Three-Dimensional Printing Applications in Food Industry

Abstract

:1. Introduction

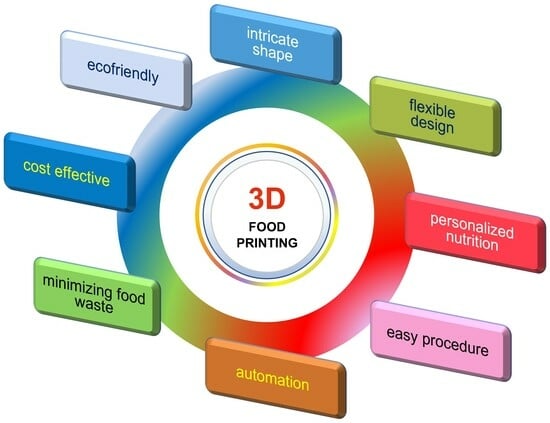

2. Advantages and Disadvantages of 3D Printing

- Three-dimensional printers leave a smaller environmental footprint than conventional manufacturing systems. Relatively limited waste is produced due to the high recyclability of the raw materials and the fact that no mechanical processing is required. The raw materials can be reused over the course of several production runs.

- Three-dimensional printing can adapt physical morphologies accurately (for example, the orientation of constitute building blocks).

- The use and selective deposition of a wide range of multifunctional materials (polymers, ceramics, composites, food powders) during printing a product can be purposely designed.

- The restrictions that traditional manufacturing normally imposes do not exist in 3D printing. It enables complex dimensions and geometries in a wide range of quantities (for example, undercuts, substructures, and topologies).

- Three-dimensional printing offers greater design flexibility and improved manufacturing adaptability (for example, foams, lattices, and cells). The only barrier is the minimum project size that can be accurately printed.

- The procedure of copying the original is easier and faster (for example, fewer requirements are needed for mold, die, or component tools). Three-dimensional structures are reproducible and impossible to make by hand alone.

- With conventional methods, parts are constructed in several steps while 3D printing manufactures parts in a single step, significantly amplifying the efficiency from design to production.

- The ability to verify a design by printing a production-ready prototype before financing expensive construction equipment (e.g., molds, accessories, and tooling) minimizes risk and financial loss during the prototyping process.

- Most 3D printers do not require highly skilled staff making labor costs much lower than traditional manufacturing. The machine works in a fully automated way to produce the part according to the file uploaded by a single operator.

- The rheological and mechanical properties of most raw materials must be modified through the addition of flow enhancers to obtain an extrudable paste-like material.

- Another drawback of 3D printing is the composite material itself. Τhe different chemical properties and storage requirements (temperature and humidity) of each component and how they are affected by the presence of the remaining components must be considered in combination when designing and piloting the 3D printing method.

- Some raw materials may be easy to extrude but cannot withstand a 3D structure, as is the case with vegetables which have a high water content.

- A lot of 3D products do not have the ability to withstand post-processing operations without losing the 3D intricate design due to cooking loss/shrinkage.

- Conventional techniques are still much faster than 3D printing. For example, a normal production line can produce up to nine thousand kilos of pasta per hour, while the printer can currently produce about four kilos per day [16].

- Three-dimensional printers currently have small print chambers which restrict the size of products that can be printed.

- Another potential problem with 3D printing is directly related to the type of machine or process used. If a printer has lower tolerance, the final product may differ from the original design. This can be fixed in post-processing but will have a negative impact on production time and cost.

- The shelf life of 3D-printed food products is limited to a few hours, while the corresponding products of traditional methods can be consumed even after 9–12 months.

3. Evolution of 3D Printing

4. Three-Dimensional Printing Processes

4.1. Selective Laser Sintering (SLS)

4.2. Hot Air Sintering (HAS)

4.3. Liquid Binding

4.4. Extrusion Method

5. Intelligent Food Packaging

6. Recent Applications of 3D Food Printing

7. Conclusions

8. Future Recommendations

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Horvath, J. A Brief History of 3D Printing. In Mastering 3D Printing; Horvath, J., Ed.; Apress: Berkeley, CA, USA, 2014; pp. 3–10. ISBN 978-1-4842-0025-4. [Google Scholar]

- Rindfleisch, A.; O’Hern, M.; Sachdev, V. The Digital Revolution, 3D Printing, and Innovation as Data. J. Prod. Innov. Manag. 2017, 34, 681–690. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Huang, D.; Fuh, J.Y.H.; Hong, G.S. An Overview of 3D Printing Technologies for Food Fabrication. Food Bioprocess Technol. 2015, 8, 1605–1615. [Google Scholar] [CrossRef]

- Sandeep, B.; Kannan, T.T.M.; Chandradass, J.; Ganesan, M.; John Rajan, A. Scope of 3D Printing in Manufacturing Industries-A Review. Mater. Today Proc. 2021, 45, 6941–6945. [Google Scholar] [CrossRef]

- Holland, S.; Foster, T.; MacNaughtan, W.; Tuck, C. Design and Characterisation of Food Grade Powders and Inks for Microstructure Control Using 3D Printing. J. Food Eng. 2018, 220, 12–19. [Google Scholar] [CrossRef]

- Agunbiade, A.; Song, L.; Agunbiade, O.; Ofoedu, C.; Chacha, J.; Duguma, H.; Hossaini, S.M.; Rasaq, W.; Shorstkii, I.; Osuji, C.; et al. Potentials of 3D Extrusion-Based Printing in Resolving Food Processing Challenges: A Perspective Review. J. Food Process Eng. 2022, 45, e13996. [Google Scholar] [CrossRef]

- Tracey, C.T.; Predeina, A.L.; Krivoshapkina, E.F.; Kumacheva, E. A 3D Printing Approach to Intelligent Food Packaging. Trends Food Sci. Technol. 2022, 127, 87–98. [Google Scholar] [CrossRef]

- Elkhattat, D.; Medhat, M. Using Technology in Smart and Intelligent Food Packages as a Communicational Tool with Consumers. In Proceedings of the 2021 World Conference on Computing and Communication Technologies (WCCCT), Dalian, China, 23–25 January 2021; pp. 108–114. [Google Scholar]

- Zhou, W.; Wu, Z.; Xie, F.; Tang, S.; Fang, J.; Wang, X. 3D Printed Nanocellulose-Based Label for Fruit Freshness Keeping and Visual Monitoring. Carbohydr. Polym. 2021, 273, 118545. [Google Scholar] [CrossRef] [PubMed]

- Lee, J. A 3D Food Printing Process for the New Normal Era: A Review. Processes 2021, 9, 1495. [Google Scholar] [CrossRef]

- Xu, W.; Jambhulkar, S.; Zhu, Y.; Ravichandran, D.; Kakarla, M.; Vernon, B.; Lott, D.G.; Cornella, J.L.; Shefi, O.; Miquelard-Garnier, G.; et al. 3D Printing for Polymer/Particle-Based Processing: A Review. Compos. Part B Eng. 2021, 223, 109102. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. 3D Printing of Meat. Meat Sci. 2019, 153, 35–44. [Google Scholar] [CrossRef]

- Singhal, S.; Rasane, P.; Kaur, S.; Garba, U.; Bankar, A.; Singh, J.; Gupta, N. 3D Food Printing: Paving Way towards Novel Foods. An. Acad. Bras. Ciênc. 2020, 92, e20180737. [Google Scholar] [CrossRef] [PubMed]

- Barilla Continues to Develop Pasta 3D Printer, Envisions Gourmet Customization—3DPrint.com. The Voice of 3D Printing/Additive Manufacturing. Available online: https://3dprint.com/151348/barilla-pasta-3d-printer/ (accessed on 17 February 2023).

- Mantihal, S.; Prakash, S.; Bhandari, B. Textural Modification of 3D Printed Dark Chocolate by Varying Internal Infill Structure. Food Res. Int. 2019, 121, 648–657. [Google Scholar] [CrossRef]

- Mueller, B. Additive Manufacturing Technologies—Rapid Prototyping to Direct Digital Manufacturing. Assem. Autom. 2012, 32. [Google Scholar] [CrossRef]

- Afoakwa, E.O.; Paterson, A.; Fowler, M. Factors Influencing Rheological and Textural Qualities in Chocolate—A Review. Trends Food Sci. Technol. 2007, 18, 290–298. [Google Scholar] [CrossRef]

- Mantihal, S.; Kobun, R.; Lee, B.-B. 3D Food Printing of as the New Way of Preparing Food: A Review. Int. J. Gastron. Food Sci. 2020, 22, 100260. [Google Scholar] [CrossRef]

- Nijdam, J.J.; LeCorre-Bordes, D.; Delvart, A.; Schon, B.S. A Rheological Test to Assess the Ability of Food Inks to Form Dimensionally Stable 3D Food Structures. J. Food Eng. 2021, 291, 110235. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Oral, M.O.; Severini, C. Analyzing the Effects of 3D Printing Process per Se on the Microstructure and Mechanical Properties of Cereal Food Products. Innov. Food Sci. Emerg. Technol. 2020, 66, 102531. [Google Scholar] [CrossRef]

- Tan, C.; Toh, W.Y.; Wong, G.; Li, L. Extrusion-Based 3D Food Printing—Materials and Machines. Int. J. Bioprinting 2018, 4, 143. [Google Scholar] [CrossRef] [PubMed]

- Standard Terminology for Additive Manufacturing Technologies. Available online: https://www.astm.org/f2792-12.html (accessed on 19 January 2023).

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d Printing Technologies Applied for Food Design: Status and Prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Jonkers, N.; van Dommelen, J.A.W.; Geers, M.G.D. Selective Laser Sintered Food: A Unit Cell Approach to Design Mechanical Properties. J. Food Eng. 2022, 335, 111183. [Google Scholar] [CrossRef]

- Qin, T.; Li, X.; Long, H.; Bin, S.; Xu, Y. Bioactive Tetracalcium Phosphate Scaffolds Fabricated by Selective Laser Sintering for Bone Regeneration Applications. Materials 2020, 13, 2268. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Wang, Y. 3D Printing: Printing Precision and Application in Food Sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef] [Green Version]

- Nikhil, A. 3D Printing Processes—Binder Jetting (Part 4/8). Available online: https://www.engineersgarage.com/3d-printing-processes-binder-jetting-part-4-8/ (accessed on 3 February 2023).

- Zhu, S.; Vazquez Ramos, P.; Heckert, O.R.; Stieger, M.; van der Goot, A.J.; Schutyser, M. Creating Protein-Rich Snack Foods Using Binder Jet 3D Printing. J. Food Eng. 2022, 332, 111124. [Google Scholar] [CrossRef]

- He, C.; Zhang, M.; Fang, Z. 3D Printing of Food: Pretreatment and Post-Treatment of Materials. Crit. Rev. Food Sci. Nutr. 2020, 60, 2379–2392. [Google Scholar] [CrossRef]

- Zhang, L.; Noort, M.; van Bommel, K. Chapter One—Towards the Creation of Personalized Bakery Products Using 3D Food Printing. In Advances in Food and Nutrition Research; Zhou, W., Gao, J., Eds.; Functional Bakery Products: Novel Ingredients and Processing Technology for Personalized Nutrition; Academic Press: Cambridge, MA, USA, 2022; Volume 99, pp. 1–35. [Google Scholar]

- Schwab, A.; Levato, R.; D’Este, M.; Piluso, S.; Eglin, D.; Malda, J. Printability and Shape Fidelity of Bioinks in 3D Bioprinting. Chem. Rev. 2020, 120, 11028–11055. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Yan, L.; Huang, D.; Lin, L. Extrusion-Based Food Printing for Digitalized Food Design and Nutrition Control. J. Food Eng. 2018, 220, 1–11. [Google Scholar] [CrossRef]

- Tejada-Ortigoza, V.; Cuan-Urquizo, E. Towards the Development of 3D-Printed Food: A Rheological and Mechanical Approach. Foods 2022, 11, 1191. [Google Scholar] [CrossRef]

- 3D Printing—Additive—Make. Available online: https://make.3dexperience.3ds.com/processes/3D-printing (accessed on 3 February 2023).

- Waghmare, R.; Suryawanshi, D.; Karadbhajne, S. Designing 3D Printable Food Based on Fruit and Vegetable Products—Opportunities and Challenges. J. Food Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Ross, M.M.; Crowley, S.V.; Crotty, S.; Oliveira, J.; Morrison, A.P.; Kelly, A.L. Parameters Affecting the Printability of 3D-Printed Processed Cheese. Innov. Food Sci. Emerg. Technol. 2021, 72, 102730. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of Rheological Properties of Mashed Potatoes on 3D Printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef] [Green Version]

- Severini, C.; Azzollini, D.; Albenzio, M.; Derossi, A. On Printability, Quality and Nutritional Properties of 3D Printed Cereal Based Snacks Enriched with Edible Insects. Food Res. Int. 2018, 106, 666–676. [Google Scholar] [CrossRef]

- Zhang, L.; Lou, Y.; Schutyser, M.A.I. 3D Printing of Cereal-Based Food Structures Containing Probiotics. Food Struct. 2018, 18, 14–22. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, D.; Wei, G.; Ma, Y.; Bhandari, B.; Zhou, P. 3D Printed Milk Protein Food Simulant: Improving the Printing Performance of Milk Protein Concentration by Incorporating Whey Protein Isolate. Innov. Food Sci. Emerg. Technol. 2018, 49, 116–126. [Google Scholar] [CrossRef] [Green Version]

- Derossi, A.; Caporizzi, R.; Azzollini, D.; Severini, C. Application of 3D Printing for Customized Food. A Case on the Development of a Fruit-Based Snack for Children. J. Food Eng. 2018, 220, 65–75. [Google Scholar] [CrossRef]

- Chen, H.; Xie, F.; Chen, L.; Zheng, B. Effect of Rheological Properties of Potato, Rice and Corn Starches on Their Hot-Extrusion 3D Printing Behaviors. J. Food Eng. 2018, 244, 150–158. [Google Scholar] [CrossRef] [Green Version]

- Yan, M.R.; Hsieh, S.; Ricacho, N. Innovative Food Packaging, Food Quality and Safety, and Consumer Perspectives. Processes 2022, 10, 747. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, X.; Guo, X.; Kong, B.; Zhang, M.; Qian, X.; Mi, S.; Sun, W. The Boom in 3D-Printed Sensor Technology. Sensors 2017, 17, 1166. [Google Scholar] [CrossRef] [PubMed]

- Justino Netto, J.M.; Ragoni, I.G.; Frezzatto Santos, L.E.; Silveira, Z.C. Selecting Low-Cost 3D Printers Using the AHP Method: A Case Study. SN Appl. Sci. 2019, 1, 335. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Brahma, S.; Mackay, J.; Cao, C.; Aliakbarian, B. The Role of Smart Packaging System in Food Supply Chain. J. Food Sci. 2020, 85, 517–525. [Google Scholar] [CrossRef] [Green Version]

- Almasi, H.; Forghani, S.; Moradi, M. Recent Advances on Intelligent Food Freshness Indicators; an Update on Natural Colorants and Methods of Preparation. Food Packag. Shelf Life 2022, 32, 100839. [Google Scholar] [CrossRef]

- Wu, S.; Wang, W.; Yan, K.; Ding, F.; Shi, X.; Deng, H.; Du, Y. Electrochemical Writing on Edible Polysaccharide Films for Intelligent Food Packaging. Carbohydr. Polym. 2018, 186, 236–242. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Mou, X.; Li, N. Preparation and Performance of Edible Screen-Printing Ink with Chitosan. In Advanced Graphic Communications, Packaging Technology and Materials; Ouyang, Y., Xu, M., Yang, L., Ouyang, Y., Eds.; Springer: Singapore, 2016; pp. 977–983. [Google Scholar]

- Caro, N.; Medina, E.; Díaz-Dosque, M.; López, L.; Abugoch, L.; Tapia, C. Novel Active Packaging Based on Films of Chitosan and Chitosan/Quinoa Protein Printed with Chitosan-Tripolyphosphate-Thymol Nanoparticles via Thermal Ink-Jet Printing. Food Hydrocoll. 2016, 52, 520–532. [Google Scholar] [CrossRef]

- Lozano-Navarro, J.I.; Díaz-Zavala, N.P.; Velasco-Santos, C.; Martínez-Hernández, A.L.; Tijerina-Ramos, B.I.; García-Hernández, M.; Rivera-Armenta, J.L.; Páramo-García, U.; Reyes-de la Torre, A.I. Antimicrobial, Optical and Mechanical Properties of Chitosan-Starch Films with Natural Extracts. Int. J. Mol. Sci. 2017, 18, 997. [Google Scholar] [CrossRef] [Green Version]

- Badawy, M.E.I.; Rabea, E.I.; El-Nouby, M.A.M.; Ismail, R.I.A.; Taktak, N.E.M. Strawberry Shelf Life, Composition, and Enzymes Activity in Response to Edible Chitosan Coatings. Int. J. Fruit Sci. 2017, 17, 117–136. [Google Scholar] [CrossRef]

- Oladzadabbasabadi, N.; Mohammadi Nafchi, A.; Ghasemlou, M.; Ariffin, F.; Singh, Z.; Al-Hassan, A.A. Natural Anthocyanins: Sources, Extraction, Characterization, and Suitability for Smart Packaging. Food Packag. Shelf Life 2022, 33, 100872. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Fabrication of Cellulose Nanofiber-Based Functional Color Indicator Film Incorporated with Shikonin Extracted from Lithospermum Erythrorhizon Root. Food Hydrocoll. 2021, 114, 106566. [Google Scholar] [CrossRef]

- Li, S.; Jiang, Y.; Zhou, Y.; Li, R.; Jiang, Y.; Alomgir Hossen, M.; Dai, J.; Qin, W.; Liu, Y. Facile Fabrication of Sandwich-like Anthocyanin/Chitosan/Lemongrass Essential Oil Films via 3D Printing for Intelligent Evaluation of Pork Freshness. Food Chem. 2022, 370, 131082. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and Intelligent Packaging in Meat Industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- Severini, C.; Derossi, A.; Ricci, I.; Caporizzi, R.; Fiore, A. Printing a Blend of Fruit and Vegetables. New Advances on Critical Variables and Shelf Life of 3D Edible Objects. J. Food Eng. 2017, 220, 89–100. [Google Scholar] [CrossRef]

- Le Tohic, C.; O’Sullivan, J.J.; Drapala, K.P.; Chartrin, V.; Chan, T.; Morrison, A.P.; Kerry, J.P.; Kelly, A.L. Effect of 3D Printing on the Structure and Textural Properties of Processed Cheese. J. Food Eng. 2018, 220, 56–64. [Google Scholar] [CrossRef]

- 3D Food Printing: Creating Shapes and Textures. Available online: https://www.tno.nl/media/5517/3d_food_printing_march_2015.pdf (accessed on 17 February 2023).

- Dick, A.; Bhandari, B.; Prakash, S. Post-Processing Feasibility of Composite-Layer 3D Printed Beef. Meat Sci. 2019, 153, 9–18. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Prakash, S.; Liu, Y. Physical Properties of 3D Printed Baking Dough as Affected by Different Compositions. Innov. Food Sci. Emerg. Technol. 2018, 49, 202–210. [Google Scholar] [CrossRef]

- Mantihal, S.; Prakash, S.; Godoi, F.C.; Bhandari, B. Optimization of Chocolate 3D Printing by Correlating Thermal and Flow Properties with 3D Structure Modeling. Innov. Food Sci. Amp Emerg. Technol. 2017, 44, 21–29. [Google Scholar] [CrossRef] [Green Version]

- Hao, L.; Mellor, S.; Seaman, O.; Henderson, J.; Sewell, N.; Sloan, M. Material Characterisation and Process Development for Chocolate Additive Layer Manufacturing. Virtual Phys. Prototyp. 2010, 5, 57–64. [Google Scholar] [CrossRef]

- Noort, M.; Bommel, K.; Renzetti, S. 3D-Printed Cereal Foods. Cereal Foods World 2017, 62, 272–277. [Google Scholar] [CrossRef]

- Multi-Material Three-Dimensional Food Printing with Simultaneous Infrared Cooking—3D Printing and Additive Manufacturing. Available online: https://www.liebertpub.com/doi/abs/10.1089/3dp.2018.0042 (accessed on 17 February 2023).

- Lipton, J.; Arnold, D.; Nigl, F.; Lopez, N.; Cohen, D.; Norén, N.; Lipson, H. Multi-Material Food Printing with Complex Internal Structure Suitable for Conventional Post-Processing. In Proceedings of the 2010 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010. [Google Scholar]

- Bareen, M.A.; Sahu, J.K.; Prakash, S.; Bhandari, B.; Naik, S. A Novel Approach to Produce Ready-to-Eat Sweetmeats with Variable Textures Using 3D Printing. J. Food Eng. 2023, 344, 111410. [Google Scholar] [CrossRef]

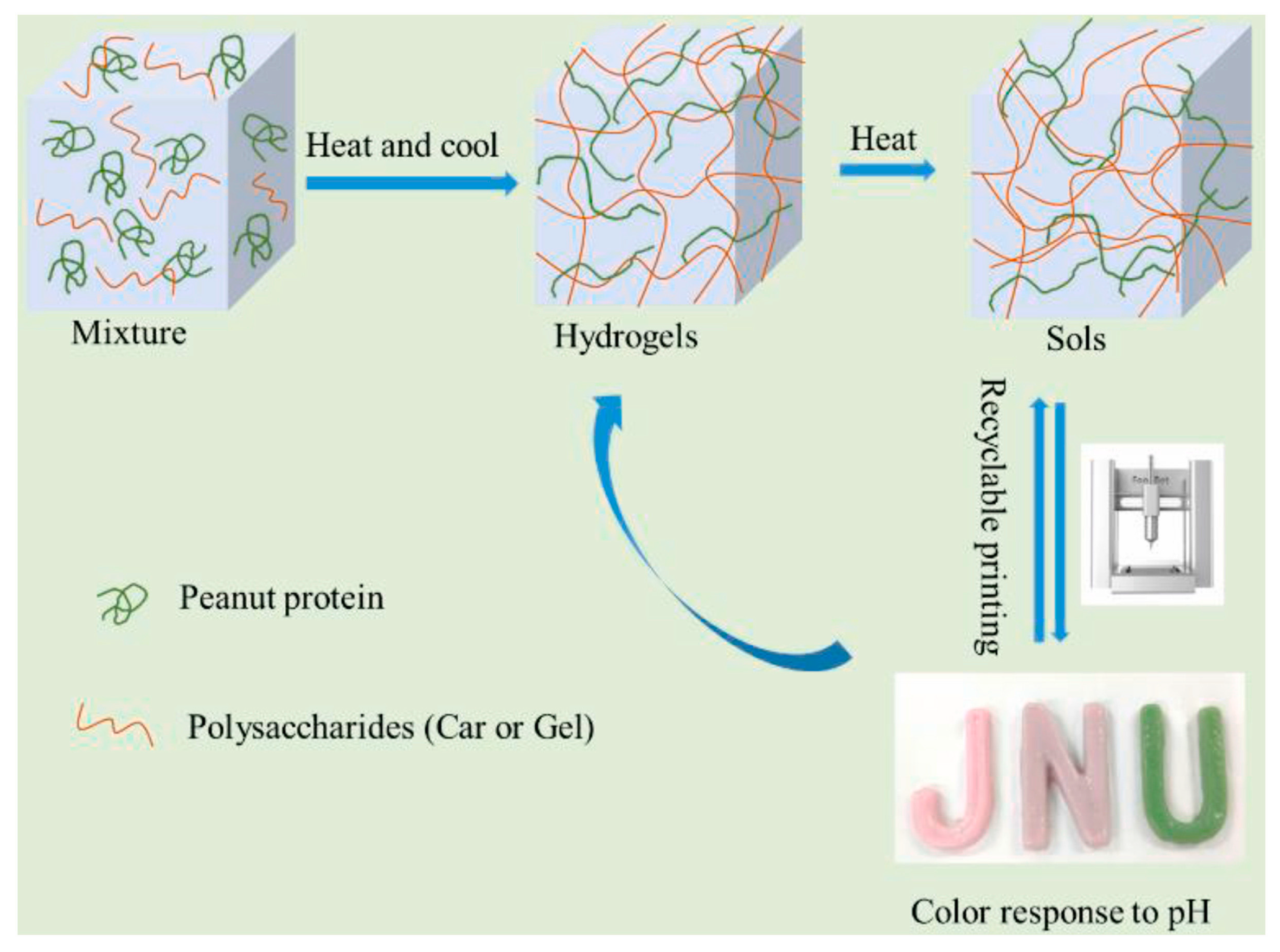

- Lin, Q.; Hu, Y.; Qiu, C.; Li, X.; Sang, S.; McClements, D.J.; Chen, L.; Long, J.; Xu, X.; Wang, J.; et al. Peanut Protein-Polysaccharide Hydrogels Based on Semi-Interpenetrating Networks Used for 3D/4D Printing. Food Hydrocoll. 2023, 137, 108332. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, C.; Li, X.; Sang, S.; McClements, D.J.; Chen, L.; Long, J.; Jiao, A.; Wang, J.; Jin, Z. Preparation of High Internal Phase Pickering Emulsion Gels Stabilized by Glycyrrhizic Acid-Zein Composite Nanoparticles: Gelation Mechanism and 3D Printing Performance. Food Hydrocoll. 2023, 135, 108128. [Google Scholar] [CrossRef]

- Qiu, L.; Zhang, M.; Bhandari, B.; Chitrakar, B.; Chang, L. Investigation of 3D Printing of Apple and Edible Rose Blends as a Dysphagia Food. Food Hydrocoll. 2023, 135, 108184. [Google Scholar] [CrossRef]

- Ahmadzadeh, S.; Ubeyitogullari, A. Generation of Porous Starch Beads via a 3D Food Printer: The Effects of Amylose Content and Drying Technique. Carbohydr. Polym. 2023, 301, 120296. [Google Scholar] [CrossRef] [PubMed]

- You, S.; Huang, Q.; Lu, X. Development of Fat-Reduced 3D Printed Chocolate by Substituting Cocoa Butter with Water-in-Oil Emulsions. Food Hydrocoll. 2023, 135, 108114. [Google Scholar] [CrossRef]

- Food 3D Printing Archives. 3D Print. Media Netw. Pulse AM Ind. 2023. Available online: https://www.voxelmatters.com/category/food/# (accessed on 17 February 2023).

- The Top 10 Companies in 3D Printed Food. Available online: https://all3dp.com/1/3d-printed-food-top-companies/ (accessed on 18 February 2023).

| Food Product | Description | Ref. |

|---|---|---|

| fruit | Fruit-based snack; provides 5–10% of energy, Ca, Fe, and vitamin D for 3–10-year-old children. | [43] |

| vegetables | Smoothie of selected fruit (kiwi, pears, avocado) and vegetables (carrots, broccoli); more appreciated appearance than the non-printed smoothie. | [59] |

| cheese | Processed cheese; 3D printing substantially affects its structural properties (texture, rheology, microstructure). | [60] |

| pasta | Various printed pasta shapes (e.g., rose-shaped). | [61] |

| meat | Multi-constituent composite meat products using beef paste and lard; suitable for sous-vide post-processing. | [62] |

| bread dough | Different composition of water, sucrose, butter, flour, and egg contents; formulation invented specifically for 3D food fabrication. | [63] |

| chocolate | Samples of hexagonal shape, with parallel, cross-sectional, and no internal support. | [64] |

| Three-dimensional prints (heart shape and logo) with suitable quality by varying the deposition parameters. | [65] | |

| cereal foods | Cookies; innovative food texture, modulation of taste perception, and sensory sensations. | [66] |

| ready-to-eat meals | A pyramid of sesame paste with chicken and shrimp paste with simultaneous infrared cooking. | [67] |

| Multi-material constructs of turkey meat, scallop, and celery. | [68] | |

| potato | Printed mashed potatoes with different concentrations of potato starch. | [28] |

| Food Product | Company Name/Process |

|---|---|

| Smoked Salmon Fillet | Austrian Revo Foods/Extrusion |

| Fruit-Flavored Droplets | Dovetailed Design Studio’s/the world’s first liquid-based 3D printer |

| Pasta (unique shapes) | Italian Barilla in collaboration with the Dutch company TNO/Fused Deposition Modeling |

| Chocolate and Cocoa Products (unique shapes and exclusive flavors) | Mona Lisa 3D Studio/ Extrusion |

| Pizza, Burgers, and Cookies | Printer Foodini/ Extrusion |

| Edible Sweet Decorations | Printer ChefJet/ Extrusion |

| Meals (proteins, carbs, other nutrients), Pizza | NASA funded Systems and Materials Research Corporation (SMRC)/Extrusion |

| Pizza | BeeHex Pizza Printer/Method |

| Chocolate | Mondelēz & 3P Innovation/Cadbury Dairy Milk 3D printer/Melt-extrusion |

| Chocolate (various shapes, sizes, and geometries) | Hershey Company in collaboration with D Systems/CocoJet, chocolate 3D printer/Extrusion |

| Products of Sugar | CandyFab/Selective Hot Air Sintering and Melting (SHASAM) |

| Vegan Meat (burgers, kababs, and sausages) | Redefine Meat/Extrusion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leontiou, A.; Georgopoulos, S.; Karabagias, V.K.; Kehayias, G.; Karakassides, A.; Salmas, C.E.; Giannakas, A.E. Three-Dimensional Printing Applications in Food Industry. Nanomanufacturing 2023, 3, 91-112. https://doi.org/10.3390/nanomanufacturing3010006

Leontiou A, Georgopoulos S, Karabagias VK, Kehayias G, Karakassides A, Salmas CE, Giannakas AE. Three-Dimensional Printing Applications in Food Industry. Nanomanufacturing. 2023; 3(1):91-112. https://doi.org/10.3390/nanomanufacturing3010006

Chicago/Turabian StyleLeontiou, Areti, Stavros Georgopoulos, Vassilios K. Karabagias, George Kehayias, Anastasios Karakassides, Constantinos E. Salmas, and Aris E. Giannakas. 2023. "Three-Dimensional Printing Applications in Food Industry" Nanomanufacturing 3, no. 1: 91-112. https://doi.org/10.3390/nanomanufacturing3010006

APA StyleLeontiou, A., Georgopoulos, S., Karabagias, V. K., Kehayias, G., Karakassides, A., Salmas, C. E., & Giannakas, A. E. (2023). Three-Dimensional Printing Applications in Food Industry. Nanomanufacturing, 3(1), 91-112. https://doi.org/10.3390/nanomanufacturing3010006