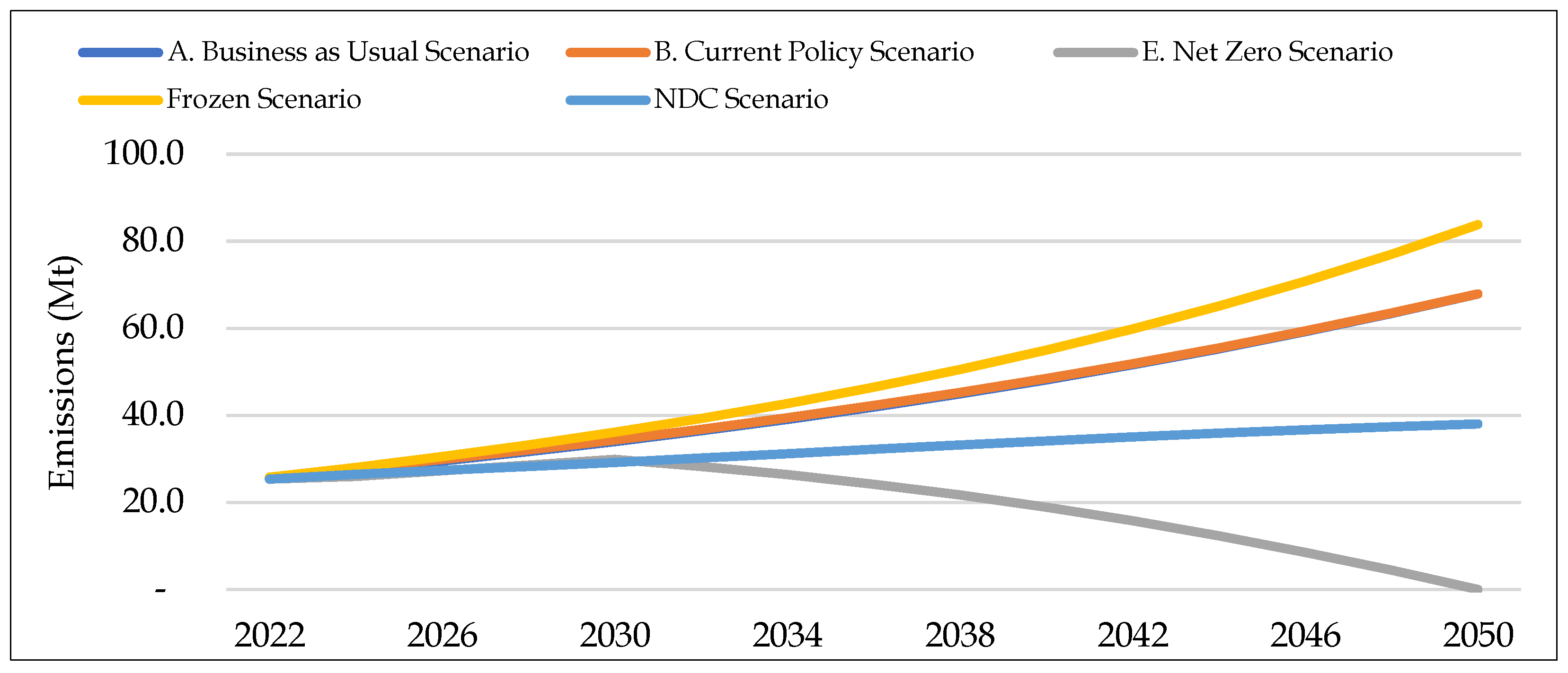

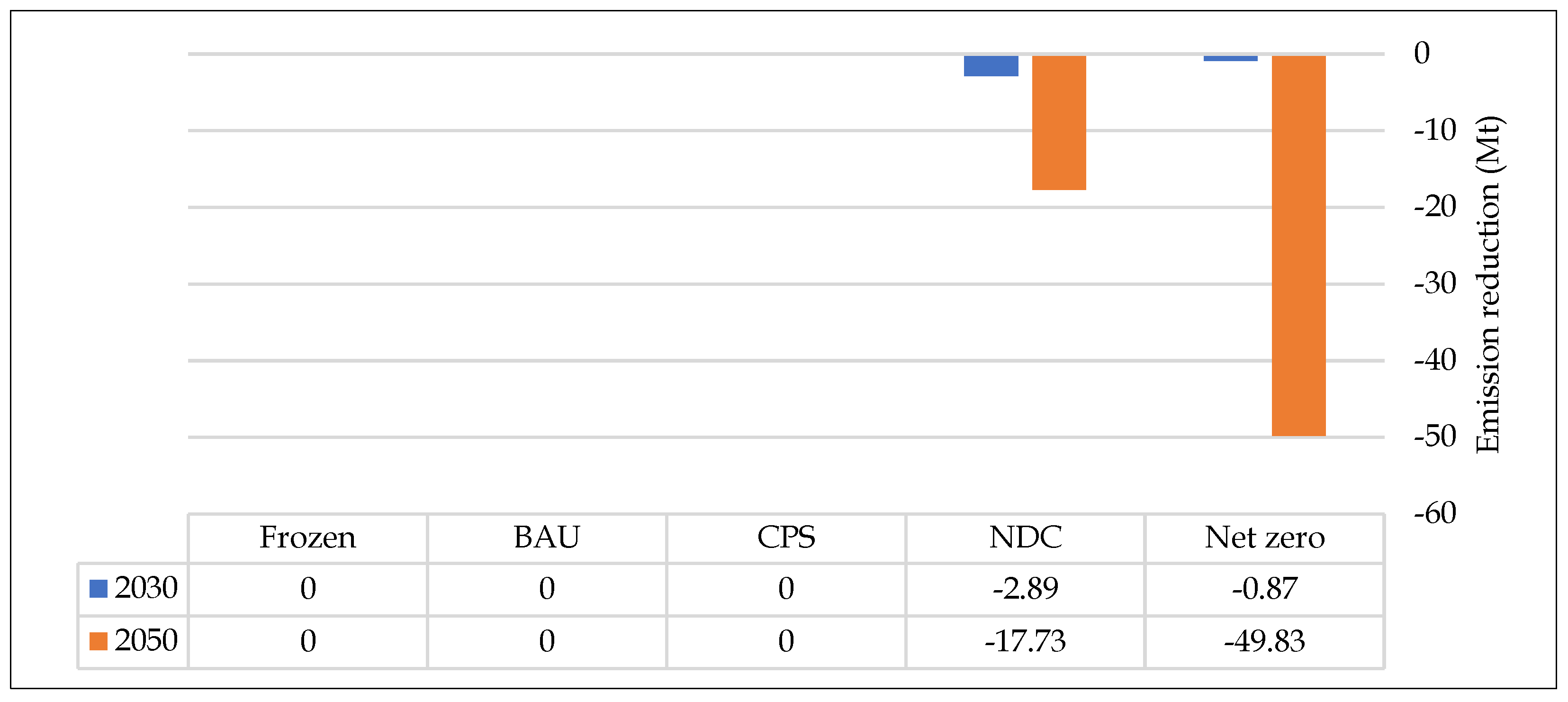

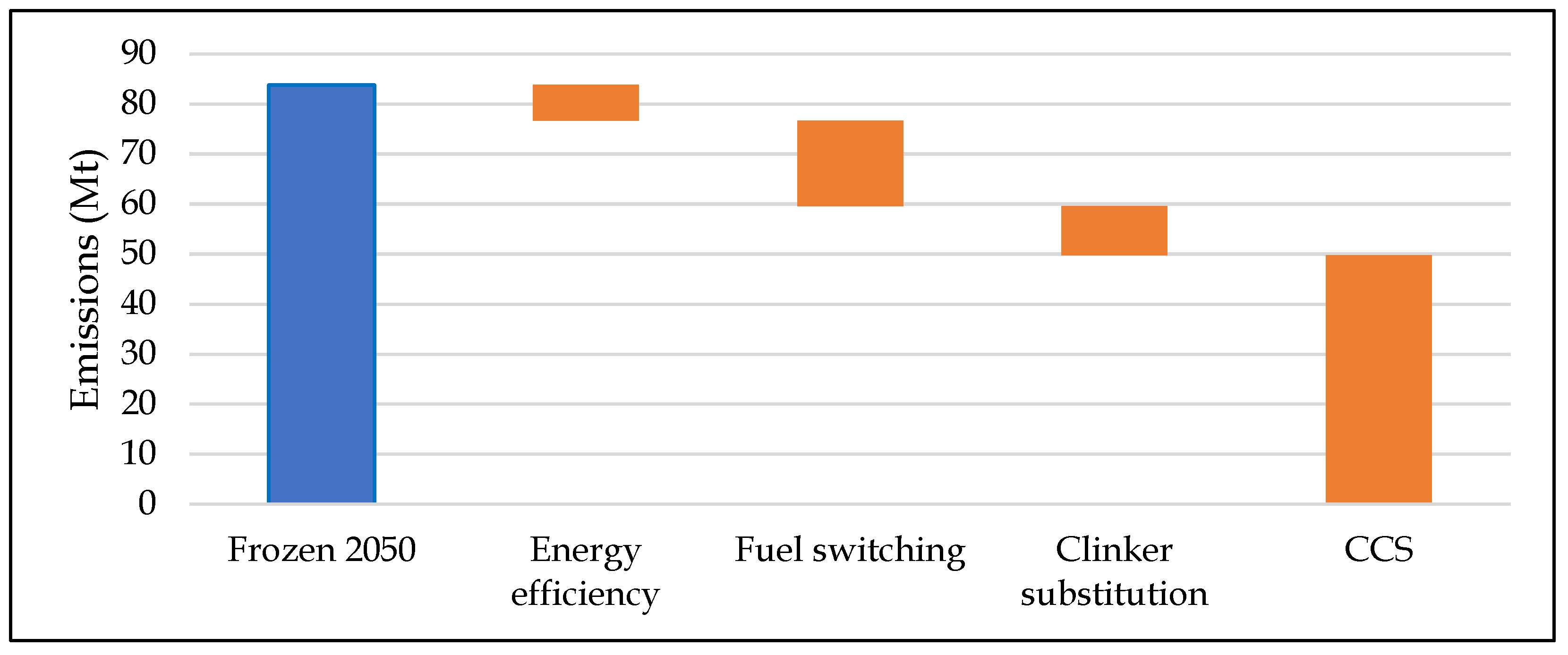

3. Results

4. Discussion

- Long-term planning, monitoring, development and regulatory support: The government can establish clear and ambitious targets for emissions reduction and CCS deployment within the cement sector along with other industrial sector targets, which should be aligned with national climate goals, such as net-zero emissions, by mid-century. This should involve developing monitoring and reporting mechanisms to track CO2 emissions, capture rates, and storage integrity. Moreover, this should be supported with robust regulatory frameworks that provide certainty and stability for CCS investments. This includes streamlined permitting processes for CCS projects, clear guidelines for CO2 storage site selection and operation, and frameworks for liability and monitoring.

- Role of finance and investment: CCS projects, including those in the cement sector, are capital-intensive due to the costs associated with capturing, transporting, and storing CO2. Financial support is essential to bridging the gap between upfront investment costs and long-term operational savings and environmental benefits. This implies the crucial role of various financial instruments, such as direct funds in the form of grants, incentives, and subsidies, and implementing carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, in creating financial incentives to help offset the high initial costs and encourage early adopters in the cement industry. Similarly, the government should harness the potential of carbon pricing mechanisms such as carbon taxes and cap-and-trade systems. CCS projects can generate revenue streams through carbon offset credits or enhanced oil recovery (EOR) operations. Cement manufacturers can monetize captured CO2 by selling carbon credits or using CO2 for EOR, providing additional financial incentives for CCS deployment. These mechanisms encourage industries to reduce emissions and invest in low-carbon technologies like CCS. Governments and international financial institutions can offer risk mitigation instruments, such as guarantees or insurance, to reduce the perceived financial risks associated with CCS investments. This helps attract private-sector capital and facilitates project financing. This includes attracting investments from financial institutions, venture capital firms, and private equity funds that recognize the potential long-term returns from CCS technology development and deployment.

- International collaboration: Given the techno-economic nature and implications of CCS, it is imperative to engage in international collaboration to share experiences, best practices, and lessons learned from CCS projects in other countries. Participating in knowledge-sharing platforms and partnerships to accelerate technology development and deployment can help build the capacity of human resources. This includes educating engineers, technicians, and policymakers on CCS technologies, operational best practices, and regulatory compliance.

- Technology innovation and R&D support: This refers to the need to invest in research and development (R&D) to advance CCS technologies tailored to the cement industry’s specific needs. It is critical to support pilot projects and demonstrations to validate technologies and scale them up for commercial deployment.

- Public–private partnerships: These can help share risks, leverage expertise, and accelerate technology development and deployment. Hence, it remains significant to foster collaboration between government, industry stakeholders (including cement manufacturers), research institutions, and international organizations to allow for the better integration of R&D, policies, regulations and the mobilization of finances and investment.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anika, O.C.; Nnabuife, S.G.; Bello, A.; Okoroafor, E.R.; Kuang, B.; Villa, R. Prospects of low and zero-carbon renewable fuels in 1.5-degree net zero emission actualisation by 2050: A critical review. Carbon Capture Sci. Technol. 2022, 5, 100072. [Google Scholar] [CrossRef]

- Bazhenov, S.; Chuboksarov, V.; Maximov, A.; Zhdaneev, O. Technical and economic prospects of CCUS projects in Russia. Sustain. Mater. Technol. 2022, 9, e00452. [Google Scholar] [CrossRef]

- Maher, A. Developing the Carbon Capture and Utilization (CCU) Market in the EU: An Analysis of the Legal and Policy Framework. Master’s Thesis, South-Eastern Finland University of Applied Sciences, Kouvola, Finland, May 2024. [Google Scholar]

- Boakye, K.; Winters, D.; Oguntola, O.; Fenton, K.; Simske, S. A Review of Strategies to Achieve Net Zero Targets in the Cement and Concrete Sectors. In Reducing Carbon Footprint—Microscale to Macroscale, Technical, Industrial and Policy Regulations; IntechOpen: Rijeka, Croatia, 2024. [Google Scholar] [CrossRef]

- Das, A.; Saini, V.; Parikh, K.; Parikh, J.; Ghosh, P.; Tot, M. Pathways to net zero emissions for the Indian power sector. Energy Strategy Rev. 2023, 45, 101042. [Google Scholar] [CrossRef]

- IPCC. Special Report on Carbon Dioxide Capture and Storage; Metz, B., Davidson, O., de Coninck, H., Loos, M., Meyer, L., Eds.; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Schakel, W.; Hung, C.R.; Tokheim, L.A.; Strømman, A.H.; Worrell, E.; Ramirez, C.A.R. Impact of fuel selection on the environmental performance of post-combustion calcium looping applied to a cement plant. Appl. Energy 2018, 210, 75–87. [Google Scholar] [CrossRef]

- Team, E.D. Turning CCS Projects in Heavy Industry and Power into Blue Chip Financial Investments. EFI Foundation, 25 August 2023. Available online: https://efifoundation.org/reports/turning-ccs-projects-in-heavy-industry-into-blue-chip-financial-investments/ (accessed on 1 January 2024).

- Shen, M.; Kong, F.; Tong, L.; Luo, Y.; Yin, S.; Liu, C.; Zhang, P.; Wang, L.; Chu, P.K.; Ding, Y. Carbon capture and storage (CCS): Development path based on carbon neutrality and economic policy. Carbon Neutrality 2022, 1, 37. [Google Scholar] [CrossRef]

- Jiao, R. Implications of Pakistani Dynastic Politics for the Construction of China-Pakistan Economic Corridor: Potential Risks and Policy Responses. In The Political Economy of the China-Pakistan Economic Corridor; Palgrave Macmillan: Singapore, 2023; pp. 135–154. [Google Scholar] [CrossRef]

- Decarbonization of Pak’s Cement Requires Strong—ProQuest. Available online: https://www.proquest.com/docview/3041146234/fulltext (accessed on 1 January 2024).

- Qureshi, S.; Zia, U.; Bashir, N. Pakistan’s Cement Sector: A Road to Decarbonization; Sustainable Development Policy Institute: Islamabad, Pakistan, 2023. [Google Scholar]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Thermal Energy Consumption for Cement | 3.9 GJ/t-cl | Electrical Energy Consumption for cement | 90 kWh/t Cement |

| Clinker-to-Cement Ratio | 0.95 | Emission Intensity | 0.79 t-CO2/t-cl |

| Energy Mix (2022) | Coal (80%), Natural Gas (12%), Electricity (1.2%), Others (6.8%) | Share of Cement in Industrial Emissions | 61% |

| Economic Growth | 4.3% (as per IGCEP) | Population Growth Rate | 2% |

| Energy Demand (2022) | 7.1 Mtoe | Commercial Floor-Space Increase | Direct Index of GDP |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zia, U.; Qureshi, S.; Aslam, H.; Zulfiqar, M. Decarbonizing Pakistan’s Cement Sector: The Role of Carbon Capture and Storage (CCS) Technologies. Eng. Proc. 2024, 75, 7. https://doi.org/10.3390/engproc2024075007

Zia U, Qureshi S, Aslam H, Zulfiqar M. Decarbonizing Pakistan’s Cement Sector: The Role of Carbon Capture and Storage (CCS) Technologies. Engineering Proceedings. 2024; 75(1):7. https://doi.org/10.3390/engproc2024075007

Chicago/Turabian StyleZia, Ubaid, Saleha Qureshi, Hina Aslam, and Muhammad Zulfiqar. 2024. "Decarbonizing Pakistan’s Cement Sector: The Role of Carbon Capture and Storage (CCS) Technologies" Engineering Proceedings 75, no. 1: 7. https://doi.org/10.3390/engproc2024075007

APA StyleZia, U., Qureshi, S., Aslam, H., & Zulfiqar, M. (2024). Decarbonizing Pakistan’s Cement Sector: The Role of Carbon Capture and Storage (CCS) Technologies. Engineering Proceedings, 75(1), 7. https://doi.org/10.3390/engproc2024075007