Wearable Actuators: An Overview

Abstract

1. Introduction

2. Wearable Actuators: Materials, Structures, Applications, Merits and Limitations

2.1. Pneumatic and Hydraulic Actuator

2.1.1. Structure

2.1.2. Applications

2.1.3. Merit and Limitations

2.2. Shape Memory Effect

2.2.1. SMAs

2.2.2. SMPs

2.2.3. Applications

2.2.4. Merits and Demerits

2.3. Thermal and Hygroscopic Expansion

2.3.1. Mechanism

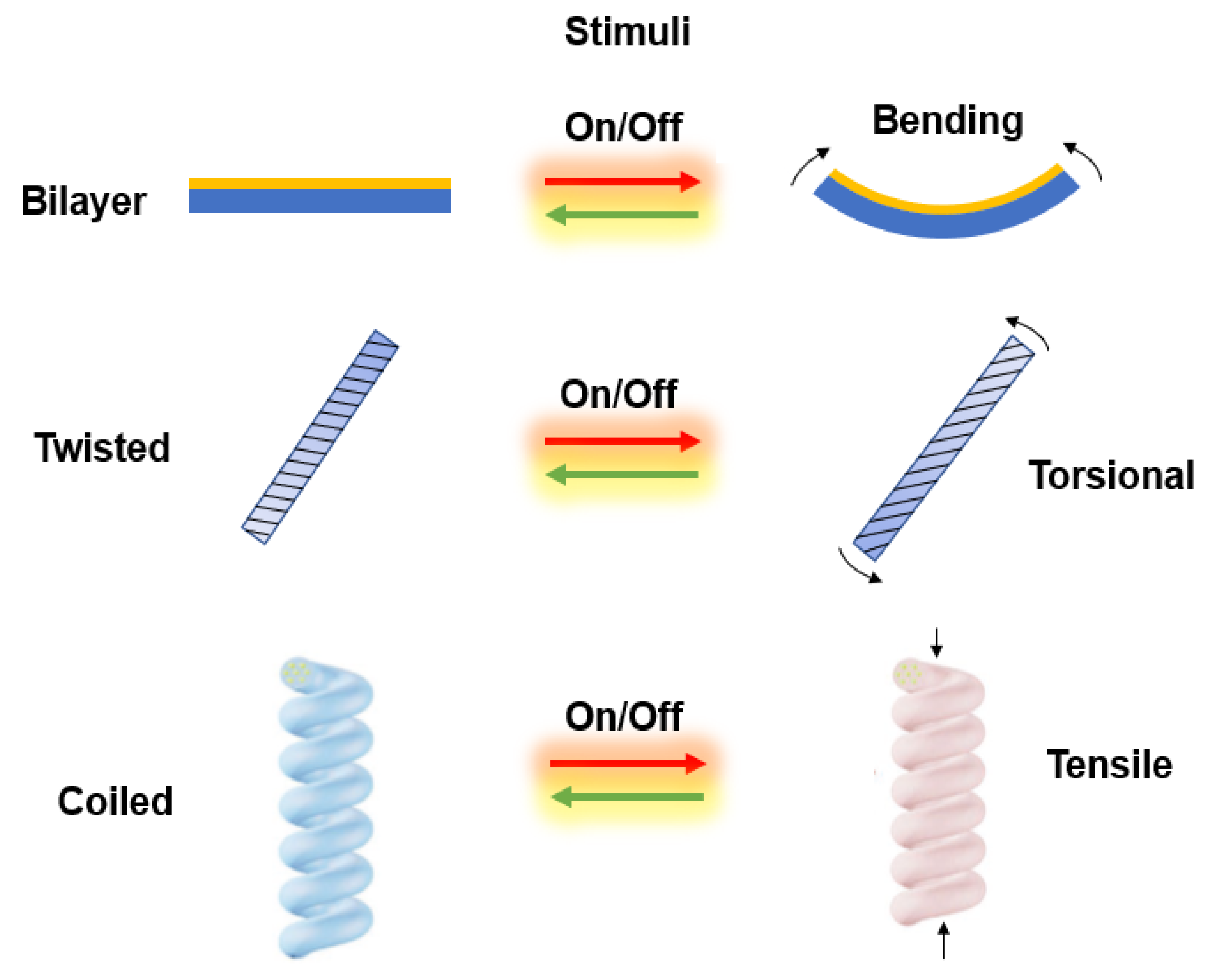

2.3.2. Structure

2.3.3. Applications

2.3.4. Merits and Limitations

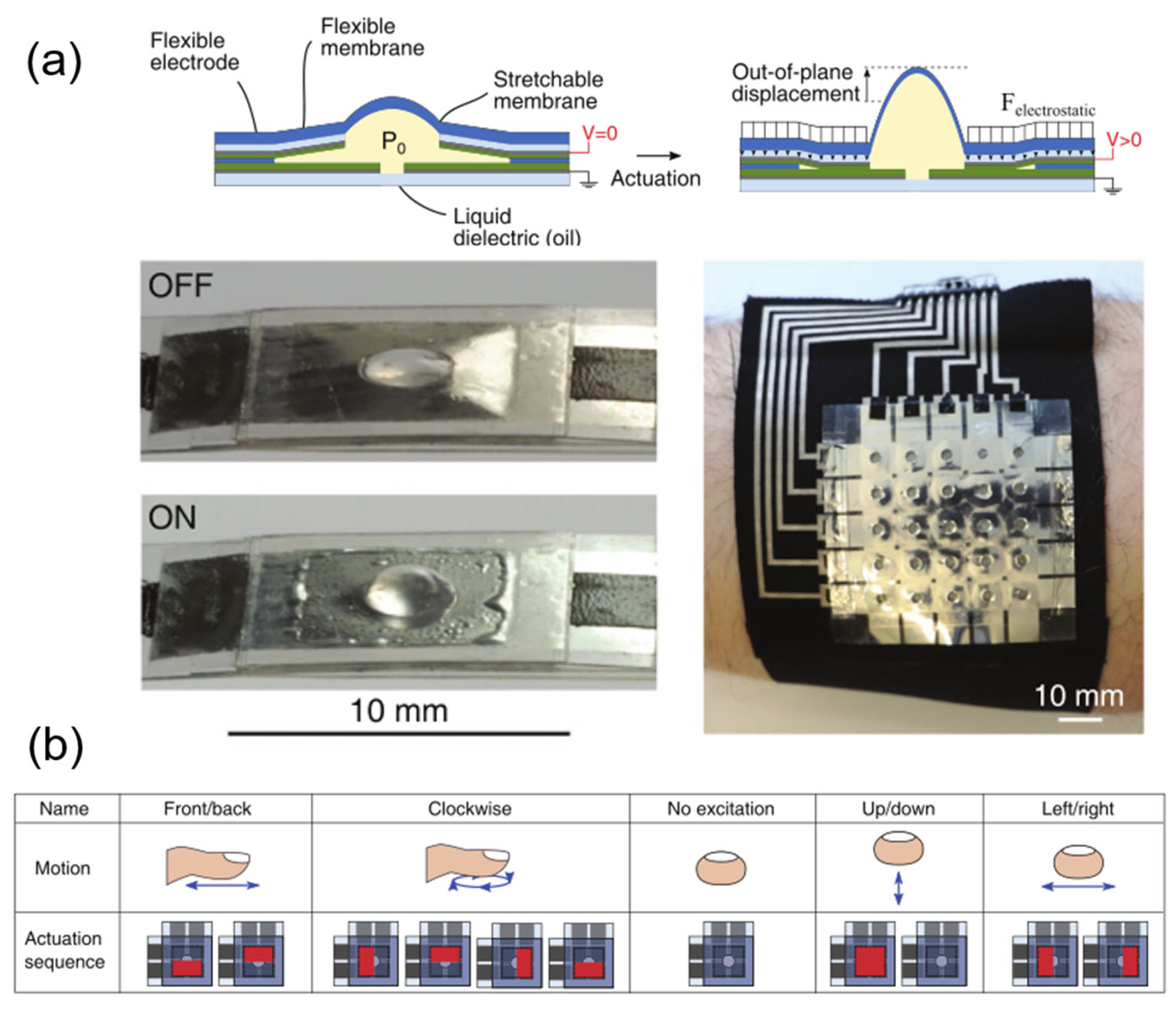

2.4. Dielectric Elastomer Actuators

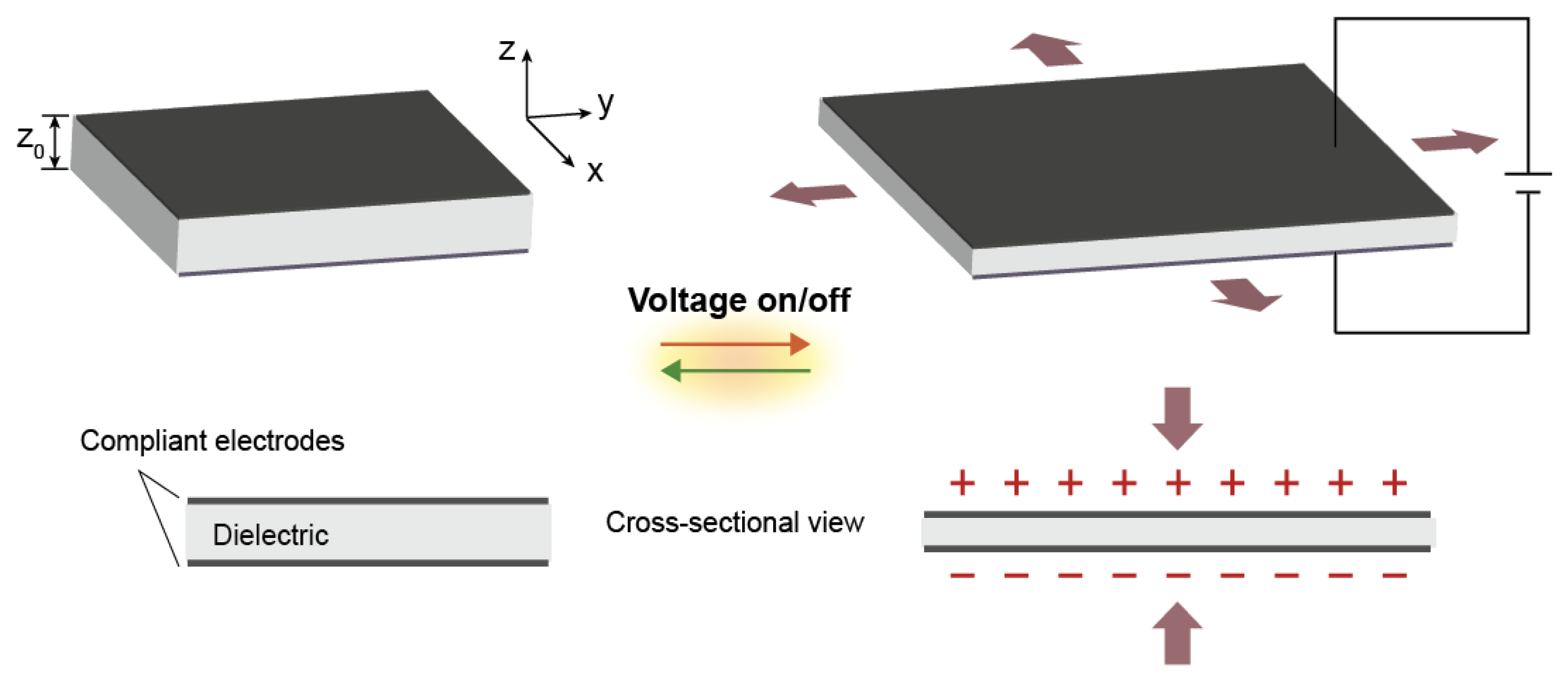

2.4.1. Mechanism

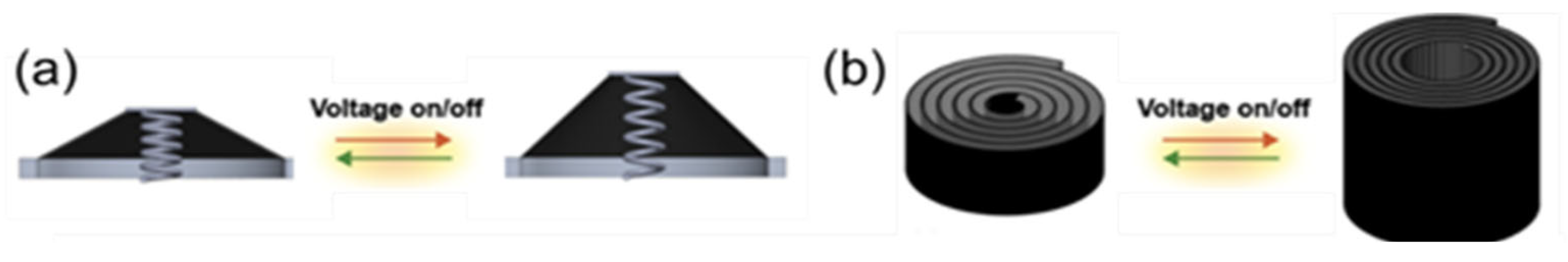

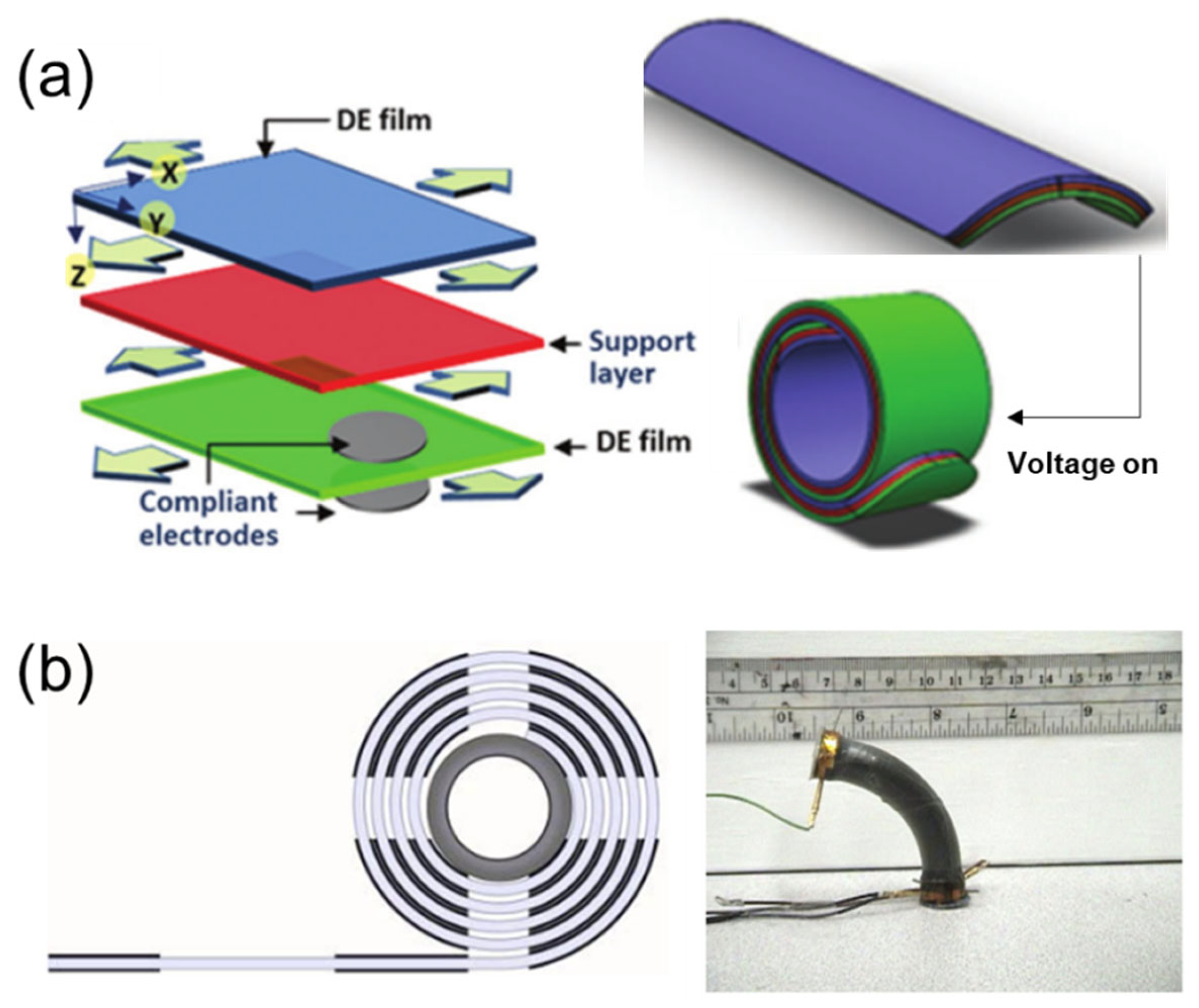

2.4.2. Structure

2.4.3. Applications

2.4.4. Merits and Limitations

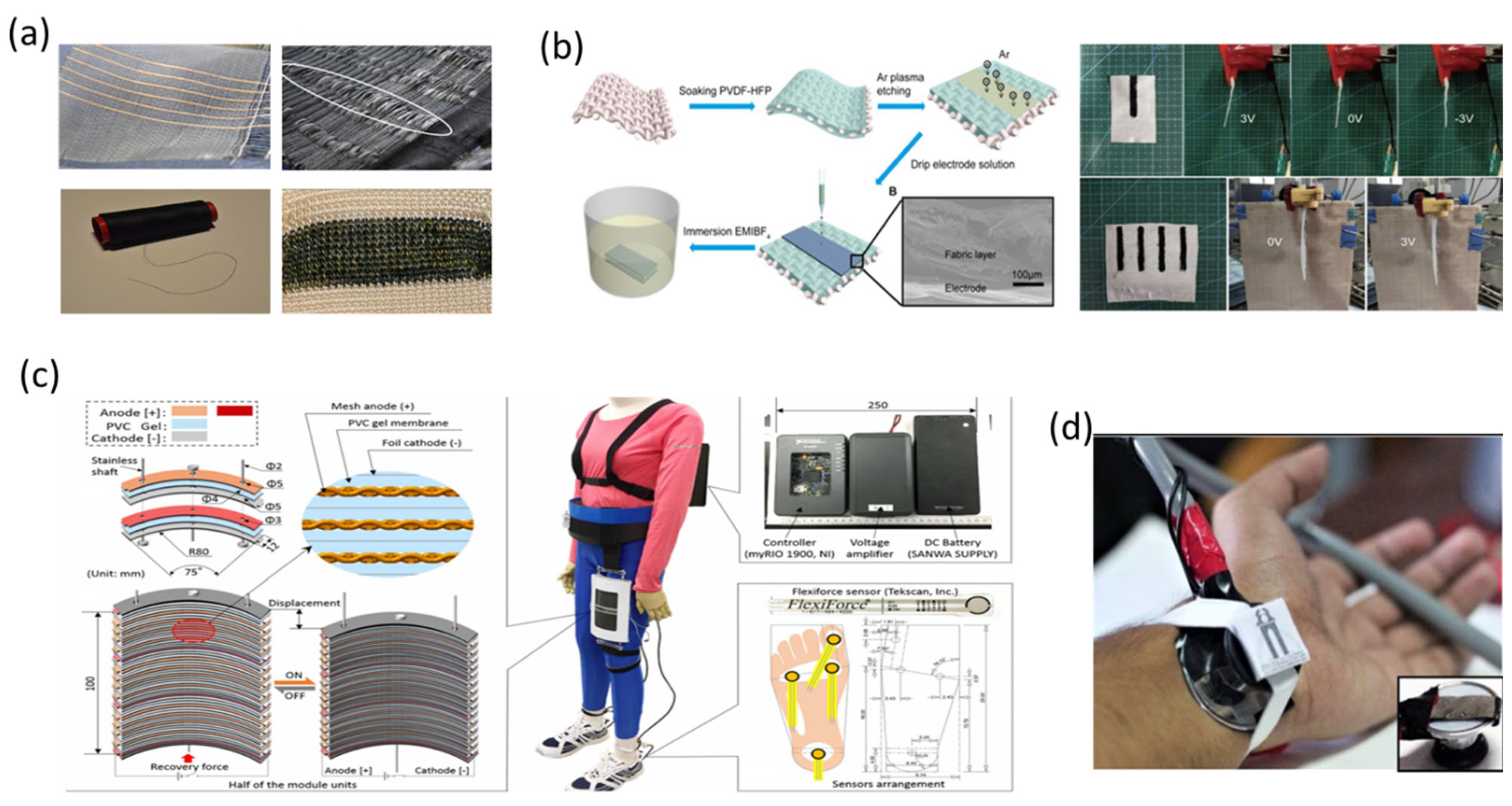

2.5. Ionic-Polymer/Metal Composites and Conducing Polymers

2.5.1. Mechanism

2.5.2. Applications

2.5.3. Merits and Limitations

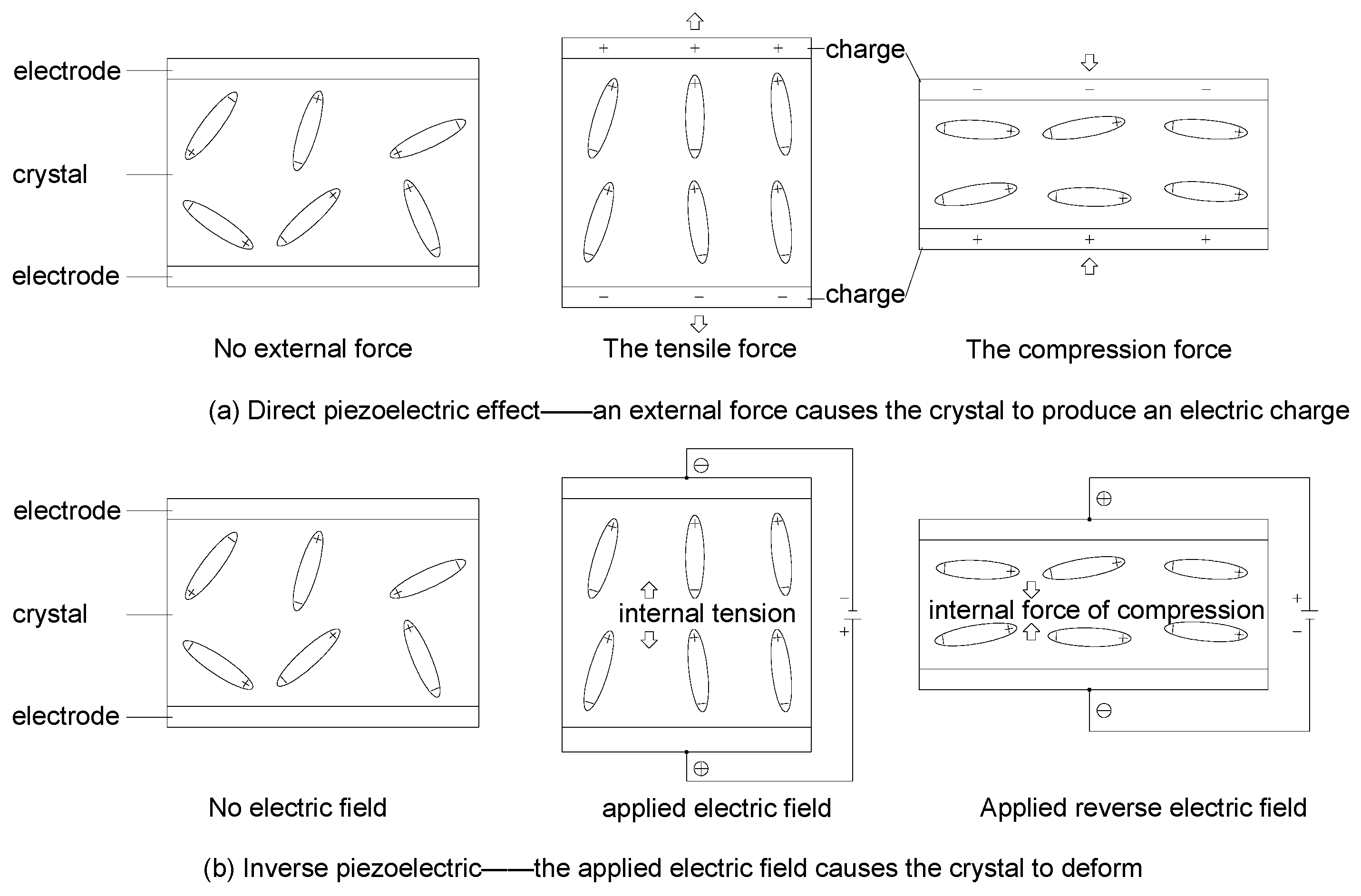

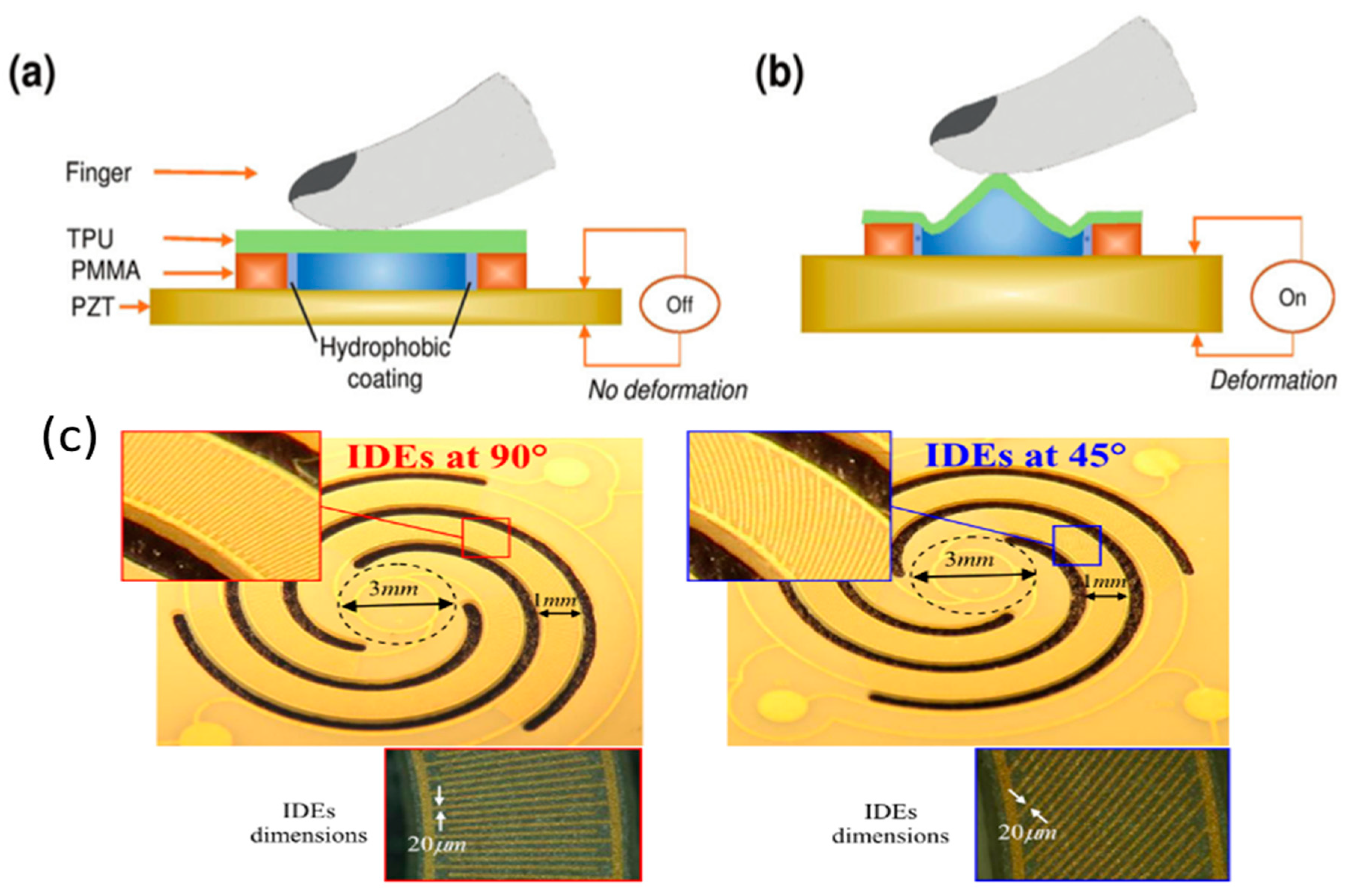

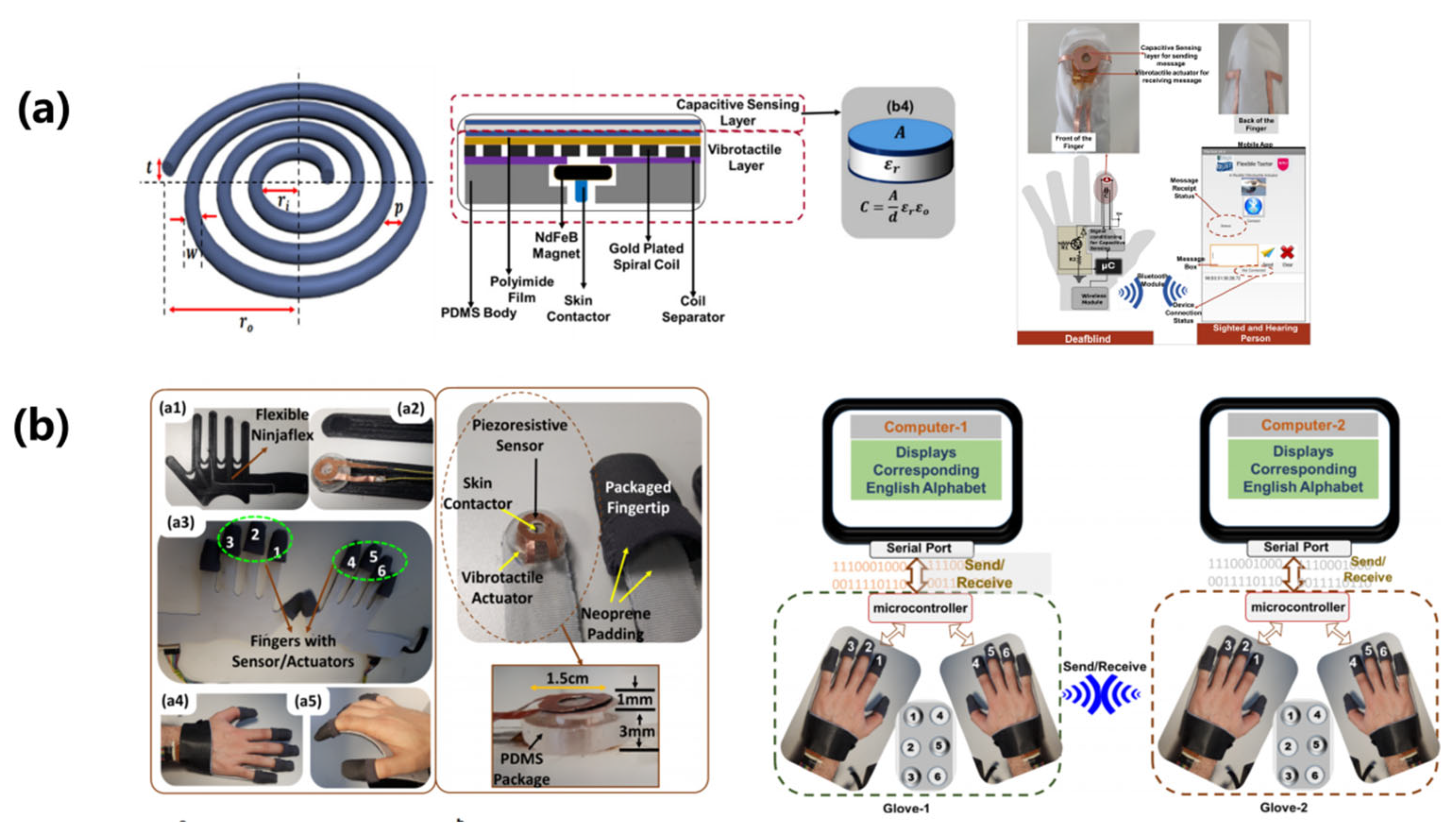

2.6. Piezoelectric Actuators

2.6.1. Mechanism

2.6.2. Structure

2.6.3. Applications

2.6.4. Merits and Limitations

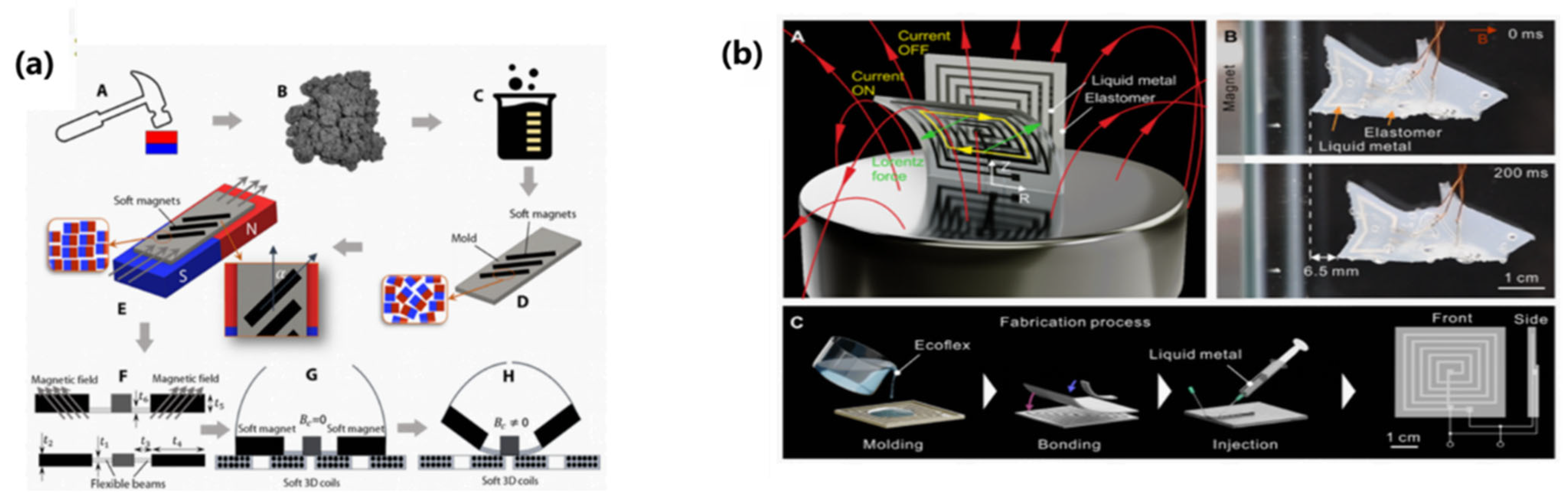

2.7. Electromagnetic Actuators

2.7.1. Mechanism

2.7.2. Structure

2.7.3. Applications

2.7.4. Merits and Limitations

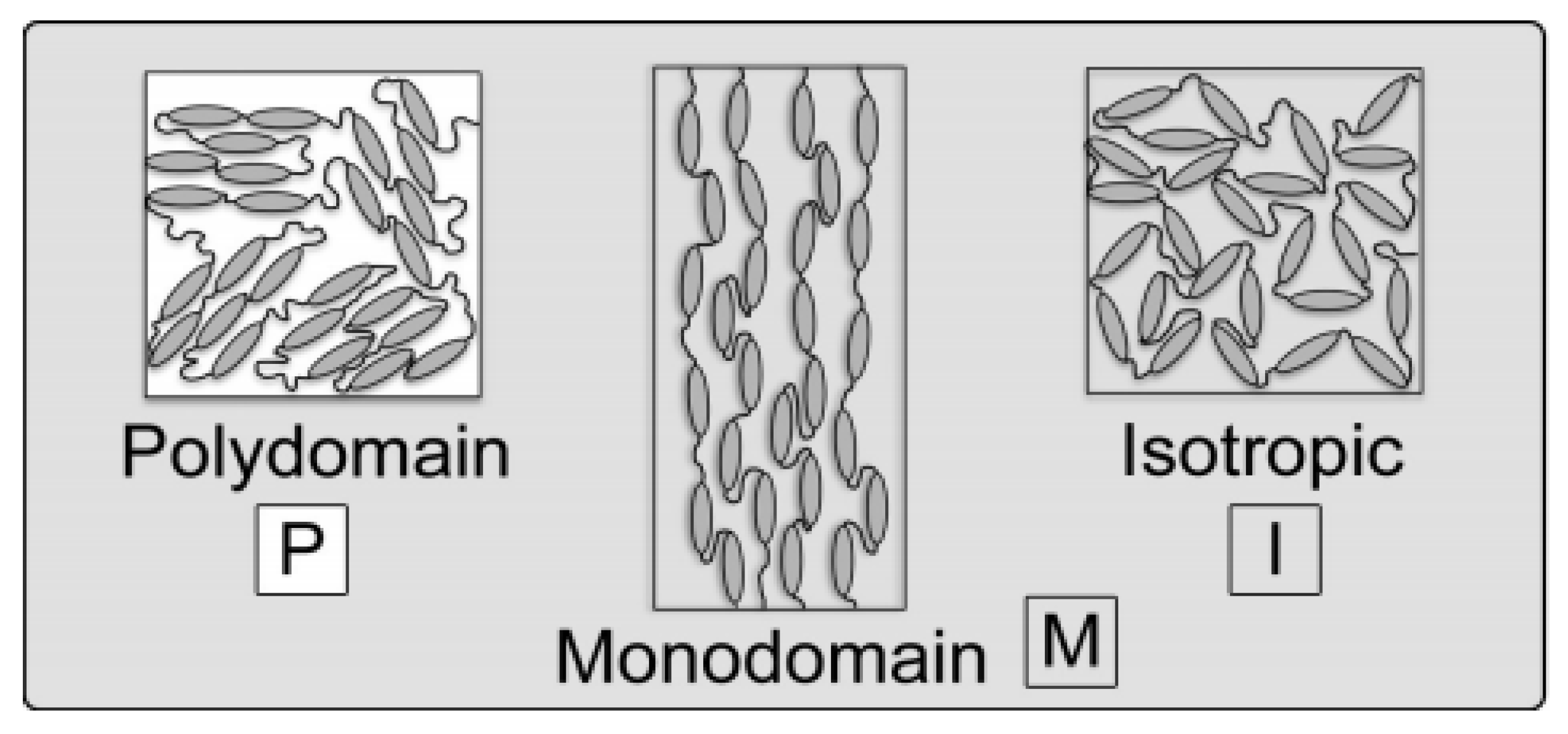

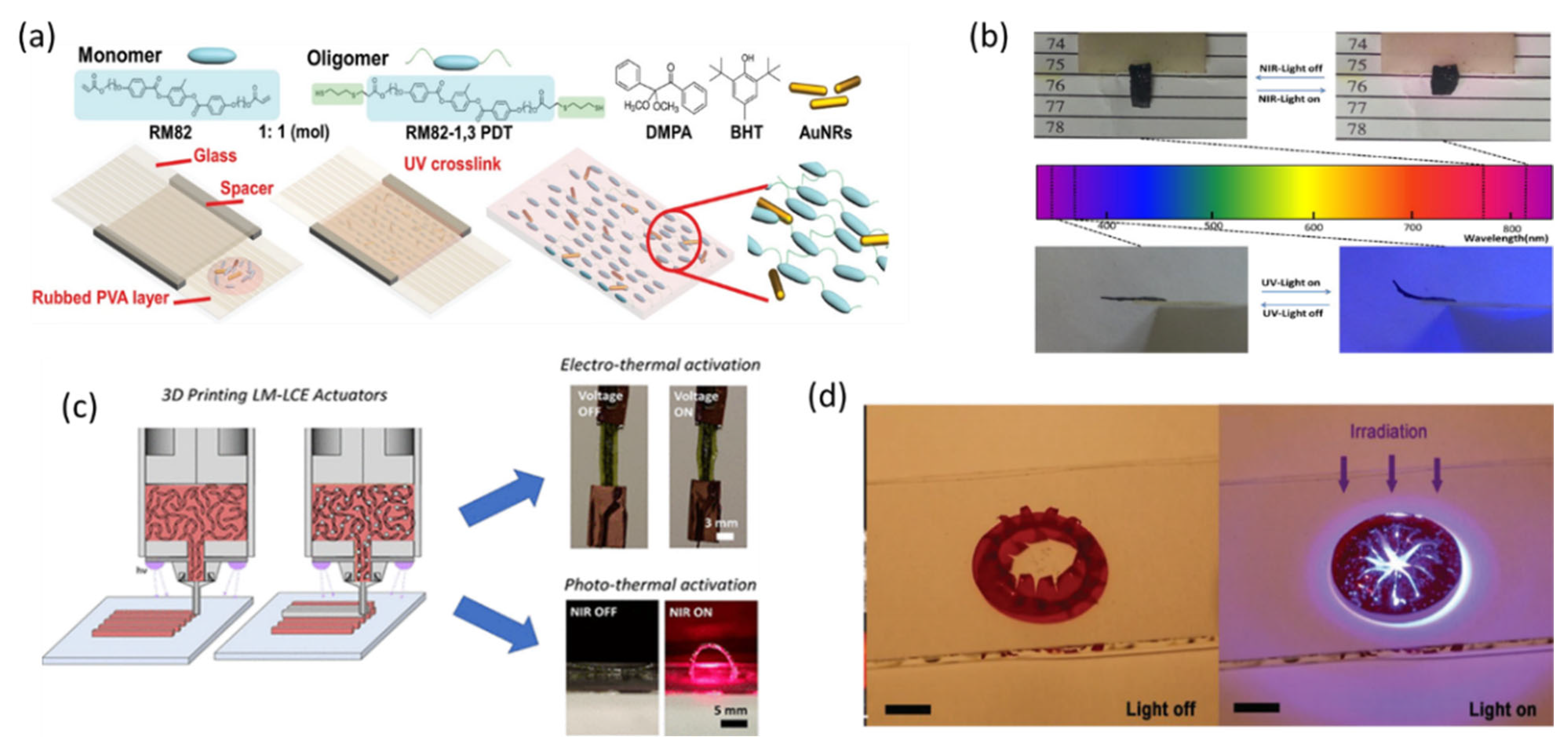

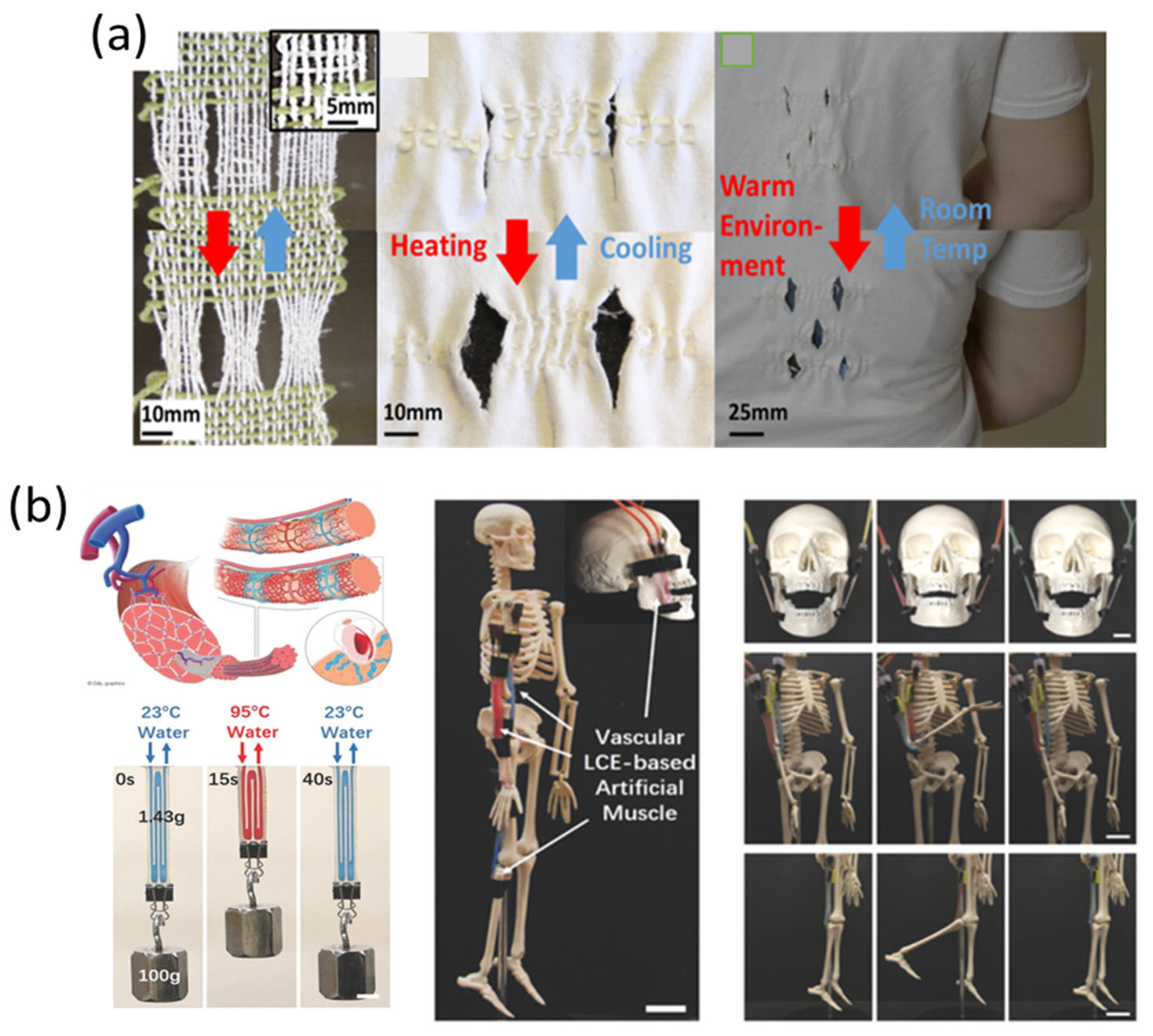

2.8. Liquid Crystal Elastomer

2.8.1. Mechanism

2.8.2. Structure

2.8.3. Applications

2.8.4. Merits and Limitations

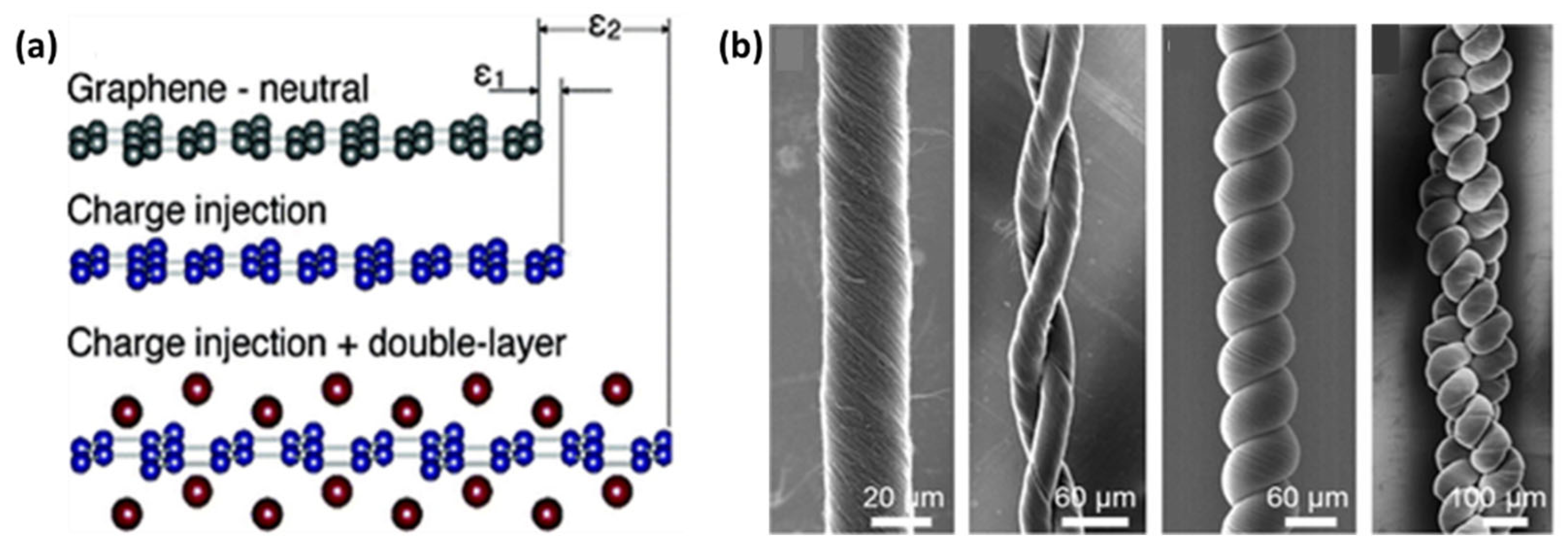

2.9. Other Actuators

2.9.1. Electric Motor

2.9.2. Carbon Nanotubes

2.9.3. Hydrogels

2.9.4. Organic Molecule-Driven Polymeric Actuators

3. Outlook

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Persson, N.K.; Martinez, J.G.; Zhong, Y.; Maziz, A.; Jager, E.W.H. Actuating Textiles: Next Generation of Smart Textiles. Adv. Mater. Technol. 2018, 3, 1700397. [Google Scholar] [CrossRef]

- Xiong, J.; Chen, J.; Lee, P.S. Functional Fibers and Fabrics for Soft Robotics, Wearables, and Human-Robot Interface. Adv. Mater. 2021, 33, 2002640. [Google Scholar] [CrossRef]

- Fritz, H.; Patzer, D.; Galen, S.S. Robotic exoskeletons for reengaging in everyday activities: Promises, pitfalls, and opportunities. Disabil. Rehabil. 2019, 41, 560–563. [Google Scholar] [CrossRef]

- Mun, S.; Yun, S.; Nam, S.; Park, S.K.; Park, S.; Park, B.J.; Lim, J.M.; Kyung, K.U. Electro-Active Polymer Based Soft Tactile Interface for Wearable Devices. IEEE Trans. Haptics 2018, 11, 15–21. [Google Scholar] [CrossRef]

- Hu, J.; Meng, H.; Li, G.; Ibekwe, S.I. A review of stimuli-responsive polymers for smart textile applications. Smart Mater. Struct. 2012, 21, 053001. [Google Scholar] [CrossRef]

- Suman, T. Shape Memory Polymers for Smart Textile Applications. In Textiles for Advanced Applications; Kumar, B., Thakur, S., Eds.; IntechOpen: London, UK, 2017. [Google Scholar] [CrossRef]

- O’Halloran, A.; O’Malley, F.; McHugh, P. A review on dielectric elastomer actuators, technology, applications, and challenges. J. Appl. Phys. 2008, 104, 9. [Google Scholar] [CrossRef]

- Mirvakili, S.M.; Hunter, I.W. Artificial Muscles: Mechanisms, Applications, and Challenges. Adv. Mater. 2018, 30, 1704407. [Google Scholar] [CrossRef] [PubMed]

- Madden, J.D.W.; Vandesteeg, N.A.; Anquetil, P.A.; Madden, P.G.A.; Takshi, A.; Pytel, R.Z.; Lafontaine, S.R.; Wieringa, P.A.; Hunter, I.W. Artificial muscle technology: Physical principles and naval prospects. IEEE J. Ocean. Eng. 2004, 29, 706–728. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Maziz, A.; Concas, A.; Khaldi, A.; Stalhand, J.; Persson, N.K.; Jager, E.W.H. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3, e1600327. [Google Scholar] [CrossRef]

- De Volder, M.; Reynaerts, D. Pneumatic and hydraulic microactuators: A review. J. Micromech. Microeng. 2010, 20, 043001. [Google Scholar] [CrossRef]

- Otten, A.; Voort, C.; Stienen, A.; Aarts, R.; van Asseldonk, E.; van der Kooij, H. LIMPACT: A Hydraulically Powered Self-Aligning Upper Limb Exoskeleton. IEEE ASME Trans. Mechatron. 2015, 20, 2285–2298. [Google Scholar] [CrossRef]

- Huber, J.E.; Fleck, N.A.; Ashby, M.F. The selection of mechanical actuators based on performance indices. Proc. R. Soc. London Ser. A Math. Phys. Eng. Sci. 1997, 453, 2185–2205. [Google Scholar] [CrossRef]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Ruhs, P.A.; Coulter, F.; Studart, A.R. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 2018, 9, 878. [Google Scholar] [CrossRef]

- Kim, S.Y.; Baines, R.; Booth, J.; Vasios, N.; Bertoldi, K.; Kramer-Bottiglio, R. Reconfigurable soft body trajectories using unidirectionally stretchable composite laminae. Nat. Commun. 2019, 10, 1–8. [Google Scholar] [CrossRef]

- Li, S.; Vogt, D.M.; Rus, D.; Wood, R.J. Fluid-driven origami-inspired artificial muscles. Proc. Natl. Acad. Sci. USA 2017, 114, 13132–13137. [Google Scholar] [CrossRef]

- Veale, A.J.; Xie, S.Q. Towards compliant and wearable robotic orthoses: A review of current and emerging actuator technologies. Med. Eng. Phys. 2016, 38, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Choi, J.; Kim, S.J.; Seo, K.-H.; Kim, J. Design of an Inflatable Wrinkle Actuator With Fast Inflation/Deflation Responses for Wearable Suits. IEEE Robot. Autom. Lett. 2020, 5, 3799–3805. [Google Scholar] [CrossRef]

- Neill, C.T.O.; Phipps, N.S.; Cappello, L.; Paganoni, S.; Walsh, C.J. A soft wearable robot for the shoulder: Design, characterization, and preliminary testing. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 1672–1678. [Google Scholar]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- Zhu, M.; Do, T.N.; Hawkes, E.; Visell, Y. Fluidic Fabric Muscle Sheets for Wearable and Soft Robotics. Soft Robot. 2020, 7, 179–197. [Google Scholar] [CrossRef] [PubMed]

- Shepherd, R.F.; Stokes, A.A.; Freake, J.; Barber, J.; Snyder, P.W.; Mazzeo, A.D.; Cademartiri, L.; Morin, S.A.; Whitesides, G.M. Using Explosions to Power a Soft Robot. Angew. Chem. Int. Ed. 2013, 52, 2892–2896. [Google Scholar] [CrossRef] [PubMed]

- Unger, M.A. Monolithic Microfabricated Valves and Pumps by Multilayer Soft Lithography. Science 2000, 288, 113–116. [Google Scholar] [CrossRef]

- Dzahir, M.; Yamamoto, S.-I. Recent Trends in Lower-Limb Robotic Rehabilitation Orthosis: Control Scheme and Strategy for Pneumatic Muscle Actuated Gait Trainers. Robotics 2014, 3, 120–148. [Google Scholar] [CrossRef]

- Walker, J.; Zidek, T.; Harbel, C.; Yoon, S.; Strickland, F.S.; Kumar, S.; Shin, M. Soft Robotics: A Review of Recent Developments of Pneumatic Soft Actuators. Actuators 2020, 9, 3. [Google Scholar] [CrossRef]

- Bose, S.; Bandyopadhyay, A. Chapter 1—Introduction to Biomaterials. In Characterization of Biomaterials; Bandyopadhyay, A., Bose, S., Eds.; Academic Press: Oxford, UK, 2013. [Google Scholar] [CrossRef]

- Sedmák, P.; Pilch, J.; Heller, L.; Kopeček, J.; Wright, J.; Sedlák, P.; Frost, M.; Šittner, P. Grain-resolved analysis of localized deformation in nickel-titanium wire under tensile load. Science 2016, 353, 559–562. [Google Scholar] [CrossRef]

- Stachiv, I.; Alarcon, E.; Lamac, M. Shape Memory Alloys and Polymers for MEMS/NEMS Applications: Review on Recent Findings and Challenges in Design, Preparation, and Characterization. Metals 2021, 11, 415. [Google Scholar] [CrossRef]

- Ölander, A. An electrochemical investigation of solid cadmium-gold alloys. J. Am. Chem. Soc. 1932, 54, 3819–3833. [Google Scholar] [CrossRef]

- Huang, W. On the selection of shape memory alloys for actuators. Mater. Design 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Šittner, P.; Heller, L.; Pilch, J.; Curfs, C.; Alonso, T.; Favier, D. Young’s modulus of austenite and martensite phases in superelastic NiTi wires. J. Mater. Eng. Perform. 2014, 23, 2303–2314. [Google Scholar] [CrossRef]

- Zareie, S.; Issa, A.S.; Seethaler, R.J.; Zabihollah, A. Recent advances in the applications of shape memory alloys in civil infrastructures: A review. Structures 2020, 27, 1535–1550. [Google Scholar] [CrossRef]

- Osada, Y.; Matsuda, A. Shape-Memory in Hydrogels. Nature 1995, 376, 219. [Google Scholar] [CrossRef]

- Lendlein, A.; Jiang, H.Y.; Junger, O.; Langer, R. Light-induced shape-memory polymers. Nature 2005, 434, 879–882. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, I.; Asaka, K.; Kiyohara, K.; Sugino, T.; Terasawa, N.; Mukai, K.; Fukushima, T.; Aida, T. Electromechanical behavior of fully plastic actuators based on bucky gel containing various internal ionic liquids. Electrochim. Acta 2009, 54, 1762–1768. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, Y.; Huang, H.; Lu, J. Recent advances in shape–memory polymers: Structure, mechanism, functionality, modeling and applications. Prog. Polym. Sci. 2012, 37, 1720–1763. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef]

- Hadi, A.; Alipour, K.; Kazeminasab, S.; Elahinia, M. ASR glove: A wearable glove for hand assistance and rehabilitation using shape memory alloys. J. Intel. Mat. Syst. Str. 2018, 29, 1575–1585. [Google Scholar] [CrossRef]

- Copaci, D.; Martín, F.; Moreno, L.; Blanco, D. SMA based elbow exoskeleton for rehabilitation therapy and patient evaluation. IEEE Access 2019, 7, 31473–31484. [Google Scholar] [CrossRef]

- Serrano, D.; Copaci, D.S.; Moreno, L.; Blanco, D. SMA based wrist exoskeleton for rehabilitation therapy. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 2318–2323. [Google Scholar]

- Kim, C.; Kim, G.; Lee, Y.; Lee, G.; Han, S.; Kang, D.; Koo, S.H.; Koh, J.-S. Shape memory alloy actuator-embedded smart clothes for ankle assistance. Smart Mater. Struct. 2020, 29, 055003. [Google Scholar] [CrossRef]

- Yao, Z.; Linnenberg, C.; Argubi-Wollesen, A.; Weidner, R.; Wulfsberg, J.P. Biomimetic design of an ultra-compact and light-weight soft muscle glove. Prod. Eng. 2017, 11, 731–743. [Google Scholar] [CrossRef]

- Park, S.J.; Park, C.H. Suit-type wearable robot powered by shape-memory-alloy-based fabric muscle. Sci. Rep. 2019, 9, 1–8. [Google Scholar]

- Copaci, D.; Cano, E.; Moreno, L.; Blanco, D. New design of a soft robotics wearable elbow exoskeleton based on shape memory alloy wire actuators. Appl. Bionics Biomech. 2017, 2017, 1605101. [Google Scholar] [CrossRef]

- Li, Y.; Chung, S.; Chan, L.; Hu, J. Characterisation of shape memory fabrics. Text. Asia 2004, 35, 32–37. [Google Scholar]

- Principles of SMP’s Environmental Temperature Adaption Feature. Available online: https://www.mcf.co.jp/en/service/diaseries/diaplex.html (accessed on 17 May 2021).

- Kim, H.; Lee, H.; Ha, I.; Jung, J.; Won, P.; Cho, H.; Yeo, J.; Hong, S.; Han, S.; Kwon, J. Biomimetic color changing anisotropic soft actuators with integrated metal nanowire percolation network transparent heaters for soft robotics. Adv. Funct. Mater. 2018, 28, 1801847. [Google Scholar] [CrossRef]

- Yao, S.; Cui, J.; Cui, Z.; Zhu, Y. Soft electrothermal actuators using silver nanowire heaters. Nanoscale 2017, 9, 3797–3805. [Google Scholar] [CrossRef] [PubMed]

- Yin, R.; Yang, B.; Ding, X.; Liu, S.; Zeng, W.; Li, J.; Yang, S.; Tao, X. Wireless Multistimulus-Responsive Fabric-Based Actuators for Soft Robotic, Human–Machine Interactive, and Wearable Applications. Adv. Mater. Technol. 2020, 5, 2000341. [Google Scholar] [CrossRef]

- Yu, W.; Chu, C. Textile Physics; Donghua University Press: Shanghai, China, 2002; pp. 2–25. [Google Scholar]

- Zhu, Q.; Jin, Y.; Wang, W.; Sun, G.; Wang, D. Bioinspired Smart Moisture Actuators Based on Nanoscale Cellulose Materials and Porous, Hydrophilic EVOH Nanofibrous Membranes. ACS Appl. Mater. Inter. 2018, 11, 1440–1448. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Tian, X.; Ras, R.H.; Ikkala, O. Sensitive Humidity-Driven Reversible and Bidirectional Bending of Nanocellulose Thin Films as Bio-Inspired Actuation. Adv. Mater. Interfaces 2015, 2, 1500080. [Google Scholar] [CrossRef]

- Mirvakili, S.M.; Hunter, I.W. Multidirectional artificial muscles from nylon. Adv. Mater. 2017, 29, 1604734. [Google Scholar] [CrossRef]

- Kanik, M.; Orguc, S.; Varnavides, G.; Kim, J.; Benavides, T.; Gonzalez, D.; Akintilo, T.; Tasan, C.C.; Chandrakasan, A.P.; Fink, Y. Strain-programmable fiber-based artificial muscle. Science 2019, 365, 145–150. [Google Scholar] [PubMed]

- Acetate-Based Conjugate Fiber Ventcool™. Available online: https://www.m-chemical.co.jp/en/products/departments/mcc/fibersmat/product/1201225_7496.html (accessed on 17 May 2021).

- Jia, T.J.; Wang, Y.; Dou, Y.Y.; Li, Y.W.; de Andrade, M.J.; Wang, R.; Fang, S.L.; Li, J.J.; Yu, Z.; Qiao, R.; et al. Moisture Sensitive Smart Yarns and Textiles from Self-Balanced Silk Fiber Muscles. Adv. Funct. Mater. 2019, 29, 1808241. [Google Scholar] [CrossRef]

- Cheng, H.; Hu, Y.; Zhao, F.; Dong, Z.; Wang, Y.; Chen, N.; Zhang, Z.; Qu, L. Moisture-activated torsional graphene-fiber motor. Adv. Mater. 2014, 26, 2909–2913. [Google Scholar] [CrossRef]

- He, S.; Chen, P.; Qiu, L.; Wang, B.; Sun, X.; Xu, Y.; Peng, H. A mechanically actuating carbon-nanotube fiber in response to water and moisture. Angew. Chem. Int. Ed. 2015, 54, 14880–14884. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Leng, X.; Jia, T.; Liu, Z. Twisted and coiled bamboo artificial muscles for moisture responsive torsional and tensile actuation. Chin. Phys. B 2020, 29, 118103. [Google Scholar] [CrossRef]

- Li, Y.; Leng, X.; Sun, J.; Zhou, X.; Wu, W.; Chen, H.; Liu, Z. Moisture-sensitive torsional cotton artificial muscle and textile. Chin. Phys. B 2020, 29, 048103. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.; Lu, Z.; Jung de Andrade, M.N.; Fang, S.; Zhang, Z.; Wu, J.; Baughman, R.H. Humidity-and Water-Responsive Torsional and Contractile Lotus Fiber Yarn Artificial Muscles. ACS Appl. Mater. Inter. 2021, 13, 6642–6649. [Google Scholar] [CrossRef]

- Mirabedini, A.; Aziz, S.; Spinks, G.M.; Foroughi, J. Wet-spun biofiber for torsional artificial muscles. Soft Robot. 2017, 4, 421–430. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhu, B.; Peng, Z.; Yin, R.; Baughman, R.H.; Tao, X. Programmable and thermally hardening composite yarn actuators with a wide range of operating temperature. Adv. Mater. Technol. 2020, 5, 2000329. [Google Scholar] [CrossRef]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.W.; Kim, S.H.; Fang, S.L.; de Andrade, M.J.; Goktepe, F.; et al. Artificial Muscles from Fishing Line and Sewing Thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.H.; Wang, W.H.; Miao, M.H. Moisture-Responsive Natural Fiber Coil-Structured Artificial Muscles. ACS Appl. Mater. Inter. 2018, 10, 32256–32264. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Miao, M. Water-responsive artificial muscles from commercial viscose fibers without chemical treatment. Mater. Res. Lett. 2020, 8, 232–238. [Google Scholar] [CrossRef]

- Lamuta, C.; Messelot, S.; Tawfick, S. Theory of the tensile actuation of fiber reinforced coiled muscles. Smart Mater. Struct. 2018, 27, 055018. [Google Scholar] [CrossRef]

- Peng, Y.; Cui, Y. Advanced textiles for personal thermal management and energy. Joule 2020, 4, 724–742. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, F.; Wang, M.; Gardner, C.J.; Kim, G.; Liu, Y.; Leng, J.; Jin, S.; Chen, R. Reversible humidity sensitive clothing for personal thermoregulation. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef]

- Zhang, X.A.; Yu, S.; Xu, B.; Li, M.; Peng, Z.; Wang, Y.; Deng, S.; Wu, X.; Wu, Z.; Ouyang, M. Dynamic gating of infrared radiation in a textile. Science 2019, 363, 619–623. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Yao, L.; Cheng, C.-Y.; Zhang, T.; Atsumi, H.; Wang, L.; Wang, G.; Anilionyte, O.; Steiner, H.; Ou, J. Harnessing the hygroscopic and biofluorescent behaviors of genetically tractable microbial cells to design biohybrid wearables. Sci. Adv. 2017, 3, e1601984. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhang, E.; Plamthottam, R.; Pei, Q. Dielectric Elastomer Artificial Muscle: Materials Innovations and Device Explorations. Acc. Chem. Res. 2019, 52, 316–325. [Google Scholar] [CrossRef]

- Pelrine, R.E.; Kornbluh, R.D.; Joseph, J.P. Electrostriction of polymer dielectrics with compliant electrodes as a means of actuation. Sens. Actuators A Phys. 1998, 64, 77–85. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Pei, Q.; Joseph, J. High-Speed Electrically Actuated Elastomers with Strain Greater Than 100%. Science 2000, 287, 836. [Google Scholar] [CrossRef]

- Shankar, R.; Ghosh, T.K.; Spontak, R.J. Dielectric elastomers as next-generation polymeric actuators. Soft Matter 2007, 3, 1116–1129. [Google Scholar] [CrossRef] [PubMed]

- Romasanta, L.J.; Lopez-Manchado, M.A.; Verdejo, R. Increasing the performance of dielectric elastomer actuators: A review from the materials perspective. Prog. Polym. Sci. 2015, 51, 188–211. [Google Scholar] [CrossRef]

- Youn, J.-H.; Jeong, S.M.; Hwang, G.; Kim, H.; Hyeon, K.; Park, J.; Kyung, K.-U. Dielectric Elastomer Actuator for Soft Robotics Applications and Challenges. Appl. Sci. 2020, 10, 640. [Google Scholar] [CrossRef]

- Brochu, P.; Pei, Q. Advances in Dielectric Elastomers for Actuators and Artificial Muscles. Macromol. Rapid Commun. 2010, 31, 10–36. [Google Scholar] [CrossRef]

- Kovacs, G.; Düring, L.; Michel, S.; Terrasi, G. Stacked dielectric elastomer actuator for tensile force transmission. Sens. Actuators A: Phys. 2009, 155, 299–307. [Google Scholar] [CrossRef]

- Chortos, A.; Hajiesmaili, E.; Morales, J.; Clarke, D.R.; Lewis, J.A. 3D Printing of Interdigitated Dielectric Elastomer Actuators. Adv. Funct. Mater. 2020, 30, 1907375. [Google Scholar] [CrossRef]

- Jung, H.S.; Yang, S.Y.; Cho, K.H.; Song, M.G.; Nguyen, C.T.; Phung, H.; Kim, U.; Moon, H.; Koo, J.C.; Nam, J.-D.; et al. Design and fabrication of twisted monolithic dielectric elastomer actuator. Int. J. Control Autom. Syst. 2017, 15, 25–35. [Google Scholar] [CrossRef]

- Zhao, H.; Hussain, A.M.; Duduta, M.; Vogt, D.M.; Wood, R.J.; Clarke, D.R. Compact Dielectric Elastomer Linear Actuators. Adv. Funct. Mater. 2018, 28, 1804328. [Google Scholar] [CrossRef]

- Phung, H.; Nguyen, C.T.; Jung, H.; Nguyen, T.D.; Choi, H.R. Bidirectional tactile display driven by electrostatic dielectric elastomer actuator. Smart Mater. Struct. 2020, 29, 035007. [Google Scholar] [CrossRef]

- Nalbach, S.; Banda, R.M.; Croce, S.; Rizzello, G.; Naso, D.; Seelecke, S. Modeling and Design Optimization of a Rotational Soft Robotic System Driven by Double Cone Dielectric Elastomer Actuators. Front. Robot. AI 2020, 6, 150. [Google Scholar] [CrossRef]

- Rosset, S.; Niklaus, M.; Dubois, P.; Shea, H.R. Large-Stroke Dielectric Elastomer Actuators With Ion-Implanted Electrodes. J. Microelectromechanical Syst. 2009, 18, 1300–1308. [Google Scholar] [CrossRef]

- Liang, D.; Lin, Z.-F.; Huang, C.-C.; Shih, W.-P. Tunable lens driven by dielectric elastomer actuator with ionic electrodes. Micro Nano Lett. 2014, 9, 869–873. [Google Scholar] [CrossRef]

- Qu, X.; Ma, X.; Shi, B.; Li, H.; Zheng, L.; Wang, C.; Liu, Z.; Fan, Y.; Chen, X.; Li, Z.; et al. Refreshable Braille Display System Based on Triboelectric Nanogenerator and Dielectric Elastomer. Adv. Funct. Mater. 2021, 31, 2006612. [Google Scholar] [CrossRef]

- Duduta, M.; Wood, R.J.; Clarke, D.R. Multilayer Dielectric Elastomers for Fast, Programmable Actuation without Prestretch. Adv. Mater. 2016, 28, 8058–8063. [Google Scholar] [CrossRef]

- Shao, H.; Wei, S.; Jiang, X.; Holmes, D.P.; Ghosh, T.K. Bioinspired Electrically Activated Soft Bistable Actuators. Adv. Funct. Mater. 2018, 28, 1802999. [Google Scholar] [CrossRef]

- Pei, Q.; Rosenthal, M.; Stanford, S.; Prahlad, H.; Pelrine, R. Multiple-degrees-of-freedom electroelastomer roll actuators. Smart Mater. Struct. 2004, 13, N86–N92. [Google Scholar] [CrossRef]

- Yan, Y.; Santaniello, T.; Bettini, L.G.; Minnai, C.; Bellacicca, A.; Porotti, R.; Denti, I.; Faraone, G.; Merlini, M.; Lenardi, C.; et al. Electroactive Ionic Soft Actuators with Monolithically Integrated Gold Nanocomposite Electrodes. Adv. Mater. 2017, 29, 1606109. [Google Scholar] [CrossRef] [PubMed]

- Pyo, D.; Ryu, S.; Kyung, K.-U.; Yun, S.; Kwon, D.-S. High-pressure endurable flexible tactile actuator based on microstructured dielectric elastomer. Appl. Phys. Lett. 2018, 112, 061902. [Google Scholar] [CrossRef]

- Acome, E.; Keplinger, C.; Gross, M.D.; Bruns, C.; Leithinger, D. Soft Electrohydraulic Actuators for Origami Inspired Shape-Changing Interfaces. In Proceedings of the CHI ’21 Extended Abstracts, Yokohama, Japan, 8–13 May 2021. [Google Scholar]

- Ren, Z.; Hu, W.; Liu, C.; Li, S.; Niu, X.; Pei, Q. Phase-Changing Bistable Electroactive Polymer Exhibiting Sharp Rigid-to-Rubbery Transition. Macromolecules 2016, 49, 134–140. [Google Scholar] [CrossRef]

- Ji, X.; Liu, X.; Cacucciolo, V.; Civet, Y.; El Haitami, A.; Cantin, S.; Perriard, Y.; Shea, H. Untethered Feel-Through Haptics Using 18-µm Thick Dielectric Elastomer Actuators. Adv. Funct. Mater. 2020, 2006639. [Google Scholar] [CrossRef]

- Lee, H.S.; Phung, H.; Lee, D.-H.; Kim, U.K.; Nguyen, C.T.; Moon, H.; Koo, J.C.; Nam, J.-D.; Choi, H.R. Design analysis and fabrication of arrayed tactile display based on dielectric elastomer actuator. Sens. Actuators A Phys. 2014, 205, 191–198. [Google Scholar] [CrossRef]

- King, H.H.; Donlin, R.; Hannaford, B. Perceptual thresholds for single vs. Multi-Finger Haptic interaction. In Proceedings of the 2010 IEEE Haptics Symposium, Waltham, MA, USA, 25–26 March 2010; pp. 95–99. [Google Scholar]

- Leroy, E.; Hinchet, R.; Shea, H. Multimode Hydraulically Amplified Electrostatic Actuators for Wearable Haptics. Adv. Mater. 2020, 32, 2002564. [Google Scholar] [CrossRef]

- Koo, I.M.; Jung, K.; Koo, J.C.; Nam, J.; Lee, Y.K.; Choi, H.R. Development of Soft-Actuator-Based Wearable Tactile Display. IEEE Trans. Robot. 2008, 24, 549–558. [Google Scholar] [CrossRef]

- Zhao, H.; Hussain, A.M.; Israr, A.; Vogt, D.M.; Duduta, M.; Clarke, D.R.; Wood, R.J. A Wearable Soft Haptic Communicator Based on Dielectric Elastomer Actuators. Soft Robot. 2020, 7, 451–461. [Google Scholar] [CrossRef]

- Carpi, F.; Mannini, A.; de Rossi, D. Elastomeric contractile actuators for hand rehabilitation splints. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 29 April 2008. [Google Scholar]

- Pourazadi, S.; Ahmadi, S.; Menon, C. Towards the development of active compression bandages using dielectric elastomer actuators. Smart Mater. Struct. 2014, 23, 065007. [Google Scholar] [CrossRef]

- Allen, D.P.; Little, R.; Laube, J.; Warren, J.; Voit, W.; Gregg, R.D. Towards an ankle-foot orthosis powered by a dielectric elastomer actuator. Mechatronics 2021, 76, 102551. [Google Scholar] [CrossRef]

- Kim, K.J.; Shahinpoor, M. Ionic polymer metal composites: II. Manufacturing techniques. Smart Mater. Struct. 2003, 12, 65–79. [Google Scholar] [CrossRef]

- Kuhn, H.; Möbius, D. Systems of Monomolecular Layers—Assembling and Physico-Chemical Behavior. Angew. Chem. Int. Ed. Engl. 1971, 10, 620–637. [Google Scholar] [CrossRef]

- Katchalsky, A. Rapid swelling and deswelling of reversible gels of polymeric acids by ionization. Experientia 1949, 5, 319–320. [Google Scholar] [CrossRef]

- Shahinpoor, M.; Kim, K.J. Ionic polymer-metal composites: I. Fundamentals. Smart Mater. Struct. 2001, 10, 819–833. [Google Scholar] [CrossRef]

- Asaka, K.; Mukai, K.; Sugino, T.; Kiyohara, K. Ionic electroactive polymer actuators based on nano-carbon electrodes. Polym. Int. 2013, 62, 1263–1270. [Google Scholar] [CrossRef]

- Wang, H.S.; Cho, J.; Park, H.W.; Jho, J.Y.; Park, J.H. Ionic polymer–metal composite actuators driven by methylammonium formate for high-voltage and long-term operation. J. Ind. Eng. Chem. 2021, 96, 194–201. [Google Scholar] [CrossRef]

- Bar-Cohen, Y. Electroactive Polymer (EAP) Actuators as Artificial Muscles: Reality, Potential, and Challenges; SPIE: Bellingham, WA USA, 2004. [Google Scholar]

- Zou, M.; Li, S.; Hu, X.; Leng, X.; Wang, R.; Zhou, X.; Liu, Z. Progresses in Tensile, Torsional, and Multifunctional Soft Actuators. Adv. Funct. Mater. 2021, 2007437. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, Y.; Li, C.; Li, Y.; Chen, W. Flexible and Electroactive Textile Actuator Enabled by PEDOT:PSS/MOF-Derivative Electrode Ink. Front. Bioeng. Biotechnol. 2020, 8, 212. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hashimoto, M. PVC gel soft actuator-based wearable assist wear for hip joint support during walking. Smart Mater. Struct. 2017, 26, 125003. [Google Scholar] [CrossRef]

- Chattaraj, R.; Bhaumik, S.; Khan, S.; Chatterjee, D. Soft wearable ionic polymer sensors for palpatory pulse-rate extraction. Sens. Actuators A Phys. 2018, 270, 65–71. [Google Scholar] [CrossRef]

- Hamlen, R.P.; Kent, C.E.; Shafer, S.N. Electrolytically Activated Contractile Polymer. Nature 1965, 206, 1149–1150. [Google Scholar] [CrossRef]

- Lu, W.; Fadeev, A.G.; Qi, B.; Smela, E.; Mattes, B.R.; Ding, J.; Spinks, G.M.; Mazurkiewicz, J.; Zhou, D.; Wallace, G.G.; et al. Use of Ionic Liquids for π-Conjugated Polymer Electrochemical Devices. Science 2002, 297, 983. [Google Scholar] [CrossRef]

- Lewis, T.W.; Spinks, G.M.; Wallace, G.G.; Mazzoldi, A.; De Rossi, D. Investigation of the applied potential limits for polypyrrole when employed as the active components of a two-electrode device. Synth. Met. 2001, 122, 379–385. [Google Scholar] [CrossRef]

- Chen, D.; Guorong, L.; Yin, Q. Piezoelectric Constants Measured from Converse Piezoelectric Effect and Piezoelectric Ceramic Actuators. J. Inorg. Mater. 1997, 12, 861–866. [Google Scholar]

- Brook, R.J. Advanced Ceramic Materials: An Overview. In Concise Encyclopedia of Advanced Ceramic Materials; Brook, R.J., Ed.; Pergamon: Oxford, UK, 1991; pp. 1–8. [Google Scholar]

- Sun, Q.; Wang, J.; Zhang, L.; Mao, P.; Liu, S.; He, L.; Kang, F.; Xue, R. Achieving high energy density and discharge efficiency in multi-layered PVDF–PMMA nanocomposites composed of 0D BaTiO3 and 1D NaNbO3@SiO2. J. Mater. Chem. C 2020, 8, 7211–7220. [Google Scholar] [CrossRef]

- Akther, A.; Castro, J.O.; Mousavi Shaegh, S.A.; Rezk, A.R.; Yeo, L.Y. Miniaturised acoustofluidic tactile haptic actuator. Soft Matter 2019, 15, 4146–4152. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Yim, J.K.; Liang, J.; Shao, Z.; Qi, M.; Zhong, J.; Luo, Z.; Yan, X.; Zhang, M.; Wang, X.; et al. Insect-scale fast moving and ultrarobust soft robot. Sci. Robot. 2019, 4, eaax1594. [Google Scholar] [CrossRef]

- Maccabi, N.; Grinberg, I.; Kassie, A.; Shmulevich, S.; Elata, D. Bulk PZT Actuator for Parallel out-of-plane motion: The Superiority of Torsion Deformation over Bending Deformation. Procedia Eng. 2016, 168, 1513–1516. [Google Scholar] [CrossRef]

- Xu, C.; Reng, Y.; Liu, S.; Zhu, J.; Liu, Y.; Wu, H. A fast rotating soft actuator based on piezoelectric vibration. Chin. Sci. Bull. 2020, 65, 109–116. [Google Scholar] [CrossRef]

- Kwon, O.D.; Yoo, J.S.; Yun, Y.J.; Lee, J.S.; Kang, S.H.; Lim, K.J. A research on the piezoelectric vibration actuator for mobile phone. In Proceedings of the 2005 International Symposium on Electrical Insulating Materials, 2005. (ISEIM 2005), Kitakyushu, Japan, 5–9 June 2005; Volume 673, pp. 676–678. [Google Scholar]

- Park, T.; Cha, Y. Soft mobile robot inspired by animal-like running motion. Sci. Rep. 2019, 9, 14700. [Google Scholar] [CrossRef]

- Jeong, S.-S.; Cheon, S.-K.; Kim, M.-H.; Song, J.-S.; Park, T.-G. Motional characteristics of ultrasonic motor using Λ (lambda)-shaped stator. Ceram. Int. 2013, 39, S715–S719. [Google Scholar] [CrossRef]

- Li, X.; Yao, Z.; Wu, R. Modeling and analysis of stick-slip motion in a linear piezoelectric ultrasonic motor considering ultrasonic oscillation effect. Int. J. Mech. Sci. 2016, 107, 215–224. [Google Scholar] [CrossRef]

- Qiu, W.; Mizuno, Y.; Koyama, D.; Nakamura, K. Efficiency improvement of hybrid transducer-type ultrasonic motor using lubricant. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 786–794. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Liu, Y.; Deng, J.; Wang, L.; Chen, W. A review on piezoelectric ultrasonic motors for the past decade: Classification, operating principle, performance, and future work perspectives. Sens. Actuators A Phys. 2020, 306, 111971. [Google Scholar] [CrossRef]

- Sauvet, B.; Laliberté, T.; Gosselin, C. Design, analysis and experimental validation of an ungrounded haptic interface using a piezoelectric actuator. Mechatronics 2017, 45, 100–109. [Google Scholar] [CrossRef]

- Zhu, M.; Sun, Z.; Zhang, Z.; Shi, Q.; He, T.; Liu, H.; Chen, T.; Lee, C. Haptic-feedback smart glove as a creative human-machine interface (HMI) for virtual/augmented reality applications. Sci. Adv. 2020, 6, eaaz8693. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Shi, Y.; Joe, P.; Ghaffari, R.; Balooch, G.; Usgaonkar, K.; Gur, O.; Tran, P.L.; Crosby, J.R.; Meyer, M.; et al. Conformal piezoelectric systems for clinical and experimental characterization of soft tissue biomechanics. Nat. Mater. 2015, 14, 728–736. [Google Scholar] [CrossRef]

- Ba, J. Research on Magnetically Controlled Miniature Soft Crawling Robot Based on Magneto-elastic Composite Material. Ph.D. Thesis, Tianjin University of Technology, Tianjin, China, 2020. [Google Scholar]

- Mao, G.; Drack, M.; Karami-Mosammam, M.; Wirthl, D.; Stockinger, T.; Schwödiauer, R.; Kaltenbrunner, M. Soft electromagnetic actuators. Sci. Adv. 2020, 6, eabc0251. [Google Scholar] [CrossRef]

- Ebrahimi, N.; Schimpf, P.; Jafari, A. Design optimization of a solenoid-based electromagnetic soft actuator with permanent magnet core. Sens. Actuators A Phys. 2018, 284, 276–285. [Google Scholar] [CrossRef]

- Pece, F.; Zarate, J.J.; Vechev, V.; Besse, N.; Gudozhnik, O.; Shea, H.; Hilliges, O. MagTics: Flexible and Thin Form Factor Magnetic Actuators for Dynamic and Wearable Haptic Feedback. In Proceedings of the 30th Annual ACM Symposium on User Interface Software and Technology, Québec City, QC, Canada, 20 October 2017; pp. 143–154. [Google Scholar]

- Yunas, J.; Mulyanti, B.; Hamidah, I.; Mohd Said, M.; Pawinanto, R.E.; Wan Ali, W.A.; Subandi, A.; Hamzah, A.A.; Latif, R.; Yeop Majlis, B. Polymer-Based MEMS Electromagnetic Actuator for Biomedical Application: A Review. Polymers 2020, 12, 1184. [Google Scholar] [CrossRef]

- Do, T.N.; Phan, H.; Nguyen, T.-Q.; Visell, Y. Miniature Soft Electromagnetic Actuators for Robotic Applications. Adv. Funct. Mater. 2018, 28, 1800244. [Google Scholar] [CrossRef]

- Guo, R.; Sheng, L.; Gong, H.; Liu, J. Liquid metal spiral coil enabled soft electromagnetic actuator. Sci. China Technol. Sci. 2018, 61, 516–521. [Google Scholar] [CrossRef]

- Ozioko, O.; Navaraj, W.; Hersh, M.; Dahiya, R. Tacsac: A Wearable Haptic Device with Capacitive Touch-Sensing Capability for Tactile Display. Sensors 2020, 20, 4780. [Google Scholar] [CrossRef]

- Ozioko, O.; Karipoth, P.; Hersh, M.; Dahiya, R. Wearable Assistive Tactile Communication Interface Based on Integrated Touch Sensors and Actuators. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 1344–1352. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.; Xie, Z.; Yu, Y.; Lee, J.; Vazquez-Guardado, A.; Luan, H.; Ruban, J.; Ning, X.; Akhtar, A.; Li, D.; et al. Skin-integrated wireless haptic interfaces for virtual and augmented reality. Nature 2019, 575, 473–479. [Google Scholar] [CrossRef]

- White, T.J.; Broer, D.J. Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nat. Mater. 2015, 14, 1087–1098. [Google Scholar] [CrossRef] [PubMed]

- Kularatne, R.S.; Kim, H.; Boothby, J.M.; Ware, T.H. Liquid Crystal Elastomer Actuators: Synthesis, Alignment, and Applications. J. Polym. Sci. Pol. Phys. 2017, 55, 395–411. [Google Scholar] [CrossRef]

- Ohm, C.; Brehmer, M.; Zentel, R. Liquid Crystalline Elastomers as Actuators and Sensors. Adv. Mater. 2010, 22, 3366–3387. [Google Scholar] [CrossRef]

- He, Q.; Wang, Z.; Wang, Y.; Minori, A.; Tolley, M.T.; Cai, S. Electrically controlled liquid crystal elastomer-based soft tubular actuator with multimodal actuation. Sci. Adv. 2019, 5, 10. [Google Scholar] [CrossRef] [PubMed]

- Yakacki, C.M.; Saed, M.; Nair, D.P.; Gong, T.; Reed, S.M.; Bowman, C.N. Tailorable and programmable liquid-crystalline elastomers using a two-stage thiol-acrylate reaction. Rsc. Adv. 2015, 5, 18997–19001. [Google Scholar] [CrossRef]

- Liu, H.R.; Tian, H.M.; Shao, J.Y.; Wang, Z.J.; Li, X.M.; Wang, C.H.; Chen, X.L. An Electrically Actuated Soft Artificial Muscle Based on a High-Performance Flexible Electrothermal Film and Liquid-Crystal Elastomer. Acs. Appl. Mater. Inter. 2020, 12, 56338–56349. [Google Scholar] [CrossRef]

- Wang, Y.C.; Dang, A.L.; Zhang, Z.F.; Yin, R.; Gao, Y.C.; Feng, L.; Yang, S. Repeatable and Reprogrammable Shape Morphing from Photoresponsive Gold Nanorod/Liquid Crystal Elastomers. Adv. Mater. 2020, 32, 2004270. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Sayed, S.M.; Guo, L.X.; Lin, B.P.; Zhang, X.Q.; Sun, Y.; Yang, H. Multi-Stimuli Responsive Carbon Nanotube Incorporated Polysiloxane Azobenzene Liquid Crystalline Elastomer Composites. Macromolecules 2016, 49, 663–671. [Google Scholar] [CrossRef]

- Ambulo, C.P.; Ford, M.J.; Searles, K.; Majidi, C.; Ware, T.H. 4D-Printable Liquid Metal-Liquid Crystal Elastomer Composites. Acs. Appl. Mater. Inter. 2021, 13, 12805–12813. [Google Scholar] [CrossRef]

- Lu, X.L.; Guo, S.W.; Tong, X.; Xia, H.S.; Zhao, Y. Tunable Photocontrolled Motions Using Stored Strain Energy in Malleable Azobenzene Liquid Crystalline Polymer Actuators. Adv. Mater. 2017, 29, 1606467. [Google Scholar] [CrossRef]

- Zeng, H.; Wani, O.M.; Wasylczyk, P.; Kaczmarek, R.; Priimagi, A. Self-Regulating Iris Based on Light-Actuated Liquid Crystal Elastomer. Adv. Mater. 2017, 29, 1701814. [Google Scholar] [CrossRef] [PubMed]

- Roach, D.J.; Yuan, C.; Kuang, X.; Li, V.C.F.; Blake, P.; Romero, M.L.; Hammel, I.; Yu, K.; Qi, H.J. Long Liquid Crystal Elastomer Fibers with Large Reversible Actuation Strains for Smart Textiles and Artificial Muscles. Acs. Appl. Mater. Inter. 2019, 11, 19514–19521. [Google Scholar] [CrossRef]

- He, Q.G.; Wang, Z.J.; Song, Z.Q.; Cai, S.Q. Bioinspired Design of Vascular Artificial Muscle. Adv. Mater. Technol. 2019, 4, 1800244. [Google Scholar] [CrossRef]

- Yoon, H.H.; Kim, D.Y.; Jeong, K.U.; Ahn, S.K. Surface Aligned Main-Chain Liquid Crystalline Elastomers: Tailored Properties by the Choice of Amine Chain Extenders. Macromolecules 2018, 51, 1141–1149. [Google Scholar] [CrossRef]

- Saed, M.O.; Ambulo, C.P.; Kim, H.; De, R.; Raval, V.; Searles, K.; Siddiqui, D.A.; Cue, J.M.O.; Stefan, M.C.; Shankar, M.R.; et al. Molecularly-Engineered, 4D-Printed Liquid Crystal Elastomer Actuators. Adv. Funct. Mater. 2019, 29, 1806412. [Google Scholar] [CrossRef]

- Butzer, T.; Lambercy, O.; Arata, J.; Gassert, R. Fully Wearable Actuated Soft Exoskeleton for Grasping Assistance in Everyday Activities. Soft Robot. 2021, 8, 128–143. [Google Scholar] [CrossRef]

- Kim, J.; Lee, G.; Heimgartner, R.; Arumukhom Revi, D.; Karavas, N.; Nathanson, D.; Galiana, I.; Eckert-Erdheim, A.; Murphy, P.; Perry, D.; et al. Reducing the metabolic rate of walking and running with a versatile, portable exosuit. Science 2019, 365, 668–672. [Google Scholar] [CrossRef]

- Zang, X.; Zhou, Q.; Chang, J.; Liu, Y.; Lin, L. Graphene and carbon nanotube (CNT) in MEMS/NEMS applications. Microelectron. Eng. 2015, 132, 192–206. [Google Scholar] [CrossRef]

- Jang, Y.; Kim, S.M.; Spinks, G.M.; Kim, S.J. Carbon Nanotube Yarn for Fiber-Shaped Electrical Sensors, Actuators, and Energy Storage for Smart Systems. Adv. Mater. 2020, 32, e1902670. [Google Scholar] [CrossRef]

- Haines, C.S.; Li, N.; Spinks, G.M.; Aliev, A.E.; Di, J.; Baughman, R.H. New twist on artificial muscles. Proc. Natl. Acad. Sci. USA 2016, 113, 11709–11716. [Google Scholar] [CrossRef] [PubMed]

- Rogers, G.W.; Liu, J.Z. Graphene actuators: Quantum-mechanical and electrostatic double-layer effects. J. Am. Chem. Soc. 2011, 133, 10858–10863. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.A.; Kim, Y.T.; Spinks, G.M.; Suh, D.; Lepro, X.; Lima, M.D.; Baughman, R.H.; Kim, S.J. All-solid-state carbon nanotube torsional and tensile artificial muscles. Nano Lett. 2014, 14, 2664–2669. [Google Scholar] [CrossRef]

- Foroughi, J.; Spinks, G.M.; Wallace, G.G.; Oh, J.; Kozlov, M.E.; Fang, S.; Mirfakhrai, T.; Madden, J.D.; Shin, M.K.; Kim, S.J.; et al. Torsional carbon nanotube artificial muscles. Science 2011, 334, 494–497. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.J.; Hyeon, J.S.; Kim, H.; Mun, T.J.; Haines, C.S.; Li, N.; Baughman, R.H.; Kim, S.J. Enhancing the Work Capacity of Electrochemical Artificial Muscles by Coiling Plies of Twist-Released Carbon Nanotube Yarns. ACS Appl. Mater. Interfaces 2019, 11, 13533–13537. [Google Scholar] [CrossRef]

- Lin, H.; Zhang, S.; Xiao, Y.; Zhang, C.; Zhu, J.; Dunlop, J.W.C.; Yuan, J. Organic Molecule-Driven Polymeric Actuators. Macromol. Rapid Commun. 2019, 40, e1800896. [Google Scholar] [CrossRef] [PubMed]

- Scheidl, R.; Winkler, B.; Kogler, H.; Ladner, P.; Haas, R.; Lukachev, E. Digital Fluid Technologies for the Steel Industry. BHM Berg Hüttenmännische Mon. 2016, 161, 504–509. [Google Scholar] [CrossRef][Green Version]

- Yang, T.-H.; Kim, J.R.; Jin, H.; Gil, H.; Koo, J.-H.; Kim, H.J. Recent Advances and Opportunities of Active Materials for Haptic Technologies in Virtual and Augmented Reality. Adv. Funct. Mater. 2021, 2008831. [Google Scholar] [CrossRef]

| Material | Stimulus | Amplitude of Stimulus | Stroke (° mm−1) | Rotary Speed (rpm) | Peak Torque (Nm/kg) | Reference |

|---|---|---|---|---|---|---|

| GO | moisture | 85% RH | 588 | 5190 | 0.082 | [64] |

| CNT | moisture | water droplet | 62.16 | - | 0.4 | [59] |

| Bamboo | moisture | wet | 64.4 | - | - | [60] |

| Cotton | moisture | wet | 42.55 | 720 | - | [61] |

| Chitosan | moisture | wet | 1155 | - | - | [63] |

| Silk | moisture | 60% RH | 547 | 975 | 0.063 | [57] |

| Lotus | moisture | 60% RH | 200 | 200 | 0.488 | [62] |

| Material | Stimulus | Amplitude of Stimulus | Strain (%) | Stress (Mpa) | Work Density (J/kg) | Reference |

|---|---|---|---|---|---|---|

| Nylon 6,6 | heat | 240 °C | 34 | 22 | 2480 | [65] |

| Polyethylene | heat | 130 °C | 16 | 16 | 2630 | [65] |

| PI/PDMS | heat | 210 °C | 20.7 | 1.2 | 158.9 | [64] |

| CF/PDMS | heat | 200 °C | 25 | 60 | 758 | [68] |

| Bamboo | moisture | 90% RH | 50 | 0.75 | 1.08 | [60] |

| Wool | moisture | wet | 38 | 2.6 | 194 | [66] |

| Viscose | moisture | wet | 35 | 0.28 | 90.4 | [67] |

| Silk | moisture | 60% RH | 70 | 3.2 | 73 | [57] |

| Lotus | moisture | 70% RH | 38 | 13 | 450 | [62] |

| Material | Viscoelasticity | Dielectric Constant (at 1 Hz) | Actuated Strain (Prestrained) | Adhesion Property | Thermal Stability | Moisture Property |

|---|---|---|---|---|---|---|

| Acrylics | High, resulting in long-term relaxation and slower response | High (4.5–4.8) | High (~380%, area) | Good | Low (−10~80 °C) | Sensitive to humidity |

| Silicones | Low, due to flexible backbone (-Si-O-) | Low (2.5–3) | Modest (~120%, linear) | Poor (low surface energy) | High (−65~240 °C) | Low rate of moistureabsorption |

| Structure | Multi-Stack | Twisted | Rolled | Cone | Buckling Diaphragm | Bending Unimorph |

|---|---|---|---|---|---|---|

| DE material | Acrylic (VHB 4910, IPN post-processed) | Silicone (Wacker Elas tosil P7670) | Silicone (Sylgard 184 and Ecoflex 0030) | Silicone (Wacker Elas Tosil) | PDMS | Formulated acrylic (oligomer: CN9014) |

| Electrode material | Silicone/ carbon-black mixture | Carbon black, graphite and ethanol | Single-walled carbon nanotubes (SWCNTs) | Carbon black | Silver nanowires (AgNWs) | SWCNTs |

| Prestrain | 200% areal | None | None | 10% areal | None | None |

| Voltage (kV) | 4.2 | 6.5 | 1 | 4.5 | 4 | 4 |

| Specific power (W/kg) | - | 13.7 | 55 | - | - | 19.5 ± 1.01 |

| Energy density (J/kg) | 12.9 | - | 0.275 | - | - | 1.95 ± 0.10 |

| Strain/displacement (without load) | 30% | 5.2% | 10% | 2.3% | 650 μm | 16 mm |

| Blocking/output force (mN) | - | - | 1000 | 185 | 255 | 12.5 ± 0.9 |

| Reference | [80] | [92] | [83] | [84] | [4] | [89] |

| Strain Mode of Actuators | Piezoelectric Constant | Strain or Displacement * | |

|---|---|---|---|

| Stretch-extending | Longitudinal | ||

| Transverse | |||

| Bending | |||

| Property | PVDF | PVDF-TRFE | PZT [8] |

|---|---|---|---|

| Piezoelectric coefficient(d31) (Pc N−1) | 30 | 25 | 350 |

| Piezoelectric coefficient(d33) (Pc N−1) | 20 | −25 | 750 |

| Modulus (Mpa) | 2500 | 2300 | 76,500 |

| Efficiency (%) | 75 [121] | - | 90 |

| Stress (Mpa) | 30–50 | 60 | 110 |

| Strain (%) | 30–400 | - | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Yang, Y.; Li, M.; Chen, E.; Mu, W.; Fisher, R.; Yin, R. Wearable Actuators: An Overview. Textiles 2021, 1, 283-321. https://doi.org/10.3390/textiles1020015

Chen Y, Yang Y, Li M, Chen E, Mu W, Fisher R, Yin R. Wearable Actuators: An Overview. Textiles. 2021; 1(2):283-321. https://doi.org/10.3390/textiles1020015

Chicago/Turabian StyleChen, Yu, Yiduo Yang, Mengjiao Li, Erdong Chen, Weilei Mu, Rosie Fisher, and Rong Yin. 2021. "Wearable Actuators: An Overview" Textiles 1, no. 2: 283-321. https://doi.org/10.3390/textiles1020015

APA StyleChen, Y., Yang, Y., Li, M., Chen, E., Mu, W., Fisher, R., & Yin, R. (2021). Wearable Actuators: An Overview. Textiles, 1(2), 283-321. https://doi.org/10.3390/textiles1020015