Mechanical Characterization of Metal–Polymer Joints Fabricated via Thermal Direct Bonding Technique †

Abstract

:1. Introduction

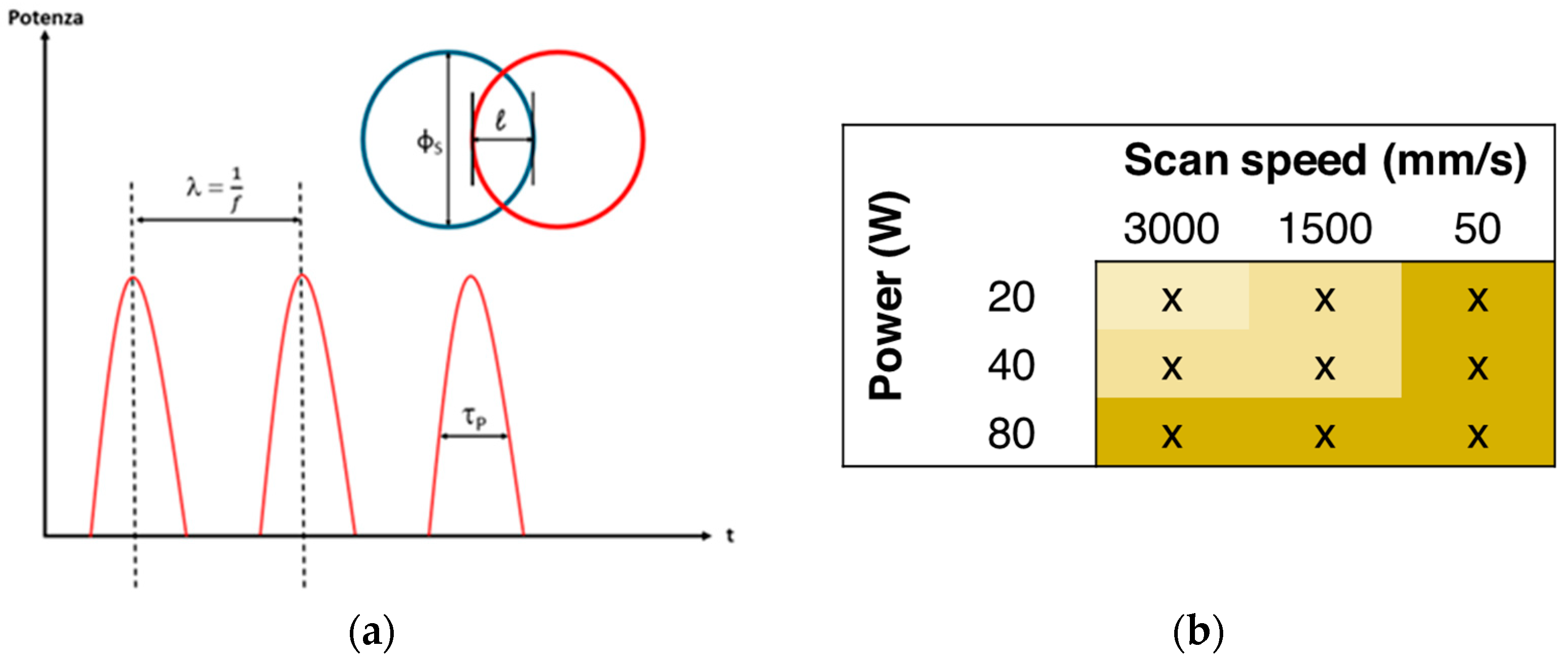

2. Materials and Methods

2.1. Materials

2.2. Joint Fabrication

3. Results

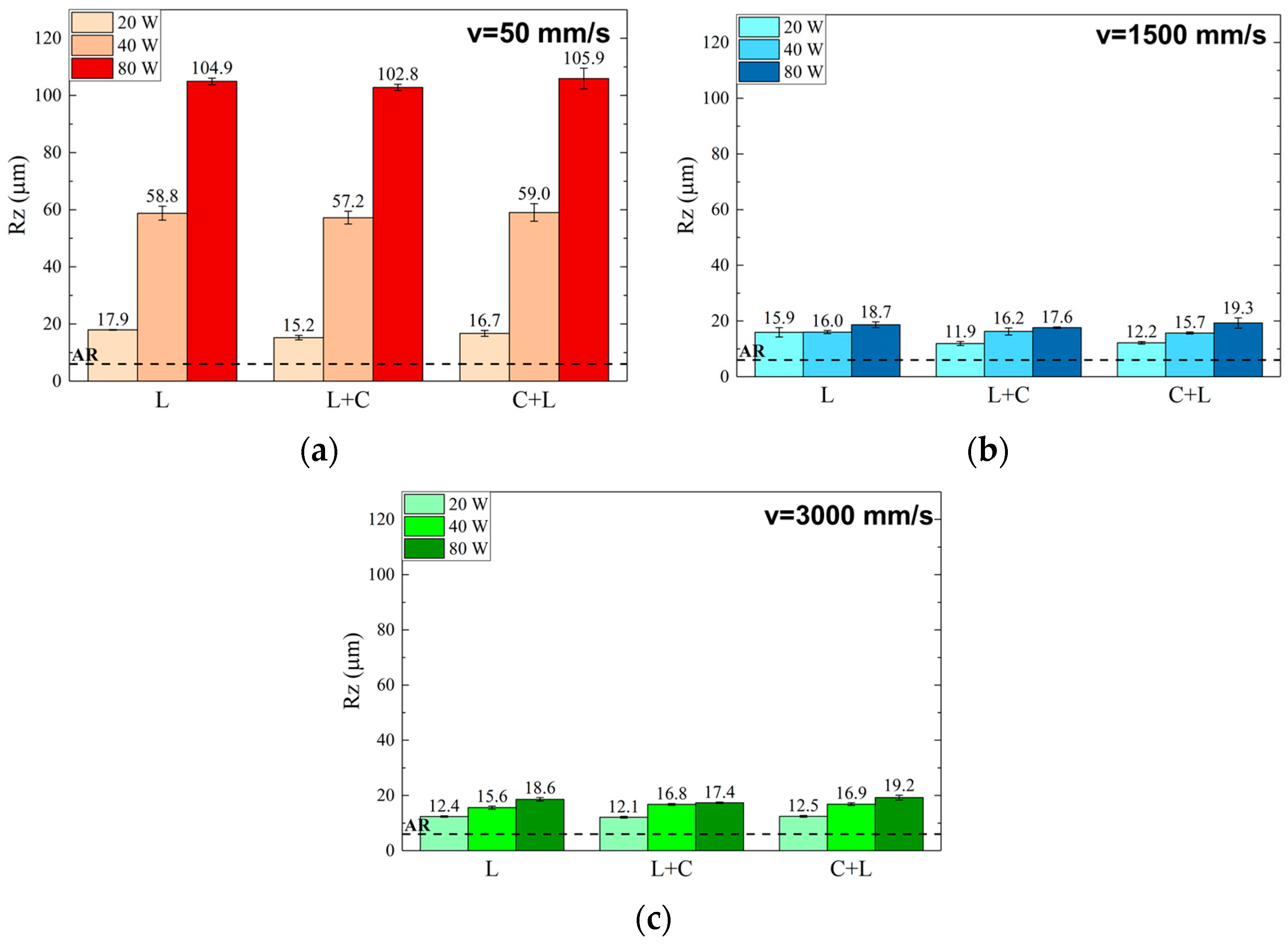

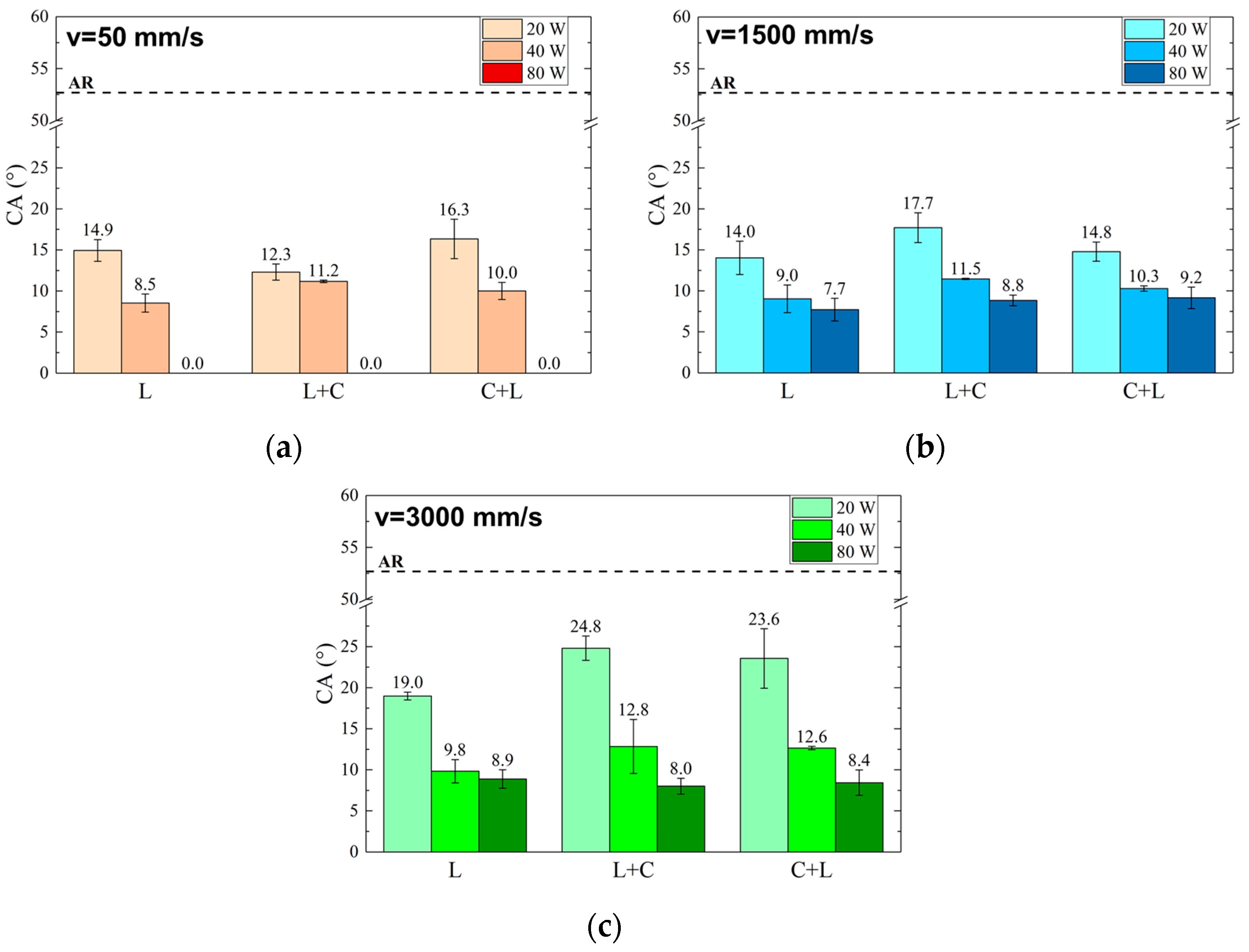

3.1. Surface Analysis

3.2. Mechanical Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations: The Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/ (accessed on 10 September 2024).

- Magarò, P.; Alaimo, G.; Carraturo, M.; Sgambitterra, E.; Maletta, C. A Novel Methodology for the Prediction of the Stress–Strain Response of Laser Powder Bed Fusion Lattice Structure Based on a Multi-Scale Approach. Mater. Sci. Eng. A 2023, 863, 144526. [Google Scholar] [CrossRef]

- Issariyapat, A.; Kariya, S.; Alhazaa, A.; Umeda, J.; Kondoh, K. Additive Manufacturing and Characterization of High Strength Ti-Zr Gyroid Scaffolds Using Pre-Mixed Ti-ZrH2 Powders. JOM 2021, 73, 4166–4176. [Google Scholar] [CrossRef]

- Huang, Y.; Gao, X.; Zhang, Y.; Ma, B. Laser Joining Technology of Polymer-Metal Hybrid Structures—A Review. J. Manuf. Process. 2022, 79, 934–961. [Google Scholar] [CrossRef]

- Klotzbach, A.; Langer, M.; Pautzsch, R.; Standfuß, J.; Beyer, E. Thermal Direct Joining of Metal to Fiber Reinforced Thermoplastic Components. J. Laser Appl. 2017, 29, 022421. [Google Scholar] [CrossRef]

- Lambiase, F.; Scipioni, S.I.; Lee, C.-J.; Ko, D.-C.; Liu, F. A State-of-the-Art Review on Advanced Joining Processes for Metal-Composite and Metal-Polymer Hybrid Structures. Materials 2021, 14, 1890. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.; Liu, J.; Xia, H.; Li, X.; Zhang, X.; Yang, H. Effects of Surface Treatment and Adhesive Thickness on the Shear Strength of Precision Bonded Joints. Polym. Test. 2021, 94, 107063. [Google Scholar] [CrossRef]

- Morano, C.; Tao, R.; Alfano, M.; Lubineau, G. Effect of Mechanical Pretreatments on Damage Mechanisms and Fracture Toughness in Cfrp/Epoxy Joints. Materials 2021, 14, 1512. [Google Scholar] [CrossRef] [PubMed]

- Shokrian, M.D.; Shelesh-Nezhad, K.; Najjar, R. The Effects of Al Surface Treatment, Adhesive Thickness and Microcapsule Inclusion on the Shear Strength of Bonded Joints. Int. J. Adhes. Adhes. 2019, 89, 139–147. [Google Scholar] [CrossRef]

- Oliveira, G.H.M.; Morozo, M.A.; Fiori, M.A.; Canto, L.B. A Method for Manufacturing a Mechanically Strong and Durable Hybrid Structure of Polyethylene–Hydroxyapatite Composite and Titanium Alloy. Polym. Eng. Sci. 2024, 64, 1548–1554. [Google Scholar] [CrossRef]

- Leone, C.; Paoletti, A.; Babu Yanala, P.; Lambiase, F. Improving Bonding Strength of Aluminium-PEEK Hybrid Metal-Polymer Joints by Two-Step Laser Surface Treatment. Opt. Laser Technol. 2024, 170, 110304. [Google Scholar] [CrossRef]

- Rechner, R.; Jansen, I.; Beyer, E. Influence on the Strength and Aging Resistance of Aluminium Joints by Laser Pre-Treatment and Surface Modification. Int. J. Adhes. Adhes. 2010, 30, 595–601. [Google Scholar] [CrossRef]

- Chu, J.; Wang, X.; Ma, Y.; Liu, H. Numerical Simulation of Melt Pool Formation in Laser Transmission Joining PET with Microtextured Surface Pretreated SUS304 Stainless Steel. Int. J. Heat Mass Transf. 2023, 216, 124560. [Google Scholar] [CrossRef]

- Kräusel, V.; Fröhlich, A.; Kroll, M.; Rochala, P.; Kimme, J.; Wertheim, R. A Highly Efficient Hybrid Inductive Joining Technology for Metals and Composites. CIRP Ann. 2018, 67, 5–8. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, H.; Zhao, Y.; Wang, S.; Su, J.; Chen, B.; Song, X.; Tan, C. Effect of Surface Texture Spacing on Interface Heat Transfer and Tensile Property of Laser-welded Steel/ CFRTP Joint. Polym. Compos. 2024, 45, 1551–1567. [Google Scholar] [CrossRef]

- ASTM D1002-10; Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal). ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

| AA6016 | PLA | |

|---|---|---|

| Young modulus [GPa] | 71 | 1.96 |

| Yield strength [MPa] | 220 | |

| Ultimate strength [MPa] | 280 | 32 |

| Elongation at break [%] | 12 | 32.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morano, C.; Morabito, A.; Bruno, L.; Alfano, M.; Pagnotta, L. Mechanical Characterization of Metal–Polymer Joints Fabricated via Thermal Direct Bonding Technique. Eng. Proc. 2025, 85, 49. https://doi.org/10.3390/engproc2025085049

Morano C, Morabito A, Bruno L, Alfano M, Pagnotta L. Mechanical Characterization of Metal–Polymer Joints Fabricated via Thermal Direct Bonding Technique. Engineering Proceedings. 2025; 85(1):49. https://doi.org/10.3390/engproc2025085049

Chicago/Turabian StyleMorano, Chiara, Andrea Morabito, Luigi Bruno, Marco Alfano, and Leonardo Pagnotta. 2025. "Mechanical Characterization of Metal–Polymer Joints Fabricated via Thermal Direct Bonding Technique" Engineering Proceedings 85, no. 1: 49. https://doi.org/10.3390/engproc2025085049

APA StyleMorano, C., Morabito, A., Bruno, L., Alfano, M., & Pagnotta, L. (2025). Mechanical Characterization of Metal–Polymer Joints Fabricated via Thermal Direct Bonding Technique. Engineering Proceedings, 85(1), 49. https://doi.org/10.3390/engproc2025085049