Strategies to Ensure Fuel Security in Brazil Considering a Forecast of Ethanol Production

Abstract

Highlights

- Sugarcane would not be enough to meet the ethanol targets set for Brazil

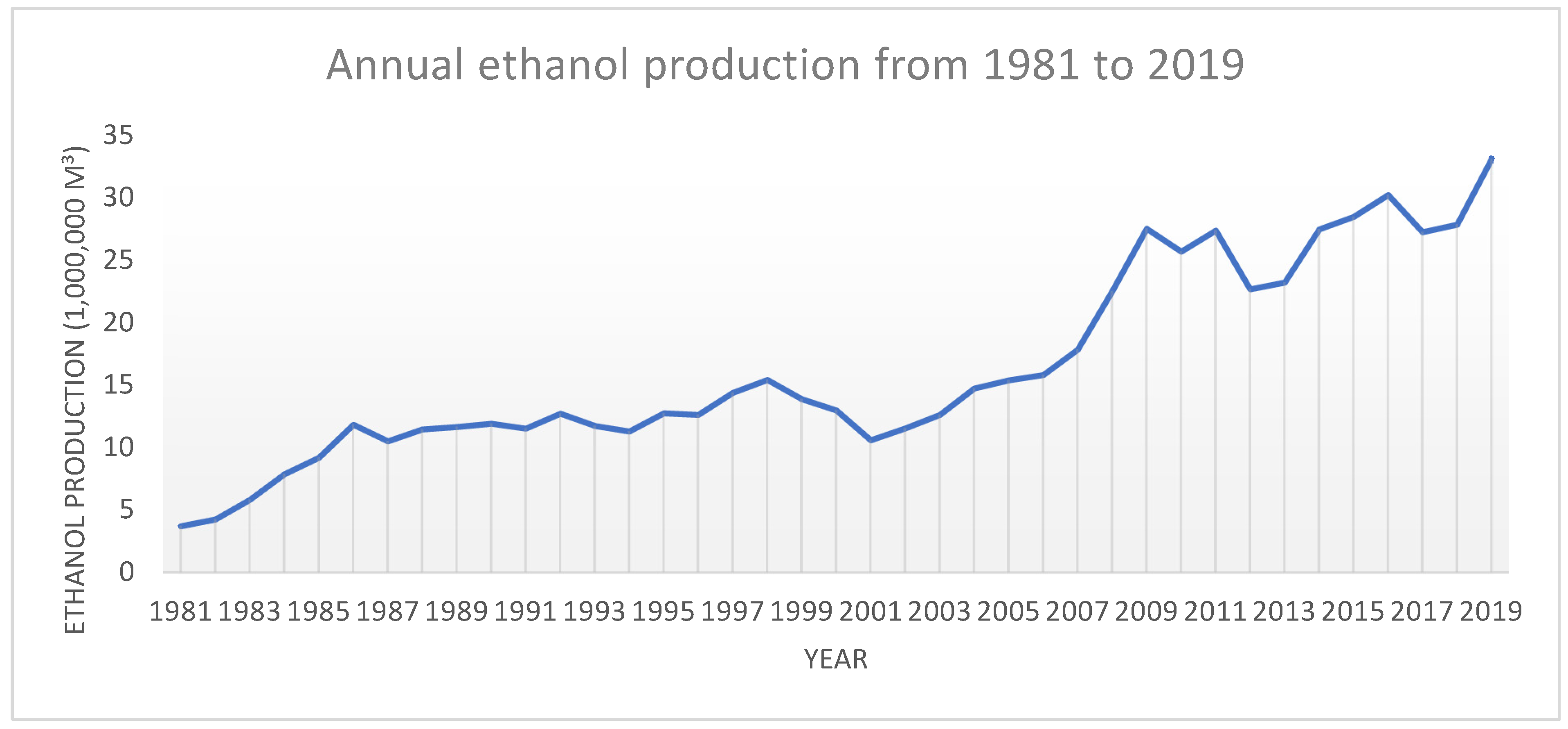

- Corn ethanol may be an attractive secondary feedstock to help supply the demand

- In Brazil, sugarcane ethanol has more advantages when compared to corn ethanol

Abstract

1. Introduction

2. Methodology

3. Theory

3.1. Sugarcane Crops in Brazil

3.2. Products Manufactured from Sugarcane

3.3. Sugar-Related Health Risks

3.4. Legal Aspects Related to Sugarcane Production

3.5. Alternative Feedstocks to Produce Ethanol

3.6. Brazilian Corn Market

4. Results and Discussion

4.1. Corn and Sugarcane Ethanol

4.2. Forecast

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| CAPES | Coordination of Superior Level Staff Improvement. |

| CBio | Decarbonization credit. |

| CO2 | Carbon dioxide. |

| COP21 | 21st Conference of the Parties. |

| DDGS | Dry Distillers Grains. |

| DGS | Distillers grains. |

| GHG | Greenhouse gases. |

| ha | Hectare. |

| Kg | Kilogram. |

| m3 | cubic meters. |

| MAPE | Mean Absolute Percentage Error. |

| MJ | Mega Joule. |

| R$ | Brazilian currency. |

| SSB | Sugar-Sweetened Beverages. |

| yr | year. |

References

- Bennertz, R.; Rip, A. The Evolving Brazilian Automotive-Energy Infrastructure: Entanglements of National Developmentalism, Sugar and Ethanol Production, Automobility and Gasoline. Energy Res. Soc. Sci. 2018, 41, 109–117. [Google Scholar] [CrossRef]

- Pimentel, L.S. Brazilian Ethanol Program. Biotechnol. Bioeng. 1980, 22, 1989–2012. [Google Scholar] [CrossRef] [PubMed]

- Stolf, R.; de Oliveira, A.P.R. The Success of the Brazilian Alcohol Program (Proalcool)-a Decadeby-Decade Brief History of Ethanol in Brazil. Eng. Agric. 2020, 40, 243–248. [Google Scholar] [CrossRef]

- Saravanan, A.P.; Pugazhendhi, A.; Mathimani, T. A Comprehensive Assessment of Biofuel Policies in the BRICS Nations: Implementation, Blending Target and Gaps. Fuel 2020, 272, 117635. [Google Scholar] [CrossRef]

- Surrey, J. Ethanol, Employment and Development: Lessons from Brazil: By A. Pereira International Labour Office, Geneva 1986, 195 Pp, 25 Swiss Fr. Energy Policy 1987, 15, 179–180. [Google Scholar] [CrossRef]

- UNICA Moagem de Cana-de-Açúcar e Produção de Açúcar e Etanol—Safra 2017/2018. Available online: http://www.unicadata.com.br/historico-de-producao-e-moagem.php?idMn=32&tipoHistorico=4&acao=visualizar&idTabela=1803&safra=2015%252F2016&estado=RS%252CSC%252CPR%252CSP%252CRJ%252CMG%252CES%252CMS%252CMT%252CGO%252CDF%252CBA%252CSE%252CAL%252CPE%252CPB%252 (accessed on 18 April 2019).

- Branco, J.E.H.; Branco, D.H.; Aguiar, E.M.d.; Caixeta Filho, J.V.; Rodrigues, L. Study of Optimal Locations for New Sugarcane Mills in Brazil: Application of a MINLP Network Equilibrium Model. Biomass Bioenergy 2019, 127, 105249. [Google Scholar] [CrossRef]

- Palazzi, R.B.; Meira, E.; Klotzle, M.C. The Sugar-Ethanol-Oil Nexus in Brazil: Exploring the Pass-through of International Commodity Prices to National Fuel Prices. J. Commod. Mark. 2022, 28, 100257. [Google Scholar] [CrossRef]

- Hira, A.; de Oliveira, L.G. No Substitute for Oil? How Brazil Developed Its Ethanol Industry. Energy Policy 2009, 37, 2450–2456. [Google Scholar] [CrossRef]

- Crago, C.L.; Khanna, M.; Barton, J.; Giuliani, E.; Amaral, W. Competitiveness of Brazilian Sugarcane Ethanol Compared to US Corn Ethanol. Energy Policy 2010, 38, 7404–7415. [Google Scholar] [CrossRef]

- Ziero, H.D.; Berni, M.D.; Buller, L.S.; Vasconcelos, L.G.; Dorileo, I.L.; Mudhoo, A.; Forster-Carneiro, T. Foresight for Corn-to-Ethanol Mills in the Southern Brazilian Amazon: Energy, Economic and Environmental Analysis. J. Environ. Chem. Eng. 2021, 9, 106740. [Google Scholar] [CrossRef]

- Da Silva, A.L.; Castañeda-Ayarza, J.A. Macro-Environment Analysis of the Corn Ethanol Fuel Development in Brazil. Renew. Sustain. Energy Rev. 2021, 135, 110387. [Google Scholar] [CrossRef]

- Barros, S. Brazil Biofuels Annual 2018; USDA: Washington, DC, USA, 2018.

- Dutta, A.; Bouri, E. Carbon Emission and Ethanol Markets: Evidence from Brazil. Biofuels Bioprod. Biorefining 2019, 13, 458–463. [Google Scholar] [CrossRef]

- Gonçalves, F.; Perna, R.; Lopes, E.; Maciel, R.; Tovar, L.; Lopes, M. Strategies to Improve the Environmental Efficiency and the Profitability of Sugarcane Mills. Biomass Bioenergy 2021, 148, 106052. [Google Scholar] [CrossRef]

- Martinelli, F.S.; Biber-Freudenberger, L.; Stein, G.; Börner, J. Will Brazil’s Push for Low-Carbon Biofuels Contribute to Achieving the SDGs? A Systematic Expert-Based Assessment. Clean. Environ. Syst. 2022, 5, 100075. [Google Scholar] [CrossRef]

- Islam, S.M. Principles of Electricity Demand Forecasting. Power Eng. J. 1997, 10, 139–143. [Google Scholar]

- Janda, K.; Kristoufek, L.; Zilberman, D. Biofuels: Policies and Impacts. Agric. Econ. 2012, 58, 372–386. [Google Scholar] [CrossRef]

- Klein, B.C.; Chagas, M.F.; Watanabe, M.D.B.; Bonomi, A.; Maciel Filho, R. Low Carbon Biofuels and the New Brazilian National Biofuel Policy (RenovaBio): A Case Study for Sugarcane Mills and Integrated Sugarcane-Microalgae Biorefineries. Renew. Sustain. Energy Rev. 2019, 115, 109365. [Google Scholar] [CrossRef]

- Rodríguez Carpio, R.; de Carvalho Miyoshi, S.; Elias, A.M.; Furlan, F.F.; de Campos Giordano, R.; Secchi, A.R. Multi-Objective Optimization of a 1G-2G Biorefinery: A Tool towards Economic and Environmental Viability. J. Clean. Prod. 2021, 284, 125431. [Google Scholar] [CrossRef]

- Araújo, O.Q.F.; de Medeiros, J.L. How Is the Transition Away from Fossil Fuels Doing, and How Will the Low-Carbon Future Unfold? Clean Technol. Environ. Policy 2021, 23, 1385–1388. [Google Scholar] [CrossRef]

- Wang, L.; Quiceno, R.; Price, C.; Malpas, R.; Woods, J. Economic and GHG Emissions Analyses for Sugarcane Ethanol in Brazil: Looking Forward. Renew. Sustain. Energy Rev. 2014, 40, 571–582. [Google Scholar] [CrossRef]

- Isabella, G.; Yu, A.S.O.; Silva, A.M.d.; Pegetti, A.L. Another Driver of the Brazilian Fuel Ethanol Supply Chain: The Consumers’ Preferences. Rev. Adm. 2017, 52, 304–316. [Google Scholar] [CrossRef]

- Ogura, A.P.; Silva, A.C.d.; Castro, G.B.; Espíndola, E.L.G.; Silva, A.L. da An Overview of the Sugarcane Expansion in the State of São Paulo (Brazil) over the Last Two Decades and Its Environmental Impacts. Sustain. Prod. Consum. 2022, 32, 66–75. [Google Scholar] [CrossRef]

- Companhia Nacional de Abastecimento/CONAB Acompanhamento Da Safra Brasileira de Cana de Açúcar—Safra 2018/19—Primeiro Levantamento, Brasília. 2018. Available online: https://www.conab.gov.br/component/k2/item/download/17727_4e54c5103a0ab4a15529e35307c79b2e (accessed on 13 December 2022).

- Spera, S.; VanWey, L.; Mustard, J. The Drivers of Sugarcane Expansion in Goiás, Brazil. Land Use Policy 2017, 66, 111–119. [Google Scholar] [CrossRef]

- Novo, A.; Jansen, K.; Slingerland, M. The Sugarcane-Biofuel Expansion and Dairy Farmers’ Responses in Brazil. J. Rural Stud. 2012, 28, 640–649. [Google Scholar] [CrossRef]

- Egeskog, A.; Barretto, A.; Berndes, G.; Freitas, F.; Holmén, M.; Sparovek, G.; Torén, J. Actions and Opinions of Brazilian Farmers Who Shift to Sugarcane—An Interview-Based Assessment with Discussion of Implications for Land-Use Change. Land Use Policy 2016, 57, 594–604. [Google Scholar] [CrossRef]

- Walter, A.; Galdos, M.V.; Scarpare, F.V.; Leal, M.R.L.V.; Seabra, J.E.A.; da Cunha, M.P.; Picoli, M.C.A.; de Oliveira, C.O.F. Brazilian Sugarcane Ethanol: Developments so Far and Challenges for the Future. Wiley Interdiscip. Rev. Energy Environ. 2014, 3, 70–92. [Google Scholar] [CrossRef]

- De Carvalho, A.L.; Menezes, R.S.C.; Nóbrega, R.S.; de Siqueira Pinto, A.; Ometto, J.P.H.B.; von Randow, C.; Giarolla, A. Impact of Climate Changes on Potential Sugarcane Yield in Pernambuco, Northeastern Region of Brazil. Renew. Energy 2015, 78, 26–34. [Google Scholar] [CrossRef]

- De Oliveira Bordonal, R.; Carvalho, J.L.N.; Lal, R.; de Figueiredo, E.B.; de Oliveira, B.G.; La Scala, N. Sustainability of Sugarcane Production in Brazil. A Review. Agron. Sustain. Dev. 2018, 38, 13. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol Production from Renewable Sources: Current Perspectives and Technological Progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- de Souza Dias, M.O.; Maciel Filho, R.; Mantelatto, P.E.; Cavalett, O.; Rossell, C.E.V.; Bonomi, A.; Leal, M.R.L.V. Sugarcane Processing for Ethanol and Sugar in Brazil. Environ. Dev. 2015, 15, 35–51. [Google Scholar] [CrossRef]

- Eliseu Nicula de Castro, R.; Maria de Brito Alves, R.; Augusto Oller do Nascimento, C.; Giudici, R. Assessment of sugarcane-based ethanol production. In Fuel Ethanol Production from Sugarcane; InTechOpen: London, UK, 2019; pp. 3–22. [Google Scholar] [CrossRef]

- Danelon, A.F.; Spolador, H.F.S.; Bergtold, J.S. The Role of Productivity and Efficiency Gains in the Sugar-Ethanol Industry to Reduce Land Expansion for Sugarcane Fields in Brazil. Energy Policy 2023, 172, 113327. [Google Scholar] [CrossRef]

- Rabelo, S.C.; Paiva, L.B.B.d.; Pin, T.C.; Pinto, L.F.R.; Tovar, L.P.; Nakasu, P.Y.S. Chapter 8—Chemical and Energy Potential of Sugarcane. In Eichler Technology and Perspectives; Santos, F., Rabelo, S.C., De Matos, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 141–163. ISBN 978-0-12-814236-3. [Google Scholar]

- Salles-Filho, S.L.M.; Castro, P.F.D.d.; Bin, A.; Edquist, C.; Ferro, A.F.P.; Corder, S. Perspectives for the Brazilian Bioethanol Sector: The Innovation Driver. Energy Policy 2017, 108, 70–77. [Google Scholar] [CrossRef]

- Makarem, N.; Bandera, E.V.; Lin, Y.; Jacques, P.F.; Hayes, R.B.; Parekh, N. Consumption of Sugars, Sugary Foods, and Sugary Beverages in Relation to Adiposity-Related Cancer Risk in the Framingham Offspring Cohort (1991–2013). Cancer Prev. Res. 2018, 11, 347–358. [Google Scholar] [CrossRef] [PubMed]

- Friberg, E.; Wallin, A.; Wolk, A. Sucrose, High-Sugar Foods, and Risk of Endometrial Cancer—A Population-Based Cohort Study. Cancer Epidemiol. Biomarkers Prev. 2011, 20, 1831–1837. [Google Scholar] [CrossRef]

- Bergallo, P.; Castagnari, V.; Fernández, A.; Mejía, R. Regulatory Initiatives to Reduce Sugar-Sweetened Beverages (SSBs) in Latin America. PLoS ONE 2018, 13, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Monterrosa, E.C.; Campirano, F.; Mayo, L.T.; Frongillo, E.A.; Cordero, S.H.; Kaufer-Horwitz, M.; Rivera, J.A. Stakeholder Perspectives on National Policy for Regulating the School Food Environment in Mexico. Health Policy Plan. 2015, 30, 28–38. [Google Scholar] [CrossRef]

- Carriedo, A.; Koon, A.D.; Encarnación, L.M.; Lee, K.; Smith, R.; Walls, H. The Political Economy of Sugar-Sweetened Beverage Taxation in Latin America: Lessons from Mexico, Chile and Colombia. Global. Health 2021, 17, 1–14. [Google Scholar] [CrossRef]

- Sandoval, R.C.; Roche, M.; Belausteguigoitia, I.; Alvarado, M.; Galicia, L.; Gomes, F.S.; Paraje, G. Excise Taxes on Sugar-Sweetened Beverages in Latin America and the Caribbean. Rev. Panam. Salud Publica 2021, 45, e21. [Google Scholar] [CrossRef]

- Lloyd-Williams, F.; Bromley, H.; Orton, L.; Hawkes, C.; Taylor-Robinson, D.; O’Flaherty, M.; McGill, R.; Anwar, E.; Hyseni, L.; Moonan, M.; et al. Smorgasbord or Symphony? Assessing Public Health Nutrition Policies across 30 European Countries Using a Novel Framework. BMC Public Health 2014, 14, 1195. [Google Scholar] [CrossRef]

- Thow, A.M.; Quested, C.; Juventin, L.; Kun, R.; Khan, A.N.; Swinburn, B. Taxing Soft Drinks in the Pacific: Implementation Lessons for Improving Health. Health Promot. Int. 2011, 26, 55–64. [Google Scholar] [CrossRef]

- Cabrera Escobar, M.A.; Veerman, J.L.; Tollman, S.M.; Bertram, M.Y.; Hofman, K.J. Evidence That a Tax on Sugar Sweetened Beverages Reduces the Obesity Rate: A Meta-Analysis. BMC Public Health 2013, 13, 1072. [Google Scholar] [CrossRef] [PubMed]

- Smith, R. Why a Macroeconomic Perspective Is Critical to the Prevention of Noncommunicable Disease. Science 2012, 337, 1501–1503. [Google Scholar] [CrossRef] [PubMed]

- Du, C.; Dias, L.C.; Freire, F. Robust Multi-Criteria Weighting in Comparative LCA and S-LCA: A Case Study of Sugarcane Production in Brazil. J. Clean. Prod. 2019, 218, 708–717. [Google Scholar] [CrossRef]

- Morales Chavez, M.M.; Sarache, W.; Costa, Y.; Soto, J. Multiobjective Stochastic Scheduling of Upstream Operations in a Sustainable Sugarcane Supply Chain. J. Clean. Prod. 2020, 276, 123305. [Google Scholar] [CrossRef]

- Capaz, R.S.; Carvalho, V.S.B.; Nogueira, L.A.H. Impact of Mechanization and Previous Burning Reduction on GHG Emissions of Sugarcane Harvesting Operations in Brazil. Appl. Energy 2013, 102, 220–228. [Google Scholar] [CrossRef]

- Ahmed, A.E.; Alam-Eldin, A.O.M. An Assessment of Mechanical vs Manual Harvesting of the Sugarcane in Sudan—The Case of Sennar Sugar Factory. J. Saudi Soc. Agric. Sci. 2015, 14, 160–166. [Google Scholar] [CrossRef]

- Rasche, L.; Sos Del Diego, R. Pros and Cons of Sugarcane Straw Recovery in São Paulo. Bioenergy Res. 2020, 13, 147–156. [Google Scholar] [CrossRef]

- Machado, C.M.D.; Cardoso, A.A.; Allen, A.G. Atmospheric Emission of Reactive Nitrogen during Biofuel Ethanol Production. Environ. Sci. Technol. 2008, 42, 381–385. [Google Scholar] [CrossRef]

- Oliveira Filho, J.d.S.; Santos, O.A.Q.d.; Rossi, C.Q.; Diniz, Y.V.d.F.G.; Fagundes, H.d.S.; Pinto, L.A.d.S.R.; Pereira, W.; Pereira, M.G. Assessing the Effects of Harvesting with and without Burning and Vinasse Application in Sugarcane Crops: Evaluation of Soil Fertility and Phosphorus Pools in Different Ethanol Production Systems. Agric. Ecosyst. Environ. 2021, 307, 107233. [Google Scholar] [CrossRef]

- Baccarin, J.G.; de Oliveira, J.A.; Mardegan, G.E. The Environmental, Social and Economic Effects of Recent Technological Changes in Sugarcane on the State of São Paulo, Brazil. J. Agrar. Chang. 2020, 20, 598–617. [Google Scholar] [CrossRef]

- Negrete, J.C. Reduction of Pollution and Diseases through a Law to Prohibit the Burning of Sugarcane. Biomed. J. Sci. Tech. Res. 2019, 16, 12286–12287. [Google Scholar] [CrossRef]

- Lima, M.; Silva Junior, C.A.d.; Pelissari, T.D.; Lourençoni, T.; Luz, I.M.S.; Lopes, F.J.A. Sugarcane: Brazilian Public Policies Threaten the Amazon and Pantanal Biomes. Perspect. Ecol. Conserv. 2020, 18, 210–212. [Google Scholar] [CrossRef]

- Pivello, V.R.; Vieira, I.; Christianini, A.V.; Ribeiro, D.B.; da Silva Menezes, L.; Berlinck, C.N.; Melo, F.P.L.; Marengo, J.A.; Tornquist, C.G.; Tomas, W.M.; et al. Understanding Brazil’s Catastrophic Fires: Causes, Consequences and Policy Needed to Prevent Future Tragedies. Perspect. Ecol. Conserv. 2021, 19, 233–255. [Google Scholar] [CrossRef]

- Chen, J.; Gong, Y.; Wang, S.; Guan, B.; Balkovic, J.; Kraxner, F. To Burn or Retain Crop Residues on Croplands? An Integrated Analysis of Crop Residue Management in China. Sci. Total Environ. 2019, 662, 141–150. [Google Scholar] [CrossRef]

- Neves, M.F.; Conejero, M.A. Sistema Agroindustrial Da Cana: Cenários e Agenda Estratégica. Econ. Apl. 2007, 11, 587–604. [Google Scholar] [CrossRef][Green Version]

- De Oliveira Bordonal, R.; de Figueiredo, E.B.; La Scala, N. Greenhouse Gas Balance Due to the Conversion of Sugarcane Areas from Burned to Green Harvest, Considering Other Conservationist Management Practices. GCB Bioenergy 2012, 4, 846–858. [Google Scholar] [CrossRef]

- Grassi, M.C.B.; Pereira, G.A.G. Energy-Cane and RenovaBio: Brazilian Vectors to Boost the Development of Biofuels. Ind. Crops Prod. 2019, 129, 201–205. [Google Scholar] [CrossRef]

- Diniz Oliveira, T.; Costa Gurgel, A.; Tonry, S. International Market Mechanisms under the Paris Agreement: A Cooperation between Brazil and Europe. Energy Policy 2019, 129, 397–409. [Google Scholar] [CrossRef]

- Theofany, H.C.; Yheni, M.; Aditiya, H.B.; Sepwin, N.S. Microwave Irradiation Pre-Treatment in Third Generation Bioethanol Production from Tropical Green Algae. J. Phys. Conf. Ser. 2019, 1402, 044046. [Google Scholar] [CrossRef]

- Eckert, C.T.; Frigo, E.P.; Albrecht, L.P.; Albrecht, A.J.P.; Christ, D.; Santos, W.G.; Berkembrock, E.; Egewarth, V.A. Maize Ethanol Production in Brazil: Characteristics and Perspectives. Renew. Sustain. Energy Rev. 2018, 82, 3907–3912. [Google Scholar] [CrossRef]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An Overview of Integration Opportunities for Sustainable Bioethanol Production from First- and Second-Generation Sugar-Based Feedstocks. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Adewuyi, A. Challenges and Prospects of Renewable Energy in Nigeria: A Case of Bioethanol and Biodiesel Production. Energy Rep. 2020, 6, 77–88. [Google Scholar] [CrossRef]

- Aba, M.M.; Le Roux, G.A.C.; Menezes, B.C. Integrated Ethanol and Gasoline Supply Chain Planning under Environmental Constraints: A Case Study of Brazil. Comput. Chem. Eng. 2022, 164, 107875. [Google Scholar] [CrossRef]

- Quintino, D.D.; David, S.A. Quantitative Analysis of Feasibility of Hydrous Ethanol Futures Contracts in Brazil. Energy Econ. 2013, 40, 927–935. [Google Scholar] [CrossRef]

- Paludo, A.; Becker, W.R.; Richetti, J.; Silva, L.C.D.A.; Johann, J.A. Mapping Summer Soybean and Corn with Remote Sensing on Google Earth Engine Cloud Computing in Parana State—Brazil. Int. J. Digit. Earth 2020, 13, 1624–1636. [Google Scholar] [CrossRef]

- Altarugio, L.M.; Savieto, J.; Machado, B.D.A.; Migliavacca, R.A.; Almeida, R.F.; Zavaschi, E.; Carneiro, L.D.M.E.S.; Vitti, G.C.; Otto, R. Optimal Management Practices for Nitrogen Application in Corn Cultivated during Summer and Fall in the Tropics. Commun. Soil Sci. Plant Anal. 2019, 50, 662–672. [Google Scholar] [CrossRef]

- Garcia, R.A.; Ceccon, G.; Sutier, G.A. da S.; dos Santos, A.L.F. Soybean-Corn Succession According to Seeding Date. Pesqui. Agropecu. Bras. 2018, 53, 22–29. [Google Scholar] [CrossRef]

- Mattos, F.L.; da Silveira, R.L.F. The Expansion of the Brazilian Winter Corn Crop and Its Impact on Price Transmission. Int. J. Financ. Stud. 2018, 6, 45. [Google Scholar] [CrossRef]

- CONAB, C.N.d.A. Acompanhamento Da Safra Brasileira: Grãos—Safra 2017/18—Nono Levantamento, Brasília. Available online: https://www.conab.gov.br/info-agro/safras/graos/boletim-da-safra-de-graos/item/download/20861_fb79e3ca2b3184543c580cd4a4aa402b (accessed on 3 June 2019).

- Abimilho Oferta e Demanda, Assoc. Bras. Das Indústrias Do Milho—AbiMilho. Available online: http://abimilho.com.br/estatisticas%0Ahttp://www.abimilho.com.br/estatisticas (accessed on 3 June 2019).

- Jian, F. A General Model to Predict Germination and Safe Storage Time of Crop Seeds. J. Stored Prod. Res. 2022, 99, 102041. [Google Scholar] [CrossRef]

- Patino, M.T.O.; Machado, M.F.; Nascimento, G.T.; de Alcantara, M.R. Analysis and Forecast of the Storage Needs of Soybeans in Brazil. Eng. Agríc. 2013, 33, 834–843. [Google Scholar] [CrossRef][Green Version]

- Gao, S.; Grebitus, C.; Schmitz, T. Effects of Risk Preferences and Social Networks on Adoption of Genomics by Chinese Hog Farmers. J. Rural Stud. 2022, 94, 111–127. [Google Scholar] [CrossRef]

- Silva, L.d.C.M.d.; Avanzi, J.C.; Peixoto, D.S.; Merlo, M.N.; Borghi, E.; Resende, Á.V.d.; Acuña-Guzman, S.F.; Silva, B.M. Ecological Intensification of Cropping Systems Enhances Soil Functions, Mitigates Soil Erosion, and Promotes Crop Resilience to Dry Spells in the Brazilian Cerrado. Int. Soil Water Conserv. Res. 2021, 9, 591–604. [Google Scholar] [CrossRef]

- Gonzalez, P.G.A.; de Jesus Gariboti, J.C.; Leal Silva, J.F.; Lopes, E.S.; Abaide, E.R.; Lopes, M.S.; Concha, V.O.C.; Felisbino, R.F.; Gomes, E.L.; Tovar, L.P. Soybean Straw as a Feedstock for Value-Added Chemicals and Materials: Recent Trends and Emerging Prospects. BioEnergy Res. 2022. [Google Scholar] [CrossRef]

- Veracini, J.L.; Walker, P.M.; Faulkner, M.J.; Hall, R.E.; Atkinson, R.L.; Wiegand, B.R. Effects of High Fat, Modified Wet, Corn Distiller’s Grains plus Solubles on Beef Steer Performance and Carcass Characteristics. Livest. Sci. 2013, 157, 151–161. [Google Scholar] [CrossRef]

- Xin, H.; Ahmad Khan, N.; Sun, K.; Sun, F.; Ur Rahman, S.; Fu, Q.; Li, Y.; Zhang, Y.; Hu, G. Batch-to-Batch Variation in Protein Molecular Structures, Nutritive Value and Ruminal Metabolism in Corn Coproducts. Anim. Feed Sci. Technol. 2020, 263, 114428. [Google Scholar] [CrossRef]

- Wood, C.; Rosentrater, K.A.; Muthukumarappan, K. Pyrolysis of Ethanol Coproducts. Ind. Crops Prod. 2014, 56, 118–127. [Google Scholar] [CrossRef]

- Canabarro, N.I.; Silva-Ortiz, P.; Nogueira, L.A.H.; Cantarella, H.; Maciel-Filho, R.; Souza, G.M. Sustainability Assessment of Ethanol and Biodiesel Production in Argentina, Brazil, Colombia, and Guatemala. Renew. Sustain. Energy Rev. 2023, 171, 113019. [Google Scholar] [CrossRef]

- Alhadas, H.M.; Valadares Filhos, S.C.; Tedeschi, L.O.; Vilela, R.S.R.; Souza, G.A.P. In Situ Evaluation of Dried Distillers Grains (DDG) and of Diets Containing Different Levels of DDG Inclusion Replacing Soybean Meal, Urea and Corn, and Development of Alternative Methods to Estimate in Vivo Digestibility of Diets. Livest. Sci. 2021, 253, 104706. [Google Scholar] [CrossRef]

- Malvandi, A.; Nicole Coleman, D.; Loor, J.J.; Feng, H. A Novel Sub-Pilot-Scale Direct-Contact Ultrasonic Dehydration Technology for Sustainable Production of Distillers Dried Grains (DDG). Ultrason. Sonochem. 2022, 85, 105982. [Google Scholar] [CrossRef]

- Schneid, K.N.; Foote, A.P.; Beck, P.A.; Farran, G.L.; Wilson, B.K. Using Whole Cottonseed to Replace Dried Distillers Grains plus Solubles and Prairie Hay in Finishing Beef Cattle Rations Balanced for Physically Effective Neutral Detergent Fiber. Appl. Anim. Sci. 2022, 38, 417–432. [Google Scholar] [CrossRef]

- Nichols, J.R.; Schingoethe, D.J.; Maiga, H.A.; Brouk, M.J.; Piepenbrink, M.S. Evaluation of Corn Distillers Grains and Ruminally Protected Lysine and Methionine for Lactating Dairy Cows. J. Dairy Sci. 1998, 81, 482–491. [Google Scholar] [CrossRef] [PubMed]

- Paz, H.A.; de Veth, M.J.; Ordway, R.S.; Kononoff, P.J. Evaluation of Rumen-Protected Lysine Supplementation to Lactating Dairy Cows Consuming Increasing Amounts of Distillers Dried Grains with Solubles. J. Dairy Sci. 2013, 96, 7210–7222. [Google Scholar] [CrossRef] [PubMed]

- Leitschuh, B.; Stewart, W.P.; van Riper, C.J. Place-Making in the Corn Belt: The Productivist Landscapes of the “Good Farmer. ” J. Rural Stud. 2022, 92, 415–424. [Google Scholar] [CrossRef]

- Kocak, E.; Bilgili, F.; Bulut, U.; Kuskaya, S. Is Ethanol Production Responsible for the Increase in Corn Prices? Renew. Energy 2022, 199, 689–696. [Google Scholar] [CrossRef]

- Grangeia, C.; Santos, L.; Lazaro, L.L.B. The Brazilian Biofuel Policy (RenovaBio) and Its Uncertainties: An Assessment of Technical, Socioeconomic and Institutional Aspects. Energy Convers. Manag. X 2022, 13, 100156. [Google Scholar] [CrossRef]

- Pasqual, J.C.; Bollmann, H.A.; Scott, C.A.; Edwiges, T.; Baptista, T.C. Assessment of Collective Production of Biomethane from Livestock Waste for Urban Transportation Mobility in Brazil and the United States. Energies 2018, 11, 997. [Google Scholar] [CrossRef]

- De Oliveira, F.C.; Coelho, S.T. Biodiesel in Brazil Should Take Off with the Newly Introduced Domestic Biofuels Policy: RenovaBio; Al Qubeissi, M., Ed.; IntechOpen: Rijeka, Croatia, 2018; p. 10. ISBN 978-1-78985-536-4. [Google Scholar]

- de Souza, L.M.; Mendes, P.; Aranda, D. Assessing the Current Scenario of the Brazilian Biojet Market. Renew. Sustain. Energy Rev. 2018, 98, 426–438. [Google Scholar] [CrossRef]

- Mani, S.; Sokhansanj, S.; Tagore, S.; Turhollow, A.F. Techno-Economic Analysis of Using Corn Stover to Supply Heat and Power to a Corn Ethanol Plant—Part 2: Cost of Heat and Power Generation Systems. Biomass Bioenergy 2010, 34, 356–364. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V.; Tiffany, D.G. Reducing Life Cycle Greenhouse Gas Emissions of Corn Ethanol by Integrating Biomass to Produce Heat and Power at Ethanol Plants. Biomass Bioenergy 2011, 35, 1103–1113. [Google Scholar] [CrossRef]

- Rezende, M.L.; Richardson, J.W. Economic Feasibility of Sugar and Ethanol Production in Brazil under Alternative Future Prices Outlook. Agric. Syst. 2015, 138, 77–87. [Google Scholar] [CrossRef]

- Lopes, M.L.; Paulillo, S.C.d.L.; Godoy, A.; Cherubin, R.A.; Lorenzi, M.S.; Giometti, F.H.C.; Bernardino, C.D.; de Amorim Neto, H.B.; de Amorim, H.V. Ethanol Production in Brazil: A Bridge between Science and Industry. Brazilian J. Microbiol. 2016, 47, 64–76. [Google Scholar] [CrossRef] [PubMed]

- Chum, H.L.; Warner, E.; Seabra, J.E.A.; Macedo, I.C. A Comparison of Commercial Ethanol Production Systems from Brazilian Sugarcane and US Corn. Biofuels Bioprod. Biorefining 2014, 8, 205–223. [Google Scholar] [CrossRef]

- MAPA Evolução Da Produtividade e Da Produção de Cana-de-Açúcar No Brasil Por Ano-Safra. Available online: http://www.agricultura.gov.br/assuntos/sustentabilidade/agroenergia/arquivos-producao/copy3_of_08a_areacolhidaCONABMAPA.pdf (accessed on 25 May 2019).

- Pignati, W.A.; e Lima, F.A.N.d.S.; de Lara, S.S.; Correa, M.L.M.; Barbosa, J.R.; Leão, L.H.D.C.; Pignatti, M.G. Distribuição Espacial Do Uso de Agrotóxicos No Brasil: Uma Ferramenta Para a Vigilância Em Saúde. Cienc. e Saude Coletiva 2017, 22, 3281–3293. [Google Scholar] [CrossRef] [PubMed]

- Mekonnen, M.M.; Romanelli, T.L.; Ray, C.; Hoekstra, A.Y.; Liska, A.J.; Neale, C.M.U. Water, Energy, and Carbon Footprints of Bioethanol from the U.S. and Brazil. Environ. Sci. Technol. 2018, 52, 14508–14518. [Google Scholar] [CrossRef] [PubMed]

- Chiu, C.C.; Shiang, W.-J.; Lin, C.J. The Water Footprint of Bioethanol. J. Clean Energy Technol. 2015, 4, 43–47. [Google Scholar] [CrossRef]

- Zetty-Arenas, A.M.; Tovar, L.P.; Alves, R.F.; Mariano, A.P.; van Gulik, W.; Maciel Filho, R.; Freitas, S. Co-Fermentation of Sugarcane Bagasse Hydrolysate and Molasses by Clostridium Saccharoperbutylacetonicum: Effect on Sugar Consumption and Butanol Production. Ind. Crops Prod. 2021, 167, 113512. [Google Scholar] [CrossRef]

- Bahú, J.O.; de Oliveira, R.A.; De Souza, L.M.A.; Rivera, E.C.; Felisbino, R.F.; Maciel Filho, R.; Tovar, L.P. Kinetic Study of Thermal Decomposition of Sugarcane Bagasse Pseudo-Components at Typical Pretreatment Conditions: Simulations of Opportunities towards the Establishment of a Feasible Primary Biorefining. Clean. Chem. Eng. 2022, 4, 100074. [Google Scholar] [CrossRef]

- Solomon, S. Post-Harvest Cane Deterioration and Its Milling Consequences. Sugar Tech 2000, 2, 1–18. [Google Scholar] [CrossRef]

- Xie, H.; Wang, F.; Yin, S.; Ren, T.; Song, A. The Preparation and Ethanol Fermentation of High-Concentration Sugars from Steam-Explosion Corn Stover. Appl. Biochem. Biotechnol. 2015, 176, 613–624. [Google Scholar] [CrossRef]

- Yu, J.; Xu, Z.; Liu, L.; Chen, S.; Wang, S.; Jin, M. Process Integration for Ethanol Production from Corn and Corn Stover as Mixed Substrates. Bioresour. Technol. 2019, 279, 10–16. [Google Scholar] [CrossRef]

- Ferreira Filho, J.B.d.S.; Horridge, M. Ethanol Expansion and Indirect Land Use Change in Brazil. Land Use Policy 2014, 36, 595–604. [Google Scholar] [CrossRef]

- Aktar, W.; Sengupta, D.; Chowdhury, A. Impact of Pesticides Use in Agriculture: Their Benefits and Hazards. Interdiscip. Toxicol. 2009, 2, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Christofoletti, C.A.; Escher, J.P.; Correia, J.E.; Marinho, J.F.U.; Fontanetti, C.S. Sugarcane Vinasse: Environmental Implications of Its Use. Waste Manag. 2013, 33, 2752–2761. [Google Scholar] [CrossRef]

- Fuess, L.T.; Altoé, M.E.; Felipe, M.C.; Garcia, M.L. Pros and Cons of Fertirrigation with in Natura Sugarcane Vinasse: Do Improvements in Soil Fertility Offset Environmental and Bioenergy Losses? J. Clean. Prod. 2021, 319, 128684. [Google Scholar] [CrossRef]

- Fuess, L.T.; Garcia, M.L.; Zaiat, M. Seasonal Characterization of Sugarcane Vinasse: Assessing Environmental Impacts from Fertirrigation and the Bioenergy Recovery Potential through Biodigestion. Sci. Total Environ. 2018, 634, 29–40. [Google Scholar] [CrossRef] [PubMed]

- Nakashima, R.N.; de Oliveira Junior, S. Comparative Exergy Assessment of Vinasse Disposal Alternatives: Concentration, Anaerobic Digestion and Fertirrigation. Renew. Energy 2020, 147, 1969–1978. [Google Scholar] [CrossRef]

- García-Sladaña, A.; Landeros-Sànchez, C.; Casta~enda-chávez, M.d.R.; Martínez-dávila, J.P.; Pérez-Vázquez, A.; Carrillo-Ávila, E. Fertirrigation with Low-Pressure Multi-Gate Irrigation Systems in Sugarcane Agroecosystems: A Review. Pedosphere 2019, 29, 1–11. [Google Scholar] [CrossRef]

- Moraes, B.S.; Junqueira, T.L.; Pavanello, L.G.; Cavalett, O.; Mantelatto, P.E.; Bonomi, A.; Zaiat, M. Anaerobic Digestion of Vinasse from Sugarcane Biorefineries in Brazil from Energy, Environmental, and Economic Perspectives: Profit or Expense? Appl. Energy 2014, 113, 825–835. [Google Scholar] [CrossRef]

- Moraes, B.S.; Zaiat, M.; Bonomi, A. Anaerobic Digestion of Vinasse from Sugarcane Ethanol Production in Brazil: Challenges and Perspectives. Renew. Sustain. Energy Rev. 2015, 44, 888–903. [Google Scholar] [CrossRef]

- UNICA Histórico de Produção e Moagem Por Produto, Dados de Produção. Available online: https://observatoriodacana.com.br/ (accessed on 14 December 2022).

- Khair, U.; Fahmi, H.; Hakim, S.A.; Rahim, R. Forecasting Error Calculation with Mean Absolute Deviation and Mean Absolute Percentage Error. J. Phys. Conf. Ser. 2017, 930. [Google Scholar] [CrossRef]

- Mackay, D.B.; Bliemel, F. Theil’s Forecast Accuracy Coefficient: A Clarification. J. Mark. Res. 2014, 10, 444–446. [Google Scholar]

| Factors | Corn | Sugarcane |

|---|---|---|

| Cost per liter (USD 1.00 equal to R$5.00) | Between R$0.97 and R$1.84 (hydrated ethanol) [93]. | R$1.80 for anhydrous ethanol and R$1.71 for hydrated ethanol [98]. |

| Stock | Possible to stock for several weeks [99]. | Must be processed immediately after the harvest [99]. |

| Fermentation time | 45 to 60 h [100]. | 6 to 12 h [100]. |

| Productivity (liters per ton of feedstock) | 400 L of ethanol per ton of corn [95]. | 70 to 85 L of ethanol per ton of sugarcane [95]. |

| Productivity (tons of feedstock per hectare) | 5.5 tons per hectare [74]. | 77 tons per hectare [101]. |

| Volume of pesticides | 7.4 L per hectare [102]. | 4.8 L per hectare [102]. |

| Volume of water | 2570 L per hectare [103,104]. | 2516 L per hectare [103,104]. |

| GHG emission | 15 to 20 g equivalent of CO2/MJ [99]. | 20 g equivalent of CO2/MJ [22]. |

| Plant working days | 345 days per year [99]. | Between 200 and 240 days per year [95]. |

| By-product | DGS [101]. | Vinasse [36,105,106]. |

| Forecasting Method | Mean Absolute Percentage Error (MAPE) | Theil’s U |

|---|---|---|

| Double Exponential Smoothing | 9.31% | 0.9514 |

| Damped Trend Non-Seasonal | 9.32% | 0.9514 |

| ARIMA (0,1,0) | 9.03% | 0.8722 |

| Single Moving Average | 9.87% | 1 |

| Single Exponential Smoothing | 9.87% | 1.05 |

| Double Moving Average | 10.84% | 1.05 |

| Year | Arima (0,1,0) (1000 m3) | Damped Trend Nonseasonal (1000 m3) | Double Exponential Smoothing (1000 m3) |

|---|---|---|---|

| 2020 | 34,639 | 34,017 | 34,021 |

| 2021 | 36,231 | 34,936 | 34,945 |

| 2022 | 37,879 | 35,854 | 35,869 |

| 2023 | 39,586 | 36,771 | 36,793 |

| 2024 | 41,351 | 37,687 | 37,717 |

| 2025 | 43,177 | 38,602 | 38,641 |

| 2026 | 45,065 | 39,516 | 39,565 |

| 2027 | 47,016 | 40,429 | 40,489 |

| 2028 | 49,033 | 41,342 | 41,413 |

| 2029 | 51,116 | 42,253 | 42,336 |

| 2030 | 53,267 | 43,164 | 43,260 |

| 2031 | 55,489 | 44,073 | 44,184 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira Gonçalves, F.; Firmani Perna, R.; Savioli Lopes, E.; Plazas Tovar, L.; Maciel Filho, R.; Savioli Lopes, M. Strategies to Ensure Fuel Security in Brazil Considering a Forecast of Ethanol Production. Biomass 2023, 3, 1-17. https://doi.org/10.3390/biomass3010001

de Oliveira Gonçalves F, Firmani Perna R, Savioli Lopes E, Plazas Tovar L, Maciel Filho R, Savioli Lopes M. Strategies to Ensure Fuel Security in Brazil Considering a Forecast of Ethanol Production. Biomass. 2023; 3(1):1-17. https://doi.org/10.3390/biomass3010001

Chicago/Turabian Stylede Oliveira Gonçalves, Felipe, Rafael Firmani Perna, Emília Savioli Lopes, Laura Plazas Tovar, Rubens Maciel Filho, and Melina Savioli Lopes. 2023. "Strategies to Ensure Fuel Security in Brazil Considering a Forecast of Ethanol Production" Biomass 3, no. 1: 1-17. https://doi.org/10.3390/biomass3010001

APA Stylede Oliveira Gonçalves, F., Firmani Perna, R., Savioli Lopes, E., Plazas Tovar, L., Maciel Filho, R., & Savioli Lopes, M. (2023). Strategies to Ensure Fuel Security in Brazil Considering a Forecast of Ethanol Production. Biomass, 3(1), 1-17. https://doi.org/10.3390/biomass3010001