Establishing Particle Size Recommendations for Cationic Asphalt Emulsions

Abstract

1. Background

2. Research Objectives

3. Methods

3.1. Asphalt Emulsion Physical Property Tests

3.1.1. Residue and Sieve Tests

3.1.2. Rotational Viscosity Test

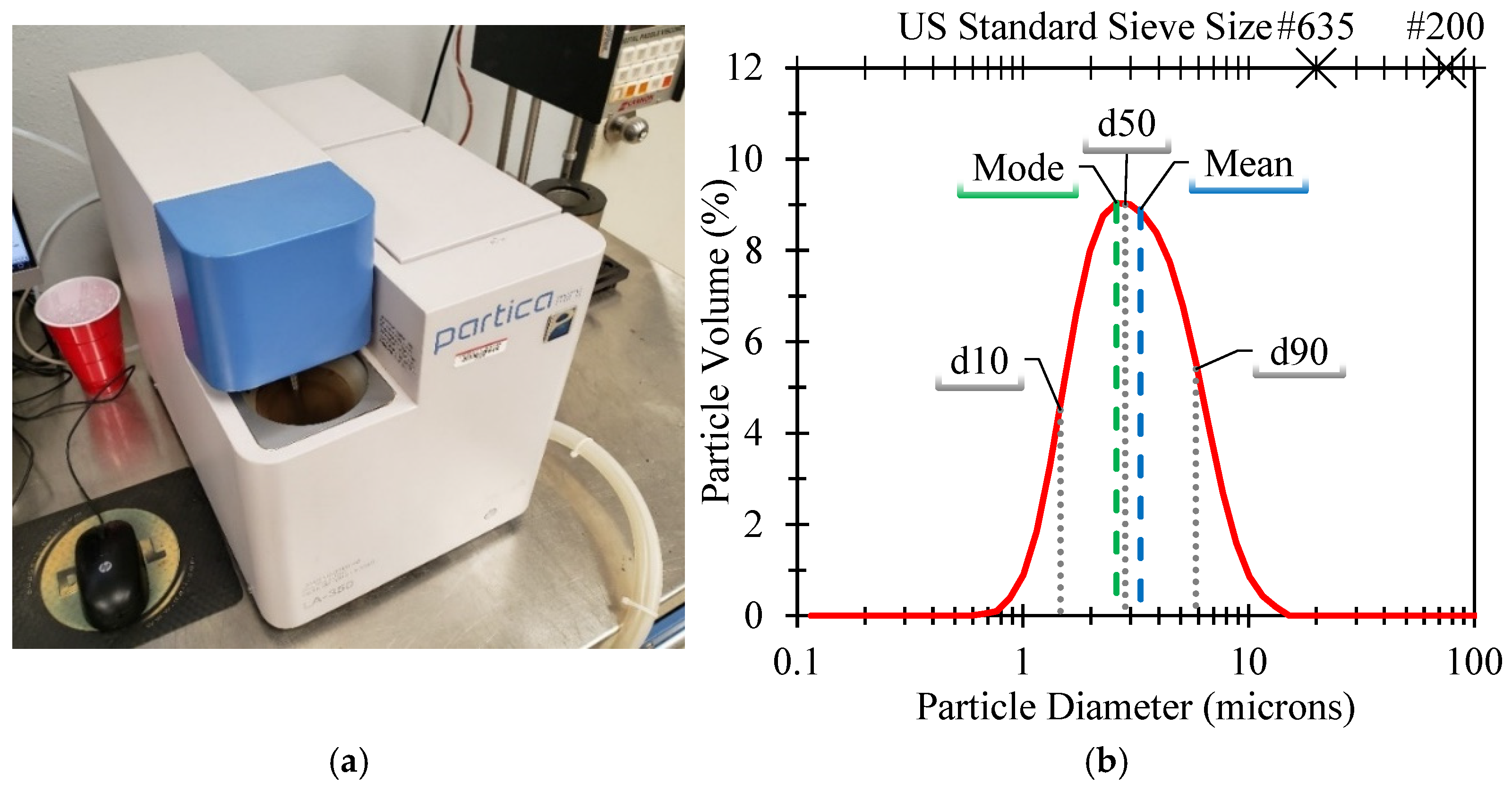

3.1.3. Particle Size Analysis (PSA)

- d10, the particle size at which 10% of the volume of material is smaller in size;

- d50, or median, the particle size at which 50% of the volume of material is smaller in size;

- d90, the particle size at which 90% of the volume of material is smaller in size;

- Mean, the arithmetic average particle size;

- Mode, the most commonly observed particle size;

- Standard deviation, a measure of closeness to the mean;

- Span, a measure of closeness to the median: span = .

3.2. CMA Mixture Performance Tests

3.2.1. Indirect Tensile (IDT) Strength Test

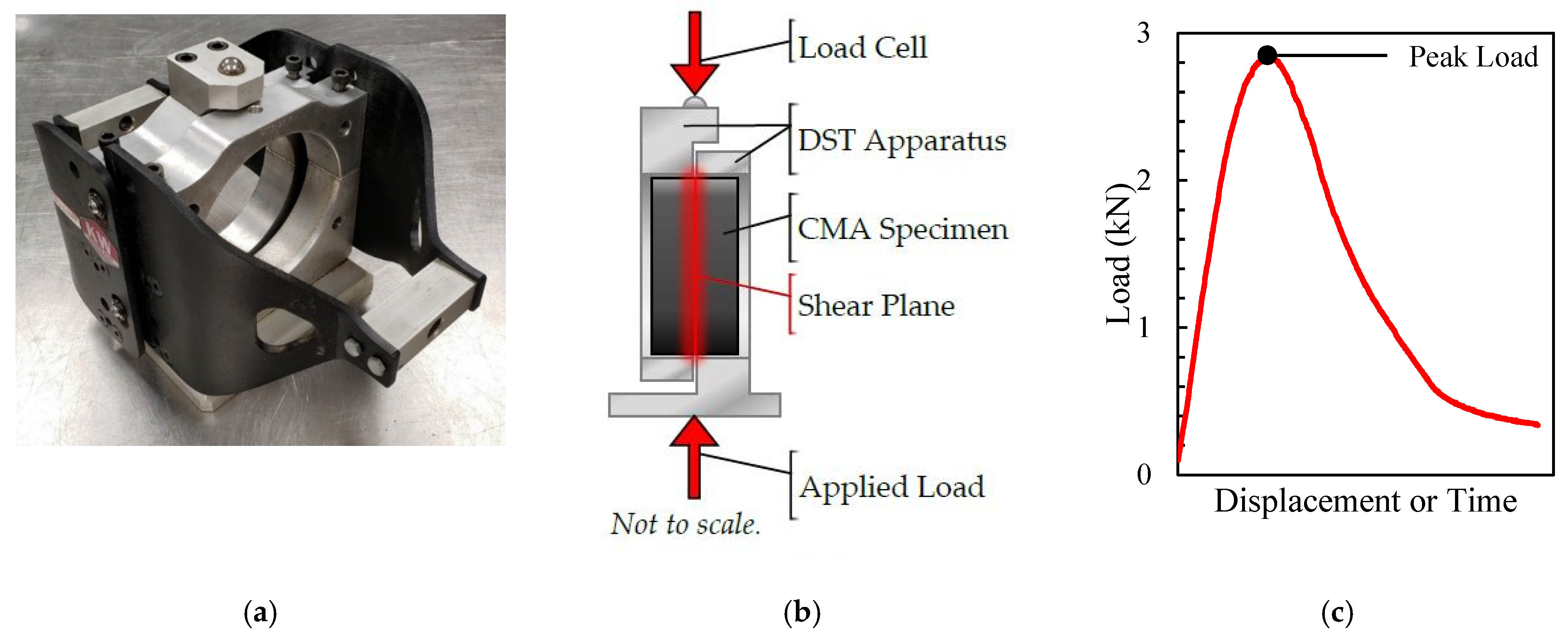

3.2.2. Direct Shear Test (DST)

4. Results and Discussion

4.1. Asphalt Emulsion Physical Properties

4.1.1. Residue and Sieve

4.1.2. Rotation Viscosity

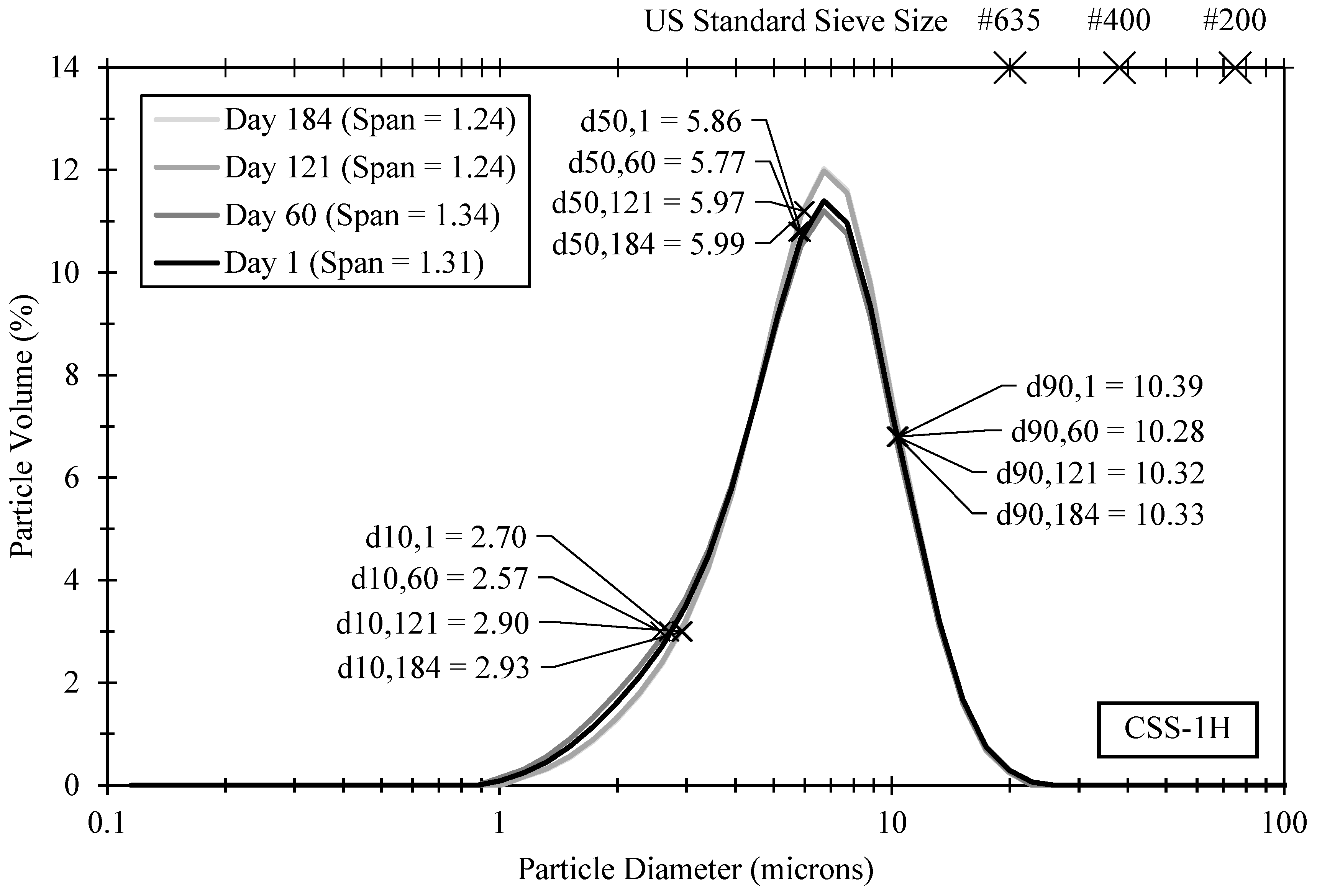

4.1.3. Particle Size Analysis (PSA)

4.2. CMA Mixture Performance Tests

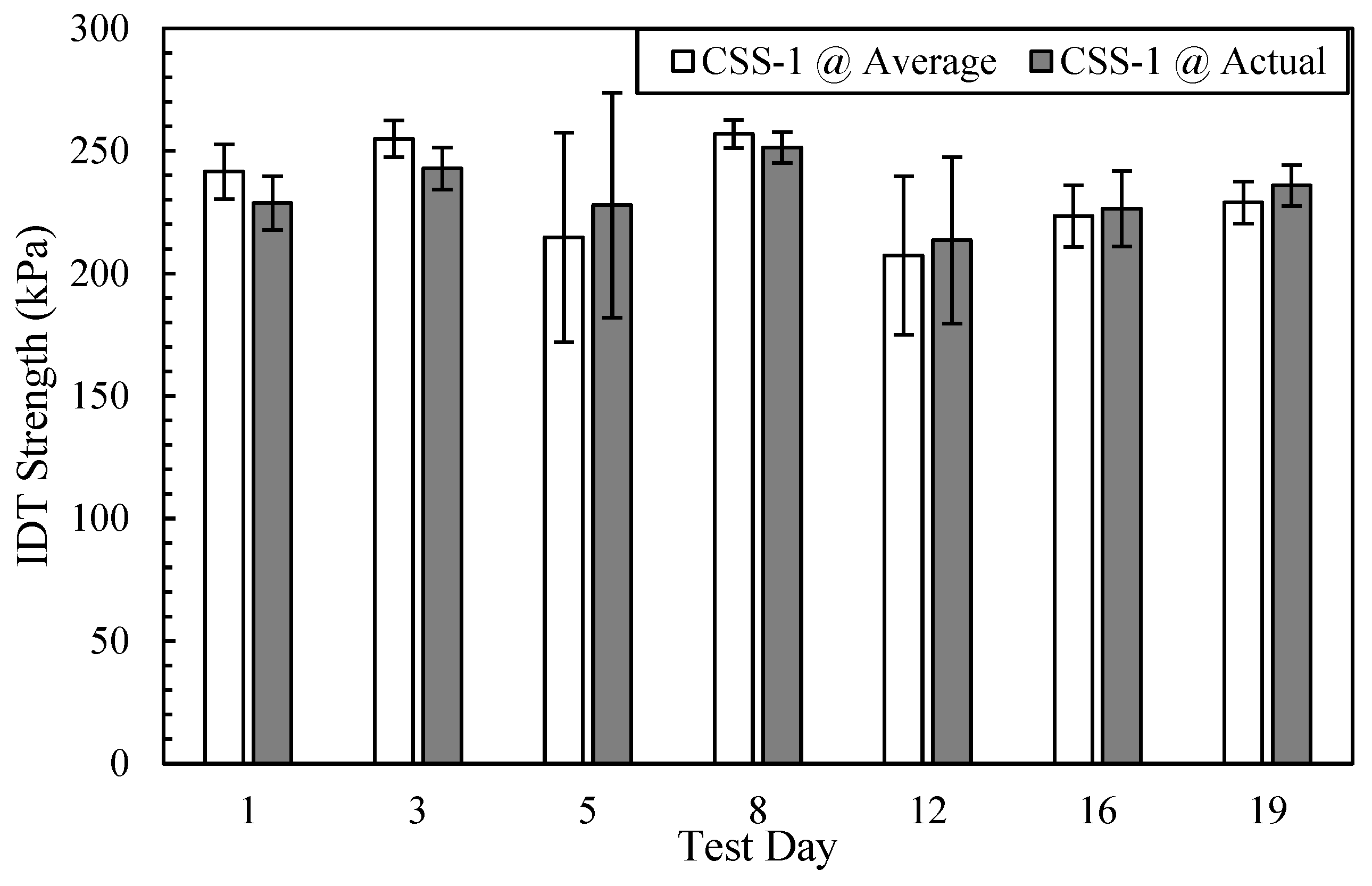

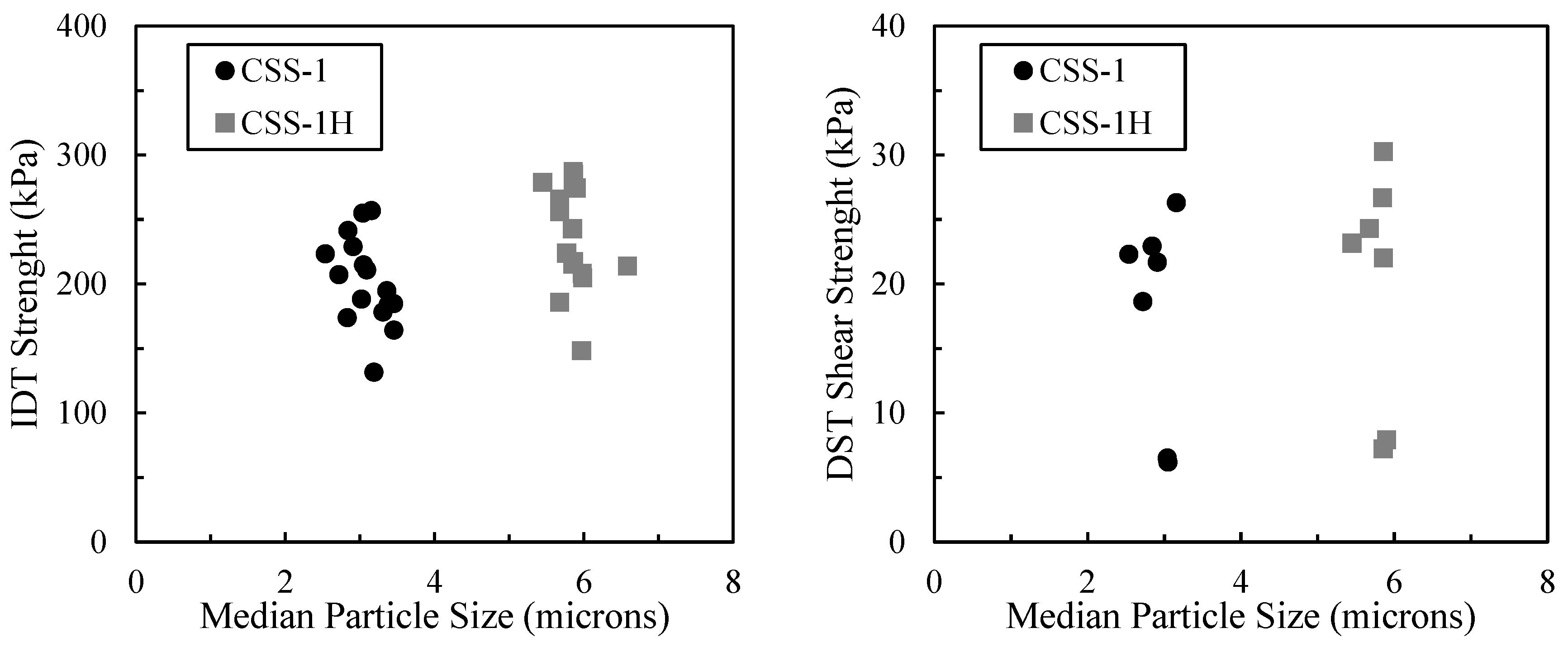

4.2.1. Indirect Tensile (IDT) Strength Test

4.2.2. Direct Shear Test (DST)

4.3. Establishing Particle Size Recommendations

5. Conclusions

- The viscosity, particle size, IDT strength, and DST strength of the CSS-1H emulsion were greater than that of the CSS-1 emulsion;

- The viscosity and particle size of both slow-setting emulsions (CSS-1, CSS-1H) changed much more slowly than reported in previous research on slow-setting and rapid-setting emulsions;

- The residue, oversized particles, and viscosity remained within specification over six months of storage;

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISSA. Design & Inspection Manual for Slurry Surfacing Systems; International Slurry Surfacing Association: Glen Ellyn, IL, USA, 2021. [Google Scholar]

- ARRA. Basic Asphalt Recycling Manual, 2nd ed.; Asphalt Recycling & Reclaiming Association: Glen Ellyn, IL, USA, 2015. [Google Scholar]

- AASHTO M 140-20; Standard Specification for Emulsified Asphalt. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- AASHTO M 208-18; Standard Specification for Cationic Emulsified Asphalt. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2018.

- AASHTO M 316-23; Standard Specification for Polymer-Modified Emulsified Asphalt. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

- AASHTO R 5-17(2021); Standard Practice for Selection and Use of Emulsified Asphalts. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2021.

- AASHTO T 59-22; Standard Method of Test for Emulsified Asphalts. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Wace, E. The Testing of Bitumen Emulsions. J. Assoc. Asph. Paving Technol. 1937, 9, 257–308. [Google Scholar]

- James, A. Overview of Asphalt Emulsions, Asphalt Emulsion Technology. In Transportation Research Circular E-C102; Transportation Research Board of the National Academies: Washington, DC, USA, 2006. [Google Scholar]

- Ronald, M.; Luis, F. Asphalt Emulsions Formulation: State-of-the-Art and Dependency of Formulation on Emulsions Properties. Constr. Build. Mater. 2016, 123, 162–173. [Google Scholar] [CrossRef]

- Chen, X.; Meng, Y.; Hu, G.; Zhou, J.; Ouyang, J. Factors Influencing the Droplet Size of Asphalt Emulsion during Fabrication. Coatings 2022, 12, 575. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y.; Zhang, Y.; Hu, S. Experimental study on the stability of asphalt emulsion for CA mortar by laser diffraction technique. Constr. Build. Mater. 2012, 28, 117–121. [Google Scholar] [CrossRef]

- Buss, A.; Pinto, I.; Guirguis, M.; Cochran, E.; Panthani, M. Enhancing the Fundamental Knowledge and Use of Asphalt Emulsions Using Systematic Scientific and Engineering Approaches; IHRB Project TR-708C; Institute for Transportation, Iowa State University: Ames, IA, USA, 2018. [Google Scholar]

- Kiihnl, L.; Braham, A. Developing a particle size specification for asphalt emulsion. Constr. Build. Mater. 2021, 293, 123414. [Google Scholar] [CrossRef]

- Diaz-Romero, P.; Braham, A. Refining particle size specification for asphalt emulsion. Constr. Build. Mater. 2022, 350, 128812. [Google Scholar] [CrossRef]

- AASHTO MP 31-17; Standard Specification for Materials for Cold Recycled Mixtures with Emulsified Asphalt. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017.

- AASHTO PP 86-20; Standard Practice for Emulsified Asphalt Content of Cold Recycled Mixture Designs. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- ASTM D6934-08(16); Standard Test Method for Residue by Evaporation of Emulsified Asphalt. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D6933-18; Standard Test Method for Oversize Particles in Emulsified Asphalts (Sieve Test). ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D7226-13(17); Standard Test Method for Determining the Viscosity of Emulsified Asphalts Using a Rotational Paddle Viscometer. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C702/C702M-18; Standard Practice for Reducing Samples of Aggregate to Testing Size. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D6931-17; Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2017.

- Casillas, S.; Braham, A. Quantifying effects of laboratory curing conditions on workability, compactability, and cohesion gain of cold in-place recycling. Road Mater. Pavement Des. 2021, 22, 2329–2351. [Google Scholar] [CrossRef]

- Horiba Ltd. Laser Scattering Particle Size Distribution Analyzer LA-350 Instruction Manual; Horiba Ltd.: Kyoto, Japan, 2016; pp. 143–144. [Google Scholar]

| Test Day | Metric | Standard Deviation a | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | S.D. b | Mode | d10 | d50 | d90 | Span c | Mean | S.D. b | d50 | Span c | |

| CSS-1 Emulsion | |||||||||||

| 1 | 3.32 | 1.84 | 2.56 | 1.47 | 2.84 | 5.84 | 1.55 | 0.19 | 0.02 | 0.25 | 0.14 |

| 2 | 3.51 | 1.92 | 2.93 | 1.55 | 3.04 | 6.12 | 1.50 | 0.14 | 0.06 | 0.14 | 0.03 |

| 4 | 3.49 | 1.86 | 3.05 | 1.57 | 3.05 | 6.03 | 1.46 | 0.07 | 0.03 | 0.07 | 0.00 |

| 7 | 5.00 | 10.5 | 3.18 | 1.62 | 3.16 | 6.28 | 1.47 | 2.60 | 15.11 | 0.15 | 0.07 |

| 11 | 3.22 | 1.84 | 2.47 | 1.40 | 2.72 | 5.76 | 1.61 | 0.21 | 0.01 | 0.27 | 0.14 |

| 15 | 2.89 | 1.43 | 2.35 | 1.43 | 2.54 | 4.84 | 1.35 | 0.36 | 0.14 | 0.36 | 0.06 |

| 18 | 3.36 | 1.81 | 2.68 | 1.51 | 2.91 | 5.84 | 1.49 | 0.13 | 0.03 | 0.15 | 0.04 |

| 25 | 3.53 | 1.86 | 3.18 | 1.59 | 3.09 | 6.07 | 1.45 | 0.02 | 0.01 | 0.01 | 0.00 |

| 32 | 3.29 | 1.80 | 2.43 | 1.47 | 2.83 | 5.76 | 1.51 | 0.02 | 0.03 | 0.02 | 0.03 |

| 39 | 3.83 | 1.84 | 3.65 | 1.85 | 3.45 | 6.33 | 1.30 | 0.09 | 0.25 | 0.04 | 0.16 |

| 46 | 3.84 | 1.85 | 3.65 | 1.85 | 3.46 | 6.34 | 1.30 | 0.09 | 0.27 | 0.04 | 0.17 |

| 60 | 3.70 | 1.89 | 3.67 | 1.65 | 3.31 | 6.28 | 1.40 | 0.12 | 0.08 | 0.15 | 0.03 |

| 74 | 3.40 | 1.61 | 3.19 | 1.63 | 3.07 | 5.62 | 1.30 | 0.04 | 0.03 | 0.04 | 0.01 |

| 121 | 3.48 | 1.58 | 3.49 | 1.72 | 3.19 | 5.65 | 1.22 | 0.41 | 0.35 | 0.31 | 0.14 |

| 141 | 3.74 | 1.81 | 3.65 | 1.78 | 3.38 | 6.20 | 1.31 | 0.02 | 0.15 | 0.08 | 0.11 |

| 168 | 3.34 | 1.56 | 3.18 | 1.65 | 3.02 | 5.50 | 1.28 | 0.02 | 0.01 | 0.03 | 0.01 |

| 184 | 3.74 | 1.84 | 3.64 | 1.76 | 3.36 | 6.26 | 1.34 | 0.02 | 0.01 | 0.02 | 0.00 |

| CSS-1H Emulsion | |||||||||||

| 1 | 6.28 | 3.05 | 6.29 | 2.70 | 5.86 | 10.4 | 1.31 | 0.08 | 0.04 | 0.08 | 0.02 |

| 2 | 6.28 | 3.06 | 6.29 | 2.69 | 5.86 | 10.4 | 1.32 | 0.08 | 0.04 | 0.07 | 0.02 |

| 4 | 6.33 | 3.10 | 6.30 | 2.68 | 5.90 | 10.5 | 1.32 | 0.02 | 0.02 | 0.03 | 0.01 |

| 7 | 6.26 | 2.97 | 6.29 | 2.75 | 5.86 | 10.3 | 1.28 | 0.06 | 0.10 | 0.08 | 0.06 |

| 11 | 5.93 | 3.24 | 6.28 | 2.14 | 5.45 | 10.3 | 1.49 | 0.08 | 0.01 | 0.06 | 0.01 |

| 15 | 6.26 | 3.01 | 6.29 | 2.70 | 5.85 | 10.3 | 1.30 | 0.03 | 0.03 | 0.03 | 0.02 |

| 18 | 6.10 | 3.08 | 6.28 | 2.46 | 5.68 | 10.2 | 1.37 | 0.10 | 0.02 | 0.10 | 0.03 |

| 25 | 6.10 | 3.08 | 6.28 | 2.46 | 5.68 | 10.2 | 1.37 | 0.10 | 0.02 | 0.10 | 0.03 |

| 32 | 6.10 | 3.07 | 6.28 | 2.46 | 5.68 | 10.2 | 1.37 | 0.10 | 0.02 | 0.10 | 0.04 |

| 39 | 6.26 | 3.00 | 6.29 | 2.71 | 5.85 | 10.3 | 1.30 | 0.03 | 0.01 | 0.03 | 0.01 |

| 46 | 6.37 | 2.80 | 6.29 | 3.10 | 5.98 | 10.1 | 1.18 | 0.14 | 0.05 | 0.13 | 0.01 |

| 60 | 6.18 | 3.04 | 6.29 | 2.57 | 5.77 | 10.3 | 1.34 | 0.05 | 0.02 | 0.05 | 0.01 |

| 74 | 6.29 | 3.00 | 6.29 | 2.72 | 5.89 | 10.3 | 1.29 | 0.02 | 0.01 | 0.02 | 0.01 |

| 121 | 6.36 | 2.94 | 6.29 | 2.90 | 5.97 | 10.3 | 1.24 | 0.06 | 0.07 | 0.04 | 0.03 |

| 141 | 7.15 | 3.60 | 7.18 | 2.99 | 6.59 | 12.0 | 1.36 | 0.52 | 0.30 | 0.47 | 0.03 |

| 168 | 6.24 | 2.85 | 6.28 | 2.87 | 5.87 | 10.0 | 1.22 | 0.05 | 0.01 | 0.05 | 0.01 |

| 184 | 6.38 | 2.93 | 6.30 | 2.93 | 5.99 | 10.3 | 1.24 | 0.05 | 0.03 | 0.04 | 0.01 |

| Type | Rapid-Setting a | |||||

|---|---|---|---|---|---|---|

| CRS-2 | CRS-2L | CRS-2P | ||||

| Grade | Min | Max | Min | Max | Min | Max |

| Tests on emulsified asphalt: | ||||||

| Median particle size (d50), μm | 1.9 | 3.0 | 10.7 | |||

| Or | ||||||

| Modal particle size, μm | 1.6 | 2.9 | 9.4 | |||

| d10, μm | 1.1 | 1.6 | 2.1 | |||

| d90, μm | 2.8 | 4.9 | 24.9 | |||

| Span | 1.0 | 1.2 | 2.9 | |||

| Type | Medium- Setting | Slow-Setting | ||||

|---|---|---|---|---|---|---|

| CMS-2 b | CSS-1 | CSS-1H | ||||

| Grade | Min | Max | Min | Max | Min | Max |

| Tests on emulsified asphalt: | ||||||

| Median particle size (d50), μm | 6.9 | 4.4 b | 6.0 | |||

| Or | ||||||

| Modal particle size, μm | 3.6 | 6.3 | ||||

| d10, μm | 3.2 | 2.4 b | 3.0 | |||

| d90, μm | 6.0 | 10.4 | ||||

| Span | 1.6 | 1.4 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turben, T.; Diaz-Romero, P.; Braham, A. Establishing Particle Size Recommendations for Cationic Asphalt Emulsions. Constr. Mater. 2025, 5, 26. https://doi.org/10.3390/constrmater5020026

Turben T, Diaz-Romero P, Braham A. Establishing Particle Size Recommendations for Cationic Asphalt Emulsions. Construction Materials. 2025; 5(2):26. https://doi.org/10.3390/constrmater5020026

Chicago/Turabian StyleTurben, Tanner, Pedro Diaz-Romero, and Andrew Braham. 2025. "Establishing Particle Size Recommendations for Cationic Asphalt Emulsions" Construction Materials 5, no. 2: 26. https://doi.org/10.3390/constrmater5020026

APA StyleTurben, T., Diaz-Romero, P., & Braham, A. (2025). Establishing Particle Size Recommendations for Cationic Asphalt Emulsions. Construction Materials, 5(2), 26. https://doi.org/10.3390/constrmater5020026