Opportunities and Limitations in Recycling Fossil Polymers from Textiles

Abstract

:1. Introduction: The Current Situation Regarding Textile Products

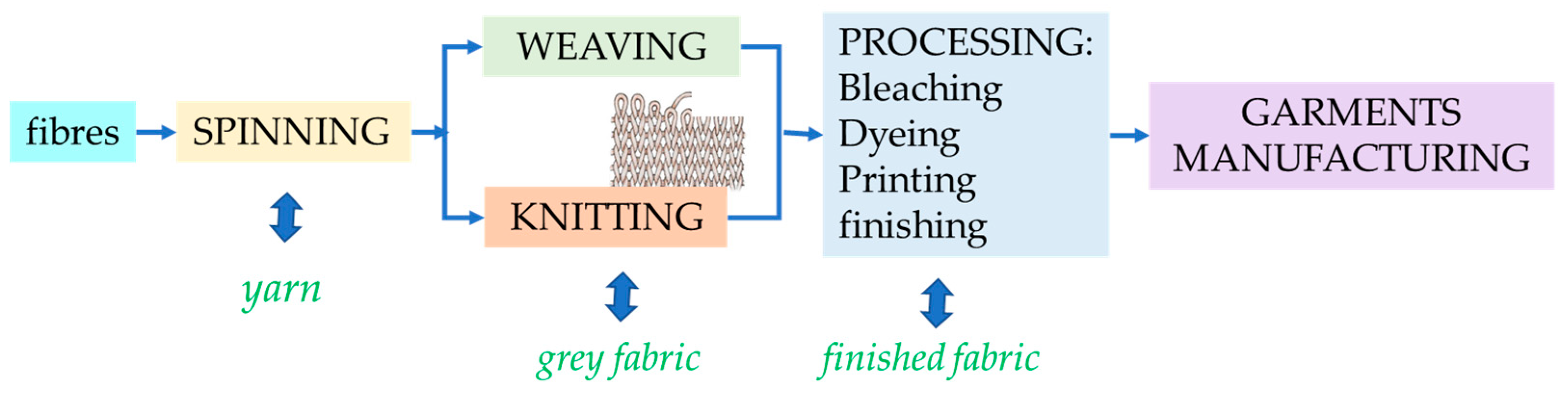

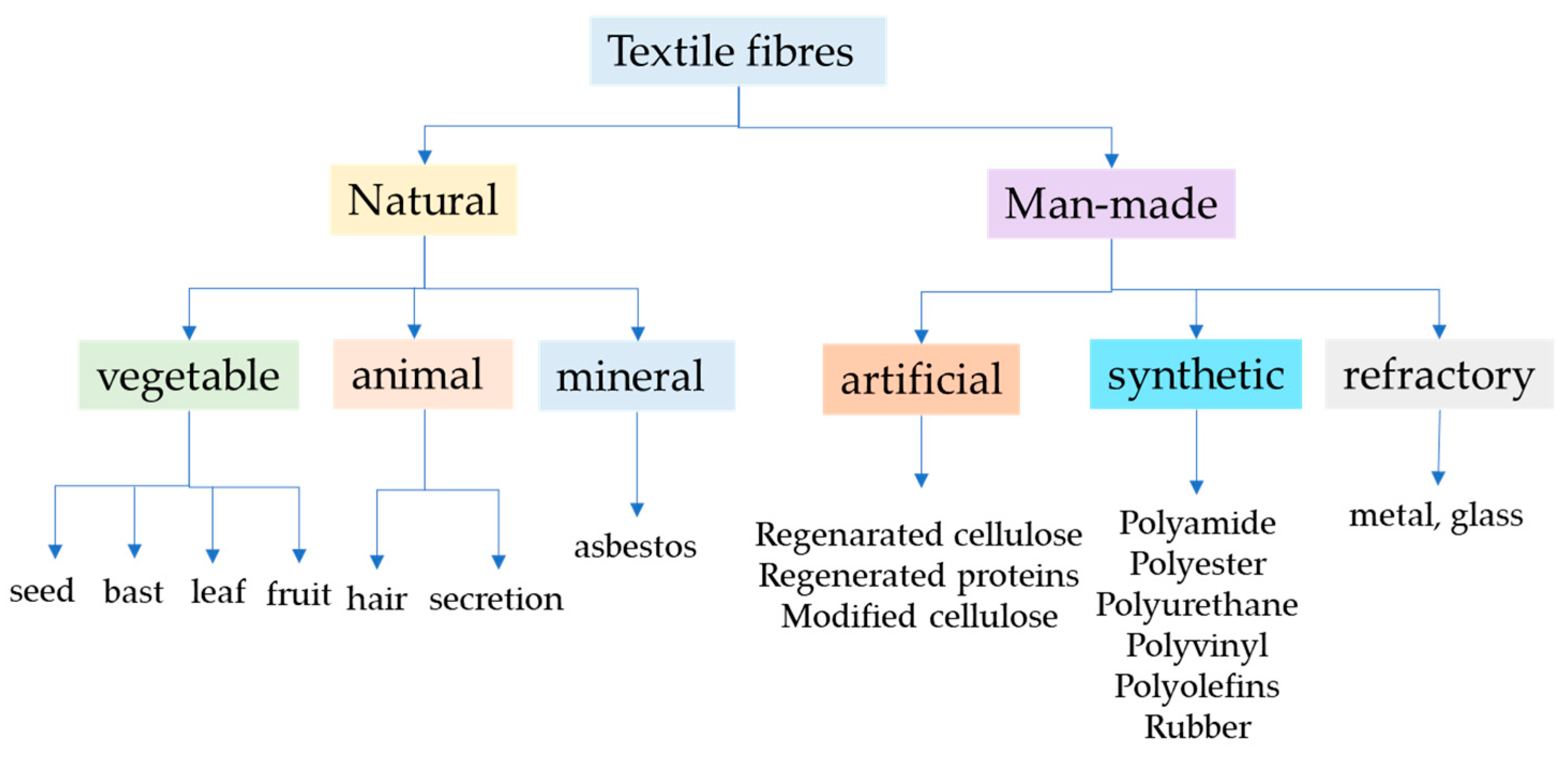

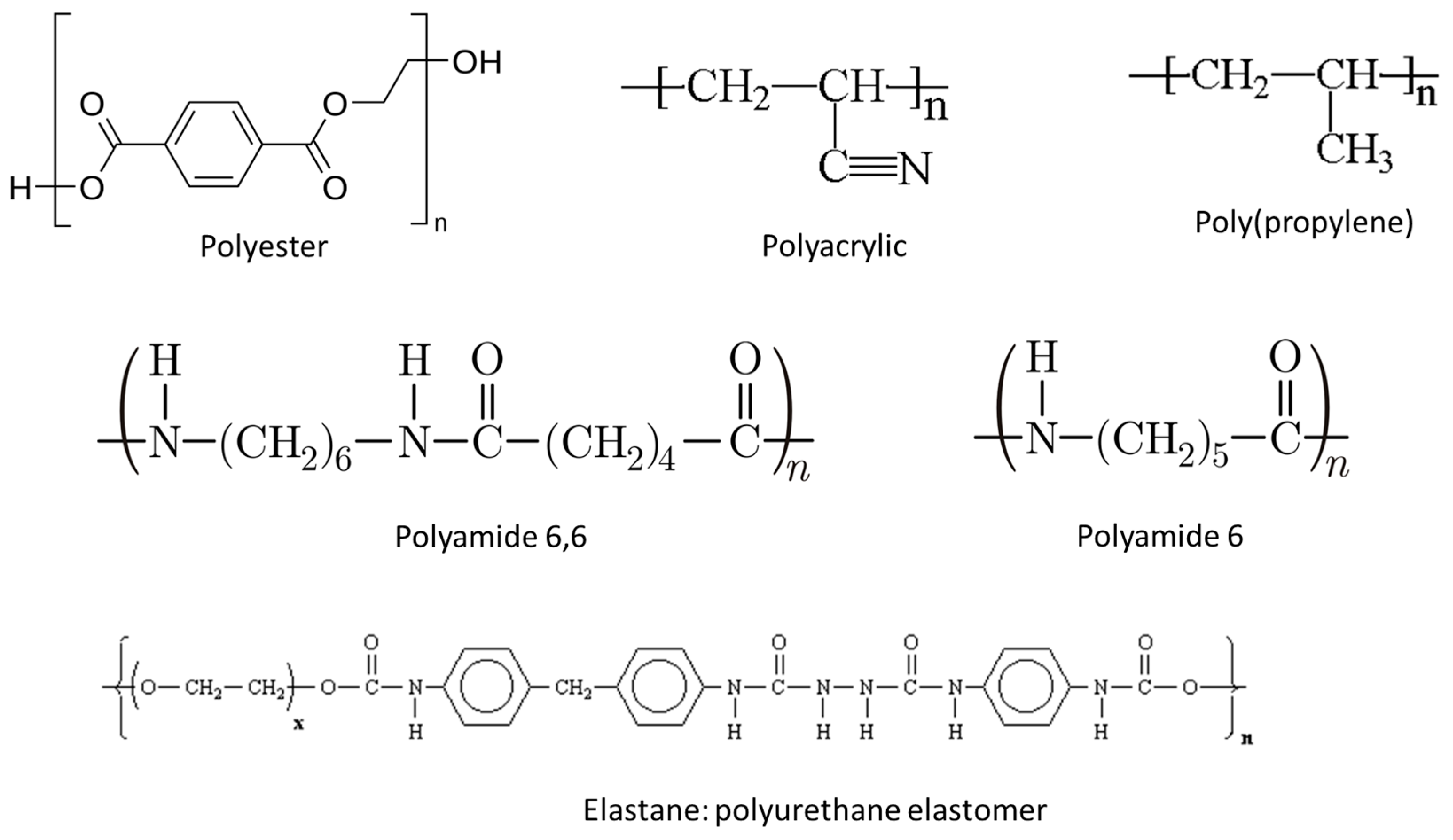

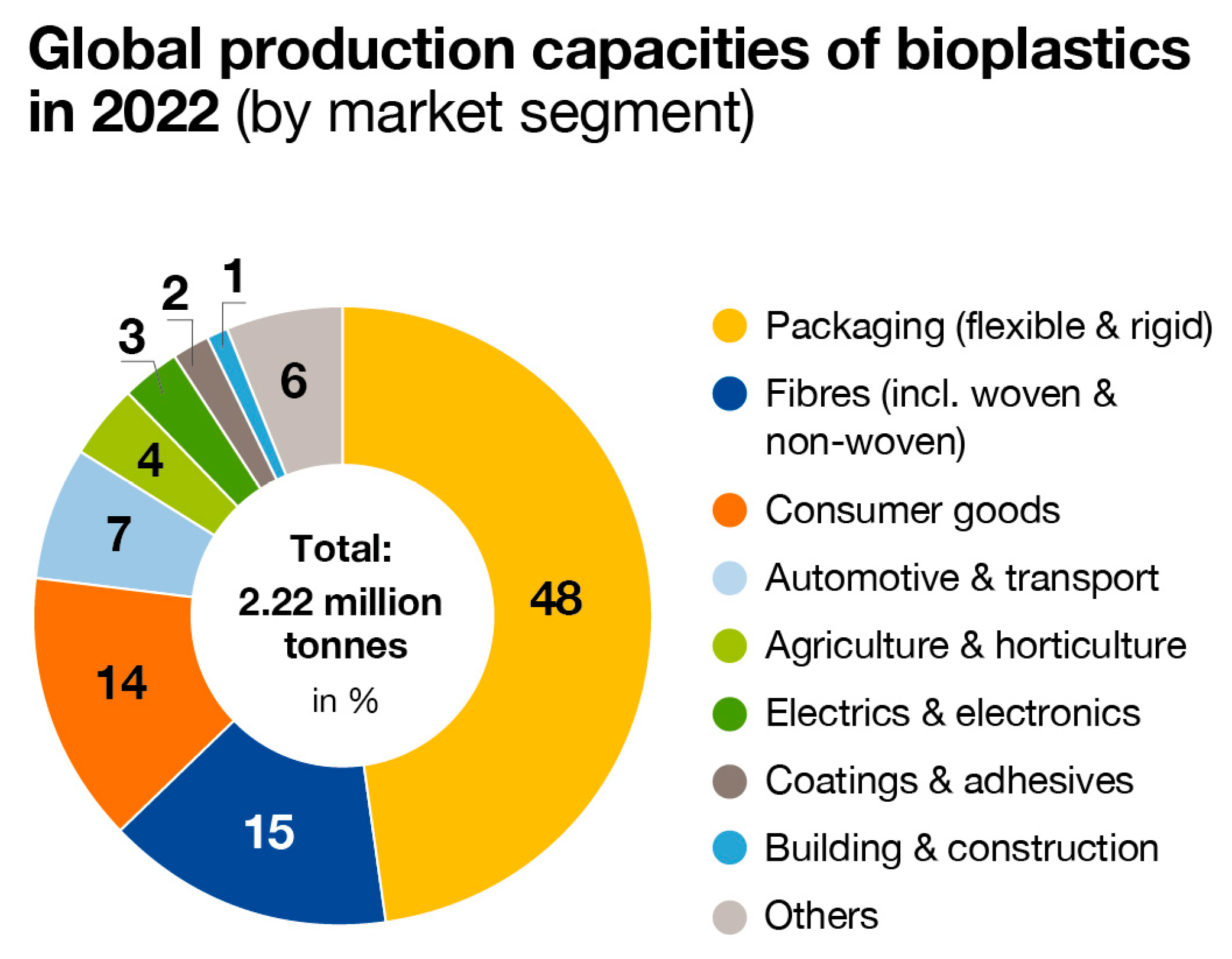

1.1. Fibres Used in Textile Products

- Cellulosics, which originate from various parts of plants

- Protein fibres, which are obtained from wool, hair and silk

- Mineral fibres, where asbestos is the only one naturally occurring

- Regenerated fibres, consisting of natural polymers, mainly cellulose, that were chemically modified

- Synthetic fibres, which are produced from monomers by polymerization

- Inorganic fibres, such as glass or ceramic fibres

1.2. Microplastics Issue

1.3. Policy Initiatives

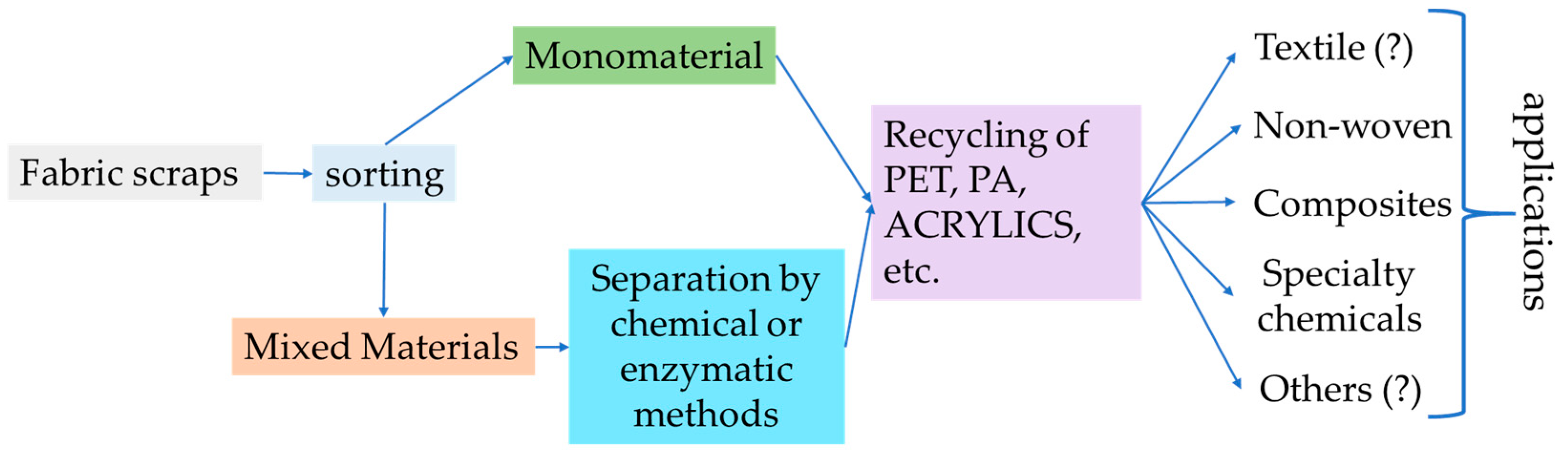

2. Sorting of Textiles: Techniques and Facilities

2.1. Sorting Methodologies

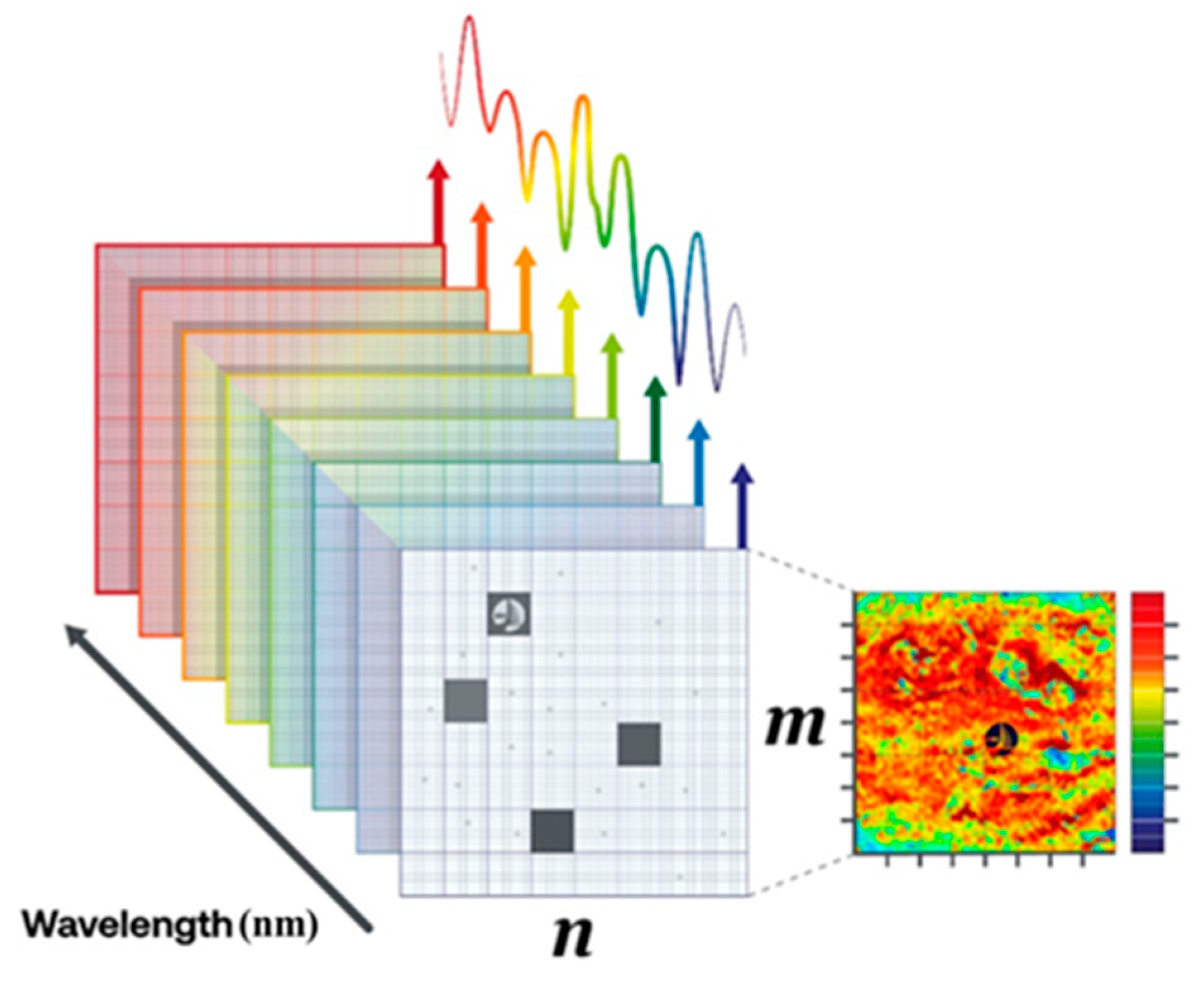

2.2. The Advent of Near-Infrared Spectroscopy in Textile Sorting

2.3. Industrial Applications of Sorting

- sorting and preparing used textiles for recycling in the Amsterdam Area, “so that we become a hub for circular textiles and circular denim”, as alderman Marieke van Doorninck said [86];

- sorting the post-consumer textiles by material into various fibre classes using optical identification technology developed by Lounais-Suomen Jätehuolto Oy (LSJH), a company owned by 17 municipalities in South-West Finland [87].

3. Recycling Fossil Polymers

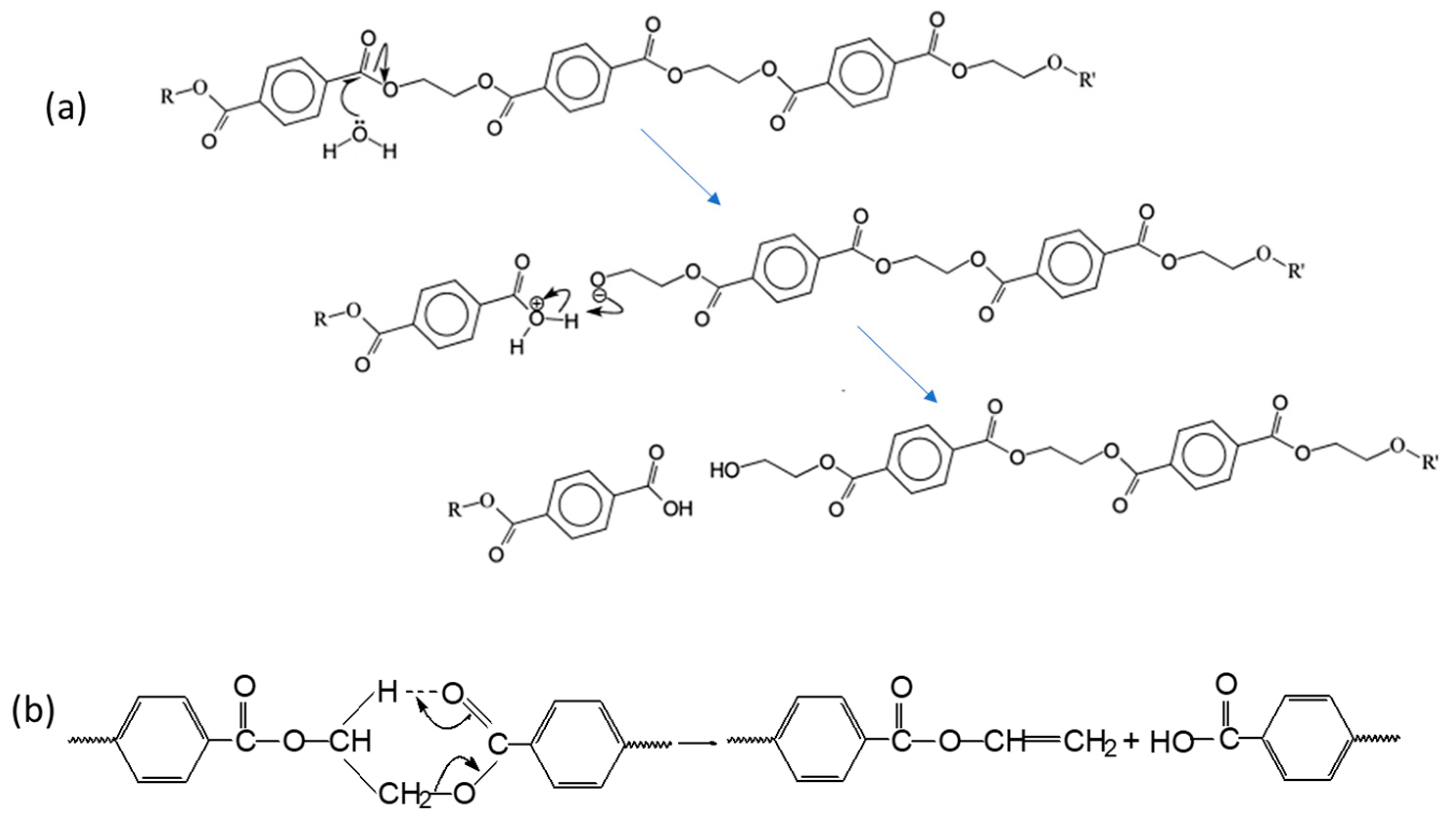

3.1. Polyester

3.2. Polyamide

3.3. Acrylic

3.4. The Case of Elastan in Mixed Polymer Fabrics Recycling

3.5. Non-Woven Production Using Recycled Fibres

- Adding an adhesive.

- Thermally fusing the fibres to each other or to the other thermoplastic fibres or powders.

- Fusing fibres by first dissolving and then re-solidifying their surfaces.

- Creating physical tangles or tuft among the fibres.

- Stitching the fibres or filaments in place.

- (a)

- spunlace non-wovens;

- (b)

- Heat-bonded non-woven fabrics

- (c)

- pulp air-laid non-wovens

- (d)

- Wet-laid non-woven

- (e)

- Spunbond non-wovens

- (f)

- Acupuncture non-wovens

- (g)

- Stitch non-wovens

3.6. Composite Production Using Waste Textile

3.7. Chemical Recycling to Obtain Separated Materials, Monomers or New Products

3.8. Enzimatic Recycling: To Monomers or New Products

4. Limitations in Textile Recycling

5. Conclusions and Perspectives

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patti, A.; Acierno, D. Towards the Sustainability of the Plastic Industry through Biopolymers: Properties and Potential Applications to the Textiles World. Polymers 2022, 14, 692. [Google Scholar] [CrossRef] [PubMed]

- Granskog, A.; Lee, L. The Fashion Industry Can Reduce Emissions across The Entire Valuechain, 2020 MacKinsey& Company Report, New York, USA. Available online: https://www.mckinsey.com/capabilities/sustainability/our-insights/sustainability-blog/the-fashion-industry-can-reduce-emissions-across-the-entire-value-chain (accessed on 10 February 2023).

- Sajn, N. Environmental Impact of the Textile and Clothing Industry, 2019. European Parliamentary Research Service, Bruxelles, Belgium. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2019/633143/EPRS_BRI(2019)633143_EN.pdf (accessed on 10 February 2023).

- Amed, I.; Berg, A.; Chandani, A.; Hedrich, A.; Jensen, J.E.; Straub, M. The State of Fashion 2022.BOF Report 2022, MacKinsey & Company. Available online: https://www.mckinsey.com/~/media/mckinsey/industries/retail/our%20insights/state%20of%20fashion/2022/the-state-of-fashion-2022.pdf (accessed on 10 February 2023).

- EllenMacArthur Foundation. Available online: www.ellenmacarthurfoundation.org (accessed on 10 February 2023).

- Morganti, P.; Coltelli, M.B. An Introduction to The Circular Economy, 1st ed.; Nova Science Publishers: New York, NY, USA, 2021; pp. 9–51. [Google Scholar]

- Ellen MacArthur Foundation, Circular Business Models: Rethinking Business Models for a Thriving Fashion Industry. Available online: https://ellenmacarthurfoundation.org/fashion-business-models/overview (accessed on 10 February 2023).

- Lu, J.J.; Hamouda, H. Current Status of Fibre Waste Recycling and its Future. Adv. Mater. Res. 2014, 878, 122–131. [Google Scholar] [CrossRef]

- Peterson, A. Towards Recycling of Textile Fibres. Master Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2015; pp. 8–18. Available online: https://odr.chalmers.se/bitstream/20.500.12380/218483/1/218483.pdf (accessed on 10 February 2023).

- Amicarelli, V.; Bux, C. Quantifying textile streams and recycling prospects in Europe by material flow analysis. Environ. Impact Assess. Rev. 2022, 97, 106878. [Google Scholar] [CrossRef]

- Schumacher, K.A.; Forster, A.L. Textiles in a circular economy: An assessment of the current landscape, challenges, and opportunities in the United States. Front. Sustain. 2022, 3, 1038323. [Google Scholar] [CrossRef]

- Uddin, F. Introductory Chapter: Textile Manufacturing Processes, IntechOpen, 2019. Available online: https://www.intechopen.com/chapters/68157 (accessed on 10 February 2023). [CrossRef] [Green Version]

- Nawab, Y. (Ed.) Textile Engineering: An Introduction; De Gruyter: Berlin, Germany, 2016; pp. 172–184. [Google Scholar]

- Shabbir, M.; Ahmed, S.; Sheikh, J.N. Frontiers of Textile Materials: Polymers, Nanomaterials, Enzymes, and Advanced Modification Techniques; Scrivener Publishing LLC: Beverly, CA, USA, 2020; pp. 13–60. [Google Scholar]

- Amor, N.; Noman, M.T.; Petru, M. Classification of Textile Polymer Composites: Recent Trends and Challenges. Polymers 2021, 13, 2592. [Google Scholar] [CrossRef]

- Aizenshtein, E.M. World production and consumption of polyester fibres and thread. Fibre Chem. 2006, 38, 264–271. [Google Scholar] [CrossRef]

- Mather, R.R. Synthetic textile fibres: Polyolefin, elastomeric and acrylic fibres. In Textiles and Fashion; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Deopura, B.L.; Padaki, N.V. Chapter 5-Synthetic Textile Fibres: Polyamide, Polyester and Aramid Fibres, In Woodhead Publishing Series in Textiles, Textiles and Fashion; Sinclair, R., Ed.; Woodhead Publishing: Sawston, UK, 2015; pp. 97–114. [Google Scholar]

- Manjula, B.; Reddy, A.B.; Sadiku, E.R.; Sivanjineyulu, V.; Molelekwa, G.F.; Jayaramudu, J.; Kumar, K.R. 18-Use of polyolefins in hygienic applications. In The Textile Institute Book Series, Polyolefin Fibres, 2nd ed; Ugbolue, S.C.O., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 539–560. [Google Scholar]

- Ben Abdessalem, S.; Ben Abdelkader, Y.; Mokhtar, S.; Elmarzougui, S. Influence of Elastane Consumption on Plated Plain Knitted Fabric Characteristics. J. Eng. Fibres Fabr. 2009, 4, 30–35. [Google Scholar] [CrossRef] [Green Version]

- Aglietto, M.; Coltelli, M.B. Riutilizzo dei Materiali Polimerici; Edizioni Nuova Cultura: Roma, Italy, 2015; Volume 11. [Google Scholar]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- European Bioplastics. Bioplastics Market Development Update 2022. Available online: https://docs.european-bioplastics.org/publications/market_data/2022/Report_Bioplastics_Market_Data_2022_short_version.pdf (accessed on 26 January 2023).

- Friedrich, D. Market and business-related key factors supporting the use of compostable bioplastics in the apparel industry: A cross-sector analysis. J. Clean. Prod. 2021, 297, 126716. [Google Scholar] [CrossRef]

- Friedrich, D. What makes bioplastics innovative for fashion retailers? An in-depth analysis according to the Triple Bottom Line Principle. J. Clean. Prod. 2021, 316, 128257. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- Sousa, A.F.; Patrício, R.; Terzopoulou, Z.; Bikiaris, D.N.; Stern, T.; Wenger, J.; Loos, K.; Lotti, N.; Siracusa, V.; Szymczyk, A.; et al. Recommendations for replacing PET on packaging, fibre, and film materials with biobased counterparts. Green Chem. 2021, 23, 8795. [Google Scholar] [CrossRef]

- BIOnTop. Novel Packaging Films and Textiles with Tailored End of Life and Performance Based on Bio-Based Copolymers and Coatings. Grant Agreement ID: 837761, 10.3030/837761. Available online: https://biontop.eu/ (accessed on 10 February 2023).

- Winnacker, M.; Rieger, B. Biobased Polyamides: Recent Advances in Basic and Applied Research. Macromol. Rapid Commun. 2016, 37, 1391–1413. [Google Scholar] [CrossRef] [PubMed]

- Kopf, S.; Åkesson, D.; Skrifvars, M. Textile Fibre Production of Biopolymers—A Review of Spinning Techniques for Polyhydroxyalkanoates in Biomedical Applications. Polym. Rev. 2023, 63, 200–245. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Wild, F.; Bugnicourt, E.; Cinelli, P.; Lindner, M.; Schmid, M.; Weckel, V.; Müller, K.; Rodriguez, P.; Staebler, A.; et al. State of the Art in the Development and Properties of Protein-Based Films and Coatings and Their Applicability to Cellulose Based Products: An Extensive Review. Coatings 2016, 6, 1. [Google Scholar] [CrossRef]

- Fernandes, M.; Padrão, J.; Ribeiro, A.I.; Fernandes, R.D.V.; Melro, L.; Nicolau, T.; Mehravani, B.; Alves, C.; Rodrigues, R.; Zille, A. Polysaccharides and Metal Nanoparticles for Functional Textiles: A Review. Nanomaterials 2022, 12, 1006. [Google Scholar] [CrossRef] [PubMed]

- Coltelli, M.-B.; Danti, S.; De Clerck, K.; Lazzeri, A.; Morganti, P. Pullulan for Advanced Sustainable Body- and Skin-Contact Applications. J. Funct. Biomater. 2020, 11, 20. [Google Scholar] [CrossRef] [Green Version]

- Montserrat Flores-Nieves, M.; Castellanos-Espinoza, R.; Estevez, M.; Aurelio Baldenegro-Pérez, L.; García Trejo, J.F.; Escamilla García, M.; Martínez Cano, B.; Martín Soto-Zarazúa, G.; España-Sánchez, B.L. Electrospun Casein fibres obtained from revalued milk with mechanical and antibacterial properties. Arab. J. Chem. 2022, 15, 104201. [Google Scholar] [CrossRef]

- Kim, T.; Kim, D.; Park, Y. Recent progress in regenerated fibres for “green” textile products. J. Clean. Prod. 2022, 376, 134226. [Google Scholar] [CrossRef]

- Bozaci, E.; Altınışık Tağaç, A. Extraction and Characterization of New Cellulosic Fibre from Catalpa bignonioides Fruits for Potential Use in Sustainable Products. Polymers 2023, 15, 201. [Google Scholar] [CrossRef]

- EU Circular Economy Action Plan (2020) European Commission. Available online: https://circulareconomy.europa.eu/platform/sites/default/files/eu-case-study-june2020-en.pdf (accessed on 10 February 2023).

- Hernandez, L.M.; Xu, E.G.; Larsson, H.C.E.; Tahara, R.; Maisura, V.B. Plastic teabags release billions of microparticles 10 February 2023 into tea. Environ. Sci. Technol. 2019, 53, 12300–12310. [Google Scholar] [CrossRef] [PubMed]

- Ragusa, A.; Svelato, A.; Santacroce, C.; Catalano, P.; Notarstefano, V. Plasticenta: First evidence of microplastics in human placenta. Environ. Int. 2021, 146, 106274. [Google Scholar] [CrossRef]

- Leslie, H.A.; Ven Velzen, M.J.M.; Brandsma, S.H.; Vethaak, A.D.; Garcia-Vallejo, J.J. Discover and quantification of plastic particle pollution in human blood. Environ. Int. 2022, 163, 107199. [Google Scholar] [CrossRef] [PubMed]

- Cabrera, A.; Garcia, R. The Environmental and Economic Costst of Single-Use Menstrual Products, Baby Nappies and Wet Wipes, Rezero Foundation Report. 2019. Available online: https://zerowasteeurope.eu/wp-content/uploads/2019/12/bffp_single_use_menstrual_products_baby_nappies_and_wet_wipes.pdf (accessed on 26 January 2023).

- Henry, B.; Laitala, K.; Klepp, I.G. Microfibres from apparel and home textiles: Pro-spects for including microplastics in environmental sustainability assessment. Sci. Total Environ. 2019, 652, 483–494. [Google Scholar] [CrossRef]

- Napper, I.E.; Thompson, R.C. Release of synthetic microplastic plastic fibres from domestic washing machines: Effects of fabric type and washing conditions. Mar. Pollut. Bull. 2016, 112, 39–45. [Google Scholar] [CrossRef] [Green Version]

- Belzagui, F.; Crespi, M.; Alvarez, A.; Gutierrez-Bouzan, C.; Vilaseca, M. Microplas-tics’ emissions: Microfibres’ detachment from textile Garments. Environ. Pollut. 2019, 248, 1028–1035. [Google Scholar] [CrossRef] [PubMed]

- Welden, N.A.; Cowie, P.R. Degradation of common polymer ropes in a sublittoral marine environment. Mar. Pollut. Bull. 2017, 118, 248–253. [Google Scholar] [CrossRef] [Green Version]

- Murphy, F.; Ewins, C.; Carbonnier, F.; Quinn, B. Wastewater treatment works (WwTW) as a source of microplastics in the aquatic environment. Environ. Sci. Technol. 2016, 50, 5800–5808. [Google Scholar] [CrossRef] [Green Version]

- Long, Z.; Pan, Z.; Wang, W.; Ren, J.; Yu, X.; Lin, L. Microplastic abundance, characteristics, and removal in wastewater treatment plants in a coastal city of China. Water Res. 2019, 155, 255–265. [Google Scholar] [CrossRef]

- Textile Exchange, 2019. Preferred Fibre and Materials Market Report. Available online: https://store.textileexchange.org/product/2019-preferred-fibre-materials-report/ (accessed on 10 February 2023).

- Ren, P.; Dou, M.; Wang, C. Abundance and removal characteristics of microplastics at a wastewater treatment plant in Zhengzhou. Environ. Sci. Pollut Res. 2020, 27, 36295–36305. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, Y.-T.; Huang, Q.-S.; Ni, B.-J. Polyethylene terephthalate microplastics affect hydrogen production from alkaline anaerobic fermentation of waste activated sludge through altering viability and activity of anaerobic microorganisms. Water Res. 2019, 163, 114881. [Google Scholar] [CrossRef] [PubMed]

- Magni, S.; Binelli, A.; Pittura, L.; Avio, C.G.; Della Torre, C.; Parenti, C.C.; Gorbi, S.; Regoli, F. The fate of microplastics in an Italian Wastewater Treatment Plant. Sci. Total Environ. 2019, 652, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Fuller, S.; Gautam, A. A procedure for measuring microplastics using pressurized fluid extraction. Environ. Sci. Technol. 2016, 50, 5774–5780. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ziajahromi, S.; Neale, P.A.; Rintoul, L.; Leusch, F.D.L. Wastewater treatment plants as a pathway for microplastics: Development of a new approach to sample wastewater-based microplastics. Water Res. 2017, 112, 93–99. [Google Scholar] [CrossRef] [PubMed]

- Mintenig, S.M.; Int-Veen, I.; Loder, M.G.J.; Primpke, S.; Gerdts, G. Identification of microplastic in effluents of waste water treatment plants using focal plane array based micro-Fourier transform infrared imaging. Water Res. 2017, 108, 365–372. [Google Scholar] [CrossRef]

- Lares, M.; Ncibi, M.C.; Sillanpa, M.; Sillanpa, M. Intercomparison study on commonly used methods to determine microplastics in wastewater and sludge samples. Environ. Sci. Pollut. Res. 2019, 26, 12109–12122. [Google Scholar] [CrossRef] [Green Version]

- Schwaferts, C.; Niessner, R.; Elsner, M.; Ivleva, N.P. Methods for the analysis of submicrometer- and nanoplastic particles in the environment. Trends Anal. Chem. 2019, 112, 52–65. [Google Scholar] [CrossRef]

- Castelvetro, V. Nylon 6 and nylon 6,6 micro- and nanoplastics: A first example of their accurate quantification, along with polyester (PET), in wastewater treatment plant sludges. J. Hazard. Mater. 2021, 407, 124364. [Google Scholar] [CrossRef]

- Kappler, A.; Fischer, M.; Scholz-Bottcher, B.M.; Oberbeckmann, S.; Labrenz, M.; Fischer, D. Comparison of μ-ATR-FTIR spectroscopy and Py-GCMS as identification tools for microplastic particles and fibres isolated from river sediments. Anal. Bioanal. Chem. 2018, 410, 5313–5327. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, L.; Halden, R.U.; Kannan, K. Polyethylene terephthalate and polycarbonate microplastics in sewage sludge collected from the United States. Environ. Sci. Technol. Lett. 2019, 6, 650–6554. [Google Scholar] [CrossRef]

- Corti, A.; Vinciguerra, V.; Iannilli, V.; Pietrelli, L.; Manariti, A.; Bianchi, S.; Petri, A.; Cifelli, M.; Domenici, V.; Castelvetro, V. Thorough multianalytical characterization and quantification of micro- and nanoplastics from Bracciano Lake’s sediments. Sustainability 2020, 12, 878. [Google Scholar] [CrossRef] [Green Version]

- Castelvetro, V.; Corti, A.; Bianchi, S.; Ceccarini, A.; Manariti, A.; Vinciguerra, V. Quantification of poly(ethylene terephthalate) micro- and nanoparticle contaminants in marine sediments and other environmental matrices. J. Hazard. Mater. 2020, 385, 121517. [Google Scholar] [CrossRef]

- Rebelein, A.; Int-Veen, I.; Kammann, U.; Peter Scharsack, J. Microplastic fibres—Underestimated threat to aquatic organisms? Sci. Total Environ. 2021, 777, 146045. [Google Scholar] [CrossRef]

- Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste (Text with EEA Relevance); 30 May 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0851&rid=5 (accessed on 14 February 2023).

- Directive (EU) 2018/852 of the European Parliament and of the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0852&from=EN (accessed on 14 February 2023).

- Commission Decision 2014/350/EU Establishing the Ecological Criteria for the Award of the EU Ecolabel for Textile Products and the Factsheet on the EU Ecolabel for Textile Products. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32014D0350&from=EN (accessed on 14 February 2023).

- 2017 Commission Staff Working Document EU Green Public Procurement Criteria for Textiles Products and Services and the 2017 JRC Technical Report EU Green Public Procurement (GPP) Criteria for Textile Products and Services. Available online: https://ec.europa.eu/environment/gpp/pdf/criteria/textiles_2017.pdf (accessed on 14 February 2023).

- Riba, J.R.; Cantero, R.; Canals, T.; Puig, R. Circular economy of post-consumer textile waste: Classification through infrared spectroscopy. J. Clean. Prod. 2020, 272, 123011. [Google Scholar] [CrossRef]

- Cura, K.; Rintala, N.; Kamppuri, T.; Saarimäki, E.; Heikkilä, P. Textile recognition and sorting for recycling at an automated line using near infrared spectroscopy. Recycling 2021, 6, 11. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M. Strategies of Recovery and Organic Recycling Used in Textile Waste Management. Int. J. Environ. Res. Public Health 2022, 19, 5859. [Google Scholar] [CrossRef]

- Zhou, C.; Han, G.; Via, B.K.; Song, Y.; Gao, S.; Jiang, W. Rapid identification of fibres from different waste fabrics using the near-infrared spectroscopy technique. Text. Res. J. 2019, 89, 3610–3616. [Google Scholar] [CrossRef]

- Liu, Z.; Li, W.; Wei, Z. Qualitative classification of waste textiles based on near infrared spectroscopy and the convolutional network. Text. Res. J. 2020, 90, 1057–1066. [Google Scholar] [CrossRef]

- Daukantienė, V. Analysis of the sustainability aspects of fashion: A literature review. Text. Res. J. 2023, 93, 991–1002. [Google Scholar] [CrossRef]

- Nørup, N.; Pihl, K.; Damgaard, A.; Scheutz, C. Development and testing of a sorting and quality assessment method for textile waste. Waste Manag. 2018, 79, 8–21. [Google Scholar] [CrossRef]

- Kuo, C.J.; Kao, C.-Y.K. Self-organizing Map Network for Automatically Recognizing Color Texture Fabric Nature. Fibres Polym. 2007, 8, 174–180. [Google Scholar]

- Hu, J.; Yang, H.; Zhao, G.; Zhou, R. Research on Online Rapid Sorting Method of Waste Textiles Based on Near-Infrared Spectroscopy and Generative Adversity Network. Comput. Intell. Neurosci. 2022, 2022, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Penner, M.H. Basic Principles of Spectroscopy. In Food Analysis, 5th ed.; Nilesen, S.S., Ed.; Springer: New York, NY, USA, 2017; pp. 79–88. [Google Scholar] [CrossRef]

- Dufour, É. Principles of Infrared Spectroscopy. In Infrared Spectroscopy for Food Quality Analysis and Control; Sun, D.W., Ed.; Academicc Press: Cambridge, MA, USA, 2009; pp. 3–27. [Google Scholar] [CrossRef]

- Li, W.; Wei, Z.; Liu, Z.; Du, Y.; Zheng, J.; Wang, H.; Zhang, S. Qualitative identification of waste textiles based on near-infrared spectroscopy and the back propagation artificial neural network. Text. Res. J. 2021, 91, 2459–2467. [Google Scholar] [CrossRef]

- Mäkelä, M.; Geladi, P. Hyperspectral near infrared imaging quantifies the heterogeneity of carbon materials. Sci. Rep. 2018, 8, 10442. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Li, C.; Yang, F. Classification of foreign matter embedded inside cotton lint using short wave infrared (SWIR) hyperspectral transmittance imaging. Comput. Electron. Agric. 2017, 139, 75–90. [Google Scholar] [CrossRef]

- Ma, J.; Sun, D.W.; Pu, H.; Cheng, J.H.; Wei, Q. Advanced Techniques for Hyperspectral Imaging in the Food Industry: Principles and Recent Applications. Annu. Rev. Food Sci. Technol. 2019, 10, 197–220. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, C. MRMR-based feature selection for classification of cotton foreign matter using hyperspectral imaging. Comput. Electron. Agric. 2015, 119, 191–200. [Google Scholar] [CrossRef]

- Blanch-Perez-del-Notario, C.; Saeys, W.; Lambrechts, A. Hyperspectral imaging for textile sorting in the visible-near infrared range. J. Spectr. Imaging 2019, 8, 1–11. [Google Scholar] [CrossRef]

- Rosales, A.; Mc Nerney, O. Sensing Technology. In Resource Efficiency of Processing Plants; Amancio-Filho, S.T., Blaga, L.-A., Eds.; Wiley: Hoboken, NJ, USA, 2018; pp. 129–157. [Google Scholar] [CrossRef]

- Kroell, N.; Chen, X.; Greiff, K.; Feil, A. Optical sensors and machine learning algorithms in sensor-based material flow characterization for mechanical recycling processes: A systematic literature review. Waste Manag. 2022, 149, 259–290. [Google Scholar] [CrossRef]

- Sommer, S. What Is the Amsterdam ‘Denim Deal’ All about? 2020, The Spinoff Modern Matters. Available online: https://www.the-spin-off.com/news/stories/Sustainability-What-is-the-Amsterdam-Denim-Deal-all-about-15643 (accessed on 13 February 2023).

- Lounais-Suomen Jätehuolto’. Post-Consumer Textile Recycling. Available online: https://poistotekstiili.lsjh.fi/en/home/ (accessed on 10 February 2023).

- Comune di Prato, Hub del Riciclo Tessile, La Presentazione in Consiglio Comunale. 2022. Available online: https://comunicati.comune.prato.it/generali/?action=dettaglio&comunicato=14202200000360 (accessed on 10 February 2023).

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.-S. Possibility Routes for Textile Recycling Technology. Polymers 2021, 13, 3834. [Google Scholar] [CrossRef]

- Raffa, P.; Coltelli, M.B.; Savi, S.; Bianchi, S.; Castelvetro, V. Chain extension and branching of poly(ethylene terephthalate) (PET) with di- and multi-functional epoxy or isocyanate additives: An experimental and modelling study. React. Funct. Polym. 2012, 72, 50–60. [Google Scholar] [CrossRef]

- Raffa, P.; Coltelli, M.B.; Castelvetro, V. Ex-panding the application field of post-consumer poly(ethylene terephthalate) through structural modification by reactive blending. J. Appl. Polym. Sci. 2014, 131, 40881. [Google Scholar] [CrossRef]

- Benyathiar, P.; Kumar, P.; Carpenter, G.; Brace, J.; Mishra, D.K. Polyethylene Terephthalate (PET) Bottle-to-Bottle Recycling for the Beverage Industry: A Review. Polymers 2022, 14, 2366. [Google Scholar] [CrossRef] [PubMed]

- Park, S.H.; Kim, S.H. Poly (ethylene terephthalate) recycling for high value added textiles. Fash. Text. 2014, 1, 1. [Google Scholar] [CrossRef] [Green Version]

- Aglietto, M.; Bibbiani, S.; Bruni, C.; Castelvetro, V.; Ciardelli, F.; Coltelli, M.-B.; Pancani, A.; Savi, S.; Suffredini, G. Shockproof Thermoplastic Material Based on Polycondensation Polymers and Its Production Method. Italian Patent No. PI2011A000090, 30 April 2014. [Google Scholar]

- Aglietto, M.; Coltelli, M.B.; Savi, S.; Lochiatto, F.; Ciardelli, F.; Giani, M. Postconsumer polyethylene terephthalate (PET)/polyolefin blends through reactive processing. J. Mater. Cycles Waste Manag. 2004, 6, 13–19. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Aglietto, M.; Ciardelli, F. Influence of the transesterification catalyst structure on the reactive compatibilization and properties of poly(ethylene terephthalate) (PET)/dibutyl succinate functionalized poly(ethylene) blends. Eur. Polym. J. 2008, 44, 1512–1524. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Della Maggiore, I.; Savi, S.; Aglietto, M.; Ciardelli, F. Modified styrene–butadiene–styrene block copolymer as compatibiliser precursor in polyethylene/poly(ethylene terephthalate) blends. Polym. Degrad. Stab. 2005, 90, 211–223. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Harrats, C.; Aglietto, M.; Groeninckx, G. Influence of Compatibilizer Precursor Structure on the Phase Distribution of Low Density Poly(ethylene) in a Poly(ethylene terephthalate) Matrix. Polym. Eng. Sci. 2008, 48, 1424–1433. [Google Scholar] [CrossRef]

- Bartoli, F.; Bruni, C.; Coltelli, M.B.; Castelvetro, V.; Ciardelli, F. Conversion of post-industrial PET-PE scraps into compatibilized plastic blends for new applications. AIP Conf. Proc. 2012, 1459, 160. [Google Scholar]

- Coltelli, M.B.; Bianchi, S.; Savi, S.; Signorini, F.; Manariti, A.; Bruni, C.; Ciardelli, F.; Castelvetro, V. Post-consumer poly(ethylene terephthalate) in composites and blends for automotive applications. In Proceedings of the ICCM 17, 17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009; Available online: https://iccm-central.org/Proceedings/ICCM17proceedings/Themes/Industry/AUTO%20APPLI%20&%20RECYC/A3.5%20Castelvetro.pdf (accessed on 31 January 2022).

- Sarioğlu, E.; Kaynak, H.K. PET Bottle Recycling for Sustainable Textiles. In Polyester; Camlibel, N.O., Ed.; IntechOpen: Rijeka, Croatia, 2017; Available online: https://doi.org/10.5772/intechopen.72589 (accessed on 14 February 2023).

- Coltelli, M.B.; Bianchi, S.; Aglietto, M. Poly(ethylene terephthalate) (PET) degradation during the Zn catalysed transesterification with dibutyl maleate functionalized polyolefins. Polymer 2007, 48, 1276–1286. [Google Scholar] [CrossRef]

- Rauwendaal, C. Polymer Extrusion; Hanser Publishers: Munich, Germany, 1994; pp. 10–61. [Google Scholar]

- Ehrig, R.J. Plastics Recycling; Hanser Publishers: Munich, Germany, 1992; pp. 56–94. [Google Scholar]

- RESYNT Project, Starting Date 1 June 2022, End Date 31 December 2022, Funded in the Framework of GALACTICA Project GA No. 872336—EU H2020 Research and Innovation Programme. Available online: https://galacticaproject.eu/orbital-beneficiaries-2nd-call/ (accessed on 31 January 2023).

- Harmsen, P.; Scheffer, M.; Bos, H. Textiles for Circular Fashion: The Logic behind Recycling Options. Sustainability 2021, 13, 9714. [Google Scholar] [CrossRef]

- Su, K.H.; Lin, J.H.; Lin, C.C. Influence of reprocessing on the mechanical properties and structure of polyamide 6. J. Mater. Process. Technol. 2007, 192–193, 532–538. [Google Scholar] [CrossRef]

- Schaffer, M.A.; Marchildon, E.K.; Mcauley, K.B.; Cunningham, M.F. Thermal Nonoxidative Degradation of Nylon 6,6. J. Macromolr. Sci. Part C Polym Rev. 2000, 40, 233–272. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Chang, B.P.; Mohanty, A.K.; Misra, M. Waste valorization in sustainable engineering materials: Reactive processing of recycled carpets waste with polyamide 6. Polym. Test. 2022, 114, 107681. [Google Scholar] [CrossRef]

- Celep, G.; Tetik, G.D.; Yilmaz, F. Limitations of Textile Recycling: The Reason behind the Development of Alternative Sustainable Fibres. In Next-Generation Textiles; Ibrahim, H., Ed.; IntechOpen: Rijeka, Yugoslavia, 2022; Available online: https://doi.org/10.5772/intechopen.105118 (accessed on 10 February 2023).

- REcycling of Waste ACrylic Textiles (REACT) Project. European Commission. ID Number: 820869 (Start Date 1 June 2019 End Date 30 September 2022). Available online: https://cordis.europa.eu/project/id/820869 (accessed on 31 January 2023).

- Nahil, M.A.; Williams, P.T. Activated carbons from acrylic textile waste. J. Anal. Appl. Pyrolysis 2010, 89, 51–59. [Google Scholar] [CrossRef]

- El Wazna, M.; El Fatihi, M.; El Bouari, A.; Cherkaoui, O. Thermophysical characterization of sustainable insulation materials made from textile waste. J. Build. Eng. 2017, 12, 196–201. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Jin, X.; Feng, C.; Creighton, C.; Hameed, N.; Parameswaranpillai, J.; Salim, N.V. On the structural evolution of textile grade polyacrylonitrile fibres during stabilization and carbonization: Towards the manufacture of low-cost carbon fibre. Polym. Degrad. Stab. 2021, 186, 10953. [Google Scholar] [CrossRef]

- Khan, A.; Iftikhar, K.; Mohsin, M.; Ahmad, J.; Sahar, N.; Rovere, M.; Tagliaferro, A. Low temperature synthesis of carbon fibres from post-consumer textile waste and their application to composites: An ecofriendly approach. Diam. Relat. Mater. 2022, 130, 109504. [Google Scholar] [CrossRef]

- Yoda, T.; Shibuya, K.; Myoubudani, H. Preparation of activated carbon fibres from mixtures of cotton and polyester fibres. Measurement 2018, 125, 572–576. [Google Scholar] [CrossRef]

- Senthilkumar, M. Elastane fabrics–A tool for stretch applications in sports. Indian J. Fibre Text. Res. 2011, 36, 300. [Google Scholar]

- Phan, K.; Ugduler, S.; Herinck, L.; Van Speybroeck, V.; De Clerk, K.; De Meester, S. A Combined Experimental and Theoretical Study on Textile Recycling: The Dissolution of Elastane. Available online: http://generalchemistry.chemeng.ntua.gr/uest/corfu2022/proceedings/XVIII/1430.pdf (accessed on 3 February 2023).

- Boschmeier, E.; Archodoulaki, V.-M.; Schwaighofer, A.; Lendl, B.; Bartl, A. A novel quantification tool for elastane in textiles using thermal treatment. Polym. Test. 2023, 118, 107920. [Google Scholar] [CrossRef]

- Yin, Y.; Yao, D.; Wang, C.; Wang, Y. Removal of spandex from nylon/spandex blended fabrics by selective polymer degradation. Text. Res. J. 2014, 84, 16–27. [Google Scholar] [CrossRef]

- Lv, F.; Yao, D.; Wang, C.; Zhu, P.; Hong, Y. Recycling of waste nylon 6/spandex blended fabrics by melt processing. Compos. Part B Eng. 2015, 77, 232–237. [Google Scholar] [CrossRef]

- Wang, L.; Huang, S.; Wang, Y. Recycling of Waste Cotton Textile Containing Elastane Fibres through Dissolution and Regeneration. Membranes 2022, 12, 355. [Google Scholar] [CrossRef]

- Kellie, G. Advances in Technical Nonwovens; Woodhead Publishing Series in Textiles; Woodhead Publishing: Sawston, UK, 2016; pp. 6–32. [Google Scholar]

- IndustryArc. Analytics, Research, Consulting. Available online: https://www.industryarc.com/Report/19540/nonwovens-market.html (accessed on 10 February 2023).

- Üstün Çetin, S.; Tayyar, A.E. Physical properties of recycled PET non-woven fabrics for buildings. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 19201. [Google Scholar]

- Hufenbach, W.; Böhm, R.; Thieme, M.; Winkler, A.; Mäder, E.; Rausch, J.; Schade, M. Polypropylene/glass fibre 3D-textile reinforced composites for automotive applications. Mater. Des. 2011, 32, 1468–1476. [Google Scholar] [CrossRef]

- Mishra, R.; Behera, B.; Militky, J. Recycling of textile waste into green composites: Performance characterization. Polym. Compos. 2014, 35, 1960–1967. [Google Scholar] [CrossRef]

- Meng, X.; Fan, W.; Ma, Y.; Wei, T.; Dou, H. Recycling of denim fabric wastes into high-performance composites using the needle-punching nonwoven fabrication route. Text. Res. J. 2020, 90, 695–709. [Google Scholar] [CrossRef]

- Tilioua, A.; Libessart, L.; Lassue, S. Characterization of the thermal properties of fibrous insulation materials made from recycled textile fibres for building applications: Theoretical and experimental analyses. Appl. Therm. Eng. 2018, 142, 56–67. [Google Scholar] [CrossRef]

- De Vallance, D.B.; Gray, J.; Lentz, H. Properties of wood/recycled textile composite panels. Wood Fibre Sci. 2012, 44, 310–318. [Google Scholar]

- Masood, Z.; Ahmad, S.; Umair, M.; Shaker, K.; Nawab. Mechanical Behaviour of Hybrid Composites Developed from Textile Waste. Fibres Text. East. Eur. 2018, 26, 46–52. [Google Scholar]

- Charoen, N.; Kampeerapappun, P.; Charoenlarp, K.; Petchwattana, N.; Jansri, E. Green Composites Based on PLA and Cotton Fabric Waste: Preparation and Characterization. Recycling 2022, 7, 78. [Google Scholar] [CrossRef]

- Rajendran, S.; Scelsi, L.; Hodzic, A.; Soutis, C.; Al-Maadeed, M.A. Environmental impact assessment of composites containing recycled plastics. Resour. Conserv. Recycl. 2012, 60, 131–139. [Google Scholar] [CrossRef]

- Dorneles De Castro, B.; De Faria, P.E.; Machado Gomes Vieira, L.; Campos Rubio, C.V.; Maziero, R.; De Matos Rodrigues, P.C.; Campos Rubio, J.C. Recycled Green PE Composites Reinforced with Woven and Randomly Arranged Sisal Fibres Processed by Hot Compression Moulding. Acta Technol. Agric. 2020, 23, 81–86. [Google Scholar] [CrossRef]

- Miranda, R.; Sosa_Blanco, C.; Bustos-Martinez, D.; Vasile, C. Pyrolysis of textile wastes: I. Kinetics and yields. J. Anal. Appl. Pyrolysis 2007, 80, 489–495. [Google Scholar] [CrossRef]

- Hee Sue, L.; Sungyup, J.; Kun-Yi, A.L.; Eilhann, E.K.; Jechan, L. Upcycling textile waste using pyrolysis process. Sci. Total Environ. 2023, 859, 160393. [Google Scholar]

- Xu, Z.; Zhang, D.; Yuan, Z.; Chen, W.; Zhang, T.; Tian, D.; Deng, H. Physicochemical and adsorptive characteristics of activated carbons from waste polyester textiles utilizing MgO template method. Environ. Sci. Pollut. Res. 2017, 24, 22602–22612. [Google Scholar] [CrossRef]

- Yousef, S.; Eimontas, J.; Striūgas, N.; Tatariants, M.; Abdelnaby, M.A.; Tuckute, S.; Kliucininkas, L. A sustainable bioenergy conversion strategy for textile waste with self-catalysts using mini-pyrolysis plant. Energy Convers. Manag. 2019, 196, 688–704. [Google Scholar] [CrossRef]

- Damayanti, D.; Wu, H.-S. Strategic Possibility Routes of Recycled PET. Polymers 2021, 13, 1475. [Google Scholar] [CrossRef]

- C&EN; Scott, A. Transforming Textiles. How Chemical Recycling Technologies Could Play a Key Role in Slashing the Textile Industry’s Environmental Footprint. 28 March 2022. Available online: https://cen.acs.org/environment/green-chemistry/Transforming-textiles/100/i11 (accessed on 10 February 2023).

- Palme, A.; Peterson, A.; de la Motte, H. Development of an efficient route for combined recycling of PET and cotton from mixed fabrics. Text. Cloth. Sustain. 2017, 3, 4. [Google Scholar] [CrossRef] [Green Version]

- HKRITA. Green Machine: Post-consumer Blended Textile Separation and Recycling by Hydrothermal Treatment Phase II. Available online: https://www.hkrita.com/en/our-innovation-tech/projects/green-machine-phase-2 (accessed on 14 February 2023).

- H&M Foundation. Green Machine—Separating Blend Textiles at Scale. Available online: https://hmfoundation.com/project/recycling-the-green-machine/ (accessed on 10 February 2023).

- Worn Again Technologies. Available online: https://wornagain.co.uk/ (accessed on 10 February 2023).

- Worn Again Technologies. The Circular Textile Economy Is Rapidly Approaching. Available online: https://wornagain.co.uk/the-circular-textile-economy-is-rapidly-approaching/ (accessed on 10 February 2023).

- SODRA. Available online: https://www.sodra.com/en/global/pulp/news-pulp/2022/oncemore-next-step-of-journey-begins-with-lenzing/ (accessed on 10 February 2023).

- CIRC. Available online: https://circ.earth/ (accessed on 10 February 2023).

- Marubeni. Available online: https://www.marubeni.com/en/news/2022/release/00049.html (accessed on 14 February 2023).

- BLOCKTEXX. Available online: https://www.blocktexx.com/ (accessed on 10 February 2023).

- BLOCKTEXX. Australian Start-Up BlockTexx Has Begun Work on What It Claims Will the the First Textile Recycling Plant Capable of Separating and Recycling Blends of Cotton and Polyester Fibres at Scale. Available online: https://www.blocktexx.com/News/Work-starts-on-plant-to-recycle-blended-fibres (accessed on 10 February 2023).

- RESYNTEX. A New Circular Economy Concept: From Textile Waste Towards Chemical and Textile Industries Feedstock. Available online: https://cordis.europa.eu/project/id/641942/it (accessed on 10 February 2023).

- TRASH2CASH. Available online: https://www.trash2cashproject.eu/ (accessed on 10 February 2023).

- RETEX. Available online: https://www.dotheretex.eu/ (accessed on 10 February 2023).

- CISUTAC. Circular and Sustainable Textiles and Clothing. Available online: https://www.cisutac.eu/ (accessed on 14 February 2023).

- TREX. Creating a Circular System for Post-Consumer Textile Waste. Available online: https://trexproject.eu/ (accessed on 14 February 2023).

- Kawai, F.; Kawabata, T.; Oda, M. Current state and perspectives related to the PET hydrolases available for biorecycling. ACS Sustain. Chem. Eng. 2020, 8, 8894–8908. [Google Scholar] [CrossRef]

- Lens-Pechakova, L.S. Recent studies on enzyme-catalysed recycling and biodegradation of synthetic polymers. Adv. Ind. Eng. Polym. Res. 2021, 4, 151–158. [Google Scholar] [CrossRef]

- Blank, L.M.; Narancic, T.; Mampel, J.; Tiso, T.; O’Connor, K. Biotechnological upcycling of plastic waste and other non-conventional feedstocks in a circular economy. Curr. Opin. Biotechnol. 2020, 62, 212–219. [Google Scholar] [CrossRef]

- Yoshida, S.; Hiraga, K.; Takehana, T.; Taniguchi, I.; Yamaji, H.; Maeda, Y.; Toyohara, K.; Miyamoto, K.; Kimura, Y.; Oda, K. A Bacterium That Degrades and Assimilates Poly(Ethylene Terephthalate). Science 2016, 351, 1196–1199. [Google Scholar] [CrossRef]

- Shirke, A.N.; White, C.; Englaender, J.A.; Zwarycz, A.; Butterfoss, G.L.; Linhardt, R.J. Stabilizing Leaf and Branch Compost Cutinase (LCC) with Glycosylation: Mechanism and Effect on PET Hydrolysis. GrossBiochemistry 2018, 57, 1190–1200. [Google Scholar] [CrossRef] [PubMed]

- Tournier, V.; Topham, C.M.; Gilles, A.; David, B.; Folgoas, C. An engineered PET depolymerase to break down and recycle plastic bottles. Nature 2020, 580, 216–219. [Google Scholar] [CrossRef]

- Jönsson, C.; Wei, R.; Biundo, A.; Landberg, J.; Schwarz Bour, L.; Pezzotti, F.; Toca, A.M.; Jacques, L.; Bornscheuer, U.T.; Syrén, P.-O. Biocatalysis in the Recycling Landscape for Synthetic Polymers and Plastics towards Circular Textiles. ChemSusChem 2021, 14, 4028–4040. [Google Scholar] [CrossRef]

- Kaabel, S.; Arciszewski, J.; Borchers, T.H.; Therien, J.P.D.; Friščić, T.; Auclair, K. Solid-State Enzymatic Hydrolysis of Mixed PET-Cotton Textiles. ChemSusChem 2023, 16, e202201613. [Google Scholar] [CrossRef]

- Singh, A.; Rorrer, N.A.; Nicholson, S.R.; Erickson, E.; DesVeaux, J.S.; Avelino, A.F.T.; Lamers, P.; Bhatt, A.; Zhang, Y.; Avery, G.; et al. Techno-economic, life-cycle, and socioeconomic impact analysis of enzymatic recycling of poly(ethylene terephthalate). Joule 2021, 5, 2479–2503. [Google Scholar] [CrossRef]

- Navone, L.; Moffitt, K.; Hansen, K.A.; Blinco, J.; Payne, A.; Speight, R. Closing the textile loop: Enzymatic fibre separation and recycling of wool/polyester fabric blends. Waste Manag. 2020, 102, 149–160. [Google Scholar] [CrossRef] [PubMed]

- Quartinello, F.; Vecchiato, S.; Weinberger, S.; Kremenser, K.; Skopek, L.; Pellis, A.; Guebitz, G.M. Highly Selective Enzymatic Recovery of Building Blocks from Wool-Cotton-Polyester Textile Waste Blends. Polymers 2018, 10, 1107. [Google Scholar] [CrossRef] [Green Version]

- Piribauer, B.; Bartl, A.; Ipsmiller, W. Enzymatic textile recycling—best practices and outlook. Waste Manag. Res. 2021, 39, 1277–1290. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.; Cavaco-Paulo, A.; Nierstrasz, V.A. Enzymatic hydrolysis and modification of core polymer fibres for textile and other applications. Adv. Text. Biotechnol. 2010, 77–97. [Google Scholar] [CrossRef]

- Carbios Company Website. Available online: https://www.carbios.com/en/enzymatic-recycling/ (accessed on 10 February 2023).

- Novozyme. Available online: https://biosolutions.novozymes.com/en/textiles (accessed on 10 February 2023).

- Sandin, G.; Peters, G.M. Environmental Impact of Textile Reuse and Recycling—A Review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

| Company and Reference | Input Stream | Technology | Product | Milestones and References |

|---|---|---|---|---|

| HKRITA/H&M Foundation [143] | Cotton/ PET | Hydrothermal decomposition of cotton into cellulose powders and the separation of polyester fibres from blended fabrics (without compromising the polyester fibre quality) | Good-quality polyester fibres to make new textile and a cellulose powder | 2021—Denim supplier ISKO gets a Green Machine from Türkiye. A consortium of actors in the textile sector, including GIZ, VF Corp and Dakota, join forces to launch a feasibility study to deploy The Green Machine in Cambodia by 2022. 2020—Kahatex, a large supplier in Indonesia, places the first order of the Green Machine. Fashion brand Monki releases the first collection made from the Green Machine technology. A pilot on cotton farming using the cellulose powder (one of the outputs from the Green Machine) is initiated in India. 2018—A pre-industrial-sized system opened in Tai Po, Hong Kong: brands and stakeholders were invited to test and implement this technology within their own operations [144]. |

| Worn-again technology [145] | Cotton/ PET from non-reusable textiles | Closed-loop solvent system able to decontaminate, separate and extract polyester and cellulose | PET and cellulosic pulp | 31 May 2022—Worn Again Technologies announces plans to build a new textile recycling demo plant in Winterthur, Switzerland [146] |

| Sodra with Once More [147] | Cotton/ PET | Cellulose pulp for textile | 3 June 2022—production capacity of OnceMore® rising to 6000 tonnes | |

| Circ, Inc (formerly, TYTON BioSciences LLC) [148] | Cotton, PET, polycotton | Heat and pressure-based hydrothermal technology | Cellulose and PET monomers | 14 July 2022—Marubeni America Corporation, has made additional investment in Circ, Inc. (formerly, TYTON BioSciences LLC) [149], that has developed methods for recycling cotton and polyester fibres from waste textiles. |

| Block Texx [150] | Cotton/ PET | Cellulose pulp and PET | 16 August 2021—Australian start-up BlockTexx has acquired a site at Logan, Queensland, and it was working on the final design for the plant. BlockTexx says production will begin in 2022, using the company’s proprietary Separation of Fibre Technology (SOFT) solution, at the plant which will recycle around 4000 tonnes of textiles in its first year [151]. |

| Project Acronym and Reference | Input Stream | Product | Key Information |

|---|---|---|---|

| RESYNTEX [152] | Cotton, nylon, PET, wool | Monomers (glucose, TPA, EG) protein hydrolysates, polyamide oligomers | UE HORIZON 2020, from June 2015 to May 2019. It developed a new demonstration process based on a synergistic chemical and biotechnological cascading separation/transformation approach of textile basic components (proteins, cellulose, polyamide and polyester) from textile blends as basic feedstock materials for chemical and textile industries. Liquid and solid waste treatment and valorisation closed the loop |

| Trash2Cash [153] | Blended textile and paper waste | Regenerated cellulose | From June 2015 to November 2018. A newly developed eco-efficient cotton fibre regeneration process (Cellulosic Regeneration), a new polyester regeneration technology (PET De-Re-polymerisation) and a polyester recycling technique (Chain Extension Upgrading) were developed |

| RETEX [154] | Cotton, Polyester | Fibre | Interreg (V programme) EU Project, from October 2016 to October 2020. Three value chains were identified to be developed to obtain fibre and plastic by mechanical recycling: (1) Cotton/polyester blends; (2) 100% cotton; (3) 100% polyester |

| CISUTAC [155] | Horizon Europe project | Fibre | Horizon Europe project, co-funded by the European Union, from September 2022 to August 2026 (ongoing). Tests for fibre-to-fibre textile recycling technologies for post-consumer polyester and cotton were carried out. Pilot scale processes demonstrated the industrial application of new technologies for textile circularity |

| T-REX [156] | Cotton Polyester Polyamide | Fibre | Horizon Europe project, from October 2022 to August 2025. It collected and sorted household textile waste and demonstrated the full recycling process of polyester, polyamide 6, and cellulosic materials from textile waste into new garments. |

| Recycling Method | Limitations |

|---|---|

| Mechanical recycling | Shorter fibres, coarse yarns and lower quality of products (mainly non-woven). Preliminary sorting can be useful for a better reliability of the process. |

| Thermo-mechanical recycling | Its quality depends on composition; thus, it is better for homogenous polymers or for some specific blends/composites with reliable composition. For this kind of recycling, preliminary sorting is necessary. |

| Chemical recycling | With the exception of pyrolysis, it requires the use of solvents or chemicals, hence generally high investments, including suitable measures for protecting health and environment, are necessary. In the case of pyrolysis, a solid absorbent and gases are obtained. Their market demand should be high in order to create a profitable supply chain. |

| Enzymatic recycling | It can be applied to ester, amide, ether or glycoside linkages; thus, it can be applied to polyesters, polyamide or cotton. Polyaddition polymers (acrylics, polyolefins, etc.) generally could not be decomposed by enzymatic paths. Preliminary homogeneization and reduction of dimensions is useful. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bianchi, S.; Bartoli, F.; Bruni, C.; Fernandez-Avila, C.; Rodriguez-Turienzo, L.; Mellado-Carretero, J.; Spinelli, D.; Coltelli, M.-B. Opportunities and Limitations in Recycling Fossil Polymers from Textiles. Macromol 2023, 3, 120-148. https://doi.org/10.3390/macromol3020009

Bianchi S, Bartoli F, Bruni C, Fernandez-Avila C, Rodriguez-Turienzo L, Mellado-Carretero J, Spinelli D, Coltelli M-B. Opportunities and Limitations in Recycling Fossil Polymers from Textiles. Macromol. 2023; 3(2):120-148. https://doi.org/10.3390/macromol3020009

Chicago/Turabian StyleBianchi, Sabrina, Flavia Bartoli, Cosimo Bruni, Cristina Fernandez-Avila, Laura Rodriguez-Turienzo, Jorge Mellado-Carretero, Daniele Spinelli, and Maria-Beatrice Coltelli. 2023. "Opportunities and Limitations in Recycling Fossil Polymers from Textiles" Macromol 3, no. 2: 120-148. https://doi.org/10.3390/macromol3020009

APA StyleBianchi, S., Bartoli, F., Bruni, C., Fernandez-Avila, C., Rodriguez-Turienzo, L., Mellado-Carretero, J., Spinelli, D., & Coltelli, M.-B. (2023). Opportunities and Limitations in Recycling Fossil Polymers from Textiles. Macromol, 3(2), 120-148. https://doi.org/10.3390/macromol3020009