Transport Cost Estimation Model of the Agroforestry Biomass in a Small-Scale Energy Chain †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area and Biomass Power Plant

2.2. Biomass Estimation

- green urban area (GUA); considering an average density of 80 trees ha−1, intervention cycles repeated every 8 years, with an estimated production of 16–32 Mg ha−1;

- sports and recreational facilities (SLF); like GUA, but considering a lower average density, 50 trees ha−1, with an average production of 10.4–20.0 Mg ha−1, and with pruning every 8 years;

- vineyards (VIY); pruning biomass of about 0.7–1.0 kg tree−1; density of 3000–4000 trees ha−1; with annual pruning;

- fruit trees and berry plantations (FBP); plantation density about 400–500 trees ha−1; pruning production estimated at 5.0–7.0 kg tree−1;

- olive grove (OGR); planting density about 180–300 trees ha−1, production of 20.0–27.0 kg tree−1, with pruning every two years;

- complex cultivation models (CCP); considering 130–260 trees ha−1, biomass production of 2.0–4.0 Mg ha−1, pruning every two years;

- land mainly occupied by agriculture (LOA); considering a density of about 400–500 trees ha−1, biomass production about 2.0–3.5 Mg ha−1, pruning every year;

- forests (FOR); considering mainly broad-leaved woods, coppices with residual biomass production of 19–26 Mg ha−1, in 25-year cycles.

2.3. Transport Cost Evaluation Model

| CTB | biomass transport cost per Mg (€ Mg−1); |

| Ttr | roundtrip travel time, obtained doubling the return travel time of the loaded truck (h); |

| Tlu | time required for loading and unloading operations (h); |

| Ctr | hourly cost of the truck (€ h−1); |

| Clo | hourly cost of the loader (€ h−1); |

| tcl | transferring coefficient; |

| Ctl | hourly cost of the truck that transfer the loader to destination and return (€ h−1); |

| bl | average biomass load considered per travel (t). |

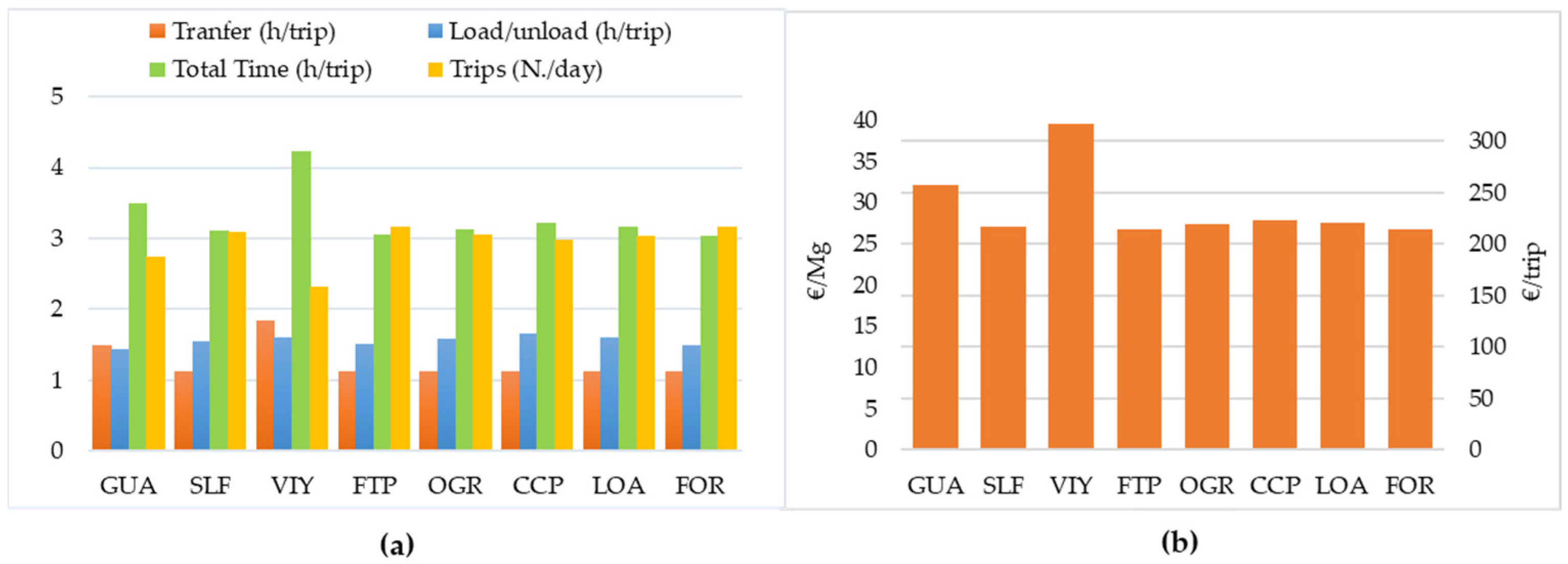

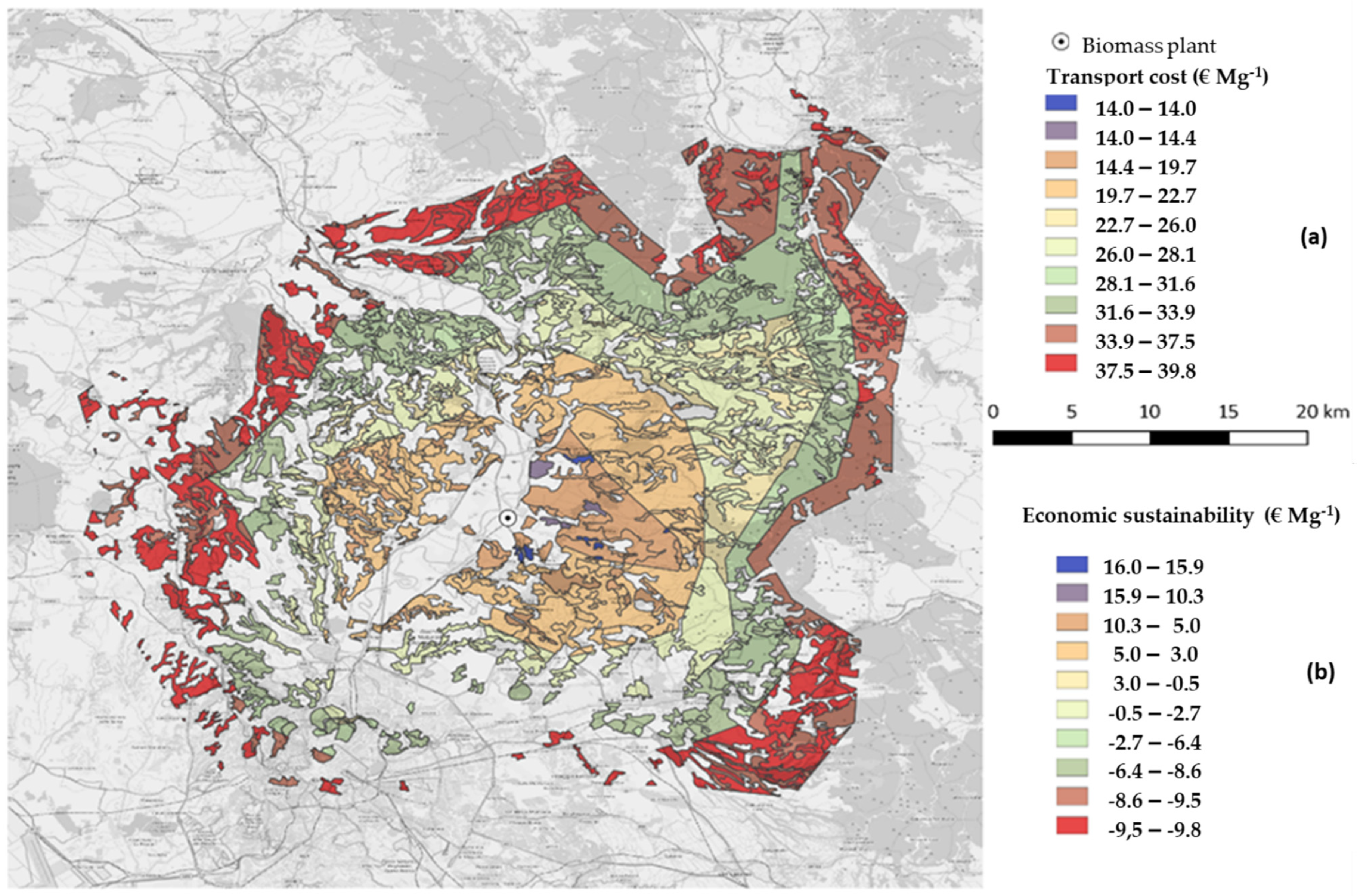

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nishiguchi, S.; Tabata, T. Assessment of social, economic, and environmental aspects of woody biomass energy utilization: Direct burning and wood pellets. Renew. Sustain. Energy Rev. 2016, 57, 1279–1286. [Google Scholar] [CrossRef]

- Tziolas, E.; Manos, B.; Bournaris, T. Planning of agro-energy districts for optimum farm income and biomass energy from crops residues. Oper. Res. 2017, 17, 535–546. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Ronda, A.; Zamora, M.C.; Calero, M. Torrefaction of olive tree pruning: Effect of operating conditions on solid product properties. Fuel 2017, 202, 109–117. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T.; Marinescu, M.; Röser, D. Strategic optimization of forest residues to bioenergy and biofuel supply chain. Int. J. Energy Res. 2015, 39, 439–452. [Google Scholar] [CrossRef]

- Paulo, H.; Azcue, X.; Barbosa, A.P.; Relvas, S. Supply chain optimization of residual forestry biomass for bioenergy production: The case study of Portugal. Biomass Bioenergy 2015, 83, 245–256. [Google Scholar] [CrossRef]

- Sierk de Jong, S.; Hoefnagels, R.; Wetterlund, E.; Pettersson, K.; Faaij, A.; Junginger, M. Cost optimization of biofuel production—The impact of scale, integration, transport and supply chain configurations. Appl. Energy 2017, 195, 1055–1070. [Google Scholar] [CrossRef]

- Zhang, Y.; Qinb, C.; Liuc, Y. Effects of population density of a village and town system on the transportation cost for a biomass combined heat and power plant. J. Environ. Manag. 2018, 223, 444–451. [Google Scholar] [CrossRef] [PubMed]

- Verani, S.; Sperandio, G.; Picchio, R.; Marchi, E.; Costa, C. Sustainability Assessment of a Self-Consumption Wood-Energy Chain on Small Scale for Heat Generation in Central Italy. Energies 2015, 8, 5182–5197. [Google Scholar] [CrossRef]

- Bascietto, M.; Sperandio, G.; Bajocco, S. Efficient Estimation of Biomass from Residual Agroforestry. ISPRS Int. J. Geo-Inf. 2020, 9, 21. [Google Scholar] [CrossRef]

- Luxen, D.; Vetter, C. Real-time routing with OpenStreetMap data. In Proceedings of the 19th ACM SIGSPATIAL International Conference on Advances in Geographic Information Systems, Chicago, IL, USA, 1–4 November 2011; ACM: New York, NY, USA, 2011; pp. 513–516. [Google Scholar]

- Miyata, E.S. Determining Fixed and Operating Costs of Logging Equipment; General Technical Report NC-55; Department of Agriculture, Forest Service, North Central Forest Experiment Station: St. Paul, MN, USA, 1980. [Google Scholar]

- Paolotti, L.; Martino, G.; Marchini, A.; Boggia, A. Economic and environmental assessment of agro-energy wood biomass supply chains. Biomass Bioenergy 2017, 97, 172–185. [Google Scholar] [CrossRef]

- Zahraee, S.M.; Shiwakoti, N.; Stasinopoulos, P. Biomass supply chain environmental and socio-economic analysis: 40-Years comprehensive review of methods, decision issues, sustainability challenges, and the way forward. Biomass Bioenergy 2020, 142, 105777. [Google Scholar] [CrossRef]

| Typology | L3 | L2 | L1 | L0 |

|---|---|---|---|---|

| 4.00 | 3.00 | 2.00 | 0.00 |

| 2.50 | 1.90 | 1.30 | 0.00 |

| 3.00 | 2.55 | 2.10 | 0.00 |

| 3.50 | 2.75 | 2.00 | 0.00 |

| 4.00 | 2.90 | 1.80 | 0.00 |

| 2.00 | 1.50 | 1.00 | 0.00 |

| 3.50 | 2.75 | 2.00 | 0.00 |

| 1.05 | 0.90 | 0.75 | 0.00 |

| Truck for Biomass Transport | Truck for Loader Transport | Forest Loader | |

|---|---|---|---|

| Purchase price (€) | 110,000 | 95,000 | 80,000 |

| Salvage value (€) | 7559 | 6528 | 8590 |

| Life time (years) | 12 | 12 | 10 |

| Total time (h) | 14,400 | 14,400 | 8000 |

| Engine Power (kW) | 309 | 280 | 88 |

| Interest rate (%) | 4.0 | 4.0 | 4.0 |

| Fuel consumption (l h−1) | 25.49 | 23.10 | 9.44 |

| Fuel price (€ l−1) | 1.50 | 1.50 | 1.10 |

| Driver cost (€ h−1) | 21.00 | 21.00 | 15.00 |

| Machine cost (€ h−1) | 71.00 | 64.00 | 35.00 |

| Total operating cost (€ h−1) | 92.00 | 85.00 | 50.00 |

| Typology | Coefficients | ||

|---|---|---|---|

| lc | yc | tc | |

| GUA | 1.00 | 0.20 | 0.37 |

| SLF | 1.05 | 0.29 | 0.34 |

| VIY | 1.15 | 0.21 | 0.43 |

| FTP | 1.05 | 0.21 | 0.33 |

| OGR | 1.10 | 0.23 | 0.34 |

| CCP | 1.10 | 0.30 | 0.35 |

| LOA | 1.15 | 0.21 | 0.34 |

| FOR | 1.00 | 0.27 | 0.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sperandio, G.; Acampora, A.; Civitarese, V.; Bajocco, S.; Bascietto, M. Transport Cost Estimation Model of the Agroforestry Biomass in a Small-Scale Energy Chain. Environ. Sci. Proc. 2021, 3, 22. https://doi.org/10.3390/IECF2020-07891

Sperandio G, Acampora A, Civitarese V, Bajocco S, Bascietto M. Transport Cost Estimation Model of the Agroforestry Biomass in a Small-Scale Energy Chain. Environmental Sciences Proceedings. 2021; 3(1):22. https://doi.org/10.3390/IECF2020-07891

Chicago/Turabian StyleSperandio, Giulio, Andrea Acampora, Vincenzo Civitarese, Sofia Bajocco, and Marco Bascietto. 2021. "Transport Cost Estimation Model of the Agroforestry Biomass in a Small-Scale Energy Chain" Environmental Sciences Proceedings 3, no. 1: 22. https://doi.org/10.3390/IECF2020-07891

APA StyleSperandio, G., Acampora, A., Civitarese, V., Bajocco, S., & Bascietto, M. (2021). Transport Cost Estimation Model of the Agroforestry Biomass in a Small-Scale Energy Chain. Environmental Sciences Proceedings, 3(1), 22. https://doi.org/10.3390/IECF2020-07891