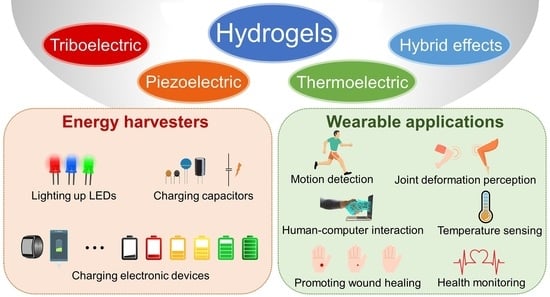

Hydrogel-Based Energy Harvesters and Self-Powered Sensors for Wearable Applications

Abstract

:1. Introduction

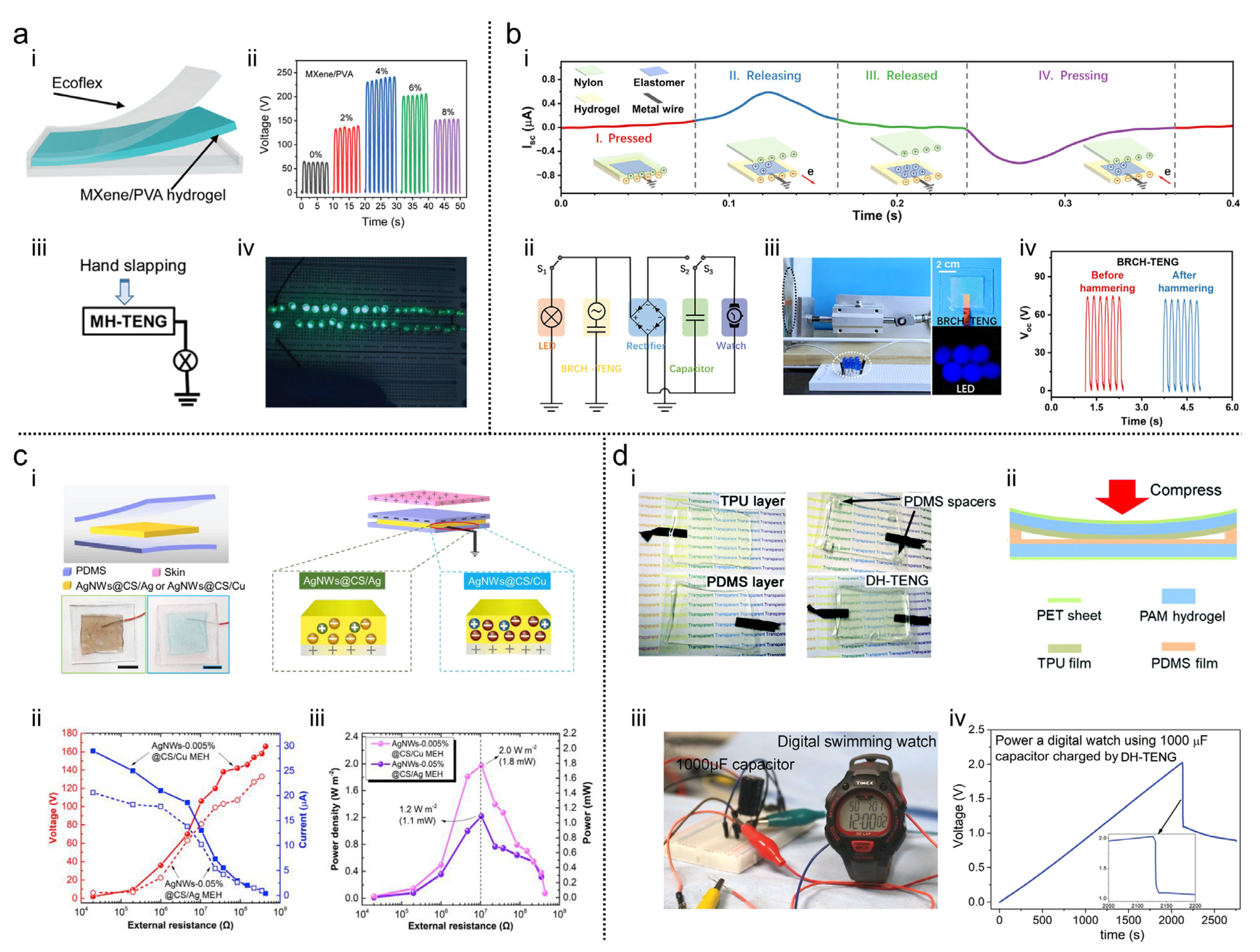

2. Hydrogel-Based TENGs

2.1. Hydrogel-Based TENGs for Energy Harvesting

2.2. Self-Powered Applications of Hydrogel-Based TENG Devices

3. Hydrogel-Based PENGs

3.1. Hydrogel-Based PENGs for Energy Harvesting

3.2. Self-Powered Applications of Hydrogel-Based PENG Devices

4. Hydrogel-Based TEGs

4.1. Hydrogel-Based TEGs for Energy Harvesting

4.2. Self-Powered Applications of Hydrogel-Based TEG Devices

5. Energy Harvesters and Self-Powered Wearable Applications Based on Hybrid Effects

5.1. Triboelectric, Piezoelectric, and Piezoresistive Effects

5.2. Photothermal and Thermoelectric Effects

5.3. Thermoelectric and Piezoresistive Effects

6. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lin, J.; Zhu, Z.; Cheung, C.F.; Yan, F.; Li, G. Digital manufacturing of functional materials for wearable electronics. J. Mater. Chem. C 2020, 8, 10587–10603. [Google Scholar] [CrossRef]

- Xu, K.; Lu, Y.; Takei, K. Multifunctional Skin-Inspired Flexible Sensor Systems for Wearable Electronics. Adv. Mater. Technol. 2019, 4, 1800628. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, Y.; Liu, Y. Wearable Electronics Based on Stretchable Organic Semiconductors. Small 2023, 19, 2206309. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Wu, J.; Yan, J.; Liu, X. Advanced Fiber Materials for Wearable Electronics. Adv. Fiber Mater. 2023, 5, 12–35. [Google Scholar] [CrossRef]

- Lee, J.-H.; Yang, G.; Kim, C.-H.; Mahajan, R.L.; Lee, S.-Y.; Park, S.-J. Flexible solid-state hybrid supercapacitors for the internet of everything (IoE). Energy Environ. Sci. 2022, 15, 2233–2258. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Pan, J.; Peng, H. Stretchable lithium-air batteries for wearable electronics. J. Mater. Chem. A 2016, 4, 13419–13424. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, Y.; Liu, X.; Lv, C.; Li, Y.; Wei, D.; Liu, Z. Carbon-Nanomaterial-Based Flexible Batteries for Wearable Electronics. Adv. Mater. 2019, 31, 1800716. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, F.; Yu, M.; Zhuang, X.; Feng, X. Two-dimensional materials for miniaturized energy storage devices: From individual devices to smart integrated systems. Chem. Soc. Rev. 2018, 47, 7426–7451. [Google Scholar] [CrossRef]

- Chen, J.; Guo, H.; Pu, X.; Wang, X.; Xi, Y.; Hu, C. Traditional weaving craft for one-piece self-charging power textile for wearable electronics. Nano Energy 2018, 50, 536–543. [Google Scholar] [CrossRef]

- Guo, H.; Yeh, M.-H.; Lai, Y.-C.; Zi, Y.; Wu, C.; Wen, Z.; Hu, C.; Wang, Z.L. All-in-One Shape-Adaptive Self-Charging Power Package for Wearable Electronics. ACS Nano 2016, 10, 10580–10588. [Google Scholar] [CrossRef]

- Li, S.; Wang, J.; Peng, W.; Lin, L.; Zi, Y.; Wang, S.; Zhang, G.; Wang, Z.L. Sustainable Energy Source for Wearable Electronics Based on Multilayer Elastomeric Triboelectric Nanogenerators. Adv. Energy Mater. 2017, 7, 1602832. [Google Scholar] [CrossRef]

- Teixeira, J.S.; Costa, R.S.; Pires, A.L.; Pereira, A.M.; Pereira, C. Hybrid dual-function thermal energy harvesting and storage technologies: Towards self-chargeable flexible/wearable devices. Dalton Trans. 2021, 50, 9983–10013. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Xiao, Y.; Deng, F.; Chen, Y.; Zhang, H. Eye-Movement-Controlled Wheelchair Based on Flexible Hydrogel Biosensor and WT-SVM. Biosensors 2021, 11, 198. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Lin, N.; He, Y.; Zuo, B. Self-Healing, Self-Adhesive Silk Fibroin Conductive Hydrogel as a Flexible Strain Sensor. ACS Appl. Mater. Interfaces 2021, 13, 40013–40031. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Yu, J.; Sun, D.; Dang, C.; Ren, W.; Shao, C.; Sun, R. Extreme environment-adaptable and fast self-healable eutectogel triboelectric nanogenerator for energy harvesting and self-powered sensing. Nano Energy 2022, 98, 107284. [Google Scholar] [CrossRef]

- Li, G.; Li, L.; Zhang, P.; Chang, C.; Xu, F.; Pu, X. Ultra-stretchable and healable hydrogel-based triboelectric nanogenerators for energy harvesting and self-powered sensing. RSC Adv. 2021, 11, 17437–17444. [Google Scholar] [CrossRef]

- Vijayakanth, T.; Shankar, S.; Finkelstein-Zuta, G.; Rencus-Lazar, S.; Gilead, S.; Gazit, E. Perspectives on recent advancements in energy harvesting, sensing and bio-medical applications of piezoelectric gels. Chem. Soc. Rev. 2023, 52, 6191–6220. [Google Scholar] [CrossRef]

- Kong, S.; Huang, Z.; Hu, Y.; Jiang, Y.; Lu, Y.; Zhao, W.; Shi, Q.; Yuan, M.; Dai, B.; Li, J.; et al. Tellurium-nanowire-doped thermoelectric hydrogel with high stretchability and seebeck coefficient for low-grade heat energy harvesting. Nano Energy 2023, 115, 108708. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Wei, S.; Lv, H.; Zhou, J.; Peng, P.; Wang, H.; Chen, G. A Wavy-Structured Highly Stretchable Thermoelectric Generator with Stable Energy Output and Self-Rescuing Capability. CCS Chem. 2021, 3, 2404–2414. [Google Scholar] [CrossRef]

- Pan, S.; Zhang, Z. Fundamental theories and basic principles of triboelectric effect: A review. Friction 2019, 7, 2–17. [Google Scholar] [CrossRef]

- Kim, K.N.; Lee, J.P.; Lee, S.H.; Lee, S.C.; Baik, J.M. Ergonomically designed replaceable and multifunctional triboelectric nanogenerator for a uniform contact. RSC Adv. 2016, 6, 88526–88530. [Google Scholar] [CrossRef]

- Rana, S.M.S.; Rahman, M.T.; Sharma, S.; Salauddin, M.; Yoon, S.H.; Park, C.; Maharjan, P.; Bhatta, T.; Park, J.Y. Cation functionalized nylon composite nanofibrous mat as a highly positive friction layer for robust, high output triboelectric nanogenerators and self-powered sensors. Nano Energy 2021, 88, 106300. [Google Scholar] [CrossRef]

- Li, S.; Peng, W.; Wang, J.; Lin, L.; Zi, Y.; Zhang, G.; Wang, Z.L. All-Elastomer-Based Triboelectric Nanogenerator as a Keyboard Cover To Harvest Typing Energy. ACS Nano 2016, 10, 7973–7981. [Google Scholar] [CrossRef] [PubMed]

- Hu, D.; Yao, M.; Fan, Y.; Ma, C.; Fan, M.; Liu, M. Strategies to achieve high performance piezoelectric nanogenerators. Nano Energy 2019, 55, 288–304. [Google Scholar] [CrossRef]

- Deng, W.; Zhou, Y.; Libanori, A.; Chen, G.; Yang, W.; Chen, J. Piezoelectric nanogenerators for personalized healthcare. Chem. Soc. Rev. 2022, 51, 3380–3435. [Google Scholar] [CrossRef]

- Pei, H.; Jing, J.; Chen, Y.; Guo, J.; Chen, N. 3D printing of PVDF-based piezoelectric nanogenerator from programmable metamaterial design: Promising strategy for flexible electronic skin. Nano Energy 2023, 109, 108303. [Google Scholar] [CrossRef]

- Zhou, Y.-X.; Lin, Y.-T.; Huang, S.-M.; Chen, G.-T.; Chen, S.-W.; Wu, H.-S.; Ni, I.C.; Pan, W.-P.; Tsai, M.-L.; Wu, C.-I.; et al. Tungsten disulfide nanosheets for piezoelectric nanogenerator and human-machine interface applications. Nano Energy 2022, 97, 107172. [Google Scholar] [CrossRef]

- Tohidi, F.; Ghazanfari Holagh, S.; Chitsaz, A. Thermoelectric Generators: A comprehensive review of characteristics and applications. Appl. Therm. Eng. 2022, 201, 117793. [Google Scholar] [CrossRef]

- Tabaie, Z.; Omidvar, A. Human body heat-driven thermoelectric generators as a sustainable power supply for wearable electronic devices: Recent advances, challenges, and future perspectives. Heliyon 2023, 9, e14707. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Y.; Deng, Y.; Gao, H.; Lin, Z.; Zhu, W.; Ye, H. A novel self-powered wireless temperature sensor based on thermoelectric generators. Energy Convers. Manag. 2014, 80, 110–116. [Google Scholar] [CrossRef]

- Hassanzadeh, A.; Baghestani, S. A New Self-Powered Temperature Sensor Based on Thermoelectric Generators. IEEE Sens. J. 2022, 22, 22421–22427. [Google Scholar] [CrossRef]

- Wu, S.; Dong, P.; Cui, X.; Zhang, Y. The strategy of circuit design for high performance nanogenerator based self-powered heart rate monitor system. Nano Energy 2022, 96, 107136. [Google Scholar] [CrossRef]

- Su, Y.; Chen, G.; Chen, C.; Gong, Q.; Xie, G.; Yao, M.; Tai, H.; Jiang, Y.; Chen, J. Self-Powered Respiration Monitoring Enabled By a Triboelectric Nanogenerator. Adv. Mater. 2021, 33, 2101262. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Zhang, Y.; Ning, C.; Ji, Q.; Peng, X.; Dong, K.; Wang, Z.L. Ultrathin Eardrum-Inspired Self-Powered Acoustic Sensor for Vocal Synchronization Recognition with the Assistance of Machine Learning. Small 2022, 18, 2106960. [Google Scholar] [CrossRef] [PubMed]

- Si, J.; Duan, R.; Zhang, M.; Liu, X. Recent Progress Regarding Materials and Structures of Triboelectric Nanogenerators for AR and VR. Nanomaterials 2022, 12, 1385. [Google Scholar] [CrossRef]

- Qiao, W.; Zhou, L.; Zhao, Z.; Liu, D.; Li, S.; An, J.; Li, X.; Gao, Y.; Yang, P.; Liu, J.; et al. A self-powered vector motion sensor for smart robotics and personalized medical rehabilitation. Nano Energy 2022, 104, 107936. [Google Scholar] [CrossRef]

- Sahoo, S.; Krishnamoorthy, K.; Pazhamalai, P.; Mariappan, V.K.; Manoharan, S.; Kim, S.-J. High performance self-charging supercapacitors using a porous PVDF-ionic liquid electrolyte sandwiched between two-dimensional graphene electrodes. J. Mater. Chem. A 2019, 7, 21693–21703. [Google Scholar] [CrossRef]

- Sahoo, S.; Ratha, S.; Rout, C.S.; Nayak, S.K. Self-charging supercapacitors for smart electronic devices: A concise review on the recent trends and future sustainability. J. Mater. Sci. 2022, 57, 4399–4440. [Google Scholar] [CrossRef]

- Wu, Z.; Cheng, T.; Wang, Z.L. Self-Powered Sensors and Systems Based on Nanogenerators. Sensors 2020, 20, 2925. [Google Scholar] [CrossRef]

- Askari, H.; Hashemi, E.; Khajepour, A.; Khamesee, M.B.; Wang, Z.L. Towards self-powered sensing using nanogenerators for automotive systems. Nano Energy 2018, 53, 1003–1019. [Google Scholar] [CrossRef]

- Aaryashree; Sahoo, S.; Walke, P.; Nayak, S.K.; Rout, C.S.; Late, D.J. Recent developments in self-powered smart chemical sensors for wearable electronics. Nano Res. 2021, 14, 3669–3689. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, M.; Qin, C.; Qian, X.; Zhang, L.; Zhou, J.; Lu, A. Transparent, conductive cellulose hydrogel for flexible sensor and triboelectric nanogenerator at subzero temperature. Carbohydr. Polym. 2021, 265, 118078. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Qu, J.; Zhang, X.; Ao, K.; Zhou, Z.; Zheng, Z.; Mu, Y.; Wu, X.; Luo, Y.; Feng, S.-P. Biomechanical Energy Harvesters Based on Ionic Conductive Organohydrogels via the Hofmeister Effect and Electrostatic Interaction. ACS Nano 2021, 15, 13427–13435. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Lv, H.; Meng, J.; Song, Z.; Meng, C.; Liu, M.; Zhang, D. Triboelectrification-Induced Electricity in Self-Healing Hydrogel for Mechanical Energy Harvesting and Ultra-sensitive Pressure Monitoring. ACS Omega 2022, 7, 18816–18825. [Google Scholar] [CrossRef]

- Shin, J.; Ji, S.; Yoon, J.; Park, J. Module-Type Triboelectric Nanogenerators Capable of Harvesting Power from a Variety of Mechanical Energy Sources. Micromachines 2021, 12, 1043. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, X.; Wang, Z.L. The sealed bionic fishtail-structured TENG based on anticorrosive paint for ocean sensor systems. Nano Energy 2023, 108, 108210. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, L.; Song, F.; Wu, J.; Zhou, Q.; Xie, L. Hybrid natural hydrogels integrated with voriconazole-loaded microspheres for ocular antifungal applications. J. Mater. Chem. B 2021, 9, 3377–3388. [Google Scholar] [CrossRef]

- Luo, X.; Zhu, L.; Wang, Y.-C.; Li, J.; Nie, J.; Wang, Z.L. A Flexible Multifunctional Triboelectric Nanogenerator Based on MXene/PVA Hydrogel. Adv. Funct. Mater. 2021, 31, 2104928. [Google Scholar] [CrossRef]

- Li, R.; Xu, Z.; Li, L.; Wei, J.; Wang, W.; Yan, Z.; Chen, T. Breakage-resistant hydrogel electrode enables ultrahigh mechanical reliability for triboelectric nanogenerators. Chem. Eng. J. 2023, 454, 140261. [Google Scholar] [CrossRef]

- Wang, L.; Daoud, W.A. Hybrid conductive hydrogels for washable human motion energy harvester and self-powered temperature-stress dual sensor. Nano Energy 2019, 66, 104080. [Google Scholar] [CrossRef]

- Jing, X.; Li, H.; Mi, H.-Y.; Feng, P.-Y.; Tao, X.; Liu, Y.; Liu, C.; Shen, C. A flexible semitransparent dual-electrode hydrogel based triboelectric nanogenerator with tough interfacial bonding and high energy output. J. Mater. Chem. C 2020, 8, 5752–5760. [Google Scholar] [CrossRef]

- Xiao, Z.; Luo, Y.; Yuan, H.; Zheng, T.; Xu, S.; Dai, G.; Yang, J. Coupling charge pump and BUCK circuits to efficiently enhance the output performance of triboelectric nanogenerator. Nano Energy 2023, 115, 108749. [Google Scholar] [CrossRef]

- Shi, M.; Yang, W.; Zhang, Z.; Zhao, M.; Wang, Z.L.; Lu, X. Hydrogels with highly concentrated salt solution as electrolytes for solid-state supercapacitors with a suppressed self-discharge rate. J. Mater. Chem. A 2022, 10, 2966–2972. [Google Scholar] [CrossRef]

- Abir, S.S.H.; Sadaf, M.U.K.; Saha, S.K.; Touhami, A.; Lozano, K.; Uddin, M.J. Nanofiber-Based Substrate for a Triboelectric Nanogenerator: High-Performance Flexible Energy Fiber Mats. ACS Appl. Mater. Interfaces 2021, 13, 60401–60412. [Google Scholar] [CrossRef]

- Bagchi, B.; Datta, P.; Fernandez, C.S.; Gupta, P.; Jaufuraully, S.; David, A.L.; Siassakos, D.; Desjardins, A.; Tiwari, M.K. Flexible triboelectric nanogenerators using transparent copper nanowire electrodes: Energy harvesting, sensing human activities and material recognition. Mater. Horiz. 2023, 10, 3124–3134. [Google Scholar] [CrossRef]

- Fan, J.; Yuan, M.; Wang, L.; Xia, Q.; Zheng, H.; Zhou, A. MXene supported by cotton fabric as electrode layer of triboelectric nanogenerators for flexible sensors. Nano Energy 2023, 105, 107973. [Google Scholar] [CrossRef]

- Wang, G.; Liu, X.; Wang, Y.; Zheng, Z.; Zhu, Z.; Yin, Y.; Zhu, L.; Wang, X. Energy Harvesting and Sensing Integrated Woven Structure Kneepad Based on Triboelectric Nanogenerators. Adv. Mater. Technol. 2023, 8, 2200973. [Google Scholar] [CrossRef]

- Xiong, Y.; Luo, L.; Yang, J.; Han, J.; Liu, Y.; Jiao, H.; Wu, S.; Cheng, L.; Feng, Z.; Sun, J.; et al. Scalable spinning, winding, and knitting graphene textile TENG for energy harvesting and human motion recognition. Nano Energy 2023, 107, 108137. [Google Scholar] [CrossRef]

- Li, Z.; Li, C.; Sun, W.; Bai, Y.; Li, Z.; Deng, Y. A Controlled Biodegradable Triboelectric Nanogenerator Based on PEGDA/Laponite Hydrogels. ACS Appl. Mater. Interfaces 2023, 15, 12787–12796. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, D.; Wang, Z.; Xi, G.; Mao, R.; Ma, Y.; Wang, D.; Tang, M.; Xu, Z.; Luan, H. Ultrastretchable, Self-Healing Conductive Hydrogel-Based Triboelectric Nanogenerators for Human-Computer Interaction. ACS Appl. Mater. Interfaces 2023, 15, 5128–5138. [Google Scholar] [CrossRef]

- Qu, M.; Shen, L.; Wang, J.; Zhang, N.; Pang, Y.; Wu, Y.; Ge, J.; Peng, L.; Yang, J.; He, J. Superhydrophobic, Humidity-Resistant, and Flexible Triboelectric Nanogenerators for Biomechanical Energy Harvesting and Wearable Self-Powered Sensing. ACS Appl. Nano Mater. 2022, 5, 9840–9851. [Google Scholar] [CrossRef]

- Rahman, M.T.; Rahman, M.S.; Kumar, H.; Kim, K.; Kim, S. Metal-Organic Framework Reinforced Highly Stretchable and Durable Conductive Hydrogel-Based Triboelectric Nanogenerator for Biomotion Sensing and Wearable Human-Machine Interfaces. Adv. Funct. Mater. 2023, 2303471. [Google Scholar] [CrossRef]

- Ma, B.; Cheng, L.; Bai, S.; Jia, X.; Ma, J.; Zhao, J.; Wang, L.; Qin, Y. 3D spirally coiled piezoelectric nanogenerator for large impact energy harvesting. Nano Energy 2023, 111, 108412. [Google Scholar] [CrossRef]

- Zhou, X.; Parida, K.; Chen, J.; Xiong, J.; Zhou, Z.; Jiang, F.; Xin, Y.; Magdassi, S.; Lee, P.S. 3D Printed Auxetic Structure-Assisted Piezoelectric Energy Harvesting and Sensing. Adv. Energy Mater. 2023, 13, 2301159. [Google Scholar] [CrossRef]

- Zong, Y.; Wang, R.; Xu, S.; Zhang, R.; Zhang, Z. Flexible Piezoelectric Nanogenerator Based on Cellulose Nanofibril/MXene Composite Aerogels for Low-Frequency Energy Harvesting. ACS Appl. Nano Mater. 2023, 6, 9021–9031. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, L.; Du, C. Progress in Piezoelectric Nanogenerators Based on PVDF Composite Films. Micromachines 2021, 12, 1278. [Google Scholar] [CrossRef]

- Yi, J.; Song, Y.; Cao, Z.; Li, C.; Xiong, C. Gram-scale Y-doped ZnO and PVDF electrospun film for piezoelectric nanogenerators. Compos. Sci. Technol. 2021, 215, 109011. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, L.; Fang, Z.; Wang, S.; Yang, T.; Zhu, L.; Hou, X.; Wang, H.; Wang, Z.L. Piezoelectric Nanogenerator Based on In Situ Growth All-Inorganic CsPbBr3 Perovskite Nanocrystals in PVDF Fibers with Long-Term Stability. Adv. Funct. Mater. 2021, 31, 2011073. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Li, Y.; Wang, Z.; Wang, W.; An, Q.; Tong, W. Piezoelectric Nanogenerators based on Graphene Oxide/PVDF Electrospun Nanofiber with Enhanced Performances by In-Situ Reduction. Mater. Today Commun. 2021, 26, 101629. [Google Scholar] [CrossRef]

- Wang, L.; Yu, Y.; Zhao, X.; Zhang, Z.; Yuan, X.; Cao, J.; Meng, W.; Ye, L.; Lin, W.; Wang, G. A Biocompatible Self-Powered Piezoelectric Poly(vinyl alcohol)-Based Hydrogel for Diabetic Wound Repair. ACS Appl. Mater. Interfaces 2022, 14, 46273–46289. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, W.; Zheng, X.; Huang, X.; Dan, N.; Wang, M.; Li, Y.; Li, Z.; Dan, W.; Wang, Y. Two-Layered Biomimetic Flexible Self-Powered Electrical Stimulator for Promoting Wound Healing. Biomacromolecules 2023, 24, 1483–1496. [Google Scholar] [CrossRef] [PubMed]

- Ge, Z.; Qiao, Y.; Zhu, W.; Xu, Y.; Fang, Q.; Wang, D.; Tang, Y.; Zhao, R.; Deng, X.; Lin, W.; et al. Highly stretchable polyester-based piezoelectric elastomer for simultaneously realization of accelerated regeneration and motion monitoring for Achilles tendon rupture. Nano Energy 2023, 115, 108751. [Google Scholar] [CrossRef]

- Pi, W.; Rao, F.; Cao, J.; Zhang, M.; Chang, T.; Han, Y.; Zheng, Y.; Liu, S.; Li, Q.; Sun, X.; et al. Sono-electro-mechanical therapy for peripheral nerve regeneration through piezoelectric nanotracts. Nano Today 2023, 50, 101860. [Google Scholar] [CrossRef]

- Xie, T.; Liu, Q.; Xue, G.; Zhang, Y.; Zhou, J.; Zhu, Z.; Gou, X. Experimental-numerical analysis of cell adhesion-mediated electromechanical stimulation on piezoelectric nanofiber scaffolds. J. Biomech. 2021, 129, 110777. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Y.; Liang, X. Piezoelectric Nanomaterials Activated by Ultrasound in Disease Treatment. Pharmaceutics 2023, 15, 1338. [Google Scholar] [CrossRef]

- Zhan, L.; Xiao, C.; Li, C.; Zhai, J.; Yang, F.; Piao, J.; Ning, C.; Zhou, Z.; Yu, P.; Qi, S. Internal Wireless Electrical Stimulation from Piezoelectric Barium Titanate Nanoparticles as a New Strategy for the Treatment of Triple-Negative Breast Cancer. ACS Appl. Mater. Interfaces 2022, 14, 45032–45041. [Google Scholar] [CrossRef]

- Dupont, M.F.; MacFarlane, D.R.; Pringle, J.M. Thermo-electrochemical cells for waste heat harvesting-progress and perspectives. Chem. Commun. 2017, 53, 6288–6302. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Heyst, B.V. A review of the state of the science on wearable thermoelectric power generators (TEGs) and their existing challenges. Renew. Sustain. Energy Rev. 2017, 73, 730–744. [Google Scholar] [CrossRef]

- Anand, S.; Gurunathan, R.; Soldi, T.; Borgsmiller, L.; Orenstein, R.; Snyder, G.J. Thermoelectric transport of semiconductor full-Heusler VFe2Al. J. Mater. Chem. C 2020, 8, 10174–10184. [Google Scholar] [CrossRef]

- Fan, T.; Xie, C.; Wang, S.; Oganov, A.R.; Cheng, L. First-principles study of thermoelectric properties of Mg2Si-Mg2Pb semiconductor materials. RSC Adv. 2018, 8, 17168–17175. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Yu, P.; Wang, L.-M.; Li, G. Preparation and thermoelectric properties of novel Tellurium-based glassy semiconductors. Scr. Mater. 2021, 203, 114038. [Google Scholar] [CrossRef]

- Zhang, J.; Dong, Z.; Tan, S.; Li, Y.; Zhang, J.; Zhang, W.; Luo, J. Designing vacancy-filled Heusler thermoelectric semiconductors by the Slater-Pauling rule. Mater. Today Energy 2022, 27, 101035. [Google Scholar] [CrossRef]

- Zheng, S.; Xiao, S.; Peng, K.; Pan, Y.; Yang, X.; Lu, X.; Han, G.; Zhang, B.; Zhou, Z.; Wang, G.; et al. Symmetry-Guaranteed High Carrier Mobility in Quasi-2D Thermoelectric Semiconductors. Adv. Mater. 2023, 35, 2210380. [Google Scholar] [CrossRef] [PubMed]

- Saberi, Y.; Sajjadi, S.A.; Mansouri, H. Comparison of thermoelectric properties of Bi2Te3 and Bi2Se0·3Te2.7 thin film materials synthesized by hydrothermal process and thermal evaporation. Ceram. Int. 2021, 47, 11547–11559. [Google Scholar] [CrossRef]

- Yuan, X.; Li, Z.; Shao, Y.; Yang, D.; Hu, K.; You, H.; Xu, Z.; Hua, S.; Liu, W.; Peng, P.; et al. Bi2Te3-based wearable thermoelectric generator with high power density: From structure design to application. J. Mater. Chem. C 2022, 10, 6456–6463. [Google Scholar] [CrossRef]

- Li, J.; Xu, T.; Ma, Z.; Li, W.; Qian, Y.; Tao, Y.; Wei, Y.; Jiang, Q.; Luo, Y.; Yang, J. Self-Healable and Stretchable PAAc/XG/Bi2Se0.3Te2.7 Hybrid Hydrogel Thermoelectric Materials. Energy Environ. Mater. 2022, e12547. [Google Scholar] [CrossRef]

- Chai, X.; Tang, J.; Li, Y.; Cao, Y.; Chen, X.; Chen, T.; Zhang, Z. Highly Stretchable and Stimulus-Free Self-Healing Hydrogels with Multiple Signal Detection Performance for Self-Powered Wearable Temperature Sensors. ACS Appl. Mater. Interfaces 2023, 15, 18262–18271. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Q.; Cheng, H.; Liu, Y.; Shu, Y.; Geng, Y.; Zheng, Y.; Qin, B.; Zhou, Y.; Chen, S.; et al. Role of Ions in Hydrogels with an Ionic Seebeck Coefficient of 52.9 mV K−1. J. Phys. Chem. Lett. 2022, 13, 4621–4627. [Google Scholar] [CrossRef]

- Tian, C.; Bai, C.; Wang, T.; Yan, Z.; Zhang, Z.; Zhuo, K.; Zhang, H. Thermogalvanic hydrogel electrolyte for harvesting biothermal energy enabled by a novel redox couple of SO4/32− ions. Nano Energy 2023, 106, 108077. [Google Scholar] [CrossRef]

- Han, C.-G.; Qian, X.; Li, Q.; Deng, B.; Zhu, Y.; Han, Z.; Zhang, W.; Wang, W.; Feng, S.-P.; Chen, G.; et al. Giant thermopower of ionic gelatin near room temperature. Science 2020, 368, 1091–1098. [Google Scholar] [CrossRef]

- Lei, Z.; Gao, W.; Wu, P. Double-network thermocells with extraordinary toughness and boosted power density for continuous heat harvesting. Joule 2021, 5, 2211–2222. [Google Scholar] [CrossRef]

- Li, N.; Khan, S.A.; Yang, K.; Zhuo, K.; Zhang, Y.; Zhang, H. A self-powered thermogalvanic organohydrogel-based touch-to-speech Braille transmission interface with temperature resistance and stretchability. Compos. Sci. Technol. 2023, 239, 110077. [Google Scholar] [CrossRef]

- Bai, C.; Wang, Z.; Yang, S.; Cui, X.; Li, X.; Yin, Y.; Zhang, M.; Wang, T.; Sang, S.; Zhang, W.; et al. Wearable Electronics Based on the Gel Thermogalvanic Electrolyte for Self-Powered Human Health Monitoring. ACS Appl. Mater. Interfaces 2021, 13, 37316–37322. [Google Scholar] [CrossRef]

- Zhang, L.; Fang, R.; Li, X.; Tian, C.; Li, J.; Cui, X.; Zhang, H. Self-powered physiological monitoring strategy enabled by adaptive dual-network thermogalvanic hydrogels. Sens. Actuators A 2023, 361, 114604. [Google Scholar] [CrossRef]

- Xu, C.; Sun, Y.; Zhang, J.; Xu, W.; Tian, H. Adaptable and Wearable Thermocell Based on Stretchable Hydrogel for Body Heat Harvesting. Adv. Energy Mater. 2022, 12, 2201542. [Google Scholar] [CrossRef]

- Han, Y.; Wei, H.; Du, Y.; Li, Z.; Feng, S.-P.; Huang, B.; Xu, D. Ultrasensitive Flexible Thermal Sensor Arrays based on High-Thermopower Ionic Thermoelectric Hydrogel. Adv. Sci. 2023, 10, 2302685. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Han, M.; Chen, H.; Cheng, X.; Song, Y.; Su, Z.; Jiang, Y.; Zhang, H. A wave-shaped hybrid piezoelectric and triboelectric nanogenerator based on P(VDF-TrFE) nanofibers. Nanoscale 2017, 9, 1263–1270. [Google Scholar] [CrossRef]

- Li, X.; Ji, D.; Yu, B.; Ghosh, R.; He, J.; Qin, X.; Ramakrishna, S. Boosting piezoelectric and triboelectric effects of PVDF nanofiber through carbon-coated piezoelectric nanoparticles for highly sensitive wearable sensors. Chem. Eng. J. 2021, 426, 130345. [Google Scholar] [CrossRef]

- Wang, S.; Tong, W.; Li, Y.; Zhang, P.; Liu, Y.; Chen, Y.; Zhang, Y. Contributions of piezoelectricity and triboelectricity to a hydroxyapatite/PVDF-HFP fiber-film nanogenerator. Nano Energy 2023, 105, 108026. [Google Scholar] [CrossRef]

- Yang, X.; Daoud, W.A. Triboelectric and Piezoelectric Effects in a Combined Tribo-Piezoelectric Nanogenerator Based on an Interfacial ZnO Nanostructure. Adv. Funct. Mater. 2016, 26, 8194–8201. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Peng, C.; Liu, X.; Wu, Z.; Zheng, F. Design and Testing of a Non-Contact MEMS Voltage Sensor Based on Single-Crystal Silicon Piezoresistive Effect. Micromachines 2022, 13, 619. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Liang, T.; Lei, C.; Li, Q.; Li, Z.; Ghaffar, A.; Xiong, J. Study on the Stability of the Electrical Connection of High-Temperature Pressure Sensor Based on the Piezoresistive Effect of P-Type SiC. Micromachines 2021, 12, 216. [Google Scholar] [CrossRef] [PubMed]

- Tian, B.; Shang, H.; Wang, D.; Liu, Y.; Wang, W. Investigation on Piezoresistive Effect of n-Type 4H-SiC Based on All-SiC Pressure Sensors. IEEE Sens. J. 2022, 22, 6435–6441. [Google Scholar] [CrossRef]

- Wu, C.; Fang, X.; Kang, Q.; Fang, Z.; Wu, J.; He, H.; Zhang, D.; Zhao, L.; Tian, B.; Maeda, R.; et al. Exploring the nonlinear piezoresistive effect of 4H-SiC and developing MEMS pressure sensors for extreme environments. Microsyst. Nanoeng. 2023, 9, 41. [Google Scholar] [CrossRef]

- Lyu, C.; Wen, B.; Bai, Y.; Luo, D.; Wang, X.; Zhang, Q.; Xing, C.; Kong, T.; Diao, D.; Zhang, X. Bone-inspired (GNEC/HAPAAm) hydrogel with fatigue-resistance for use in underwater robots and highly piezoresistive sensors. Microsyst. Nanoeng. 2023, 9, 99. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Zheng, L.; Tang, R.; Nie, K.; Wang, Z.; Jin, C.; Sun, Q. Double-Network Hierarchical-Porous Piezoresistive Nanocomposite Hydrogel Sensors Based on Compressive Cellulosic Hydrogels Deposited with Silver Nanoparticles. ACS Sustain. Chem. Eng. 2020, 8, 7480–7488. [Google Scholar] [CrossRef]

- Xia Zhang, Y.; He, Y.; Liang, Y.; Tang, J.; Yang, Y.; Ming Song, H.; Zrínyi, M.; Mei Chen, Y. Sensitive piezoresistive pressure sensor based on micropyramid patterned tough hydrogel. Appl. Surf. Sci. 2023, 615, 156328. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, Q.; Horvat, J.; Lewis, R.A. Piezoresistive and Electrical Properties of a Catecholic Amino Acid-Polyacrylamide Single-Walled Carbon Nanotube Hydrogel Hybrid Network. ACS Appl. Polym. Mater. 2021, 3, 671–678. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Z.; Zhao, G.; Zhang, Z.; Zhao, X.; Wan, X.; Zhang, Y.; Wang, Z.L.; Li, L. Stretchable Unsymmetrical Piezoelectric BaTiO3 Composite Hydrogel for Triboelectric Nanogenerators and Multimodal Sensors. ACS Nano 2022, 16, 1661–1670. [Google Scholar] [CrossRef]

- Cheng, P.; Wang, D.; Schaaf, P. A Review on Photothermal Conversion of Solar Energy with Nanomaterials and Nanostructures: From Fundamentals to Applications. Adv. Sustain. Syst. 2022, 6, 2200115. [Google Scholar] [CrossRef]

- Mateo, D.; Cerrillo, J.L.; Durini, S.; Gascon, J. Fundamentals and applications of photo-thermal catalysis. Chem. Soc. Rev. 2021, 50, 2173–2210. [Google Scholar] [CrossRef] [PubMed]

- Du, S.; Lu, Z.; Gao, L.; Ge, Y.; Xu, X.; Zhang, H. Salmonella typhimurium detector based on the intrinsic peroxidase-like activity and photothermal effect of MoS2. Microchim. Acta 2020, 187, 627. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.; Zhang, P.; Zhou, G. Hydrothermal synthesis of highly stable copper sulfide nanorods for efficient photo-thermal conversion. Mater. Lett. 2018, 217, 71–74. [Google Scholar] [CrossRef]

- Zhao, Y.; Sadat, M.E.; Dunn, A.; Xu, H.; Chen, C.-H.; Nakasuga, W.; Ewing, R.C.; Shi, D. Photothermal effect on Fe3O4 nanoparticles irradiated by white-light for energy-efficient window applications. Sol. Energy Mater. Sol. Cells 2017, 161, 247–254. [Google Scholar] [CrossRef]

- Joseph Fortenbaugh, R.; Lear, B.J. On-demand curing of polydimethylsiloxane (PDMS) using the photothermal effect of gold nanoparticles. Nanoscale 2017, 9, 8555–8559. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Ahmed Khan, S.; Li, N.; Fang, R.; Huang, Z.; Zhang, H. Thermogalvanic gel patch for self-powered human motion recognition enabled by photo-thermal-electric conversion. Chem. Eng. J. 2023, 473, 145247. [Google Scholar] [CrossRef]

- Bai, C.; Li, X.; Cui, X.; Yang, X.; Zhang, X.; Yang, K.; Wang, T.; Zhang, H. Transparent stretchable thermogalvanic PVA/gelation hydrogel electrolyte for harnessing solar energy enabled by a binary solvent strategy. Nano Energy 2022, 100, 107449. [Google Scholar] [CrossRef]

- Gao, M.; Peh, C.K.; Phan, H.T.; Zhu, L.; Ho, G.W. Solar Absorber Gel: Localized Macro-Nano Heat Channeling for Efficient Plasmonic Au Nanoflowers Photothermic Vaporization and Triboelectric Generation. Adv. Energy Mater. 2018, 8, 1800711. [Google Scholar] [CrossRef]

- Bai, C.; Zhang, J.; Yang, K.; Zhang, Z.; Zhang, H. A vertical stretchable self-powered light sensor based on thermogalvanic gel electrolyte via photo-thermal-electric conversion. Sens. Actuators A 2023, 354, 114305. [Google Scholar] [CrossRef]

- Gao, F.-L.; Min, P.; Gao, X.-Z.; Li, C.; Zhang, T.; Yu, Z.-Z.; Li, X. Integrated temperature and pressure dual-mode sensors based on elastic PDMS foams decorated with thermoelectric PEDOT:PSS and carbon nanotubes for human energy harvesting and electronic-skin. J. Mater. Chem. A 2022, 10, 18256–18266. [Google Scholar] [CrossRef]

- Horta Romarís, L.; González Rodríguez, M.V.; Huang, B.; Costa, P.; Lasagabáster Latorre, A.; Lanceros-Mendez, S.; Abad López, M.J. Multifunctional electromechanical and thermoelectric polyaniline-poly(vinyl acetate) latex composites for wearable devices. J. Mater. Chem. C 2018, 6, 8502–8512. [Google Scholar] [CrossRef]

- Gao, X.-Z.; Gao, F.-L.; Liu, J.; Li, Y.; Wan, P.; Yu, Z.-Z.; Li, X. Self-Powered Resilient Porous Sensors with Thermoelectric Poly(3,4-ethylenedioxythiophene):Poly(styrenesulfonate) and Carbon Nanotubes for Sensitive Temperature and Pressure Dual-Mode Sensing. ACS Appl. Mater. Interfaces 2022, 14, 43783–43791. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Zhuang, Z.; Zhao, Y.; Liu, B.; Liao, Y.; Yu, Z.; Yang, P.; Liu, K. Stretchable and Self-Powered Temperature-Pressure Dual Sensing Ionic Skins Based on Thermogalvanic Hydrogels. ACS Appl. Mater. Interfaces 2022, 14, 44792–44798. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Li, N.; Zhang, Z.; Cui, X.; Zhang, H. Hydrogel-Based Energy Harvesters and Self-Powered Sensors for Wearable Applications. Nanoenergy Adv. 2023, 3, 315-342. https://doi.org/10.3390/nanoenergyadv3040017

Wang Z, Li N, Zhang Z, Cui X, Zhang H. Hydrogel-Based Energy Harvesters and Self-Powered Sensors for Wearable Applications. Nanoenergy Advances. 2023; 3(4):315-342. https://doi.org/10.3390/nanoenergyadv3040017

Chicago/Turabian StyleWang, Zhaosu, Ning Li, Zhiyi Zhang, Xiaojing Cui, and Hulin Zhang. 2023. "Hydrogel-Based Energy Harvesters and Self-Powered Sensors for Wearable Applications" Nanoenergy Advances 3, no. 4: 315-342. https://doi.org/10.3390/nanoenergyadv3040017

APA StyleWang, Z., Li, N., Zhang, Z., Cui, X., & Zhang, H. (2023). Hydrogel-Based Energy Harvesters and Self-Powered Sensors for Wearable Applications. Nanoenergy Advances, 3(4), 315-342. https://doi.org/10.3390/nanoenergyadv3040017