A Review of Recent Developments in Composites Made of Recycled Carbon Fiber Textiles

Abstract

:1. Introduction

2. Carbon Fiber Recycling

3. Textiles Manufactured Using Recycled Carbon Fibers

3.1. Isotropic Textiles

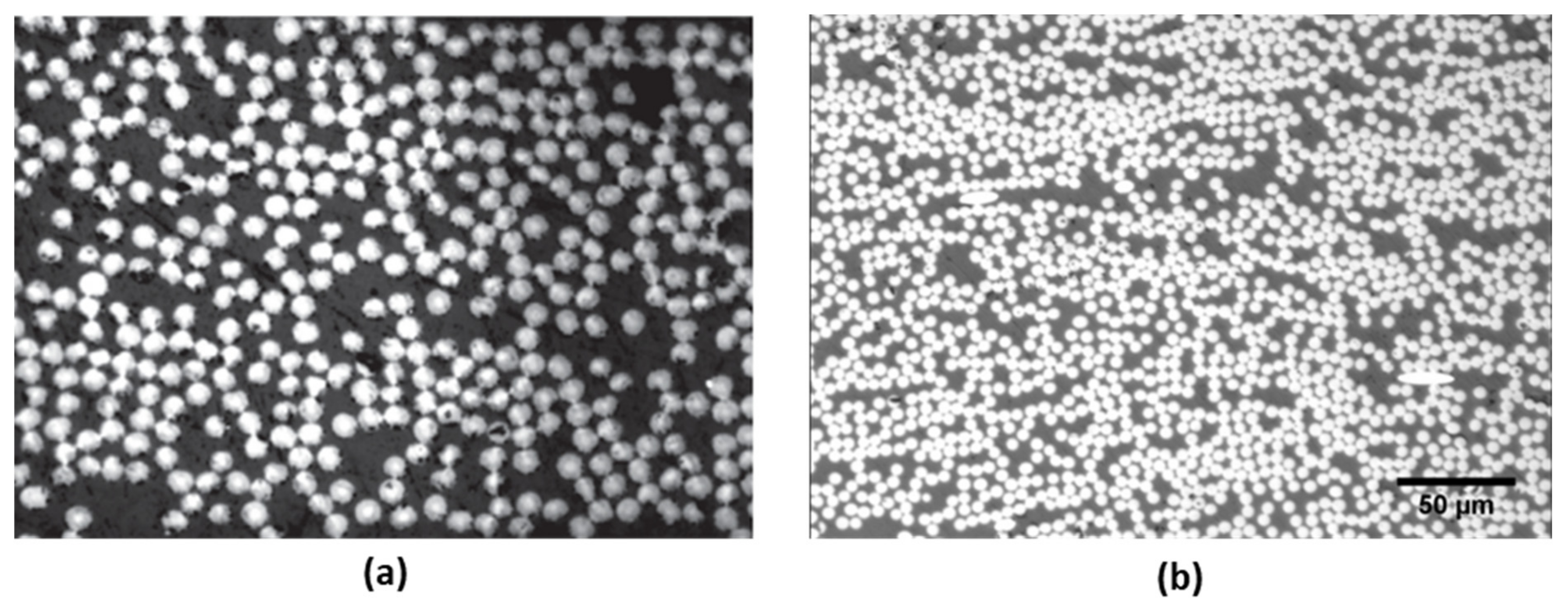

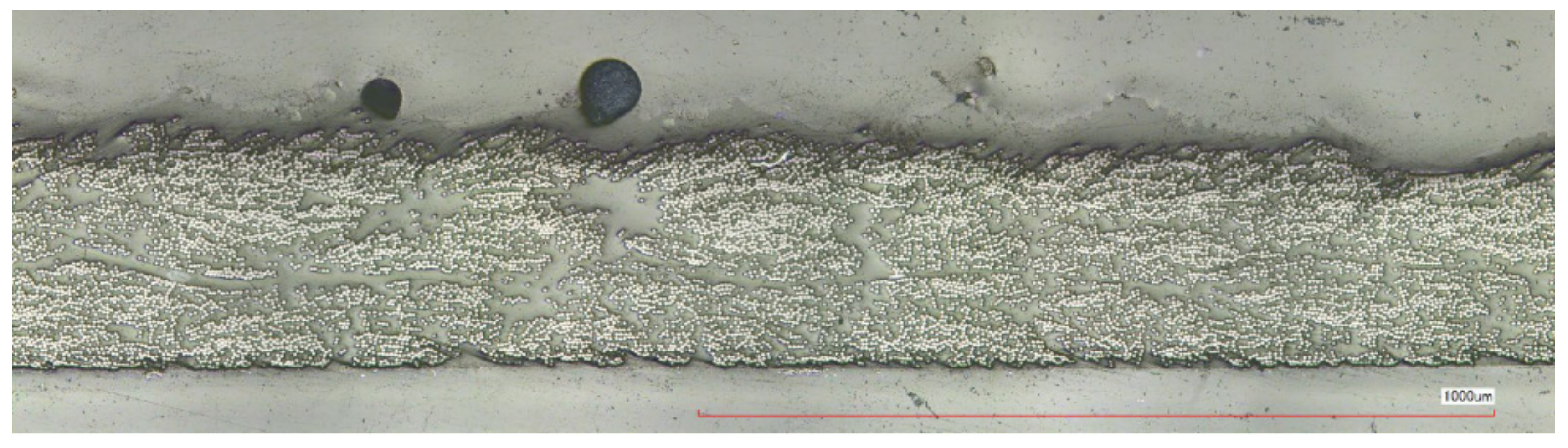

3.1.1. Wet-Laid

3.1.2. Air-Laid

3.2. Anisotropic Textiles

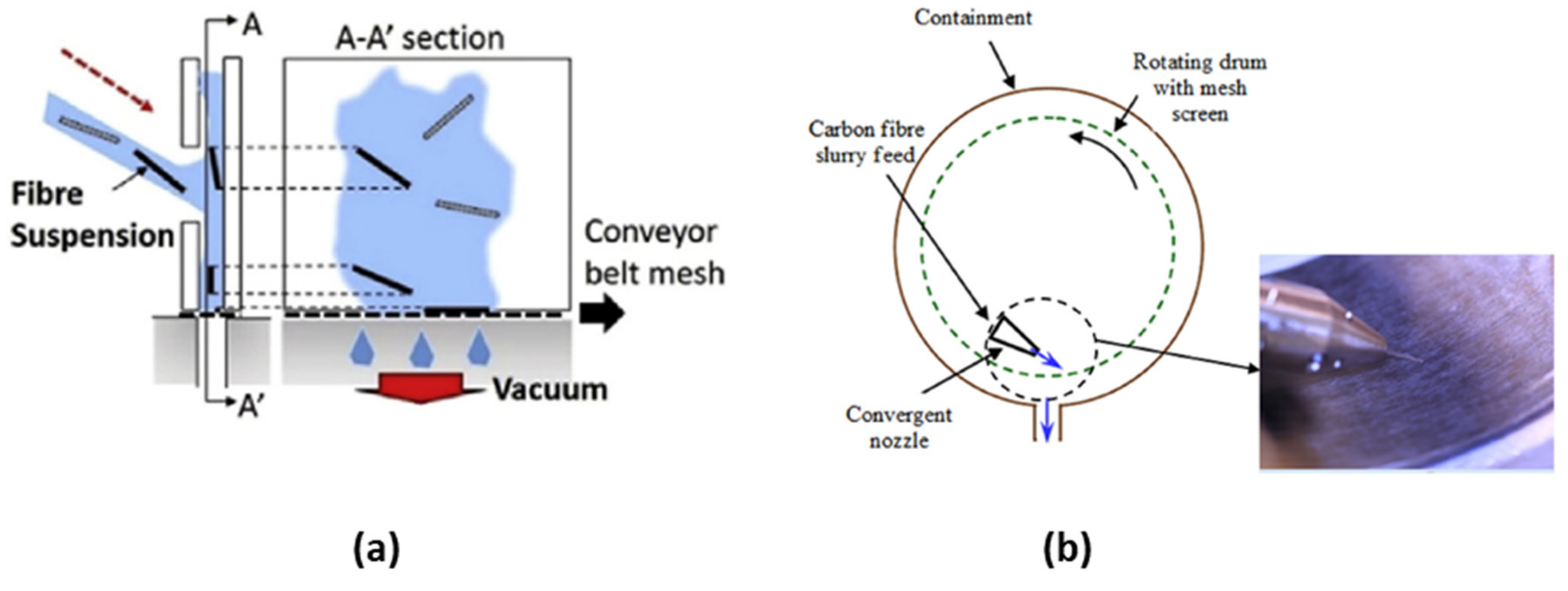

3.2.1. Wet-Laid

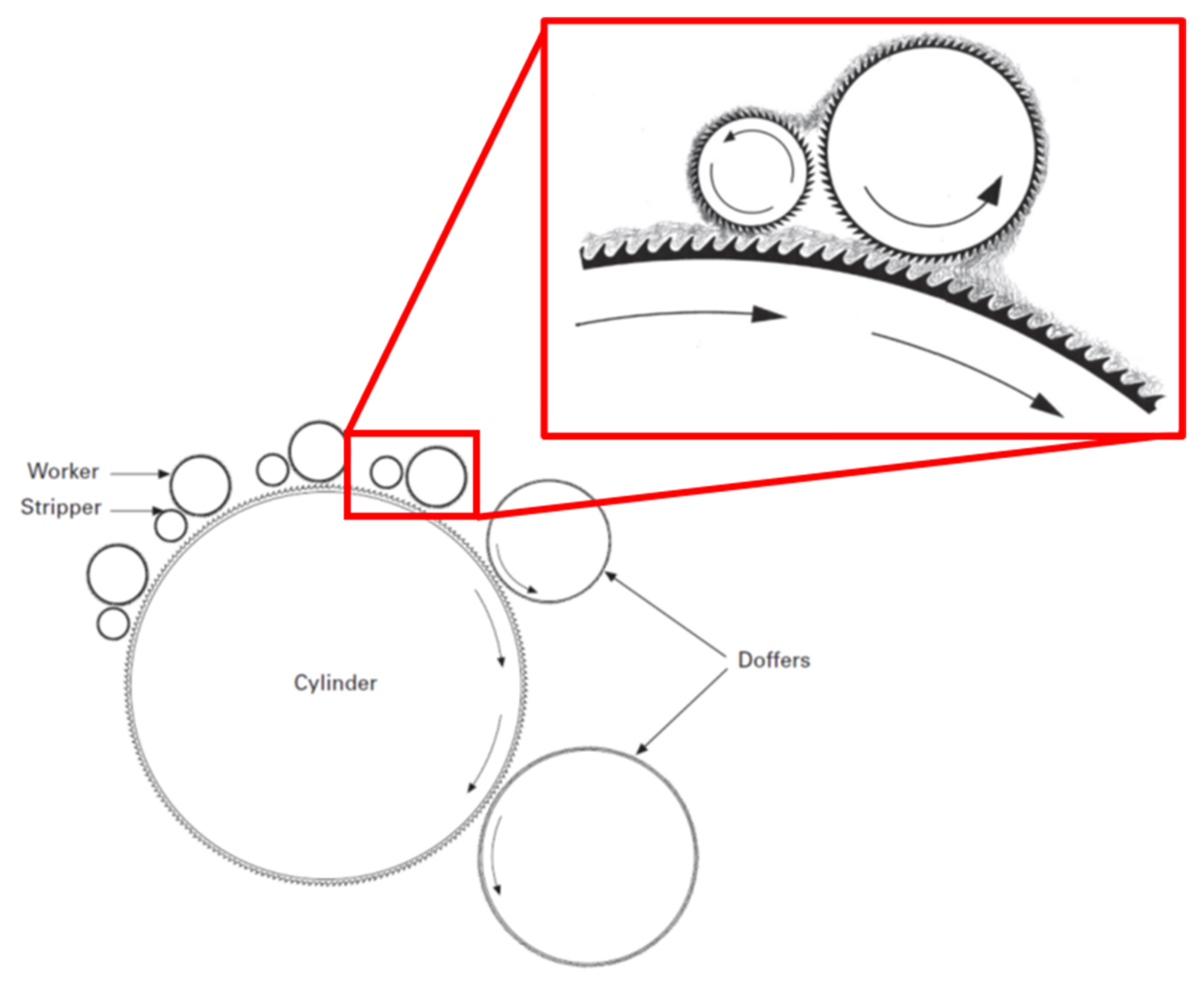

3.2.2. Carding

3.2.3. Yarn Spinning

3.2.4. Highly Aligned Preforms

4. Mechanical Properties of Recycled Carbon Fiber Textile Composites

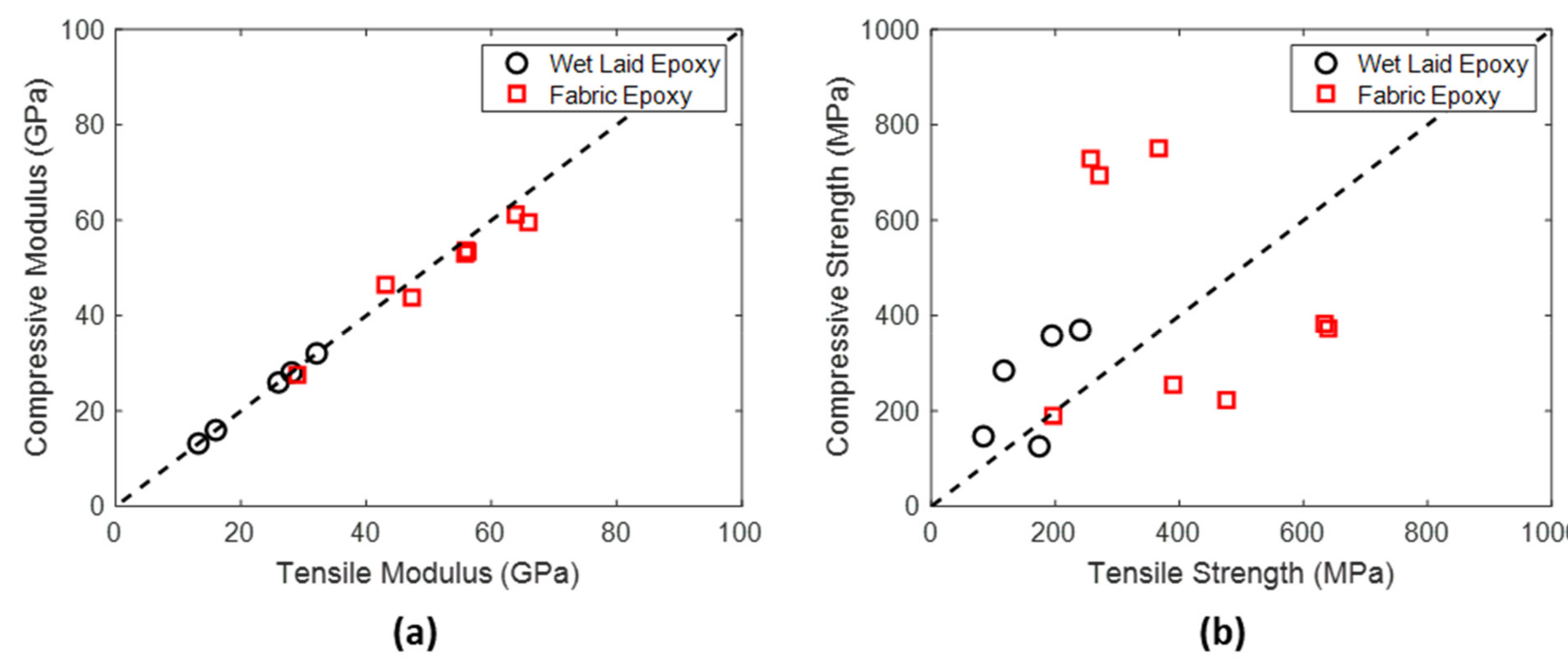

4.1. Isotropic Textile Properties

4.1.1. Wet-Laid

4.1.2. Air-Laid

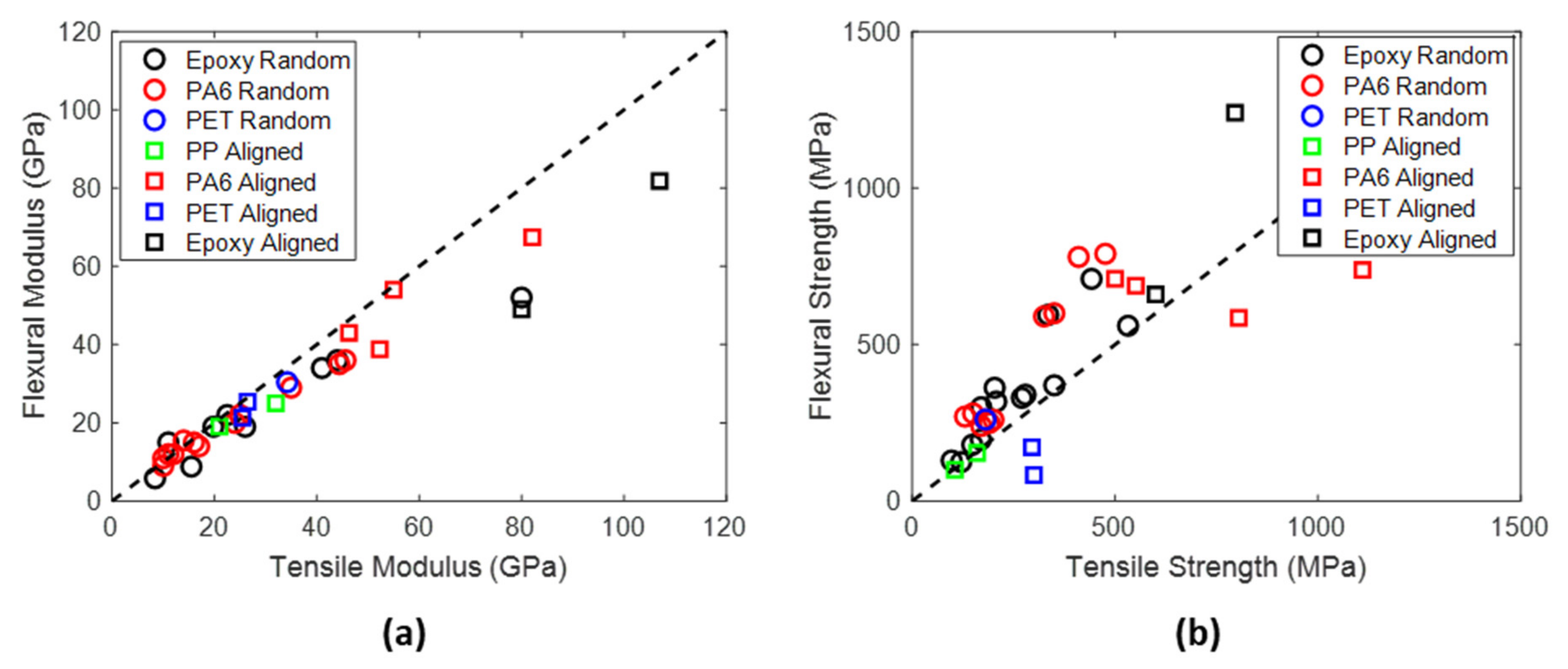

4.2. Anisotropic Textile Properties

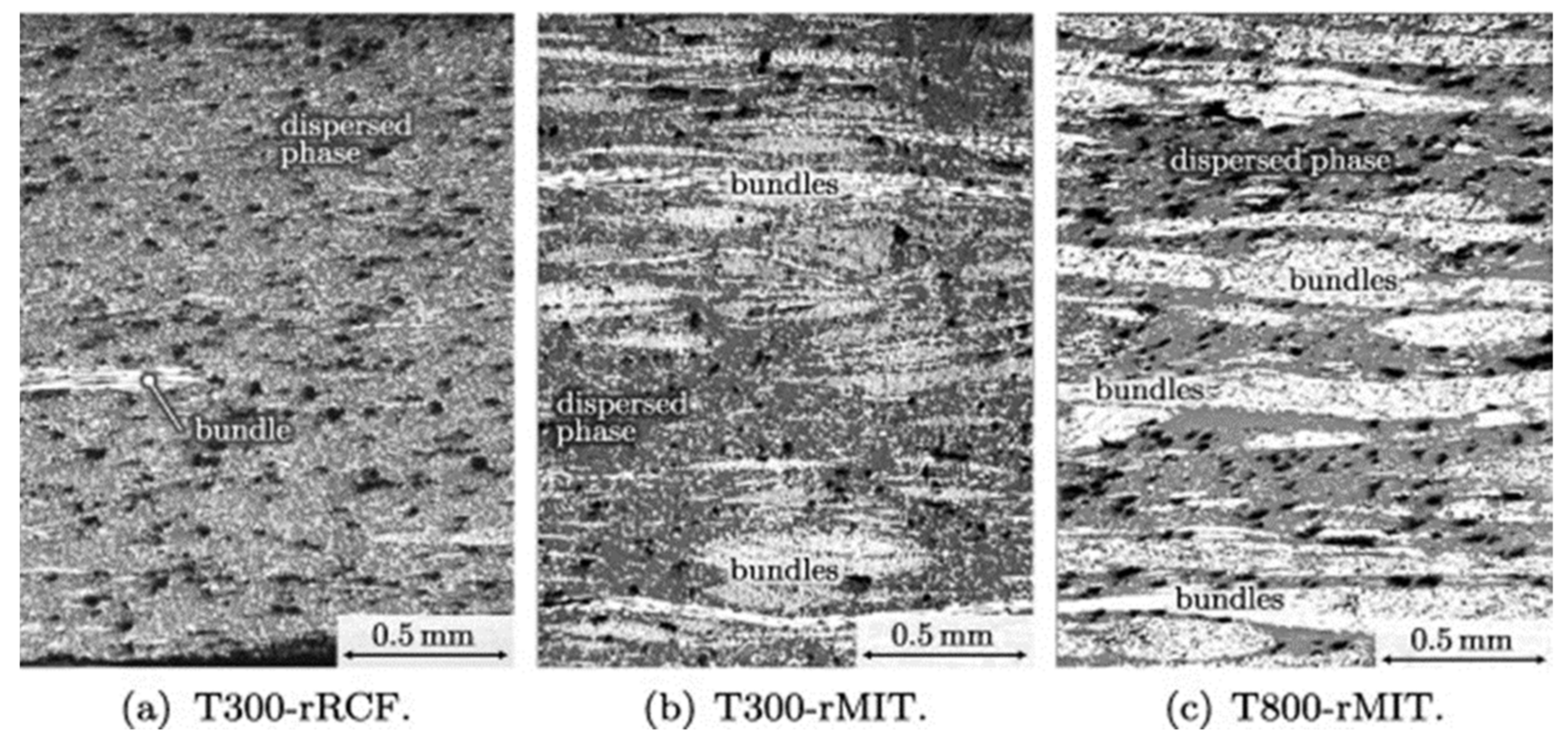

4.2.1. Wet-Laid

4.2.2. Carding

4.2.3. Yarn Spinning

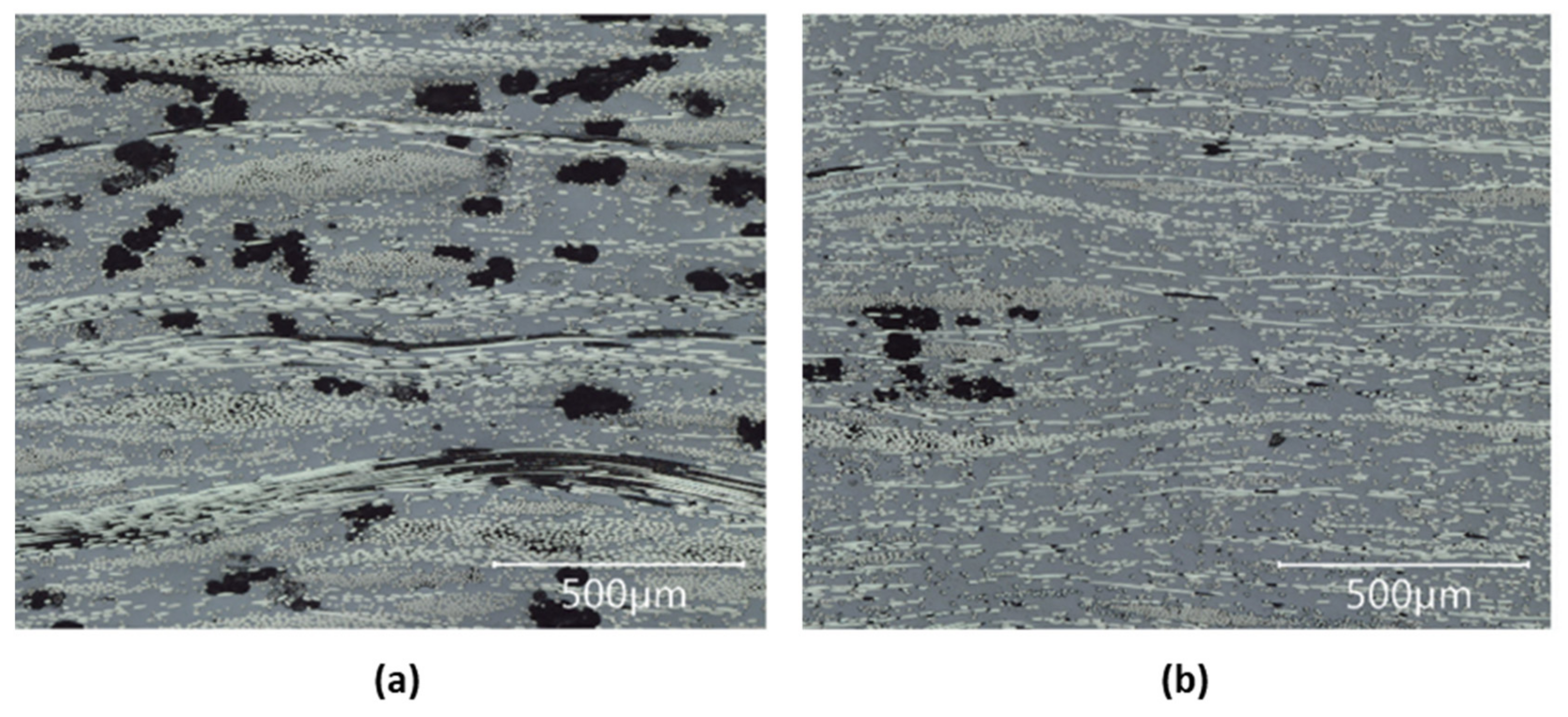

4.2.4. Highly Aligned Preforms

4.3. General Trends in Mechanical Properties of Recycled Carbon Fiber Composites

5. Unique Functions of Recycled Carbon Fiber Textile Composites

5.1. Crash Energy Absorption

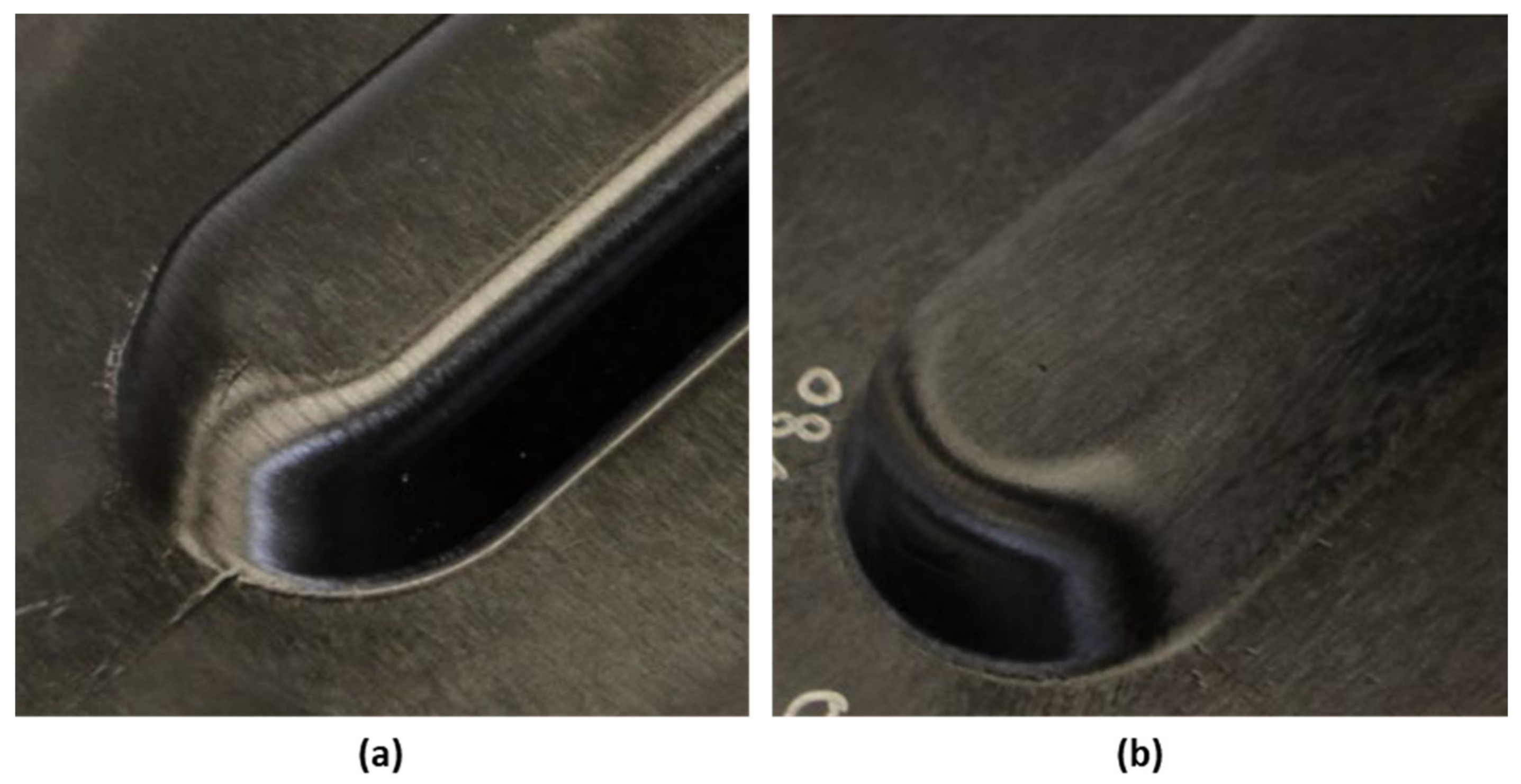

5.2. Deep Drawability

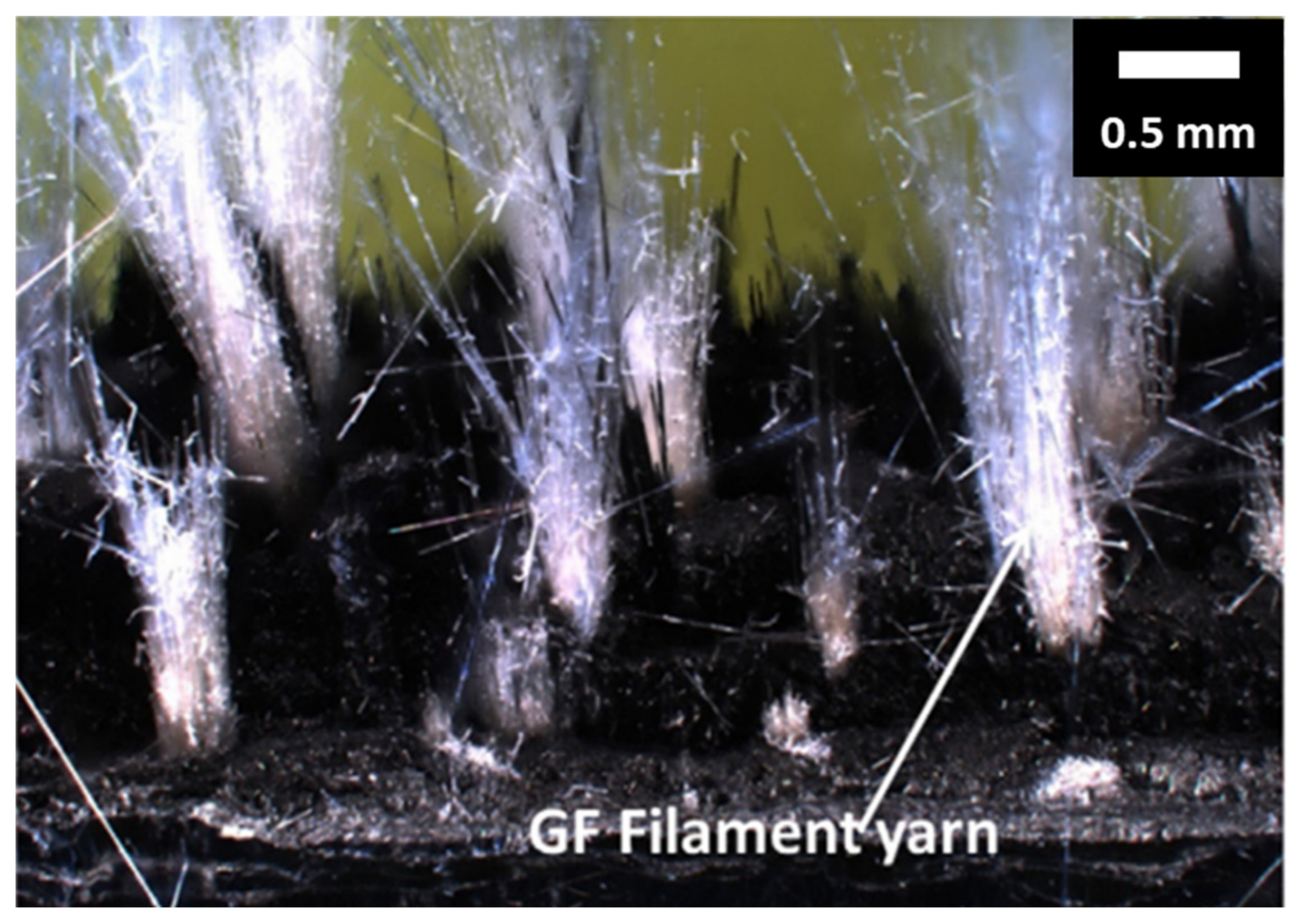

5.3. Hybrid Composites

5.4. Electromagnetic Shielding

5.5. High-Rate Manufacturing

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Joost, W.J. Reducing vehicle weight and improving U.S. energy efficiency using integrated computational materials engineering. J. Miner. Met. Mater. Soc. 2012, 64, 1032–1038. [Google Scholar] [CrossRef] [Green Version]

- U.S. Driving Research and Innovation for Vehicle Efficiency and Energy Sustainability. Materials Technical Team Roadmap; U.S. Drive: Washington, WA, USA, 2017.

- Meng, F.; McKechnie, J.; Pickering, S.J. An assessment of financial viability of recycled carbon fibre in automotive applications. Compos. Part A Appl. Sci. Manuf. 2018, 109, 207–220. [Google Scholar]

- Snudden, J.P.; Ward, C.; Potter, K. Reusing automotive composites production waste. Reinf. Plast. 2014, 58, 20–27. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Khurshid, M.F.; Hengstermann, M.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Recent developments in the processing of waste carbon fibre for thermoplastic composites—A review. J. Compos. Mater. 2020, 54, 1925–1944. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef] [Green Version]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent progress in recycling carbon fibre reinforced composites and dry carbon fibre wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Rybicka, J.; Tiwari, A.; Leeke, G.A. Technology readiness level assessment of composites recycling technologies. J. Clean. Prod. 2016, 112, 1001–1012. [Google Scholar] [CrossRef] [Green Version]

- Harris, J.; Kline, S.; Wheeler, J.L.; Bradley, D.; Kooduvalli, K.; Franc, A.; Brosius, D. Closing the loop on automotive carbon fiber prepreg manufacturing scrap-fender case study. In Proceedings of the International SAMPE Technical Conference, Virtual Conference, 4–7 May 2020. [Google Scholar]

- May, D.; Goergen, C.; Friedrich, K. Multifunctionality of polymer composites based on recycled carbon fibers: A review. Adv. Ind. Eng. Polym. Res. 2021, 4, 70–81. [Google Scholar] [CrossRef]

- Li, X.; Bai, R.; McKechnie, J. Environmental and financial performance of mechanical recycling of carbon fibre reinforced polymers and comparison with conventional disposal routes. J. Clean. Prod. 2016, 127, 451–460. [Google Scholar] [CrossRef]

- Raghvendra, K.M.; Sravanthi, L. Fabrication Techniques of Micro/Nano Fibres based Nonwoven Composites: A Review. Mod. Chem. Appl. 2017, 5, 206. [Google Scholar] [CrossRef]

- Ghossein, H.; Hassen, A.A.; Paquit, V.; Love, L.J.; Vaidya, U.K. Innovative Method for Enhancing Carbon Fibers Dispersion in Wet-Laid Nonwovens. Mater. Today Commun. 2018, 17, 100–108. [Google Scholar] [CrossRef]

- Kessel, F.; Klopsch, L.; Jehle, V.; Biller, N.J.; Frieß, M.; Shi, Y.; Cepli, D.; Keck, M.; Jemmali, R. Wet-laid nonwoven based ceramic matrix composites: An innovative and highly adaptable short fiber reinforcement for ceramic hybrid and gradient materials. J. Eur. Ceram. Soc. 2021, 41, 4048–4057. [Google Scholar] [CrossRef]

- Ahrens, R.A. Wet-laid forming of nonwoven fabrics. In Proceedings of the TAPPI Nonwovens Symposium, Myrtle Beach, SC, USA, 19–21 April 1982; pp. 39–40. [Google Scholar]

- Caba, A.C.; Loos, A.C.; Batra, R.C. Fiber-fiber interactions in carbon mat thermoplastics. Compos. Part A Appl. Sci. Manuf. 2007, 38, 469–483. [Google Scholar] [CrossRef]

- White, C. Wet-laid web formation. Handb. Nonwovens 2006, 112–142. [Google Scholar] [CrossRef]

- Brydon, A.G.; Pourmohammadi, A. Dry-laid web formation. In Handbook of Nonwovens; Woodhead Publishing: Sawston, UK, 2006; pp. 16–111. [Google Scholar] [CrossRef]

- Deng, C.; Hou, J.; Zhang, X.; Gong, R.H.; Jin, X. Controllable anisotropic properties of wet-laid hydroentangled nonwovens. Tappi J. 2019, 18, 173–180. [Google Scholar] [CrossRef]

- Manis, F.; Stegschuster, G. Influences on textile and mechanical properties of recycled carbon fiber nonwovens produced by carding. J. Compos. Sci. 2021, 5, 209. [Google Scholar] [CrossRef]

- Barnett, P.R.; Gilbert, C.L.; Penumadu, D. Repurposed/recycled discontinuous carbon fiber organosheet development and composite properties. Compos. Part C Open Access 2021, 4, 100092. [Google Scholar] [CrossRef]

- Hengstermann, M.; Raithel, N.; Abdkader, A.; Hasan, M.M.B.; Cherif, C. Development of new hybrid yarn construction from recycled carbon fibers for high performance composites. Part-I: Basic processing of hybrid carbon fiber/polyamide 6 yarn spinning from virgin carbon fiber staple fibers. Text. Res. J. 2016, 86, 1307–1317. [Google Scholar] [CrossRef] [Green Version]

- Akonda, M.H.; El-Dessouky, H.M.; Lawrence, C.A.; Weager, B.M. A novel non-crimped thermoplastic fabric prepreg from waste carbon and polyester fibres. J. Compos. Mater. 2014, 48, 843–851. [Google Scholar] [CrossRef]

- Akonda, M.H.; Stefanova, M.; Potluri, P.; Shah, D.U. Mechanical properties of recycled carbon fibre/polyester thermoplastic tape composites. J. Compos. Mater. 2017, 51, 2655–2663. [Google Scholar] [CrossRef] [Green Version]

- Reichert, O.; Ausheyks, L.; Baz, S.; Hehl, J.; Gresser, G.T. Innovative RC staple fiber tapes—New potentials for CF recyclates in CFRP through highly oriented carbon staple fiber structures. Key Eng. Mater. 2019, 809 KEM, 509–514. [Google Scholar] [CrossRef]

- Rimmel, O.; May, D.; Goergen, C.; Poeppel, A.; Mitschang, P. Development and validation of recycled carbon fiber-based binder tapes for automated tape laying processes. J. Compos. Mater. 2019, 53, 3257–3268. [Google Scholar] [CrossRef] [Green Version]

- Akonda, M.H.; Lawrence, C.A.; Weager, B.M. Recycled carbon fibre-reinforced polypropylene thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 79–86. [Google Scholar] [CrossRef]

- Hengstermann, M.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Development of a new hybrid yarn construction from recycled carbon fibers (rCF) for high-performance composites. Part-II: Influence of yarn parameters on tensile properties of composites. Text. Res. J. 2017, 87, 1655–1664. [Google Scholar] [CrossRef] [Green Version]

- Christian, G.; Stephan, B.; Peter, M.; Gresser, G.T. Recycled carbon fibers in complex structural parts-organic sheets made of rCF staple fiber yarns. Key Eng. Mater. 2017, 742 KEM, 602–609. [Google Scholar]

- Reese, J.; Vorhof, M.; Hoffmann, G.; Böhme, K.; Cherif, C. Joule heating of dry textiles made of recycled carbon fibers and PA6 for the series production of thermoplastic composites. J. Eng. Fiber. Fabr. 2020, 15, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Potter, K.D.; Wisnom, M.R. A novel manufacturing method for aligned discontinuous fibre composites (High Performance-Discontinuous Fibre method). Compos. Part A Appl. Sci. Manuf. 2014, 65, 175–185. [Google Scholar] [CrossRef]

- Longana, M.L.; Ong, N.; Yu, H.N.; Potter, K.D. Multiple closed loop recycling of carbon fibre composites with the HiPerDiF (High Performance Discontinuous Fibre) method. Compos. Struct. 2016, 153, 271–277. [Google Scholar] [CrossRef] [Green Version]

- Aravindan, P.; Becagli, F.; Longana, M.L.; Blok, L.G.; Pozegic, T.R.; Huntley, S.J.; Rendall, T.; Hamerton, I. Remanufacturing of woven carbon fibre fabric production waste into high performance aligned discontinuous fibre composites. J. Compos. Sci. 2020, 4, 68. [Google Scholar] [CrossRef]

- Longana, M.L.; Yu, H.N.; Jalavand, M.; Wisnom, M.R.; Potter, K.D. Aligned discontinuous intermingled reclaimed/virgin carbon fibre composites for high performance and pseudo-ductile behaviour in interlaminated carbon-glass hybrids. Compos. Sci. Technol. 2017, 143, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Tapper, R.J.; Longana, M.L.; Yu, H.; Hamerton, I.; Potter, K.D. Development of a closed-loop recycling process for discontinuous carbon fibre polypropylene composites. Compos. Part B Eng. 2018, 146, 222–231. [Google Scholar] [CrossRef] [Green Version]

- Tapper, R.J.; Longana, M.L.; Hamerton, I.; Potter, K.D. A closed-loop recycling process for discontinuous carbon fibre polyamide 6 composites. Compos. Part B Eng. 2019, 179, 107418. [Google Scholar] [CrossRef]

- Liu, Z.; Turner, T.A.; Wong, K.H.; Pickering, S.J. Development of high performance recycled carbon fibre composites with an advanced hydrodynamic fibre alignment process. J. Clean. Prod. 2021, 278, 123785. [Google Scholar] [CrossRef]

- Gillet, A.; Mantaux, O.; Cazaurang, G. Characterization of composite materials made from discontinuous carbon fibres within the framework of composite recycling. Compos. Part A Appl. Sci. Manuf. 2015, 75, 89–95. [Google Scholar] [CrossRef]

- Oliveux, G.; Bailleul, J.L.; Gillet, A.; Mantaux, O.; Leeke, G.A. Recovery and reuse of discontinuous carbon fibres by solvolysis: Realignment and properties of remanufactured materials. Compos. Sci. Technol. 2017, 139, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Pickering, S.J.; Ziu, Z.; Turner, T.A.; Wong, K.H. Applications for carbon fibre recovered from composites. IOP Conf. Ser. Mater. Sci. Eng. 2016, 139. [Google Scholar] [CrossRef]

- Van de Werken, N.; Reese, M.S.; Taha, M.R.; Tehrani, M. Investigating the effects of fiber surface treatment and alignment on mechanical properties of recycled carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2019, 119, 38–47. [Google Scholar] [CrossRef]

- Heider, D.; Tierney, J.; Deitzel, J.; Kubota, M.; Thiravong, J.; Gargitter, V.; Burris, W.; Morris, J.; Shevchenko, N.; Yarlagadda, S.; et al. Closed loop recycling of CFRP into highly aligned high performance short fiber composites using the tuff process. In Proceedings of the International SAMPE Technical Conference, St. Charlotte, NC, USA, 20–23 May 2019. [Google Scholar]

- Yarlagadda, S.; Deitzel, J.; Heider, D.; Tierney, J.; Gillespie, J.W. Tailorable Universal Feedstock for Forming (TUFF): Overview and performance. In Proceedings of the International SAMPE Technical Conference, St. Charlotte, NC, USA, 20–23 May 2019. [Google Scholar]

- Gan, K.W.; Ho, Y.W.; Ow, Z.Y.; Israr, H.A.; Wong, K.J. Aligned discontinuous carbon fibre tows in hybrid composites and their tensile behaviour: An experimental study. J. Compos. Mater. 2019, 53, 3893–3907. [Google Scholar] [CrossRef]

- Gopalraj, S.K.; Kärki, T. A study to investigate the mechanical properties of recycled carbon fibre/glass fibre-reinforced epoxy composites using a novel thermal recycling process. Processes 2020, 8, 954. [Google Scholar] [CrossRef]

- Wong, K.H.; Pickering, S.J.; Turner, T.A.; Warrior, N.A. Compression moulding of a recycled carbon fibre reinforced epoxy composite. In Proceedings of the International SAMPE Symposium and Exhibition, Baltimore, MD, USA, 18–21 May 2009; Volume 54. [Google Scholar]

- Szpieg, M.; Wysocki, M.; Asp, L.E. Mechanical performance and modelling of a fully recycled modified CF/PP composite. J. Compos. Mater. 2011, 46, 1503–1517. [Google Scholar] [CrossRef]

- Wong, K.H.; Turner, T.A.; Pickering, S.J. Challenges in Developing Nylon Composites Commingled With Discontinuous Recycled Carbon Fibre. In Proceedings of the ECCM16-16th European Conference on Composite Materials, Seville, Spain, 22–26 June 2014. [Google Scholar]

- Toray Composite Materials America. T700S Standard Modulus Carbon Fiber; Toray Composite Materials America: Tacoma, WA, USA, 2018. [Google Scholar]

- Toray Composite Materials America. T800H Intermediate Modulus Carbon Fiber; Toray Composite Materials America: Tacoma, WA, USA, 2018. [Google Scholar]

- Hengstermann, M.; Hasan, M.M.B.; Scheffler, C.; Abdkader, A.; Cherif, C. Development of a new hybrid yarn construction from recycled carbon fibres for high-performance composites. Part III: Influence of sizing on textile processing and composite properties. J. Thermoplast. Compos. Mater. 2021, 34, 409–430. [Google Scholar] [CrossRef]

- SGL Group SIGRAFIL®. Continuous Carbon Fiber Tow; SGL Technologies GmbH: Meitingen, Germany, 2016. [Google Scholar]

- Harper, L.T. Discontinuous Carbon Fibre Composites for Automotive Applications. PhD. Thesis, University of Nottingham, Nottingham, UK, 2006. [Google Scholar]

- Hexcel Corporation. HexTow IM7 Carbon Fiber; Hexcel Corporation: Stamford, CT, USA, 2020; pp. 1–2. [Google Scholar]

- Janney, M.A.; Newell, W.L.; Geiger, E.; Baitcher, N.; Gunder, T. Manufacturing complex geometry composites with recycled carbon fiber. In Proceedings of the International SAMPE Symposium and Exhibition, Baltimore, MD, USA, 18–21 May 2009; Volume 54. [Google Scholar]

- Heil, J.P.; Gavin, J.B.; George, P.E.; Cuomo, J.J. Composite panels made from the wetlay process using recycled carbon fiber. In Proceedings of the International SAMPE Technical Conference, Long Beach, CA, USA, 23–26 May 2011. [Google Scholar]

- Szpieg, M.; Wysocki, M.; Asp, L.E. Reuse of polymer materials and carbon fibres in novel engineering composite materials. Plastics, Rubber and Composites. Macromol. Eng. 2009, 38, 419–425. [Google Scholar] [CrossRef]

- Giannadakis, K.; Szpieg, M.; Varna, J. Mechanical Performance of a Recycled Carbon Fibre/PP Composite. Exp. Mech. 2011, 51, 767–777. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. The influence of micromechanical properties and reinforcement architecture on the mechanical response of recycled composites. Compos. Part A Appl. Sci. Manuf. 2014, 56, 213–225. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Akiyama, T.; Lee, H.; Ohsawa, I.; Takahashi, J. Mechanical properties of recycled carbon fiber reinforced thermoplastics made by carbon fiber paper. In Proceedings of the 16th European Conference on Composite Materials, Seville, Spain, 22–26 June 2014; 2014. [Google Scholar]

- Wei, H.; Nagatsuka, W.; Lee, H.; Ohsawa, I.; Sumimoto, K.; Wan, Y.; Takahashi, J. Mechanical properties of carbon fiber paper reinforced thermoplastics using mixed discontinuous recycled carbon fibers. Adv. Compos. Mater. 2018, 27, 19–34. [Google Scholar] [CrossRef]

- Huan, X.; Shi, K.; Yan, J.; Lin, S.; Li, Y.; Jia, X.; Yang, X. High performance epoxy composites prepared using recycled short carbon fiber with enhanced dispersibility and interfacial bonding through polydopamine surface-modification. Compos. Part B Eng. 2020, 193, 107987. [Google Scholar] [CrossRef]

- Yan, X.; Wang, X.; Yang, J.; Zhao, G. Optimization of process parameters of recycled carbon fiber-reinforced thermoplastic prepared by the wet-laid hybrid nonwoven process. Text. Res. J. 2021, 91, 1565–1577. [Google Scholar] [CrossRef]

- Heilos, K.; Fischer, H.; Hofmann, M.; Miene, A. Nonwovens made of recycled carbon fibres (rCF) used for production of sophisticated carbon fibre-reinforced plastics. Vlakna Text. 2020, 27, 65–75. [Google Scholar]

- Feraboli, P.; Kawakami, H.; Wade, B.; Gasco, F.; DeOto, L.; Masini, A. Recyclability and reutilization of carbon fiber fabric/epoxy composites. J. Compos. Mater. 2012, 46, 1459–1473. [Google Scholar] [CrossRef]

- Meredith, J.; Cozien-Cazuc, S.; Collings, E.; Carter, S.; Alsop, S.; Lever, J.; Coles, S.R.; Wood, B.M.; Kirwan, K. Recycled carbon fibre for high performance energy absorption. Compos. Sci. Technol. 2012, 72, 688–695. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. The effect of recycling on the mechanical response of carbon fibres and their composites. Compos. Struct. 2012, 94, 3669–3684. [Google Scholar] [CrossRef] [Green Version]

- Baek, Y.M.; Shin, P.S.; Kim, J.H.; Park, H.S.; Kwon, D.J.; DeVries, K.L.; Park, J.M. Investigation of Interfacial and Mechanical Properties of Various Thermally-Recycled Carbon Fibers/Recycled PET Composites. Fibers Polym. 2018, 19, 1767–1775. [Google Scholar] [CrossRef]

- Turner, T.A.; Pickering, S.J.; Warrior, N.A. Development of high value composite materials using recycled carbon fibre. Int. SAMPE Symp. Exhib. 2009, 54, 151–156. [Google Scholar]

- Pimenta, S.; Pinho, S.T.; Robinson, P.; Wong, K.H.; Pickering, S.J. Mechanical analysis and toughening mechanisms of a multiphase recycled CFRP. Compos. Sci. Technol. 2010, 70, 1713–1725. [Google Scholar] [CrossRef] [Green Version]

- Shah, D.U.; Schubel, P.J. On recycled carbon fibre composites manufactured through a liquid composite moulding process. J. Reinf. Plast. Compos. 2015, 35, 533–540. [Google Scholar] [CrossRef]

- Wölling, J.; Schmieg, M.; Manis, F.; Drechsler, K. Nonwovens from Recycled Carbon Fibres—Comparison of Processing Technologies. Procedia CIRP 2017, 66, 271–276. [Google Scholar] [CrossRef]

- Barnett, P.R.; Young, S.A.; Patel, N.J.; Penumadu, D. Prediction of strength and modulus of discontinuous carbon fiber composites considering stochastic microstructure. Compos. Sci. Technol. 2021, 211, 108857. [Google Scholar] [CrossRef]

- Wei, H.; Lee, H.; Nagatsuka, W.; Ohsawa, I.; Kawabe, K.; Murakami, T.; Sumitomo, K.; Takahashi, J. Systematic comparison between carding and paper-making method for producing discontinuous recycled carbon fiber reinforced thermoplastics. ICCM Int. Conf. Compos. Mater. 2015, 2015, 19–24. [Google Scholar]

- Marcel, H.; Dirk, W.; Bernd, G.; Heike, I.G.; Daisy, N. Development of nonwoven preforms made of pure recycled carbon fibres (rCF) for applications of composite materials. Key Eng. Mater. 2017, 742 KEM, 555–561. [Google Scholar]

- Lopes, L.; Bessa, J.; Mota, C.; Cunha, F.; Almeida, N.; Fangueiro, R. Characterization of recycled carbon fibers reinforcing thermoplastic polymers. In Proceedings of the 18th AUTEX World Textile Conference, Istanbul, Turkey, 20–22 June 2018. [Google Scholar]

- Xiao, B.; Zaima, T.; Shindo, K.; Kohira, T.; Morisawa, J.; Wan, Y.; Yin, G.; Ohsawa, I.; Takahashi, J. Characterization and elastic property modeling of discontinuous carbon fiber reinforced thermoplastics prepared by a carding and stretching system using treated carbon fibers. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105598. [Google Scholar] [CrossRef]

- Krishna Kumar, K.; Hutchinson, A.R.; Broughton, J.G. Static shear response of recycled carbon fibre composites for structural applications. Compos. Struct. 2020, 246, 112358. [Google Scholar] [CrossRef]

- Genna, S.; Papa, I.; Lopresto, V.; Tagliaferri, V. Mechanical characterisation of CFRP laminates with recycled carbon fiber obtained by resin infusion under Flexible Tooling (RIFT) technology. Compos. Sci. Technol. 2020, 199, 108328. [Google Scholar] [CrossRef]

- Hasan, M.M.B.; Nitsche, S.; Abdkader, A.; Cherif, C. Carbon fibre reinforced thermoplastic composites developed from innovative hybrid yarn structures consisting of staple carbon fibres and polyamide 6 fibres. Compos. Sci. Technol. 2018, 167, 379–387. [Google Scholar] [CrossRef]

- Hasan, M.M.B.; Abdkader, A.; Cherif, C.; Spennato, F. Fibre hybrid composites consisting of discontinuous waste carbon fibre and continuous glass filaments developed for load-bearing structures with improved impact strength. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105610. [Google Scholar] [CrossRef]

- Mischo, F.; Goergen, C.; Schmeer, S.; Mitschang, P. Use of recycled carbon staple fibers in an advanced thermoforming process and analysis of its crash performance. Adv. Manuf. Polym. Compos. Sci. 2020, 6, 48–56. [Google Scholar] [CrossRef]

- Wilson, P.R.; Ratner, A.; Stocker, G.; Syred, F.; Kirwan, K.; Coles, S.R. Interlayer hybridization of virgin carbon, recycled carbon and natural fiber laminates. Materials 2020, 13, 4955. [Google Scholar] [CrossRef]

- Longana, M.L.; Ondra, V.; Yu, H.; Potter, K.D.; Hamerton, I. Reclaimed carbon and flax fibre composites: Manufacturing and mechanical properties. Recycling 2018, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- Barnett, P.R.; Hulett, B.M.; Penumadu, D. Crashworthiness of recycled carbon fiber composites. Compos. Struct. 2021, 272, 114232. [Google Scholar] [CrossRef]

- Dirk, H.; Lukaszewicz, J.A. Automotive Composite Structures for Crashworthiness; John Wiley & Sons Ltd.: West Sussex, UK, 2013; ISBN 9781118535288. [Google Scholar] [CrossRef]

- Price, J.N.; Hull, D. Axial crushing of glass fibre-polyester composite cones. Compos. Sci. Technol. 1987, 28, 211–230. [Google Scholar] [CrossRef]

- Yarlagadda, S.; Advani, S.; Deitzel, J.; Heider, D.; Molligan, D.; Simacek, P.; Tierney, J.; Gillespie, J.W. Formability of TUFF Composite Blanks. In Proceedings of the International SAMPE Technical Conference, Charlotte, NC, USA, 20–23 May 2019. [Google Scholar]

- Goergen, C.; Schommer, D.; Duhovic, M.; Mitschang, P. Deep drawing of organic sheets made of hybrid recycled carbon and thermoplastic polyamide 6 staple fiber yarns. J. Thermoplast. Compos. Mater. 2020, 33, 754–778. [Google Scholar] [CrossRef]

- Koike, J.; Okubo, K.; Fujii, T. Effect of needle punching on strengthof stampable sandwich sheet fabricated with bamboo fiber and recycled carbon fibermat. In Proceedings of the ICCM International Conferences on Composite Materials, Jeju Island, Korea, 21–26 August 2011. [Google Scholar]

- Bachmann, J.; Wiedemann, M.; Wierach, P. Flexural Mechanical Properties of Hybrid Epoxy Composites Reinforced with Nonwoven Made of Flax Fibres and Recycled Carbon Fibres. Aerospace 2018, 5, 107. [Google Scholar] [CrossRef] [Green Version]

- Tse, B.; Yu, X.; Gong, H.; Soutis, C. Flexural Properties of Wet-Laid Hybrid Nonwoven Recycled Carbon and Flax Fibre Composites in Poly-Lactic Acid Matrix. Aerospace 2018, 5, 16. [Google Scholar] [CrossRef] [Green Version]

- Wei, H.; Nagatsuka, W.; Ohsawa, I.; Sumimoto, K.; Takahashi, J. Influence of small amount of glass fibers on mechanical properties of discontinuous recycled carbon fiber-reinforced thermoplastics. Adv. Compos. Mater. 2019, 28, 321–334. [Google Scholar] [CrossRef]

- Wong, K.H.; Pickering, S.J.; Rudd, C.D. Recycled carbon fibre reinforced polymer composite for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2010, 41, 693–702. [Google Scholar] [CrossRef]

- Goergen, C.; Klingler, A.; Grishchuk, S.; May, D.; Wetzel, B.; Mitschang, P. Novel approach in b-staging of an epoxy resin for development of rCF non-woven prepregs for RTP processing. Key Eng. Mater. 2019, 809 KEM, 521–526. [Google Scholar] [CrossRef]

| Fiber Type | Tensile Modulus (GPa) | Tensile Strength (MPa) | Source |

|---|---|---|---|

| T300 | 217.8 | 4160 | [49] |

| CF-PYR-H-1 | 93.4 | 3119 | [50] |

| T600SC | 223 | 2732 | [51] |

| T700 | 230 * | 4900 * | [52] |

| T800 | 294 * | 5490 * | [53] |

| Sigrafil C T50 | 208.7 | 3599 | [54] |

| Sigrafil C T24 | 270 * | 5000 * | [55] |

| TR50S | 225 | 2860 | [30] |

| C124 | 225 * | 4344 * | [34] |

| HTS40 | 225 * | 4350 * | [35] |

| HTA 5131 | 238 * | 3833 * | [56] |

| IM-7 | 276 * | 5516 * | [57] |

| MR60H | 290 * | 5680 * | [36] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barnett, P.R.; Ghossein, H.K. A Review of Recent Developments in Composites Made of Recycled Carbon Fiber Textiles. Textiles 2021, 1, 433-465. https://doi.org/10.3390/textiles1030023

Barnett PR, Ghossein HK. A Review of Recent Developments in Composites Made of Recycled Carbon Fiber Textiles. Textiles. 2021; 1(3):433-465. https://doi.org/10.3390/textiles1030023

Chicago/Turabian StyleBarnett, Philip R., and Hicham K. Ghossein. 2021. "A Review of Recent Developments in Composites Made of Recycled Carbon Fiber Textiles" Textiles 1, no. 3: 433-465. https://doi.org/10.3390/textiles1030023

APA StyleBarnett, P. R., & Ghossein, H. K. (2021). A Review of Recent Developments in Composites Made of Recycled Carbon Fiber Textiles. Textiles, 1(3), 433-465. https://doi.org/10.3390/textiles1030023