Mechanical Response of Reactive Extruded Biocomposites Based on Recycled Poly(lactic Acid) (R-PLA)/Recycled Polycarbonate (R-PC) and Cellulosic Fibers with Different Aspect Ratios

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Compositions

- R-PLA: It is an industrial processing waste recovered from products obtained through a thermoforming process with PLA2003D (Natureworks LLC, Minnetonka, MN, USA), a thermoplastic resin with a density of 1.24 g/cm3, extrusion grade. The regrinding of the scraps (previously passed through a metal detector to avoid contamination of the material) has been achieved by Romei s.r.l (Florence, Italy), and it is followed by further filtering and homogenization of the granules before subsequent use.

- R-PC: The same process explained in the first bullet point, an example of post-industrial recovery becoming raw material, is used by Romei s.r.l. (Firenze, Italy) to recover, regrind and sieve recycled polycarbonate scraps from thermoformed objects produced with Bisphenol A Polycarbonate grade S3000 (Mitsubishi Chemical Co., Tokyo, Japan) having a density of 1.20 g/cm3.

- CATA: Triacetin (TA), also known as glycerine triacetate, and TetraButylAmmonium TetraPhenylBorate (TBATPB), both purchased from Sigma-Aldrich—Merck, were used as catalysts for interchange reactions. Phuong et al. [32] explained how the reaction occurs from a mechanistic point of view. The interchange reaction of the modified PLA with PC can produce block copolymers with varying lengths and branching points. The presence of branching creates an irregular structure that is probably responsible for the peculiar thermal properties of the blends. In the presence of cellulose fibers, the catalyst will also interact with it due to the hydroxyl groups present on the surface of the cellulose itself.

- Lyocell fibers: Tencel® FCP-10/400 microfibers (Lenzing, Austria) with an aspect ratio of 36 were provided by Lenzing AG, Austria. According to this manufacturer, these fibers have a density of 1.5 g/cm3.

- Arbocel fibers: Two different types of extra short-fibers, kindly provided by J Rettenmaier Sohne® (Rosenberg, Germany), were used:

- ○

- Arb I (ARBOCEL® 600BE/PU) (mean diameter 20 µm, mean fiber length 60 µm, mean aspect ratio 3, bulk density: 200–260 g/L).

- ○

- Arb II (ARBOCEL® BWW40) (mean diameter 20 µm, mean fiber length 200 µm, mean aspect ratio 10, bulk density: 110–145 g/L).

2.2. Processing

2.3. Testing Methodologies

3. Results

3.1. Morphological Evaluation

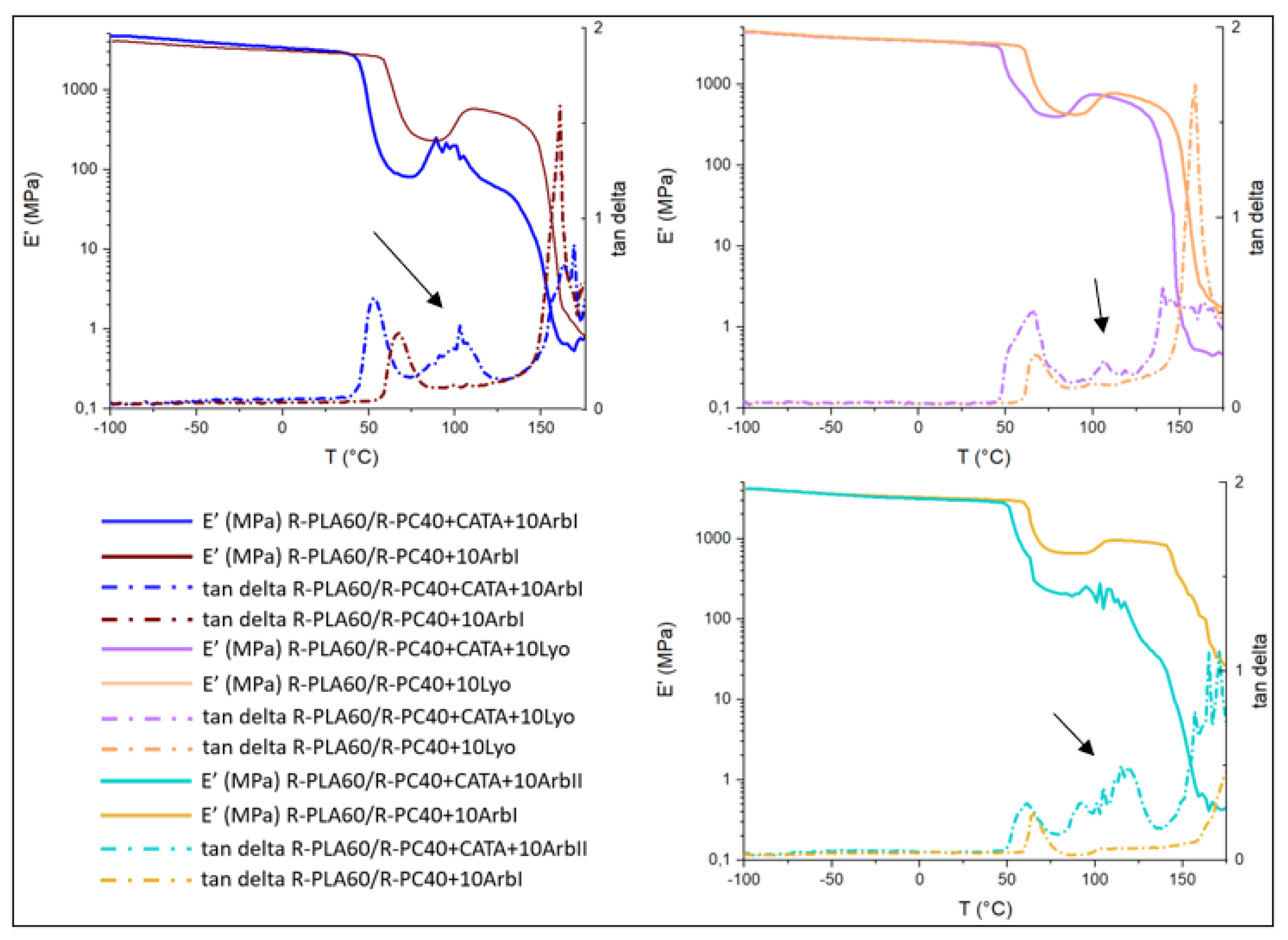

3.2. DMTA Analysis

3.3. Tensile and Impact Properties

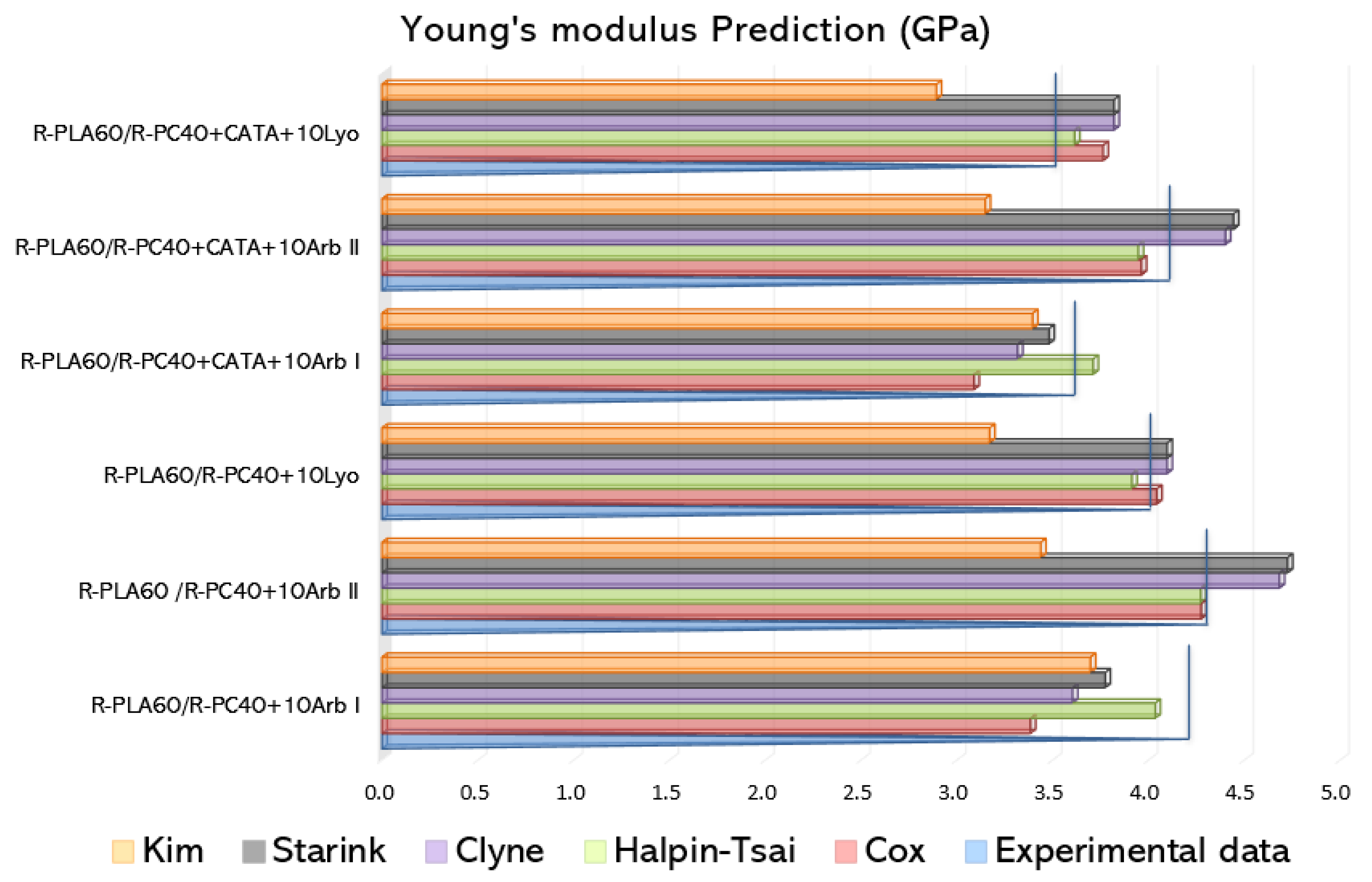

3.4. Elastic Modulus Predictive Models Comparison

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schrijvers, D.; Hool, A.; Blengini, G.A.; Chen, W.-Q.; Dewulf, J.; Eggert, R.; van Ellen, L.; Gauss, R.; Goddin, J.; Habib, K.; et al. A review of methods and data to determine raw material criticality. Resour. Conserv. Recycl. 2020, 155, 104617. [Google Scholar] [CrossRef]

- Muñoz Meneses, R.A.; Cabrera-Papamija, G.; Machuca-Martínez, F.; Rodríguez, L.A.; Diosa, J.E.; Mosquera-Vargas, E. Plastic recycling and their use as raw material for the synthesis of carbonaceous materials. Heliyon 2022, 8, e09028. [Google Scholar] [CrossRef] [PubMed]

- Courgneau, C.; Rusu, D.; Henneuse, C.; Ducruet, V.; Lacrampe, M.F.; Krawczak, P. Characterisation of low-odour emissive polylactide/cellulose fibre biocomposites for car interior. Express Polym. Lett. 2013, 7, 787–804. [Google Scholar] [CrossRef]

- Notta-Cuvier, D.; Odent, J.; Delille, R.; Murariu, M.; Lauro, F.; Raquez, J.M.; Bennani, B.; Dubois, P. Tailoring polylactide (PLA) properties for automotive applications: Effect of addition of designed additives on main mechanical properties. Polym. Test. 2014, 36, 1–9. [Google Scholar] [CrossRef]

- Sukumaran, N.P.; Gopi, S. Overview of biopolymers. In Biopolymers and Their Industrial Applications; Thomas, S., Gopi, S., Amalraj, A.B.T., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–19. ISBN 978-0-12-819240-5. [Google Scholar]

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing Biobased Recyclable Polymers for Plastics. Trends Biotechnol. 2020, 38, 50–67. [Google Scholar] [CrossRef]

- Miller, L.; Soulliere, K.; Sawyer-Beaulieu, S.; Tseng, S.; Tam, E. Challenges and alternatives to plastics recycling in the automotive sector. Materials 2014, 7, 5883–5902. [Google Scholar] [CrossRef] [Green Version]

- Shevchenko, T.; Ranjbari, M.; Shams Esfandabadi, Z.; Danko, Y.; Bliumska-Danko, K. Promising Developments in Bio-Based Products as Alternatives to Conventional Plastics to Enable Circular Economy in Ukraine. Recycling 2022, 7, 20. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M.; Botta, L.; Mistretta, M.C.; Ceraulo, M.; Scaffaro, R. Degradation of polymer blends: A brief review. Polym. Degrad. Stab. 2017, 145, 79–92. [Google Scholar] [CrossRef]

- Blanco, I.; Ingrao, C.; Siracusa, V. Life-Cycle Assessment in the Polymeric Sector: A Comprehensive Review of Application Experiences on the Italian Scale. Polymers 2020, 12, 1212. [Google Scholar] [CrossRef]

- Sarasini, F.; Fiore, V. A systematic literature review on less common natural fibres and their biocomposites. J. Clean. Prod. 2018, 195, 240–267. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F. Heavy vehicles on the road towards the circular economy: Analysis and comparison with the automotive industry. Resour. Conserv. Recycl. 2018, 135, 108–122. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.; Cinelli, P.; Lazzeri, A. Evaluation of Mechanical and Interfacial Properties of Bio-Composites Based on Poly(Lactic Acid) with Natural Cellulose Fibers. Int. J. Mol. Sci. 2019, 20, 960. [Google Scholar] [CrossRef] [Green Version]

- Gigante, V.; Aliotta, L.; Phuong, V.T.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Effects of waviness on fiber-length distribution and interfacial shear strength of natural fibers reinforced composites. Compos. Sci. Technol. 2017, 152, 129–138. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Garrison, T.F.; Murawski, A.; Quirino, R.L. Bio-Based Polymers with Potential for Biodegradability. Polymers 2016, 8, 262. [Google Scholar] [CrossRef]

- Lee, C.; Pang, M.M.; Koay, S.C.; Choo, H.L.; Tshai, K.Y. Talc filled polylactic-acid biobased polymer composites: Tensile, thermal and morphological properties. SN Appl. Sci. 2020, 2, 354. [Google Scholar] [CrossRef] [Green Version]

- Gigante, V.; Canesi, I.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rubber Toughening of Polylactic Acid (PLA) with Poly(butylene adipate-co-terephthalate) (PBAT): Mechanical Properties, Fracture Mechanics and Analysis of Ductile-to-Brittle Behavior while Varying Temperature and Test Speed. Eur. Polym. J. 2019, 115, 125–137. [Google Scholar] [CrossRef]

- Aliotta, L.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rigid filler toughening in PLA-Calcium Carbonate composites: Effect of particle surface treatment and matrix plasticization. Eur. Polym. J. 2019, 113, 78–88. [Google Scholar] [CrossRef]

- Delbreilh, L.; Dargent, E.; Grenet, J.; Saiter, J.-M.; Bernès, A.; Lacabanne, C. Study of poly(bisphenol A carbonate) relaxation kinetics at the glass transition temperature. Eur. Polym. J. 2007, 43, 249–254. [Google Scholar] [CrossRef]

- Nevalainen, K.; Vuorinen, J.; Villman, V.; Suihkonen, R.; Järvelä, P.; Sundelin, J.; Lepistö, T. Characterization of twin-screw-extruder-compounded polycarbonate nanoclay composites. Polym. Eng. Sci. 2009, 49, 631–640. [Google Scholar] [CrossRef]

- Aid, S.; Eddhahak, A.; Ortega, Z.; Froelich, D.; Tcharkhtchi, A. Experimental study of the miscibility of ABS/PC polymer blends and investigation of the processing effect. J. Appl. Polym. Sci. 2017, 134, 1–9. [Google Scholar] [CrossRef]

- Ganguly, A.; Channe, P.; Jha, R.; Mitra, S.; Saha, S. Review on transesterification in polycarbonate–poly(butylene terephthalate) blend. Polym. Eng. Sci. 2021, 61, 650–661. [Google Scholar] [CrossRef]

- Van den Oever, M.; Molenveld, K. Replacing fossil based plastic performance products by bio-based plastic products—Technical feasibility. N. Biotechnol. 2017, 37, 48–59. [Google Scholar] [CrossRef] [PubMed]

- Tien, N.-D.; Prud’homme, R.E. Crystallization Behavior of Semicrystalline Immiscible Polymer Blends. In Crystallization in Multiphase Polymer Systems; Thomas, S., Arif, P.M., Gowd, E.B., Kalarikkal, N.B.T.-C., Eds.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 181–212. ISBN 978-0-12-809453-2. [Google Scholar]

- Liu, C.; Lin, S.; Zhou, C.; Yu, W. Influence of catalyst on transesterification between poly(lactic acid) and polycarbonate under flow field. Polymer 2013, 54, 310–319. [Google Scholar] [CrossRef]

- Zhou, L.; Zhao, G.; Jiang, W. Effects of Catalytic Transesterification and Composition on the Toughness of Poly(lactic acid)/Poly(propylene carbonate) Blends. Ind. Eng. Chem. Res. 2016, 55, 5565–5573. [Google Scholar] [CrossRef]

- Chelghoum, N.; Guessoum, M.; Fois, M.; Haddaoui, N. Contribution of Catalytic Transesterification Reactions to the Compatibilization of Poly(lactic acid)/Polycarbonate Blends: Thermal, Morphological and Viscoelastic Characterization. J. Polym. Environ. 2018, 26, 342–354. [Google Scholar] [CrossRef]

- Phuong, V.T.; Coltelli, M.-B.; Anguillesi, I.; Cinelli, P.; Lazzeri, A. Modification of the mechanical behavior in the glass transition region of poly(lactic acid) (PLA) through catalyzed reactive extrusion with poly(carbonate) (PC). In Proceedings of the AIP Conference Proceedings, 7th International Conference on Times of Polymers (TOP) and Composites 2014, Ischia, Italy, 22–26 June 2014; American Institute of Physics: College Park, MD, USA, 2014; Volume 1599, pp. 142–145. [Google Scholar]

- Penco, M.; Lazzeri, A.; Phuong, V.T.; Cinelli, P. Copolymers Based on Polyester and Aromatic Polycarbonate. WO2012025907A1, 26 August 2011. [Google Scholar]

- Phuong, V.T.; Coltelli, M.-B.B.; Cinelli, P.; Cifelli, M.; Verstichel, S.; Lazzeri, A. Compatibilization and property enhancement of poly(lactic acid)/polycarbonate blends through triacetin-mediated interchange reactions in the melt. Polymer 2014, 55, 4498–4513. [Google Scholar] [CrossRef]

- Phuong, V.T.; Gigante, V.; Aliotta, L.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Reactively extruded ecocomposites based on poly(lactic acid)/bisphenol A polycarbonate blends reinforced with regenerated cellulose microfibers. Compos. Sci. Technol. 2017, 139, 127–137. [Google Scholar] [CrossRef]

- Srithep, Y.; Rungseesantivanon, W.; Hararak, B.; Suchiva, K. Processing and characterization of poly(lactic acid) blended with polycarbonate and chain extender. J. Polym. Eng. 2014, 34, 665–672. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Lin, G.-P.; Wang, Y.-Z. Super Toughened and High Heat-Resistant Poly(Lactic Acid) (PLA)-Based Blends by Enhancing Interfacial Bonding and PLA Phase Crystallization. Ind. Eng. Chem. Res. 2015, 54, 5643–5655. [Google Scholar] [CrossRef]

- Wei, L.; Stark, N.M.; McDonald, A.G. Interfacial improvements in biocomposites based on poly (3-hydroxybutyrate) and poly (3-hydroxybutyrate-co-3-hydroxyvalerate) bioplastics reinforced and grafted with α-cellulose fibers. Green Chem. 2015, 17, 4800–4814. [Google Scholar] [CrossRef]

- Rahman, A.; Fehrenbach, J.; Ulven, C.; Simsek, S.; Hossain, K. Utilization of wheat-bran cellulosic fibers as reinforcement in bio-based polypropylene composite. Ind. Crops Prod. 2021, 172, 114028. [Google Scholar] [CrossRef]

- Shesan, O.J.; Stephen, A.C.; Chioma, A.G.; Neerish, R.; Rotimi, S.E. Fiber-Matrix Relationship for Composites Preparation. In Renewable and Sustainable Composites; Stephen, A.C., Ed.; IntechOpen: Rijeka, Croatia, 2019; Chapter 2; ISBN 978-1-78984-216-6. [Google Scholar]

- Karami, G.; Garnich, M. Micromechanical study of thermoelastic behavior of composites with periodic fiber waviness. Compos. Part B Eng. 2005, 36, 241–248. [Google Scholar] [CrossRef]

- Aliotta, L.; Vannozzi, A.; Panariello, L.; Gigante, V.; Coltelli, M.-B.; Lazzeri, A. Sustainable Micro and Nano Additives for Controlling the Migration of a Biobased Plasticizer from PLA-Based Flexible Films. Polymers 2020, 12, 1366. [Google Scholar] [CrossRef]

- Scatto, M.; Salmini, E.; Castiello, S.; Coltelli, M.B.; Conzatti, L.; Stagnaro, P.; Andreotti, L.; Bronco, S. Plasticized and nanofilled poly(lactic acid)-based cast films: Effect of plasticizer and organoclay on processability and final properties. J. Appl. Polym. Sci. 2013, 127, 4947–4956. [Google Scholar] [CrossRef]

- Cristea, M.; Ionita, D.; Iftime, M.M. Dynamic Mechanical Analysis Investigations of PLA-Based Renewable Materials: How Are They Useful? Materials 2020, 13, 5302. [Google Scholar] [CrossRef]

- Bourkas, G.; Prassianakis, I.; Kytopoulos, V.; Sideridis, E.; Younis, C. Estimation of Elastic Moduli of Particulate Composites by New Models and Comparison with Moduli Measured by Tension, Dynamic, and Ultrasonic Tests. Adv. Mater. Sci. Eng. 2010, 2010, 891824. [Google Scholar] [CrossRef] [Green Version]

- Cordin, M.; Bechtold, T.; Pham, T. Effect of fibre orientation on the mechanical properties of polypropylene–lyocell composites. Cellulose 2018, 25, 7197–7210. [Google Scholar] [CrossRef] [Green Version]

- Bogoeva-Gaceva, G.; Avella, M.; Malinconico, M.; Buzarovska, A.; Grozdanov, A.; Gentile, G.; Errico, M.E. Natural fiber eco-composites. Polym. Compos. 2007, 28, 98–107. [Google Scholar] [CrossRef]

- Akrivos, V.; Muransky, O.; Depradeux, L.; Smith, M.C.; Vasileiou, A.; Deaconu, V.; Kapadia, P. On the Accurate Prediction of Residual Stress in a Three-Pass Slot Nickel-Base Repair Weld by Numerical Simulations. J. Manuf. Mater. Process. 2022, 6, 61. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Clyne, T.W. A simple development of the shear lag theory appropriate for composites with a relatively small modulus mismatch. Mater. Sci. Eng. A 1989, 122, 183–192. [Google Scholar] [CrossRef]

- Starink, M.J.; Syngellakis, S. Shear lag models for discontinuous composites: Fibre end stresses and weak interface layers. Mater. Sci. Eng. A 1999, 270, 270–277. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.G. Effects of fiber aspect ratio evaluated by elastic analysis in discontinuous composites. J. Mech. Sci. Technol. 2008, 22, 411. [Google Scholar] [CrossRef]

- Andersons, J.; Kirpluks, M.; Cabulis, U. Reinforcement Efficiency of Cellulose Microfibers for the Tensile Stiffness and Strength of Rigid Low-Density Polyurethane Foams. Materials 2020, 13, 2725. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Young, R.J. The Young’s modulus of a microcrystalline cellulose. Cellulose 2001, 8, 197–207. [Google Scholar] [CrossRef]

- Luo, Z.; Li, X.; Shang, J.; Zhu, H.; Fang, D. Modified rule of mixtures and Halpin–Tsai model for prediction of tensile strength of micron-sized reinforced composites and Young’s modulus of multiscale reinforced composites for direct extrusion fabrication. Adv. Mech. Eng. 2018, 10, 168781401878528. [Google Scholar] [CrossRef]

- Aliotta, L.; Lazzeri, A. A proposal to modify the Kelly-Tyson equation to calculate the interfacial shear strength (IFSS) of composites with low aspect ratio fibers. Compos. Sci. Technol. 2020, 186, 107920. [Google Scholar] [CrossRef]

| Formulation | R-PLA (wt. %) | R-PC (wt. %) | Arb I (wt. %) | Arb II (wt. %) | Lyocell (wt. %) | TA (wt. %) | TBATPB (wt. %) |

|---|---|---|---|---|---|---|---|

| R-PLA60/R-PC40 + 10ArbI | 54 | 36 | 10 | - | - | - | - |

| R-PLA60/R-PC40 + 10ArbII | 54 | 36 | - | 10 | - | - | - |

| R-PLA60/R-PC40 + 10Lyo | 54 | 36 | - | - | 10 | - | - |

| R-PLA60/R-PC40 + 10ArbI + CATA | 50.9 | 33.9 | 10 | - | - | 5 | 0.2 |

| R-PLA60/R-PC40 + 10ArbII + CATA | 50.9 | 33.9 | - | 10 | - | 5 | 0.2 |

| R-PLA60/R-PC40 + 10Lyo + CATA | 50.9 | 33.9 | - | - | 10 | 5 | 0.2 |

| Model | Ecomposite |

|---|---|

| Cox | |

| Halpin-Tsai | |

| Clyne | |

| Starink | |

| Kim |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gigante, V.; Aliotta, L.; Coltelli, M.-B.; Lazzeri, A. Mechanical Response of Reactive Extruded Biocomposites Based on Recycled Poly(lactic Acid) (R-PLA)/Recycled Polycarbonate (R-PC) and Cellulosic Fibers with Different Aspect Ratios. Macromol 2022, 2, 509-521. https://doi.org/10.3390/macromol2040032

Gigante V, Aliotta L, Coltelli M-B, Lazzeri A. Mechanical Response of Reactive Extruded Biocomposites Based on Recycled Poly(lactic Acid) (R-PLA)/Recycled Polycarbonate (R-PC) and Cellulosic Fibers with Different Aspect Ratios. Macromol. 2022; 2(4):509-521. https://doi.org/10.3390/macromol2040032

Chicago/Turabian StyleGigante, Vito, Laura Aliotta, Maria-Beatrice Coltelli, and Andrea Lazzeri. 2022. "Mechanical Response of Reactive Extruded Biocomposites Based on Recycled Poly(lactic Acid) (R-PLA)/Recycled Polycarbonate (R-PC) and Cellulosic Fibers with Different Aspect Ratios" Macromol 2, no. 4: 509-521. https://doi.org/10.3390/macromol2040032

APA StyleGigante, V., Aliotta, L., Coltelli, M.-B., & Lazzeri, A. (2022). Mechanical Response of Reactive Extruded Biocomposites Based on Recycled Poly(lactic Acid) (R-PLA)/Recycled Polycarbonate (R-PC) and Cellulosic Fibers with Different Aspect Ratios. Macromol, 2(4), 509-521. https://doi.org/10.3390/macromol2040032