Use of Recycled Aggregates in Lime Mortars for Conservation of Historical Buildings

Abstract

:1. Introduction

2. Materials and Methods

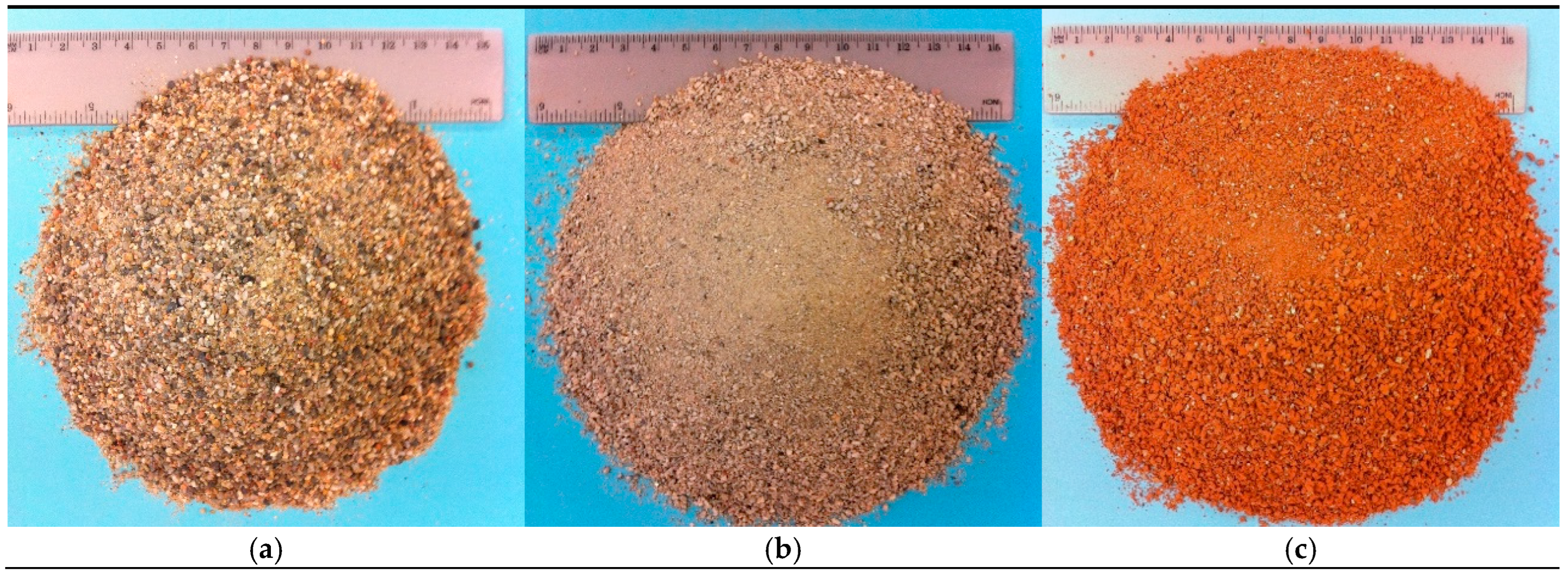

2.1. Materials

2.2. Methods

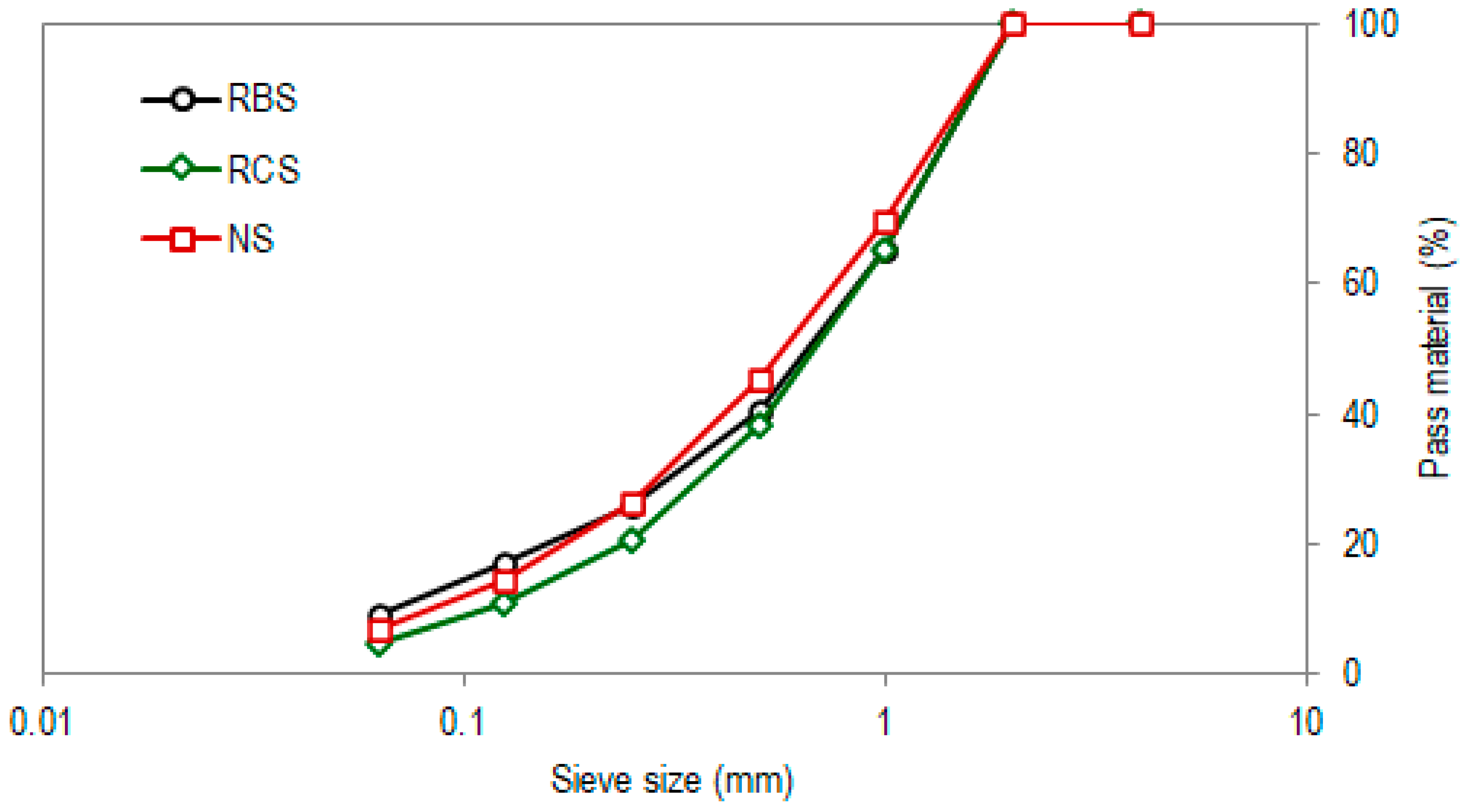

2.2.1. Characterisation of Materials

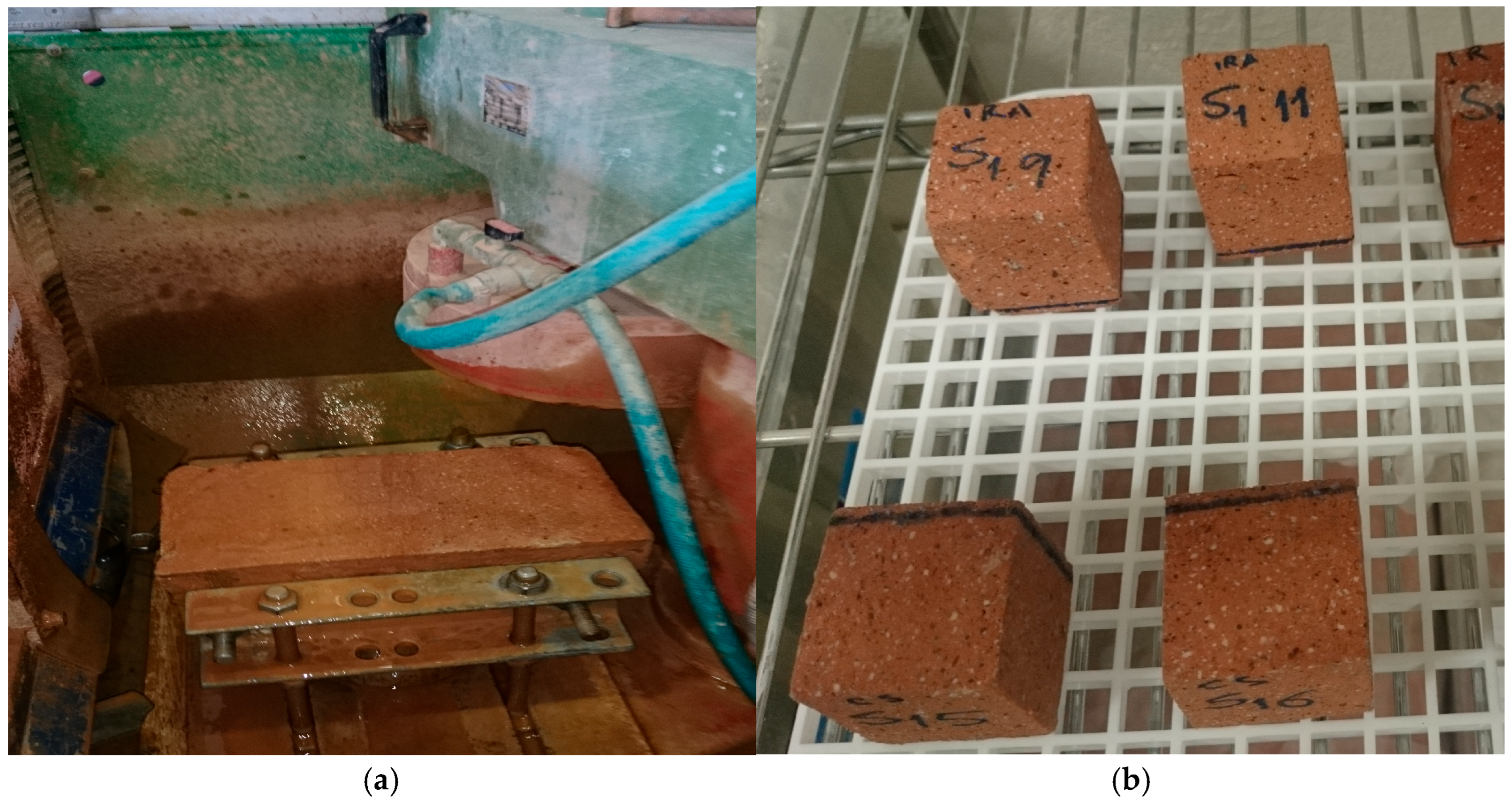

2.2.2. Mix Design, Sample Preparation and Fresh State Properties of the Mortars and Stack Walls

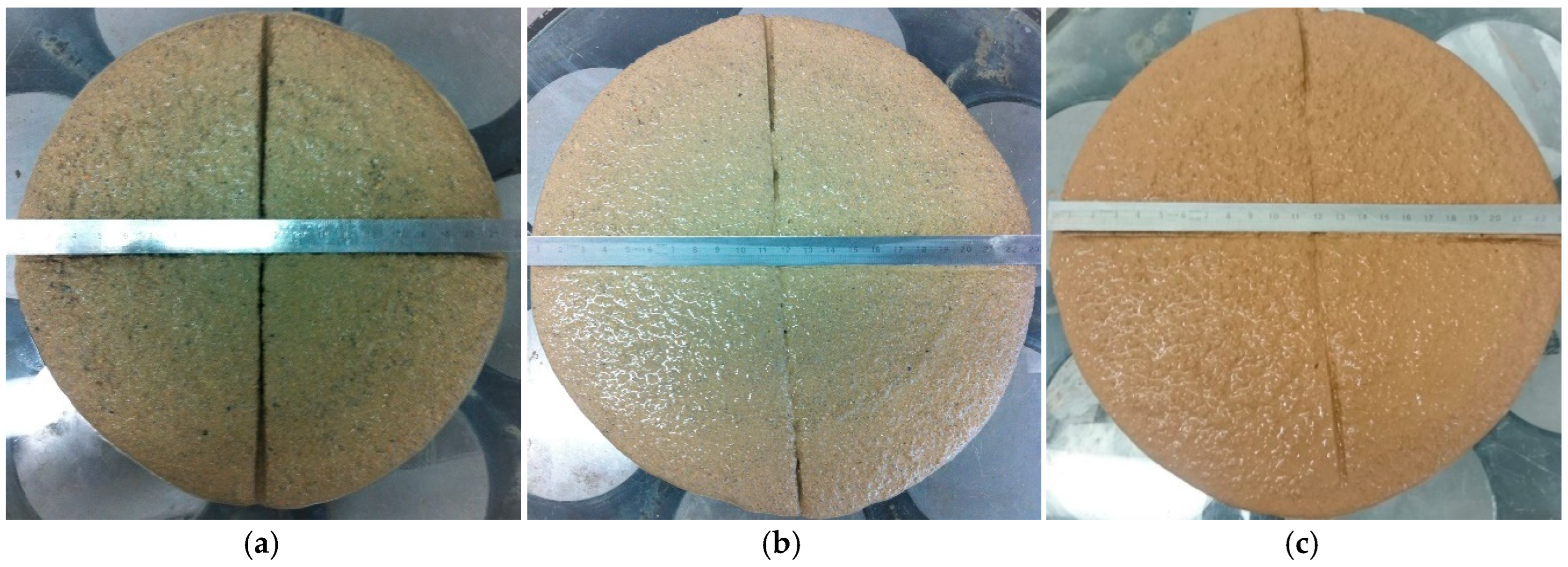

2.2.3. Compressive Strength, Flexural Strength and Modulus of Elasticity of Bricks and Mortar

3. Results

3.1. Density, Porosity, Water Absorption and Aggregate Index of the Materials

3.2. Fresh Properties of Mortars

3.3. Dry Density, Water Absorption and Porosity of Mortars

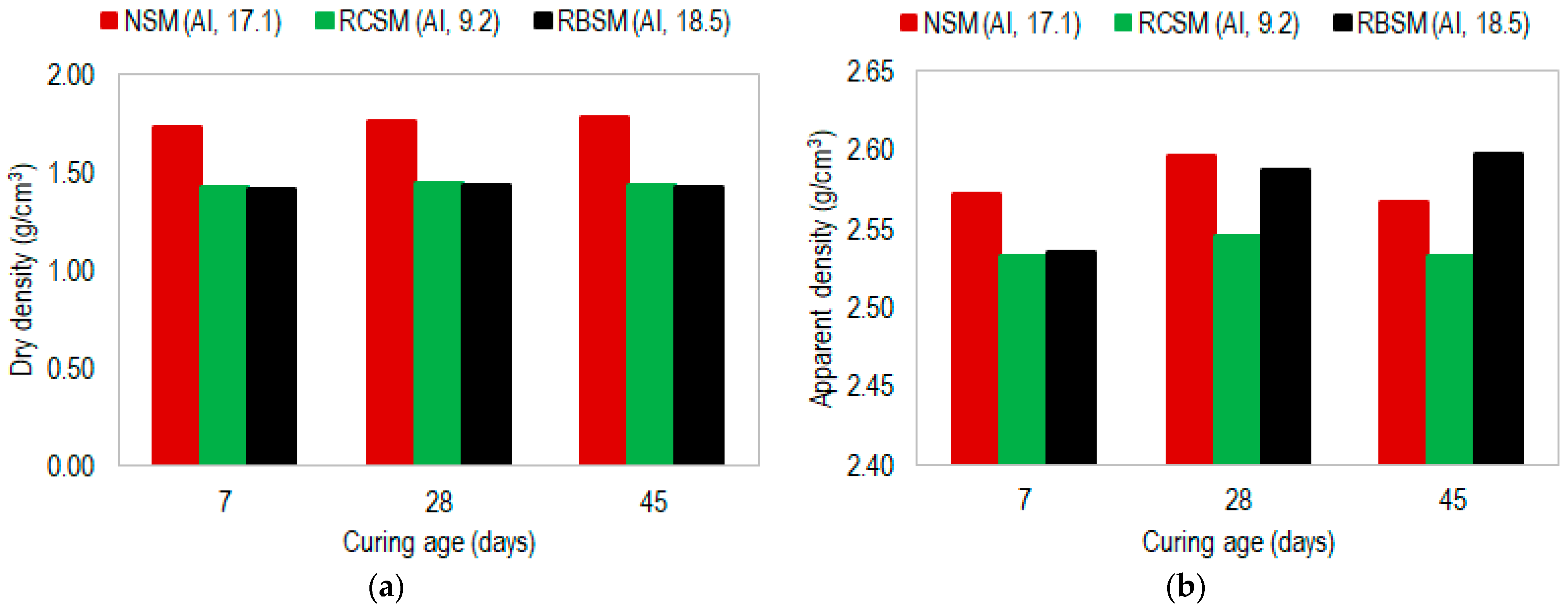

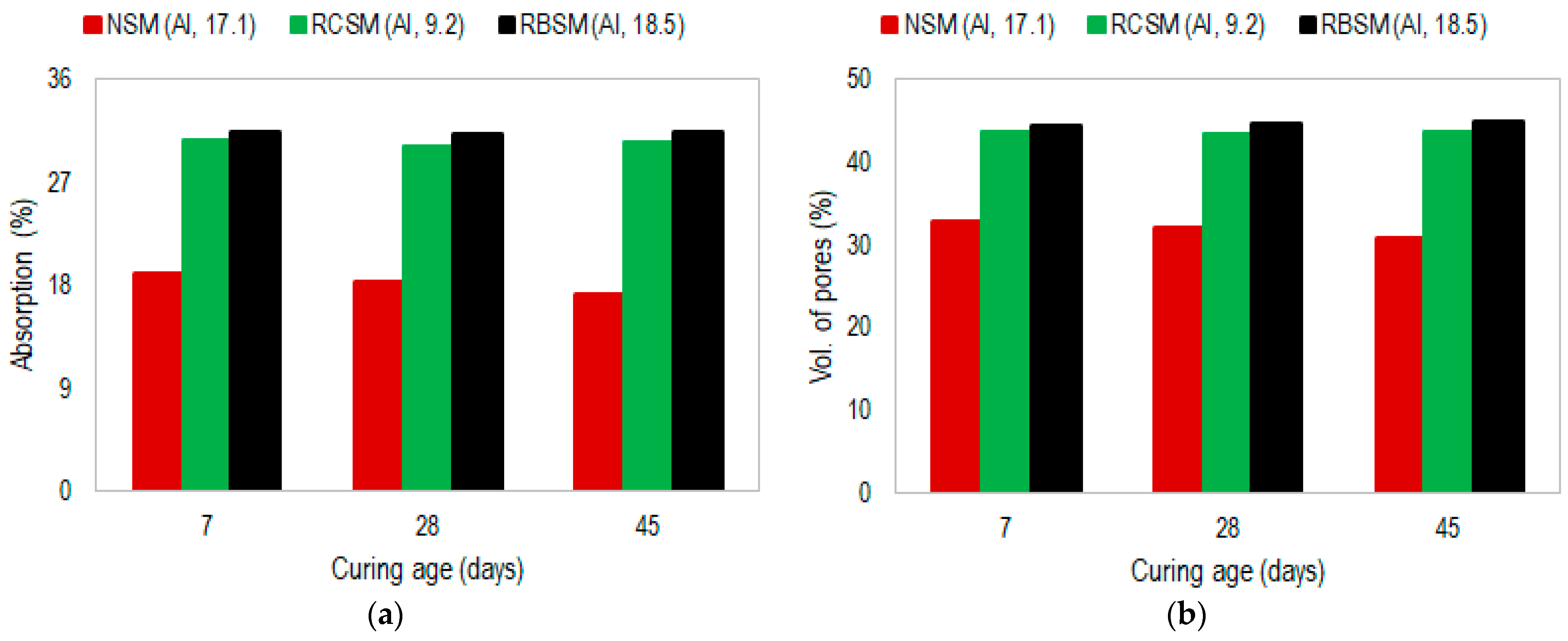

3.4. Mechanical Properties of Bricks and Mortar

4. Discussion

5. Conclusions

- ▪

- Based on the table flow results, the workability of the RCSM and RBSM were similar and slightly higher than that of the reference mortar. Pre-soaking the recycled aggregates to the saturated-surface dry state, which increased the effective w/b ratio, is believed to increase the workability of the resulting mortars.

- ▪

- Due to the porous nature of the aggregates, the bulk density of the RCSM and RBSM were lower than that of the NSM. The true or apparent density of the RBSM equalled that of the RCSM at the age of 7 days but was less than that of the reference mortar. After 28 days, due to pozzolanic reactions, i.e., the formation of hydration products, the RBSM became denser than the other two mixes.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Restuccia, L.; Spoto, C.; Ferro, G.A.; Tulliani, J.M. Recycled mortars with C&D waste. Procedia Struct. Integr. 2016, 2, 2896–2904. [Google Scholar]

- Kumar, G.S. Influence of fluidity on mechanical and permeation performances of recycled aggregate mortar. Constr. Build. Mater. 2019, 213, 404–412. [Google Scholar] [CrossRef]

- Mora-Ortiz, R.S.; Díaz, S.A.; Del Angel-Meraz, E.; Magaña-Hernández, F. Recycled fine aggregates from mortar debris and red clay brick to fabricate masonry mortars: Mechanical analysis. Materials 2022, 15, 7707. [Google Scholar] [CrossRef] [PubMed]

- Neno, C.; Brito, J.D.; Veiga, R. Using fine recycled concrete aggregate for mortar production. Mater. Res. 2014, 17, 168–177. [Google Scholar] [CrossRef]

- Mora-Ortiz, R.S.; Munguía-Balvanera, E.; Díaz, S.A.; Magaña-Hernández, F.; Angel-Meraz, D.; Bolaina-Juárez, Á. Mechanical behaviour of masonry mortars made with recycled mortar aggregate. Materials 2020, 13, 2373. [Google Scholar] [CrossRef]

- Sabai, S.M.M.; Lichtenberg, J.J.; Egmond, E.L.C.; Florea, M.M.; Brouwers, H.J.H. Construction and demolition waste characteristics in Tanzania. Huria J. Open Univ. Tanzania 2016, 23, 1–19. [Google Scholar]

- Zhang, D.; Zhao, J.; Wang, D.; Xu, C.; Zhai, M.; Ma, X. 2018 Comparative study on the properties of three hydraulic lime mortar systems: Natural hydraulic lime mortar, cement-aerial lime-based mortar and slag-aerial lime-based mortar. Constr. Build. Mater. 2018, 186, 42–52. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Performance of cementitious renderings and masonry mortars containing recycled aggregates from construction and demolition wastes. Constr. Build. Mater. 2016, 105, 400–415. [Google Scholar] [CrossRef]

- Rosado, S.; Costafreda, J.; Martín, D.; Presa, L.; Gullón, L. 2022 Recycled Aggregates from Ceramic and Concrete in Mortar Mixes: A Study of Their Mechanical Properties. Materials 2022, 15, 8933. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, X.; Xiong, G.; Wang, C.; Liu, D.; Zhao, L. Recycling of crushed waste clay brick as aggregates in cement mortars: An approach from macro-and micro-scale investigation. Constr. Build. Mater. 2021, 274, 122068. [Google Scholar] [CrossRef]

- Yue, W.; Wang, B. Ceramic-added lime and cement mortars: A review of applications in building products. Sci. Progress. 2024, 107, 00368504241266559. [Google Scholar] [CrossRef] [PubMed]

- Böke, H.; Akkurt, S.; İpekoğlu, B.; Uğurlu, E. Characteristics of brick used as aggregate in historic brick-lime mortars and plasters. Cem. Concr. Res. 2006, 36, 1115–1122. [Google Scholar] [CrossRef]

- Raini, I.; Raini, I.; El Bougrini, A.; Cherifix, H.; El Qandil, M. Valorization of concrete and brick waste as sustainable alternatives in Lime Mortar: Physical, mechanical, and durability performance. J. Ecol. Eng. 2025, 26, 40–53. [Google Scholar] [CrossRef]

- Papayianni, I.; Stefanidou, M. Mortars for intervention in monuments and historical buildings. WIT Trans. Built Environ. 2003, 66, 58–63. [Google Scholar]

- Ling, H.Y.; Wang, C.; Su, Z.; Chen, S.; Chen, H.; Qian, S.; Li, D.S.; Yan, C.; Kiefel, M.; Lai, C.; et al. Amylopectin from Glutinous Rice as a Sustainable Binder for High-Performance Silicon Anodes. Energy Environ. Mater. 2021, 4, 263–268. [Google Scholar] [CrossRef]

- Maldonado, N.G.; Martín, P.; del Solar, G.G.; Domizio, M. Historic Masonry. In Heritage; Intech Open: London, UK, 2019. [Google Scholar]

- Borges, C.; Santos Silva, A.; Veiga, R. Durability of ancient lime mortars in humid environment. Constr. Build. Mater. 2014, 66, 606–620. [Google Scholar] [CrossRef]

- Aly, M.; Pavia, S. Mechanical and hygric properties of natural hydraulic lime (NHL) mortars with pozzolans. In Proceedings of the Third Conference on Smart Monitoring, Assessment and Rehabilitation of Civil Structures (SMAR), Antalya, Turkey, 7–9 September 2015. [Google Scholar]

- Maravelaki-Kalaitzaki, P.; Bakolas, A.; Karatasios, I.; Kilikoglou, V. Hydraulic lime mortars for the restoration of historic masonry in Crete. Cem. Concr. Res. 2005, 35, 1577–1586. [Google Scholar] [CrossRef]

- Stefanidou, M.; Anastasiou, E.; Georgiadis Filikas, K. Recycled sand in lime-based mortars. Waste Manag. 2014, 34, 2595–2602. [Google Scholar] [CrossRef]

- Lanas, J.; Alvarez-Galindo, J.I. Masonry repair lime-based mortars: Factors affecting the mechanical behaviour. Cem. Concr. Res. 2003, 33, 1867–1876. [Google Scholar] [CrossRef]

- Lima, P.R.L.; Leite, M.B. Influence of CDW Recycled Aggregate on Drying Shrinkage of Mortar. Open J. Civ. Civil Eng. 2012, 2, 53–57. [Google Scholar] [CrossRef]

- Cabrera-Covarrubias, F.G.; Gómez-Soberón, J.M.; Almaral-Sánchez, J.L.; Arredondo-Rea, S.P.; Corral-Higuera, R. Mechanical properties of mortars containing recycled ceramic as a fine aggregate replacement. Rev. De La Construcción 2015, 14, 22–29. [Google Scholar] [CrossRef]

- De Almeida, N.G.; Faria, P.; Pinto, A.P.F. Lime mortars with rice husk ash for ancient masonry. In Proceedings of the HMC08—1st Historical Mortars Conference: Characterization, Diagnosis, Conservation, Repair and Compatibility, Lisbon, Portugal, 24–26 September 2008; pp. 24–26. [Google Scholar]

- Schueremans, L.; Cizer, Ö.; Janssens, E.; Serré, G.; Van Balen, K. Characterization of repair mortars for the assessment of their compatibility: Research and practice. Constr. Build. Mater. 2011, 25, 4338–4350. [Google Scholar] [CrossRef]

- Hughes, J.J. RILEM TC 203-RHM: Repair mortars for historic masonry. Mater. Struct. 2012, 45, 1287–1294. [Google Scholar]

- Válek, J.; Hughes, J.J.; Pique, F.; Gulotta, D.; van Hees, R.; Papayiani, I. Recommendation of RILEM TC 243-SGM: Functional requirements for surface repair mortars for historic buildings. Mater. Struct. 2019, 52, 28. [Google Scholar] [CrossRef]

- Apostolopoulou, M.; Aggelakopoulou, E.; Bakolas, A.; Moropoulou, A. Compatible Mortars for the Sustainable Conservation of Stone in Masonries. In Advanced Materials for the Conservation of Stone; Springer: Cham, Switzerland, 2018; pp. 97–123. [Google Scholar]

- Arizzi, A.; Viles, H.; Cultrone, G. Experimental testing of the durability of lime-based mortars used for rendering historic buildings. Constr. Build. Mater. 2012, 28, 807–818. [Google Scholar] [CrossRef]

- EN 459-1:2015; Building Lime-Part 1: Definitions, Specifications and Conformity Criteria. CEN: Brussels, Belgium, 2015.

- D 422-63; Standard Test Method for Particle—Size analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- Von Konow, T. Aggregate grain size distribution—A major influence on many properties of lime mortars for restoration. In Proceedings of the EUROMAT 2003, Symposium P2–Materials and Conservation of Cultural Heritage, Nice, France, 7–12 September 2003; EPFL: Lausanne, Switzerland, 2003. [Google Scholar]

- RILEM Technical Committees. CPC 14.2: Bulk density of aggregates for concrete. In RILEM Technical Recommendations for the Testing and use of Construction Materials; E& FN SPON: London, UK, 1979; pp. 47–48. [Google Scholar]

- EN 1097-6:2000; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. CEN: Brussels, Belgium, 2013.

- C 1506–03; Standard Test Method for Water Retention of Hydraulic Cement—Based Mortars and Plasters. ASTM International: West Conshohocken, PA, USA, 2003.

- C 231; Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. ASTM International: West Conshohocken, PA, USA, 2014.

- C 1437-15; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2015.

- RILEM Technical Committees. CPC 10.1: Density of compacted fresh concrete. In RILEM Technical Recommendations for Testing and Use of Construction Materials; E&FN SPON: London, UK, 1975; p. 30. [Google Scholar]

- RILEM Technical Committees. LUMA A6: Compressive Strength of mortar. In RILEM Technical Recommendations for the Testing & Use of Construction Materials; E& FN SPON: London, UK, 1991; pp. 469–470. [Google Scholar]

- RILEM Technical Committees. LUMB B1: Compressive strength of small walls and prisms. In RILEM Technical Recommendations for Testing and use of Construction Materials; E&FN SPON: London, UK, 1991; pp. 474–477. [Google Scholar]

- Pelà, L.; Peverini, A.; Garijo, L.; Roca, P. 2014 Experimental calibration of in-situ sampling and testing of historical masonry. In Proceedings of the 9th International Conference on Structural Analysis of Historical Constructions, UNAM, Mexico City, Mexico, 14–17 October 2014; pp. 1–12. [Google Scholar]

- Pelà, L.; Canella, E.; Aprile, A.; Roca, P. Compression test of masonry core samples extracted from existing brickwork. Constr. Build. Mater. 2016, 119, 230–240. [Google Scholar] [CrossRef]

- RILEM Technical Committees. LUM A1: Compressive strength of masonry units. In RILEM Recommendations for the Testing and Use of Construction Materials; E&FN SPON: London, UK, 1991; pp. 456–458. [Google Scholar]

- RILEM Technical Committees. LUM A2: Flexural strength of masonry units. In RILEM Recommendations for the Testing and Use of Construction Materials; E&FN SPON: London, UK, 1991; pp. 459–461. [Google Scholar]

- RILEM Technical Committees. CPC 8: Modulus of elasticity of concrete in compression. In RILEM Recommendations for Use and Testing of Construction Materials; E&FN SPON: London, UK, 1975; pp. 25–27. [Google Scholar]

- RILEM Technical Committees. LUMA7: Flexural strength of mortar. In RILEM Recommendations for the Testing and Use of Construction Materials; E&FN SPON: London, UK, 1991; pp. 472–473. [Google Scholar]

- Fernandes, F.M.; Lourenço, P.B.; Castro, F. Ancient Clay Bricks: Manufacture and Properties. In Materials, Technologies and Practice in Historic Heritage Structures; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

| Property | Units | Brick 1 | Brick 2 | Lime | NS | RCS | RBS |

|---|---|---|---|---|---|---|---|

| Apparent density | g/cm3 | 2.61 | 2.55 | 2.53 | 2.68 | 2.65 | 2.70 |

| Dry density | g/cm3 | 1.82 | 1.81 | - | 2.60 | 2.08 | 2.08 |

| Surface saturated density | g/cm3 | - | - | - | 2.63 | 2.30 | 2.31 |

| Loose density | g/cm3 | - | - | 0.60 | 1.54 | 1.18 | 1.18 |

| Compacted density | g/cm3 | - | - | 0.66 | 1.65 | 1.25 | 1.28 |

| Water absorption | % | 16.6 | 16.1 | - | 1.1 | 10.3 | 10.7 |

| Vol of pores | % | 30.2 | 29.0 | - | - | - | - |

| Aggregate index, AI | - | - | - | - | 17.1 | 9.2 | 18.5 |

| Material | Volume | Weight (g) | ||

|---|---|---|---|---|

| Lime | 1 | 236 | 236 | 236 |

| Sand | 2.5 | 1450 (NS) | 1203 (RCS) | 1080 (RBS) |

| Water | 0.8 | 320 | 320 | 320 |

| Property | Unit | NSM | RCSM | RBSM |

|---|---|---|---|---|

| Table flow | cm | 10.6 | 12.9 | 13.6 |

| Water retention | % | 57.8 | 57.3 | 55.0 |

| Air content | % | 4 | 5 | 4 |

| Fresh density | g/cm3 | 2.03 | 1.83 | 1.82 |

| Property | Unit | Material | |

|---|---|---|---|

| Brick 1 | Brick 2 | ||

| Compressive strength | MPa | 22 ± 6 | 30 ± 6 |

| Flexural strength | MPa | 6.5 ± 0.5 | 7.5 ± 1.5 |

| Modulus of elasticity | MPa | 8072 ± 100 | 10,240 ± 119 |

| Property | Unit | Stack Prism With Respect to Mortar Type | ||

|---|---|---|---|---|

| NSM | RCSM | RBSM | ||

| Compressive strength | MPa | 10.1 ± 1.51 | 10.4 ± 1.75 | 10.2 ± 0.47 |

| Modulus of elasticity | MPa | 1888 | 2431 | 2350 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kilumile, M.; Barra, M.; Mohamed, F.; Aponte, D. Use of Recycled Aggregates in Lime Mortars for Conservation of Historical Buildings. Constr. Mater. 2025, 5, 28. https://doi.org/10.3390/constrmater5020028

Kilumile M, Barra M, Mohamed F, Aponte D. Use of Recycled Aggregates in Lime Mortars for Conservation of Historical Buildings. Construction Materials. 2025; 5(2):28. https://doi.org/10.3390/constrmater5020028

Chicago/Turabian StyleKilumile, Menard, Marilda Barra, Fatma Mohamed, and Diego Aponte. 2025. "Use of Recycled Aggregates in Lime Mortars for Conservation of Historical Buildings" Construction Materials 5, no. 2: 28. https://doi.org/10.3390/constrmater5020028

APA StyleKilumile, M., Barra, M., Mohamed, F., & Aponte, D. (2025). Use of Recycled Aggregates in Lime Mortars for Conservation of Historical Buildings. Construction Materials, 5(2), 28. https://doi.org/10.3390/constrmater5020028