Viscoelastic Properties of Biscuit Doughs with Different Lipidic Profiles Fortified with a Casein Hydrolysate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Ingredients of the Biscuit Doughs

2.2. Biscuit Dough Samples Preparation

2.3. Rheological Tests

2.3.1. Amplitude Sweeps

2.3.2. Frequency Sweeps

2.3.3. Yield Stress Test

2.4. Statistical Analysis

3. Results and Discussion

3.1. Overview

3.2. Linear Viscoelastic Range (LVER)

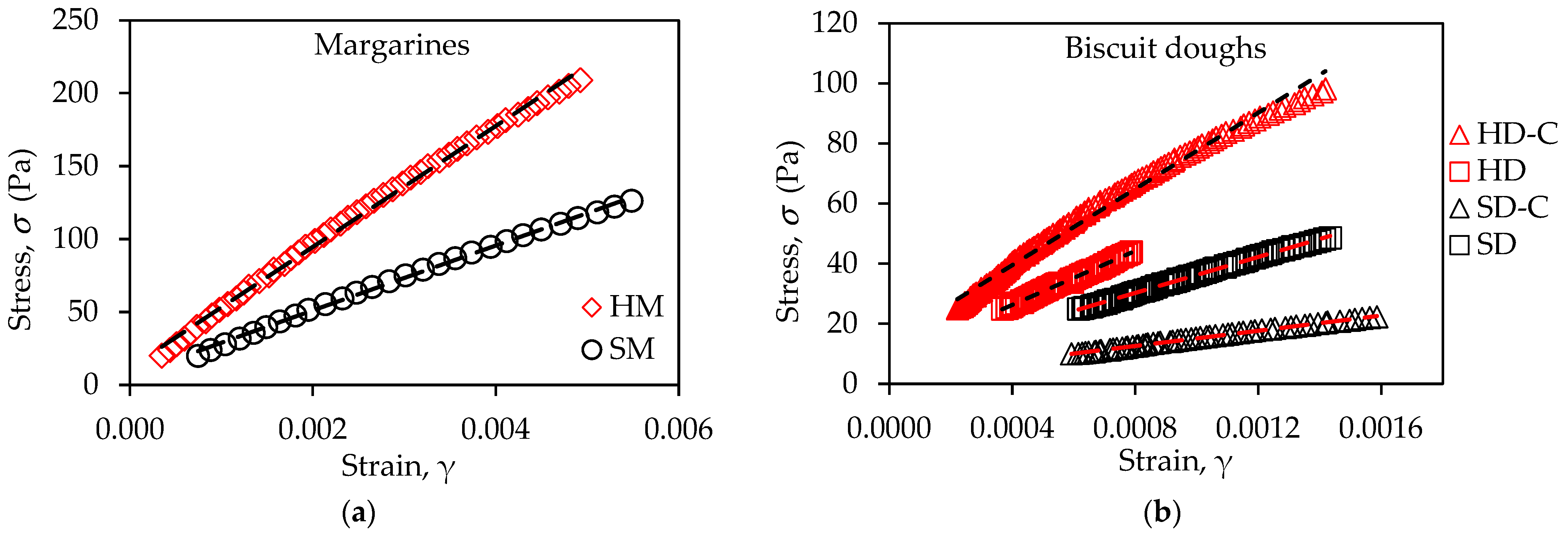

3.2.1. LVER for Soft/Hard Margarines (SM/HM) and Biscuit Doughs (SD/HD)

3.2.2. Effect of the Casein Hydrolysate on the LVER of Soft/Hard Biscuit Doughs

3.3. Mechanical Spectra

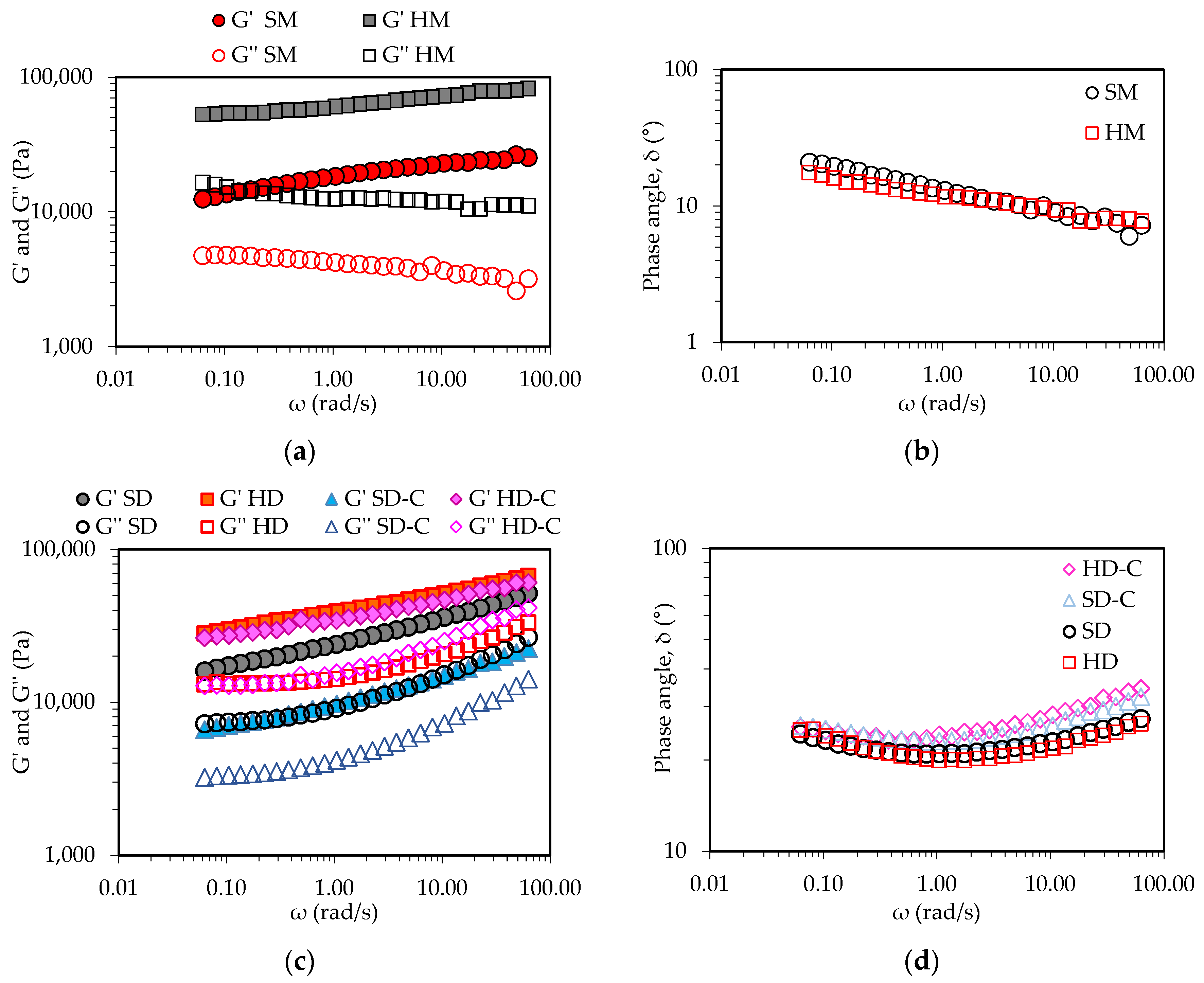

3.3.1. Mechanical Spectra for Soft/Hard Margarines (SM/HM) and Biscuit Doughs (SD/HD)

3.3.2. Influence of CH on Mechanical Spectra of Biscuit Doughs

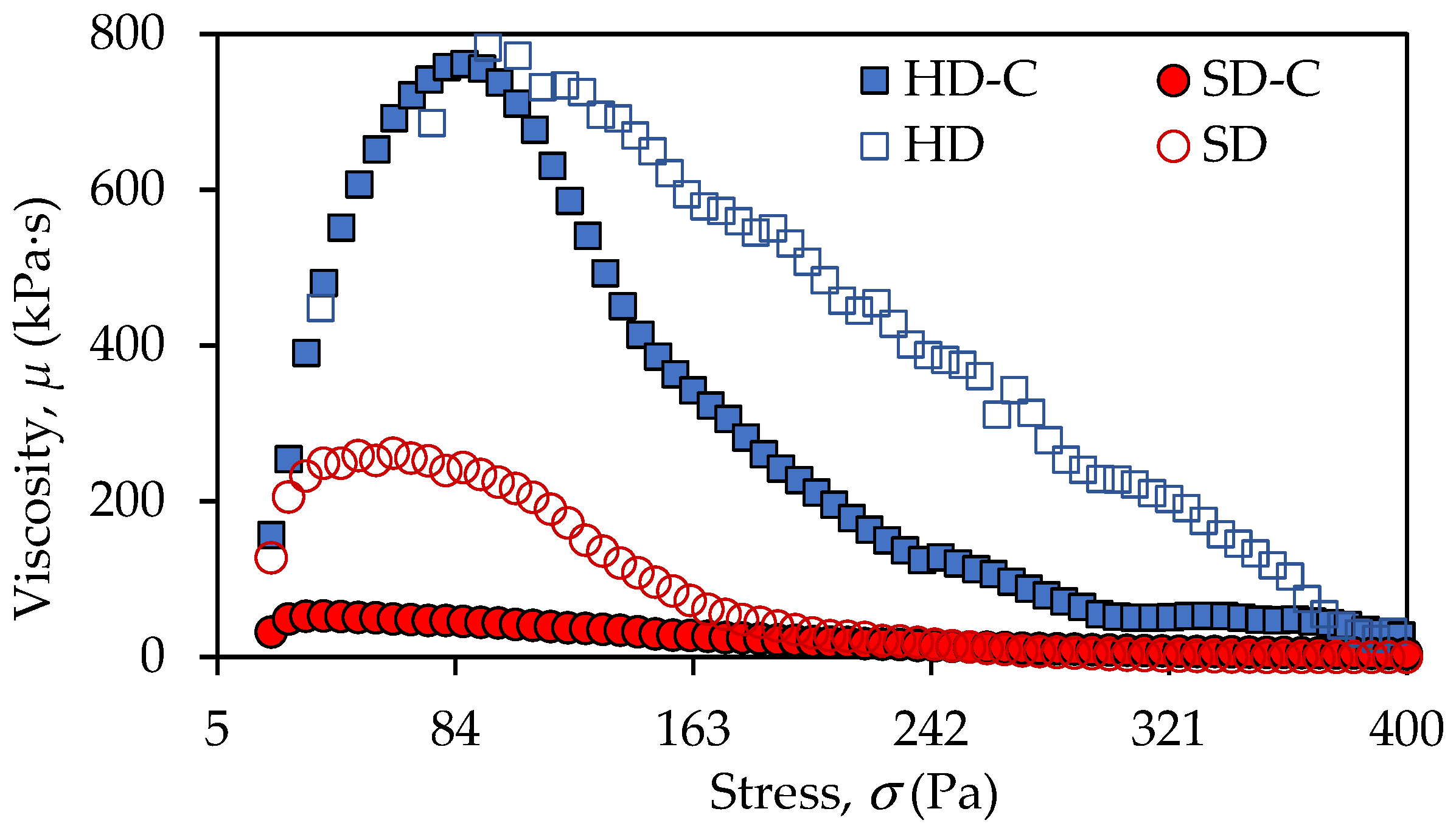

3.4. Study of the Yield Point

Comparison between Hard and Soft Biscuit Dough: Influence of CH on the Yield Point

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manley, D. Short dough biscuits. In Technology of Biscuits, Crackers and Cookies, 3rd ed.; Manley, D., Ed.; Woodhead Publishing: Cambridge, UK, 2000; pp. 274–284. [Google Scholar] [CrossRef]

- Pal, R. Rheology of Particulate Dispersions and Composites; CRC Press: Boca Raton, FL, USA, 2006; pp. 3–19. [Google Scholar]

- Mamat, H.; Hill, S.E. Effect of fat types on the structural and textural properties of dough and semi-sweet biscuit. J. Food Sci. Technol. 2014, 51, 1998–2005. [Google Scholar] [CrossRef]

- Ooms, N.; Pareyt, B.; Brijs, K.; Delcour, J.A. Ingredient functionality in multilayered dough margarine systems and the resultant pastry products: A review. Food Sci. Nutr. 2016, 56, 2101–2114. [Google Scholar] [CrossRef]

- Ghotra, B.S.; Dyal, S.D.; Narine, S.S. Lipid shortenings: A review. Food Res. Int. 2002, 35, 1015–1048. [Google Scholar] [CrossRef]

- Khousari, F.; Saberi, F.; Kowalczewski, L.P.; Lorenzo, J.M.; Kieliszek, M. Effect of the various fats on the structural characteristics of the hard dough biscuit. LWT-Food Sci. Technol. 2022, 159, 113227. [Google Scholar] [CrossRef]

- Ismail, N.H.; Sahri, M.M.; Hamid, R.A. Influence of palm based fluid shortening on the physical and textural properties of biscuits. J. Oil Palm Res. 2018, 30, 299–305. [Google Scholar] [CrossRef]

- Tarancón, P.; Hernández, M.J.; Salvador, A.; Sanz, T. Relevance of creep and oscillatory tests for understanding how cellulose emulsions function as fat replacers in biscuits. LWT Food Sci. 2015, 62, 640–646. [Google Scholar] [CrossRef]

- Devi, A.; Khatkar, B.S. Physicochemical, rheological and functional properties of fats and oils in relation to cookie quality: A review. J. Food Sci. Technol. 2016, 53, 3633–3641. [Google Scholar] [CrossRef]

- Troncoso, R.; Pérez-Guerra, N.; Torrado, A.; Tovar, C.A. Influence of casein hydrolysates and yeast on the rheological properties of wheat dough. Gels 2022, 8, 689. [Google Scholar] [CrossRef]

- Semba, R.D. The Rise and Fall of Protein Malnutrition in Global Health. Ann. Nutr. Metab. 2016, 69, 79–88. [Google Scholar] [CrossRef]

- Nogueira, A.C.; Steel, C.J. Protein enrichment of biscuits: A review. Food Rev. Int. 2018, 34, 796–809. [Google Scholar] [CrossRef]

- Sert, D.; Demir, M.K.; Ertaş, N. Rheological, physical and sensorial evaluation of cookies supplemented with dairy powders. Food Sci. Technol. Int. 2016, 22, 196–202. [Google Scholar] [CrossRef] [PubMed]

- Neklyudov, A.D.; Ivankin, A.N.; Berdutina, A.V. Properties and uses of protein hydrolysates (Review). Appl. Biochem. Microbiol. 2000, 36, 452–459. [Google Scholar] [CrossRef]

- Skibsted, L.H. Mineral nutrient interaction: Improving bioavailability of calcium and iron. Food Sci. Biotechnol. 2016, 25, 1233–1241. [Google Scholar] [CrossRef] [PubMed]

- Gani, A.; Broadway, A.A.; Ahmad, M.; Ashwar, B.A.; Wani, A.A.; Wani, S.M.; Masoodi, F.A.; Khatkar, B.S. Effect of whey and casein protein hydrolysates on rheological, textural and sensory properties of cookies. J. Food Sci. Technol. 2015, 52, 5718–5726. [Google Scholar] [CrossRef] [PubMed]

- Gallagher, E.; Kenny, S.; Arendt, E.K. Impact of dairy protein powders on biscuit quality. Eur. Food Res. Technol. 2005, 221, 237–243. [Google Scholar] [CrossRef]

- Acevedo-Fani, A.; Singh, H.J. Food structure and nutrition interface: New perspectives in designing healthy and sustainable Foods. J. Agric. Food Chem. 2022, 70, 5291–5298. [Google Scholar] [CrossRef] [PubMed]

- Campo-Deaño, L.; Tovar, C. The effect of egg albumen on the viscoelasticity of crab sticks made from Alaska Pollock and Pacific Whiting surimi. Food Hydrocoll. 2009, 23, 1641–1646. [Google Scholar] [CrossRef]

- Borderias, A.J.; Tovar, C.A.; Domínguez-Timón, F.; Díaz, M.T.; Pedrosa, M.M.; Moreno, H.M. Characterization of healthier mixed surimi gels obtained through partial substitution of myofibrillar proteins by pea protein isolates. Food Hydrocoll. 2020, 107, 105976. [Google Scholar] [CrossRef]

- Figura, L.O.; Teixeira, A.A. Food Physics, 2nd ed.; Springer: Berlin, Germany, 2023; pp. 120–143. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook, 5th ed.; Vincentz Network: Hannover, Germany, 2020; pp. 114–141. [Google Scholar]

- Tanislav, A.E.; Pușcaș, A.; Păucean, A.; Mureșan, A.E.; Semeniuc, C.A.; Mureșan, V.; Mudura, E. Evaluation of structural behavior in the process dynamics of oleogel-based tender dough products. Gels 2022, 8, 317. [Google Scholar] [CrossRef]

- Moreno, H.M.; Domínguez-Timón, F.; Díaz, M.T.; Pedrosa, M.M.; Borderías, A.J.; Tovar, C.A. Evaluation of gels made with different commercial pea protein isolate: Rheological, structural and functional properties. Food Hydrocoll. 2020, 99, 105375. [Google Scholar] [CrossRef]

- Narine, S.S.; Marangoni, A.G. Elastic modulus as an indicator of macroscopic hardness of fat crystal networks. LWT-Food Sci. Technol. 2001, 34, 33–40. [Google Scholar] [CrossRef]

- Nijenhuis, K. Advances in Polymer Science; Springer: Berlin, Germany, 1997; pp. 2–12. [Google Scholar] [CrossRef]

- Buresová, I.; Masaríková, L.; Hrivna, L.; Kulhanová, S.; Bures, D. The comparison of the effect of sodium caseinate, calcium caseinate, carboxymethyl cellulose and xanthan gum on rice-buckwheat dough rheological characteristics and textural and sensory quality of bread. LWT Food Sci. Technol. 2016, 68, 659–666. [Google Scholar] [CrossRef]

- Karlsson, A.O.; Ipsen, R.; Schrader, k.; Ardö, Y. Relationship between physical properties of casein micelles and rheology of skim milk concentrate. J. Dairy Sci. 2005, 88, 3784–3797. [Google Scholar] [CrossRef] [PubMed]

| Dough Ingredients | SD | SD-C | HD | HD-C |

|---|---|---|---|---|

| Wheat Flour (g/100 g) | 46.02 (100%) | 41.99 (100%) | 43.92 (100%) | 41.97 (100%) |

| Margarine (g/100 g) | 32.34 1 (70%) | 32.12 1 (76%) | 33.57 2 (76%) | 32.13 2 (77%) |

| Sugar (g/100 g) | 19.27 (42%) | 19.20 (46%) | 20.04 (46%) | 19.21 (46%) |

| Water (g/100 g) | 2.21 (4.8%) | 2.21 (5.3%) | 2.30 (5.2%) | 2.20 (5.2%) |

| Salt (g/100 g) | 0.16 (0.4%) | 0.16 (0.4%) | 0.16 (0.4%) | 0.16 (0.4%) |

| CH (g/100 g) | - | 4.33 (10%) | - | 4.33 (10%) |

| Sample | a (kPa) | b (Pa) | r2 | E (J/m3) | δ (°) | γmax |

|---|---|---|---|---|---|---|

| SM | 22.23 ± 0.20 a | 6.65 ± 0.66 a | 0.998 | 0.361 ± 0.034 a | 10.60 ± 0.25 a | 0.00549 ± 0.00051 a |

| HM | 41.42 ± 0.35 b | 11.86 ± 0.98 b | 0.997 | 0.560 ± 0.260 a | 11.70 ± 2.10 a | 0.00493 ± 0.0023 a |

| SD | 29.95 ± 0.13 c | 6.32 ± 0.13 a | 0.998 | 0.030 ± 0.004 b | 24.58 ± 0.41 b | 0.00143 ± 0.00019 b |

| HD | 44.95 ± 0.31 d | 8.29 ± 0.18 c | 0.997 | 0.014 ± 0.003 c | 19.60 ± 1.20 c | 0.00079 ± 0.00015 c |

| SD-C | 12.67 ± 0.07 e | 2.49 ± 0.07 d | 0.998 | 0.016 ± 0.002 c | 27.44 ± 0.61 d | 0.00159 ± 0.00018 b |

| HD-C | 63.42 ± 0.57 f | 14.14 ± 0.40 e | 0.989 | 0.079 ± 0.023 d | 22.90 ± 3.20 bc | 0.00142 ± 0.00042 b |

| Sample | G0′ (kPa) | n′ | G0″ (kPa) | n″ |

|---|---|---|---|---|

| SM | 17.8 ± 5.0 a | 0.103 ± 0.003 a | 4.18 ± 0.96 a | –0.069 ± 0.005 a |

| HM | 62 ± 17 b | 0.069 ± 0.002 b | 13.1 ± 2.6 bc | –0.050 ± 0.004 b |

| SD | 24.4 ± 3.3 a | 0.166 ± 0.002 c | 10.0 ± 1.3 b | 0.188 ± 0.009 c |

| HD | 39.1 ± 5.1 d | 0.122 ± 0.001 e | 15.8 ± 1.7 c | 0.131 ± 0.010 e |

| SD-C | 10.0 ± 1.2 c | 0.177 ± 0.003 d | 4.66 ± 0.61 a | 0.214 ± 0.011 d |

| HD-C | 35.4 ± 4.4 d | 0.123 ± 0.003 e | 17.1 ± 3.2 c | 0.178 ± 0.009 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Troncoso, R.; Torrado, A.; Pérez-Guerra, N.; Tovar, C.A. Viscoelastic Properties of Biscuit Doughs with Different Lipidic Profiles Fortified with a Casein Hydrolysate. Macromol 2024, 4, 437-447. https://doi.org/10.3390/macromol4020025

Troncoso R, Torrado A, Pérez-Guerra N, Tovar CA. Viscoelastic Properties of Biscuit Doughs with Different Lipidic Profiles Fortified with a Casein Hydrolysate. Macromol. 2024; 4(2):437-447. https://doi.org/10.3390/macromol4020025

Chicago/Turabian StyleTroncoso, Ricardo, Ana Torrado, Nelson Pérez-Guerra, and Clara A. Tovar. 2024. "Viscoelastic Properties of Biscuit Doughs with Different Lipidic Profiles Fortified with a Casein Hydrolysate" Macromol 4, no. 2: 437-447. https://doi.org/10.3390/macromol4020025

APA StyleTroncoso, R., Torrado, A., Pérez-Guerra, N., & Tovar, C. A. (2024). Viscoelastic Properties of Biscuit Doughs with Different Lipidic Profiles Fortified with a Casein Hydrolysate. Macromol, 4(2), 437-447. https://doi.org/10.3390/macromol4020025