Predictive Maintenance and Predictive Repair of Road Vehicles—Opportunities, Limitations and Practical Applications †

Abstract

1. Introduction

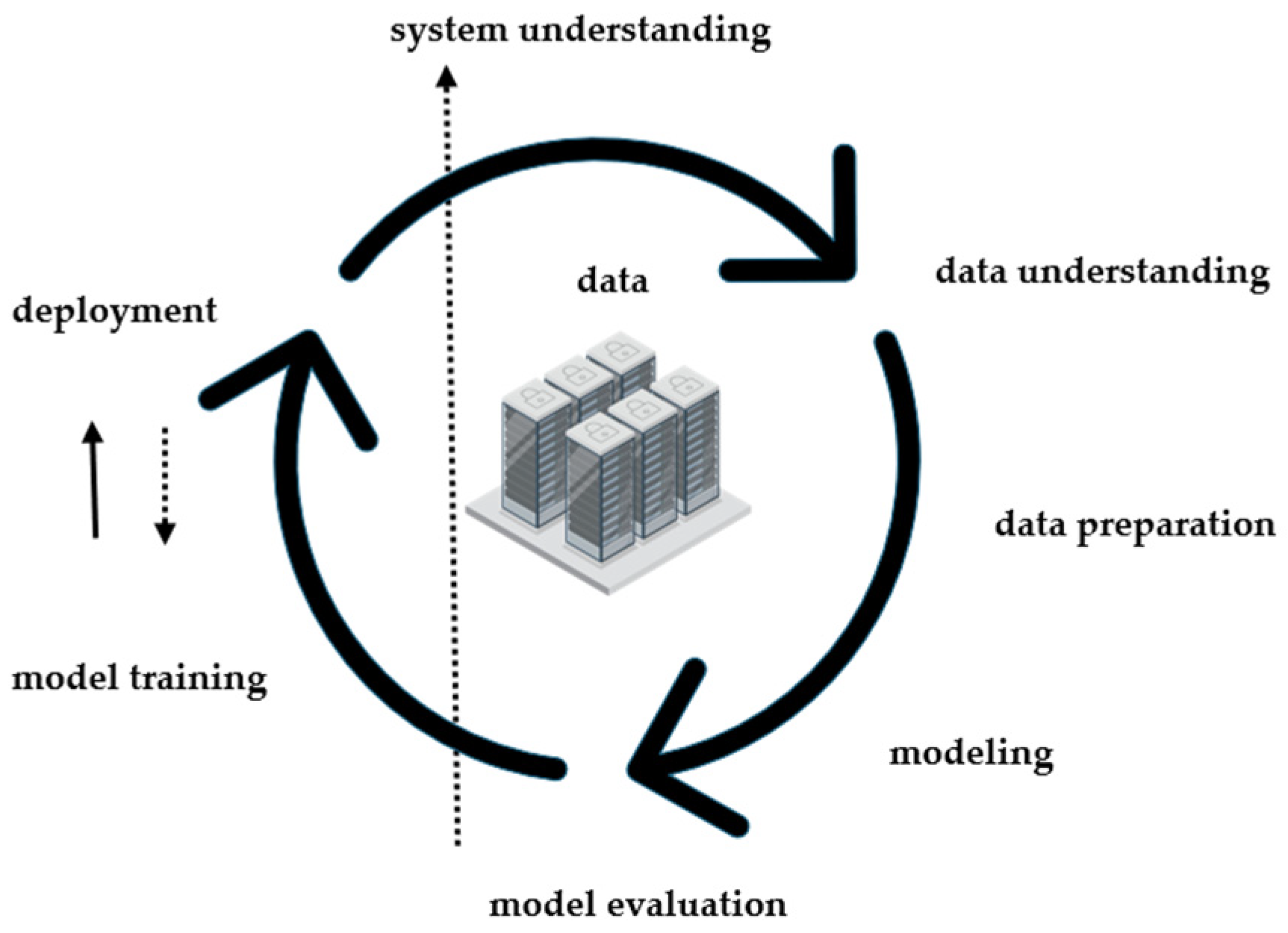

2. Method of Predictive Maintenance/Repair Process Supported by Machine Learning in the Automotive Industry

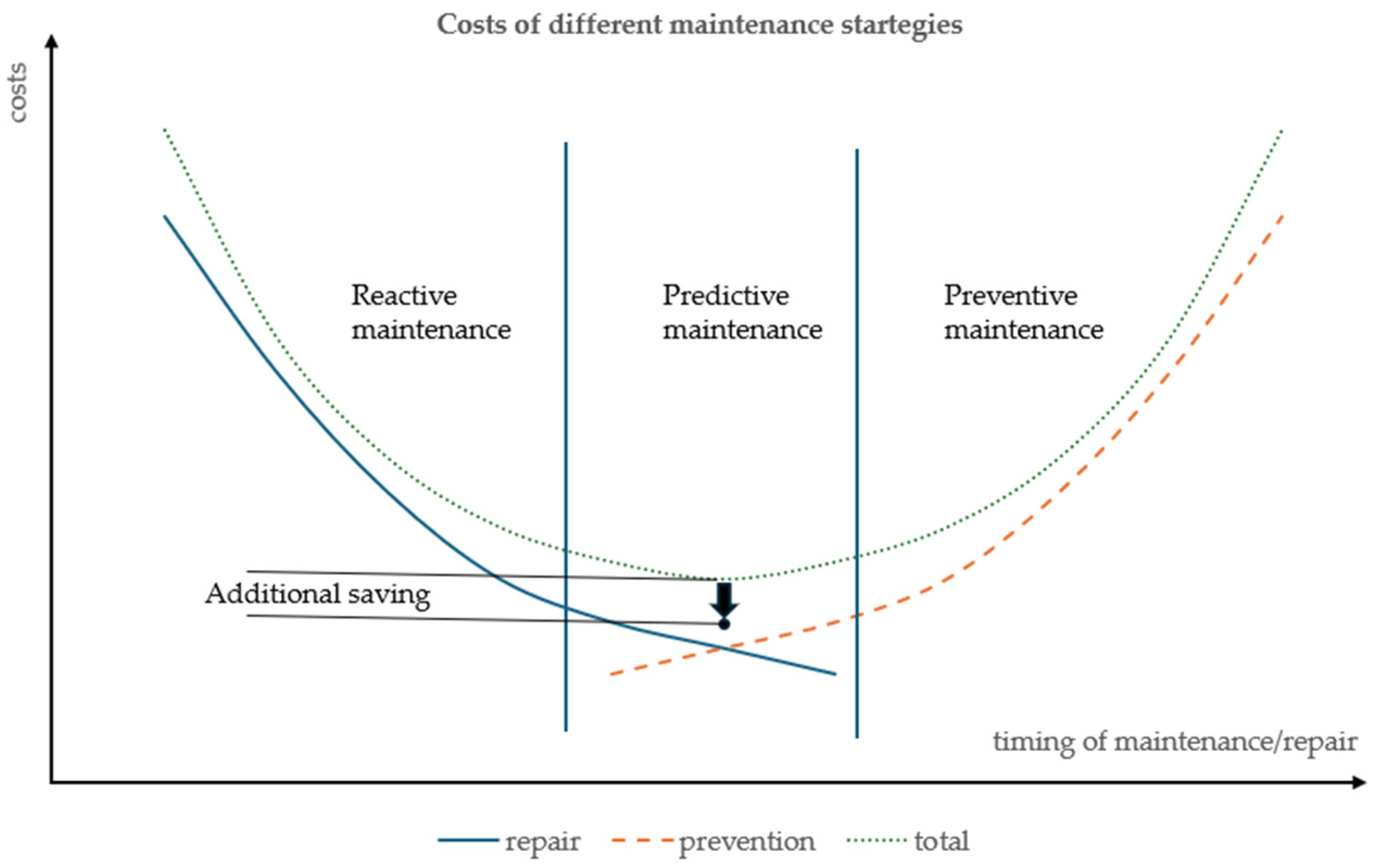

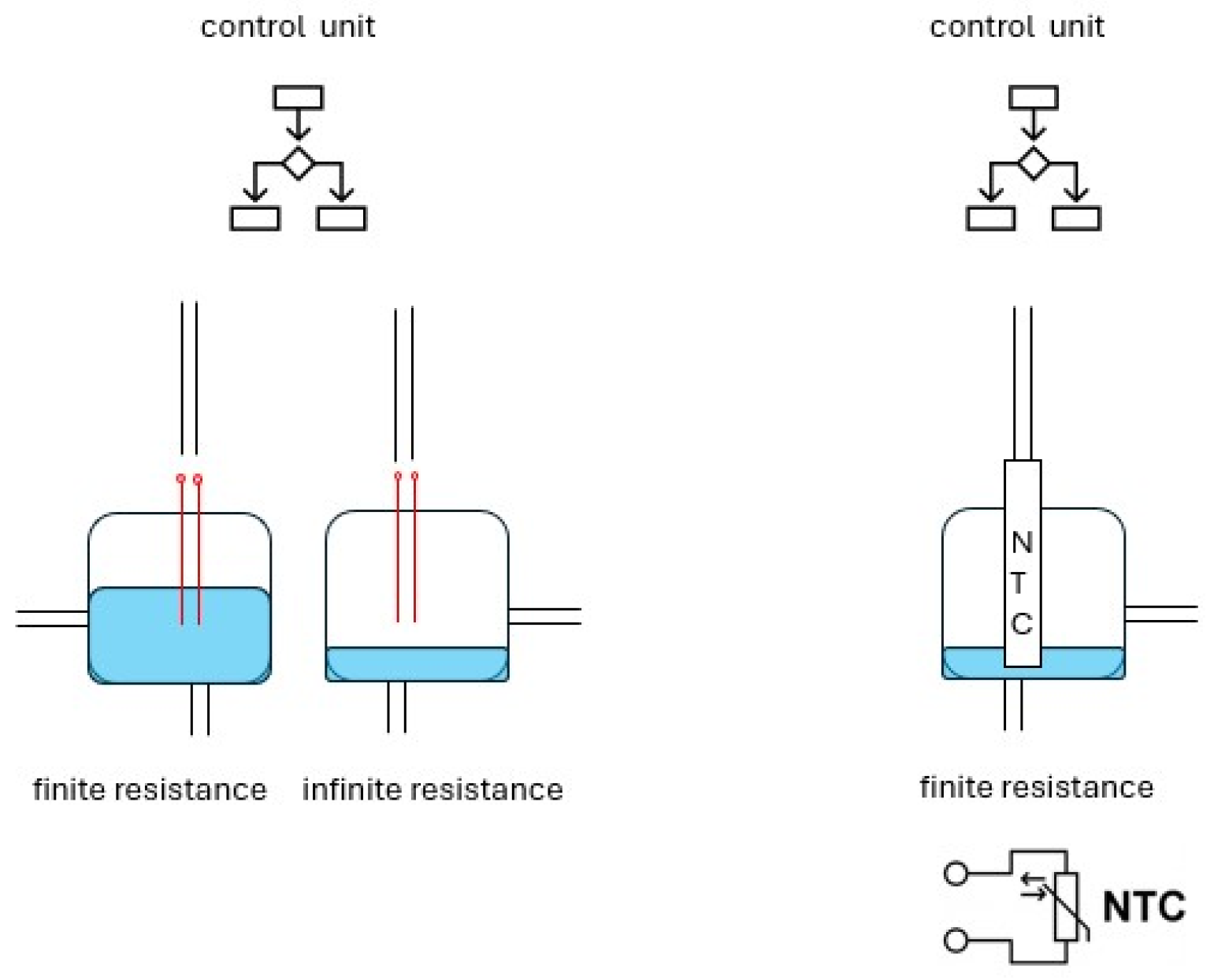

2.1. Predictive Maintenance (PM) in the Automotive Sector

2.2. Preventive Repair or Service (PS) in the Automotive Sector

- handling of cars within/outside of warranty period;

- warranty parts’ cost charges to suppliers;

- reliability of models, since affected parts are still functional at the time of repair;

- product liability legislation: handling of tow-in vs. other issues with the same symptom, and business case approaches.

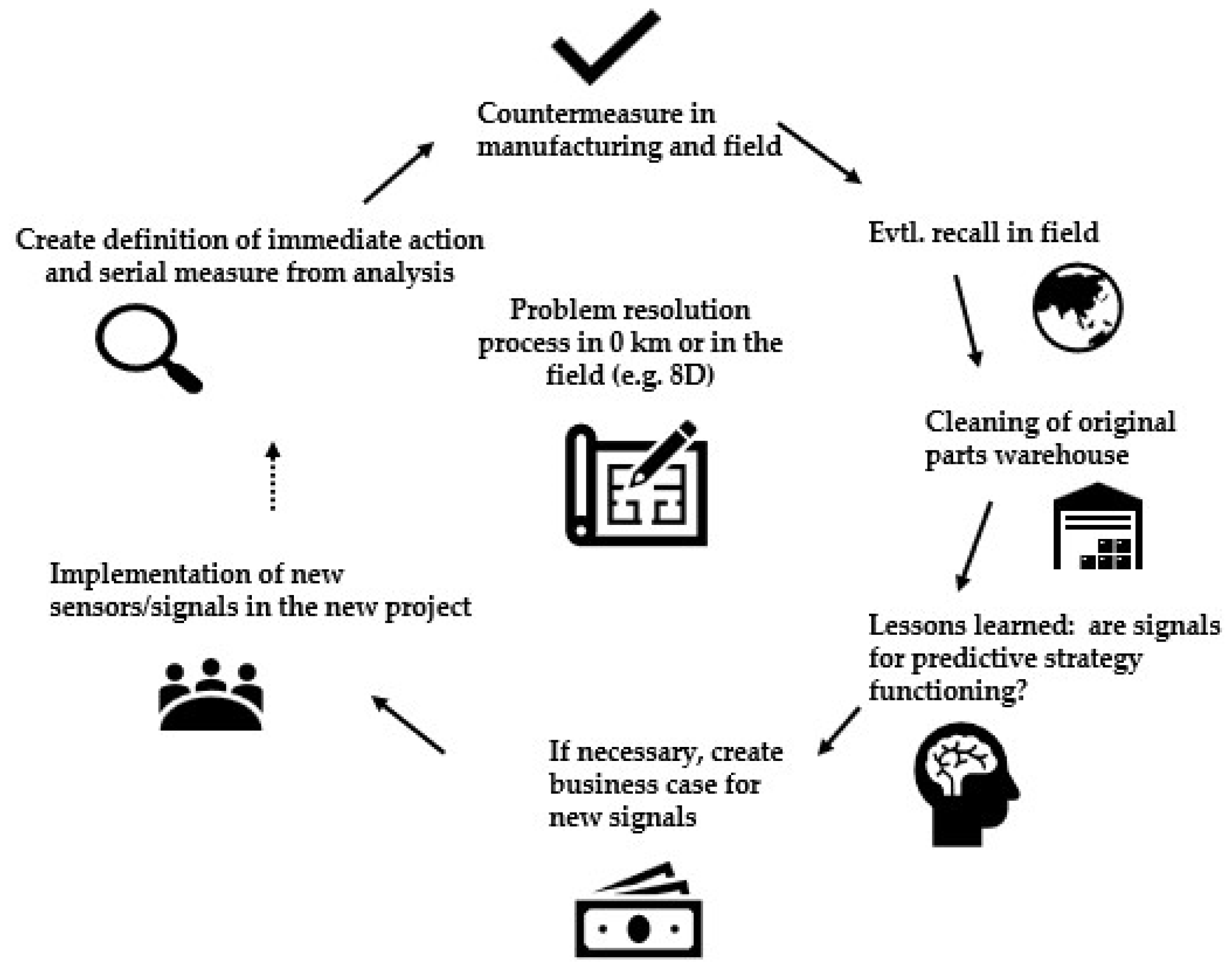

2.3. A Possible Process for Automotive Field Observation

- definition of critical vehicle systems;

- data collecting campaign—GDPR in the EU must be considered [13];

- modeling (see Figure 1 above);

- determining of affected cars;

- service countermeasures with customer contact;

- Ni represents the number of inspections;

- C reactive: costs of reactive repairs in the case of unpredictable failures;

- C preventive: costs of preventive maintenance, e.g., oil and oil filters, air filters, V-belts, etc.;

- C predictive: predictable repair costs, e.g., the replacing of high voltage battery modules;

- C mob: the saving of mobility costs in the case of preventing tow-ins (rental cars, towing in…).

3. Results and Findings: Limits of Use Cases of Predictive Maintenance and Predictive Repair

4. Conclusions: Starting of Lessons Learned Process Required

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Theissler, A.; Pérez-Velázquez, J.; Kettelgerdes, M.; Elger, G. Predictive maintenance enabled by machine learning: Use cases and challenges in the automotive industry. Reliab. Eng. Syst. Saf. 2021, 215, 107864. [Google Scholar] [CrossRef]

- Furch, J.; Krobot, Z. Trends in Predictive and Proactive Maintenance of Motor Vehicles. Acta Univ. Agric. Silvic. Mendel. Brun. 2020, 68, 311–322. [Google Scholar] [CrossRef]

- Nagy, J.; Lakatos, I. Possibilities of Using of Online Vehicle Diagnostics in the Future. In Vehicle and Automotive Engineering 4; VAE 2022; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Arena, F.; Collotta, M.; Luca, L.; Ruggieri, M.; Termine, F.G. Predictive Maintenance in the Automotive Sector: A Literature Review. Math. Comput. Appl. 2022, 27, 2. [Google Scholar] [CrossRef]

- Johnson, N.; Edwards, S.E.V.; Silas, D.; Jaspher, G.; Kathrine, W. Predictive Vehicle Maintenance using Deep Neural Networks. In Proceedings of the 2024 International Conference on Cognitive Robotics and Intelligent Systems, Coimbatore, India, 17–19 April 2024. [Google Scholar] [CrossRef]

- Martínez-Plumed, F.; Contreras-Ochando, L.; Ferri, C.; Hernández-Orallo, J.; Kull, M.; Lachiche, N.; Ramírez-Quintana, M.J.; Flach, P. CRISP-DM Twenty Years Later: From Data Mining Processes to Data Science Trajectories. IEEE Trans. Knowl. Data Eng. 2021, 33, 3048–3061. [Google Scholar] [CrossRef]

- Grall, A.; Dieulle, L.; Bérenguer, C.; Roussignol, M. Continuous-Time Predictive-Maintenance Scheduling for a Deteriorating System. IEEE Trans. Reliab. 2002, 51, 141–150. [Google Scholar] [CrossRef]

- Gou, B.; Xu, Y.; Feng, X. State-of-Health Estimation and Remaining-Useful-Life Prediction for Lithium-Ion Battery Using a Hybrid Data-Driven Method. IEEE Trans. Veh. Technol. 2020, 39, 10854–10867. [Google Scholar] [CrossRef]

- Van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive maintenance using digital twins: A systematic literature review. Inf. Softw. Technol. 2022, 151, 107008. [Google Scholar] [CrossRef]

- Bedi, V.K.; Rana, K.; Mahata, P.; Ghosh, P.; Mukhopadhyay, R. A Predictive Approach to Estimate Tyre Wear Characteristics. SAE Technical Paper; SAE: Warrendale, PA, USA, 2024. [Google Scholar] [CrossRef]

- Nagy, J.; Lakatos, I. Implementation of Online Predictive Maintenance in the Car Production and in the Service. In Proceedings of the 27th International Film Festival of Kerala, Kerala, India, 9–16 December 2022. [Google Scholar]

- Mai, V.N.; Yoon, D.S.; Choi, S.B.; Kim, G.W. Explicit model predictive control of semi-active suspension systems with magneto-rheological dampers subject to input constraints. J. Intell. Mater. Syst. Struct. 2020, 31, 1157–1170. [Google Scholar] [CrossRef]

- Regulation (EU) 2016/679 of the European Parliament and of the Council of 27 April 2016 on the Protection of Natural Persons with Regard to the Processing of PERSONAL Data and on the Free Movement of Such Data (General Data Protection Regulation, GDPR). Available online: https://eur-lex.europa.eu/eli/reg/2016/679/oj (accessed on 25 October 2024).

- Regulation (EU) 2022/0302 of the European Parliament and of the Council on Liability for Defective Products. Available online: https://eur-lex.europa.eu/procedure/DE/2022_302?uri=PROCEDURE%3A2022_302 (accessed on 25 October 2024).

- Regulation (EU) 2019/2021 of the European Parliament and of the Council Laying Down Rules on Market Surveillance and Compliance of Products. Available online: https://eur-lex.europa.eu/eli/reg/2019/2021/oj (accessed on 25 October 2024).

- Realyvásquez-Vargas, A.; Arredondo-Soto, K.C.; García-Alcaraz, J.; Macías, E.J. Improving a Manufacturing Process Using the 8Ds Method. A Case Study in a Manufacturing Company. Appl. Sci. 2020, 10, 2433. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagy, J.; Lakatos, I. Predictive Maintenance and Predictive Repair of Road Vehicles—Opportunities, Limitations and Practical Applications. Eng. Proc. 2024, 79, 27. https://doi.org/10.3390/engproc2024079027

Nagy J, Lakatos I. Predictive Maintenance and Predictive Repair of Road Vehicles—Opportunities, Limitations and Practical Applications. Engineering Proceedings. 2024; 79(1):27. https://doi.org/10.3390/engproc2024079027

Chicago/Turabian StyleNagy, Jozsef, and Istvan Lakatos. 2024. "Predictive Maintenance and Predictive Repair of Road Vehicles—Opportunities, Limitations and Practical Applications" Engineering Proceedings 79, no. 1: 27. https://doi.org/10.3390/engproc2024079027

APA StyleNagy, J., & Lakatos, I. (2024). Predictive Maintenance and Predictive Repair of Road Vehicles—Opportunities, Limitations and Practical Applications. Engineering Proceedings, 79(1), 27. https://doi.org/10.3390/engproc2024079027