Effect of Alumina as an Anti-Soiling Nanomaterial for Enhancing Photovoltaic Performance †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Substrate Preparation

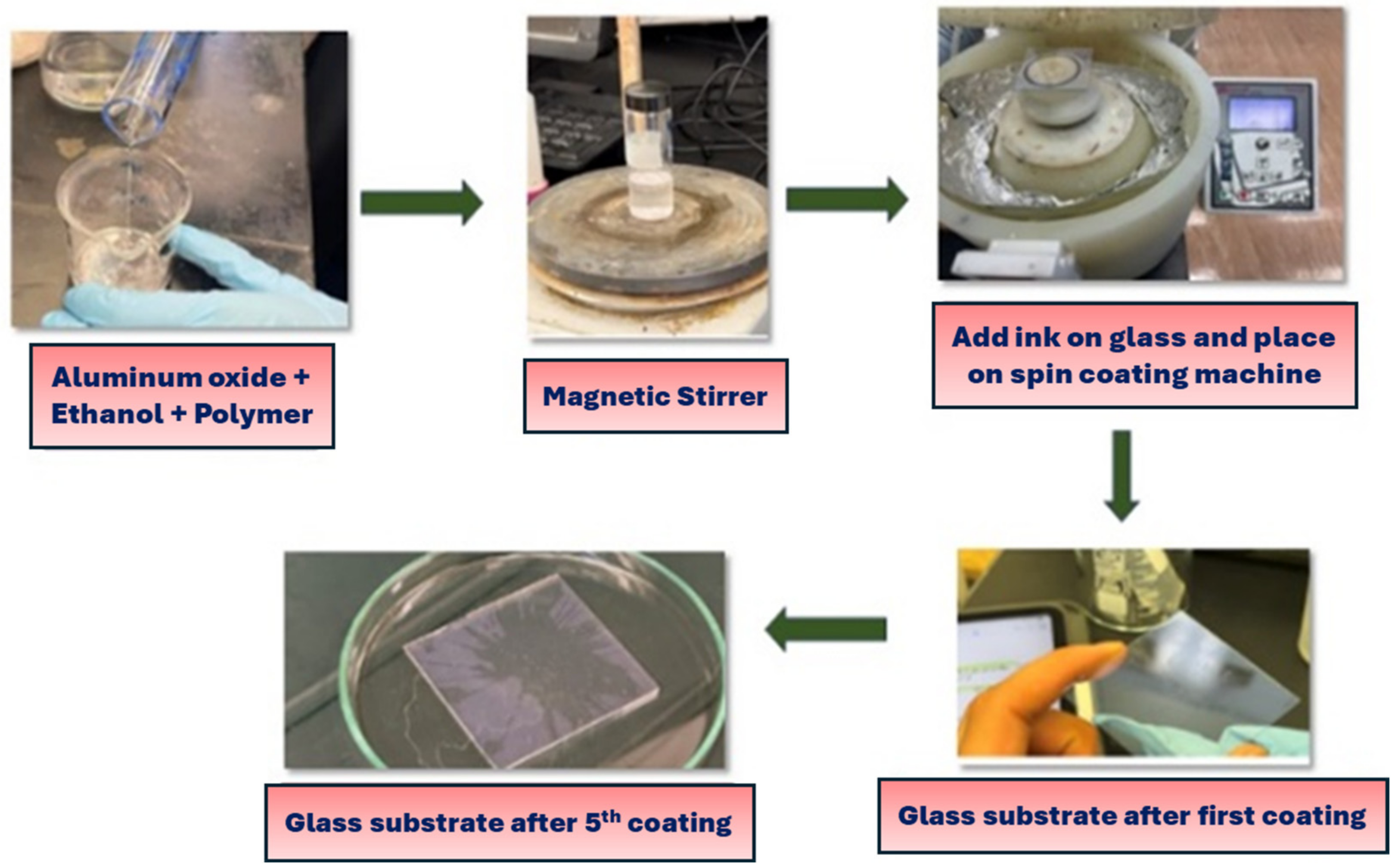

2.3. Deposition by Spin Coating

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hachicha, A.A.; Al-Sawafta, I.; Said, Z. Impact of dust on the performance of solar photovoltaic (PV) systems under United Arab Emirates weather conditions. Renew. Energy 2019, 141, 287–297. [Google Scholar] [CrossRef]

- Hossain, M.I.; Ali, A.; Benito, V.B.; Figgis, B.; Aïssa, B. Anti-Soiling Coatings for Enhancement of PV Panel Performance in Desert Environment: A Critical Review and Market Overview. Materials 2022, 15, 7139. [Google Scholar] [CrossRef] [PubMed]

- Rudnicka, M.; Klugmann-Radziemska, E. Soiling Effect Mitigation Obtained by Applying Transparent Thin-Films on Solar Panels: Comparison of Different Types of Coatings. Materials 2021, 14, 964. [Google Scholar] [CrossRef] [PubMed]

- Sarkın, A.S.; Ekren, N.; Sağlam, Ş. A review of anti-reflection and self-cleaning coatings on photovoltaic panels. Solar Energy 2020, 199, 63–73. [Google Scholar] [CrossRef]

- Piliougine, M.; Cañete, C.; Moreno, R.; Carretero, J.; Hirose, J.; Ogawa, S.; Sidrach-de-Cardona, M. Comparative analysis of energy produced by photovoltaic modules with anti-soiling coated surface in arid climates. Appl. Energy 2013, 112, 626–634. [Google Scholar] [CrossRef]

- Ebert, D.; Bhushan, B. Transparent, Superhydrophobic, and Wear-Resistant Coatings on Glass and Polymer Substrates Using SiO2, ZnO, and ITO Nanoparticles. Langmuir 2012, 28, 11391–11399. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, B.; Liu, T.; Xu, C.; Ge, Z. Controllable fabrication of superhydrophobic TiO2 coating with improved transparency and thermostability. Colloids Surf. A: Physicochem. Eng. Asp. 2014, 441, 298–305. [Google Scholar] [CrossRef]

- Fares, E. Inkjet printing of metal oxide coatings for enhanced photovoltaic soiling environmental applications. Glob. J. Environ. Sci. Manag. 2022, 8, 485–502. [Google Scholar]

- Balakrishnan, G.; Ray, P.K.; Kumar, R.; Chaudhary, R.K.; Kumar, R.; Roy, P.K.; Gopinath, R. Preparation of Alumina (Al2O3) Thin Films By Sol-Gel Dip Coating And Characterization. Int. J. Curr. Adv. Res. 2017, 6, 1–5. [Google Scholar]

- Isaifan, R.J.; Samara, A.; Suwaileh; Johnson, D.; Yuming, W.; Abdallah, A.A.; Aissa, B. Improved Self-cleaning Properties of an Efficient and Easy to Scale up TiO2 Thin Films Prepared by Adsorptive Self-Assembly. Sci. Rep. 2017, 7, 9466. [Google Scholar] [CrossRef] [PubMed]

| Sample Al2O3 | Type | Coordinates of Glass Sample Location | Before (g) | After (g) | Diff. (g) |

|---|---|---|---|---|---|

| Glass substrate 1 | Bare glass | 25°22′45.1″ N | 13.5727 | 13.5792 | 0.0065 |

| Coated | 51°29′21.0″ E | 13.6375 | 13.6412 | 0.0037 | |

| Glass substrate 2 | Bare glass | 25°10′23.2″ N | 14.0297 | 14.0374 | 0.0077 |

| Coated | 51°35′35.9″ E | 14.1035 | 14.1077 | 0.0042 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alardah, A.H.S.; Alrasheed, A.M.; Alemadi, F.A.; Bonthula, S.; Fares, E.; Boddula, R.; Radwan, A.B.; Al-Qahtani, N. Effect of Alumina as an Anti-Soiling Nanomaterial for Enhancing Photovoltaic Performance. Mater. Proc. 2024, 18, 2. https://doi.org/10.3390/materproc2024018002

Alardah AHS, Alrasheed AM, Alemadi FA, Bonthula S, Fares E, Boddula R, Radwan AB, Al-Qahtani N. Effect of Alumina as an Anti-Soiling Nanomaterial for Enhancing Photovoltaic Performance. Materials Proceedings. 2024; 18(1):2. https://doi.org/10.3390/materproc2024018002

Chicago/Turabian StyleAlardah, Ala H. S., Alfajer M. Alrasheed, Fatima Ahmad Alemadi, Sumalatha Bonthula, Enas Fares, Rajender Boddula, Ahmed Bahgat Radwan, and Noora Al-Qahtani. 2024. "Effect of Alumina as an Anti-Soiling Nanomaterial for Enhancing Photovoltaic Performance" Materials Proceedings 18, no. 1: 2. https://doi.org/10.3390/materproc2024018002

APA StyleAlardah, A. H. S., Alrasheed, A. M., Alemadi, F. A., Bonthula, S., Fares, E., Boddula, R., Radwan, A. B., & Al-Qahtani, N. (2024). Effect of Alumina as an Anti-Soiling Nanomaterial for Enhancing Photovoltaic Performance. Materials Proceedings, 18(1), 2. https://doi.org/10.3390/materproc2024018002