Abstract

Côte d’Ivoire has substantially neglected crop residues from farms in rural areas, so this study aimed to provide strategies for the sustainable conversion of these products to hydrogen. The use of existing data showed that, in the Côte d’Ivoire, there were up to 16,801,306 tons of crop residues from 11 crop types in 2019, from which 1,296,424.84 tons of hydrogen could potentially be derived via theoretical gasification and dark fermentation approaches. As 907,497.39 tons of hydrogen is expected annually, the following estimations were derived. The three hydrogen-project implementation scenarios developed indicate that Ivorian industries could be supplied with 9,026,635 gigajoules of heat, alongside 17,910 cars and 4732 buses in the transport sector. It was estimated that 817,293.95 tons of green ammonia could be supplied to farmers. According to the study, 5,727,992 households could be expected to have access to 1718.40 gigawatts of electricity. Due to these changes in the transport, energy, industry, and agricultural sectors, a reduction of 1,644,722.08 tons of carbon dioxide per year could theoretically be achieved. With these scenarios, around 263,276.87 tons of hydrogen could be exported to other countries. The conversion of crop residues to hydrogen is a promising opportunity with environmental and socio-economic impacts. Therefore, this study requires further extensive research.

1. Introduction

Energy contributes significantly to sustainable development and is indispensable for humans, as it is involved in almost all sectors of activity such as infrastructure, agriculture, people’s livelihoods, and the environment. Moreover, energy stimulates national development and increases economic security. As such, the global energy demand is rapidly increasing, and, as energy consumption is heavily governed by fossil-fuel use, including oil, coal, and natural gas [1], these primary energy sources are being depleted due to constant exploitation. In addition, their utilization has dramatically changed the climate pattern, leading to global warming, with a negative impact on the Earth. In fact, along the fossil-fuel value chain, from extraction to end-use, there are considerable greenhouse gas emissions into the atmosphere. To date, frequent floods, droughts, heatwaves, severe hurricanes, and rising sea levels have increased public health risks, water crises, food insecurity, natural ecosystem perturbation, and population displacement, among other impacts [2]. Climate change is a worldwide issue, severely affecting the environment, society, and the global economy [3,4,5].

The need for innovative, clean, affordable, and reliable energy sources in the global energy system is imperative. In 2015, at the Conference of the Parties (COP21) in Paris, 194 countries decided to tackle climate change by limiting global warming to 1.5 °C [6], making renewable energy an important subject of discussion in the energy sector.

Hydrogen is an energy carrier whose production requires different methods depending on the energy source—renewable or fossil. According to IRENA [7], global hydrogen production— totaling 75 MtH2/year in pure hydrogen and another 45 MtH2/year in mixing gasses—is dominated by fossil fuel use, accounting for about 95 percent of the total, with around 47%, 21%, and 27% from natural gas, oil, and coal, respectively, and only approximately 5% from water electrolysis.

Hydrogen’s various production routes are characterized according to color codes: green hydrogen is the cleanest and most environmentally friendly, produced through renewable energy; gray hydrogen is based on natural gas, or methane, using a steam methane-reforming process without capturing the carbon dioxide, becoming blue hydrogen when the carbon is captured and stored (CCS); turquoise hydrogen is derived from solid carbon through methane pyrolysis; black or brown hydrogen is generated through black or brown coal (lignite) gasification, respectively; pink hydrogen is produced using nuclear energy as a source of electricity; and hydrogen naturally occurring underground is known as white hydrogen [8] and is found in many countries, including Mali in Africa.

Africa has huge green hydrogen potential. Indeed, the African Hydrogen Atlas (H2Atlas Africa), developed by the Forschungszentrum Jülich GmbH Institute for Energy and Climate Research, estimates that West Africa alone can produce about 120,000 TWh of green hydrogen per year using wind and solar energy [9]. Mukelabai et al. [10] have shown that the regional bio-hydrogen potential ranges from 0.03 to 0.06 Gt/year. Currently, several initiatives have been put into place, including the African Alliance for Green Hydrogen (AGHA), bringing together Egypt, Kenya, Mauritania, Morocco, Namibia, and South Africa to strengthen collaboration on capacity building, financing, policy design and certification in the hydrogen sector [11]. Various African countries already have their own strategies, as well as ongoing and upcoming projects. For instance, Mauritania has launched green hydrogen mega projects, thanks to a 15 GW electrolyzer supplied with 30 GW of solar and wind power. The Aman project, estimated to cost USD 40 billion, will have an annual capacity of 1.7 million tons of hydrogen, alongside the Nour Electrolyzer project, with 1.2 million tons per year, and the Masdar‒Infinity‒Conjuncta green hydrogen project, with 1.36 million tons per year [12]. Similarly, Namibia is also developing several key projects to make full use of its hydrogen potential. Hyphen Hydrogen Energy developed the Tsau Khaeb project, with a capacity of 3 GW, which could generate 300,000 tons per year, with an overall cost of USD 9.4 billion. Other projects include the 2.5 GW Tumoneni project, the 50 MW Swakopmund project, and the 42 MW Daures Green Hydrogen Village project. The country also aims to develop three hydrogen valleys in Kharas, the port of Walvis Bay, and Kunene. In South Africa, a series of projects are already underway. An environmentally friendly ammonia facility with a capacity of 780,000 tons per year is being developed by Hive Hydrogen, with an estimated cost of USD 4.6 billion and a German subsidy of EUR 15 million for the HySHiFT renewable hydrogen project [13]. Egypt is also making a significant effort, with twenty-one green energy projects under development, showing the country’s desire to become a global energy hub. Among these projects are the development of a green ammonia plant with a capacity of 3 million tons per year, a 4 GW electrolyzer plant developed by Masdar and the Hassan Allam Holding Group, and the 3.6 GW electrolyzer project developed by Globeleq. Morocco also has green hydrogen initiatives on its agenda: the biggest project, developed by CWP Global and other companies, aims to produce 900,000 tons of hydrogen per year, while other projects are planning for 710,000 tons a year of green hydrogen production [13]. Nations such as Nigeria, Kenya, and Rwanda are also exploring the hydrogen sector, and all ECOWAS countries are currently incorporating hydrogen policies into their national development plans. Over 120 West African students are receiving capacity-building training in the hydrogen sector through the West African Science Service Centre for Climate Change and Adapted Land Use, sponsored by the German Federal Ministry of Education and Research.

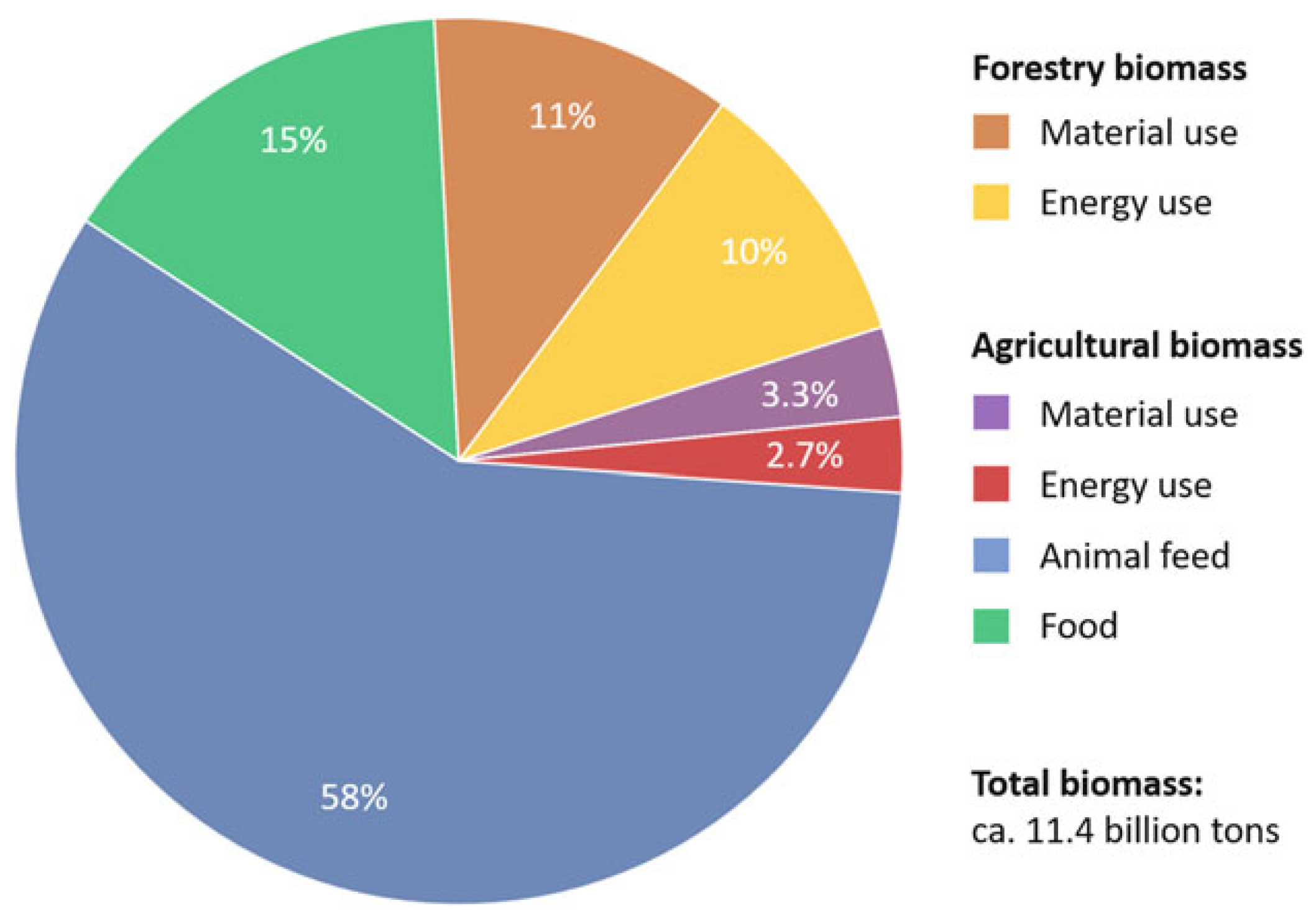

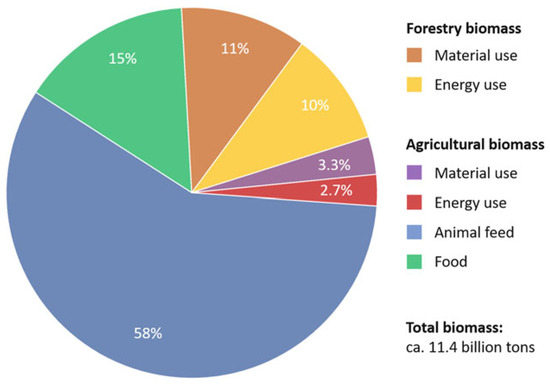

Among the various methods, the conversion of biomass to hydrogen is a promising solution that can be enacted through biological or thermochemical processes. Biomass—defined as the fraction of biodegradable products, waste, and residues from agriculture, plants, animal substances, households, and industries [14]—is an abundant, renewable, and environmentally friendly source. According to Zörb et al. [15], approximately 11.4 billion tons of biomass are generated annually from the agricultural sector and forests worldwide (see Figure 1). However, only a small fraction, approximately 2.7% (0.3078 billion tons) of agricultural residues and 10% (1.14 billion tons) of forestry biomass, is utilized for energy production, while the majority is intended for animal feed.

Figure 1.

Global use of harvested forestry and agricultural biomass [15].

The Côte d’Ivoire, a country situated in West Africa (longitudes 8°30′ and 2°30′ W; latitudes 4°30′ and 10°30′ N) within the intertropical zone, has a square-like shape, with an estimated area of 322,460 km2 and an estimated population of 28,262,050 inhabitants. Its economy is largely based on agriculture [16]. Despite the abundance of crop residues generated across various regions, they are not often valued, and most are abandoned or burned on farms, emitting greenhouse gasses such as methane and contributing to environmental pollution. Addressing these challenges is crucial and will lead to environmental sustainability, energy independence, security, and economic opportunities.

This study aims to propose a strategic plan for the sustainable conversion of crop residues to hydrogen by assessing the potential of this resource in Côte d’Ivoire, determining its hydrogen potential, and developing scenarios based on the use of hydrogen in this country, considering its production, distribution, and utilization. This study also analyzes the impact of said scenarios, encompassing environmental and social dimensions and providing a holistic view of how hydrogen use from crop residues can shape the Côte d’Ivoire’s energy landscape and contribute to its sustainable development.

2. Materials and Methods

2.1. Data Collection

This study utilizes existing data (secondary data), an efficient and reliable method that reduces the time and costs associated with data collection. Specifically, the data regarding the biomass generated in the Côte d’Ivoire in 2019 were extracted from a study conducted by the German Agency for International Cooperation (GIZ) on the biomass potential in the Côte d’Ivoire [17]. To address missing data on certain crops, supplementary information was obtained from the Food and Agriculture Organization of the United Nations’ website [18]. These combined sources provided the necessary data to evaluate the biomass potential, which were subsequently used to estimate the hydrogen potential.

2.2. Data Processing and Analysis

The hydrogen potential of crop residues was evaluated through theoretical calculation. Various methods to theoretically estimate hydrogen potential exist in the literature. However, in this study, gasification and dark-fermentation processes were preferred. The former appears to be a promising technology for dry biomass and has a high hydrogen content (25–30%) and a conversion efficiency of up to 85%, depending on the feedstock. It is a thermochemical process that converts solid biomass into biofuel, such as synthesis gas (syngas) [19]. In general, the biomass gasification reaction can be expressed as follows:

If the fractions of , and involved in the process are assumed to be combustion products and the in the syngas is negligible, Equation (2) changes to the following:

This equation could be followed by a water–gas shift reaction to enhance the hydrogen potential in practice, as follows:

Using simplified Equation (2), the carbon, hydrogen, and oxygen contents in the crop residues were collected from previous works [20]. Then, the equations for each feedstock were generated and balanced, and the hydrogen potential of each crop residue was determined. These approaches are similar to those proposed by Cárdenas et al. [21]. Similarly, for high-moisture biomass such as cashew apples, a dark-fermentation process is used to assess the hydrogen potential. Zagrodnik and Seifert [22] demonstrated that, in general, during the process, glucose () reacts with water () to yield acetic acid (), carbon dioxide (), and hydrogen (). By considering the general dark fermentation equation for any carbohydrate substrate and the percentage of carbon, hydrogen, and oxygen present in a cashew apple, the theoretical hydrogen potential of the cashew apple could be determined. Furthermore, the scenarios were based on hypothetical calculations. Equation (4) can be used to estimate the heat potential:

with 120 MJ/kg being the lowest heating value of hydrogen on a mass basis. In addition, the electrical potential is given by Equation (5):

where 33 kWh/kg is the amount of electricity that can be generated from 1 kg of hydrogen using a fuel cell [23]. To find the number of vehicles, US DOE [24] and Nekkers et al. [25] demonstrated that 1 kg of hydrogen can run a fuel-cell electric vehicle (FCEV) for up to 60 miles (96.56 km) for cars and 10.19 miles (16.4 km) for buses. The fuel-cell efficiency considered here was 60%. Therefore, based on these data, it was assumed that the average daily kilometers of cars and buses in Côte d’Ivoire was approximately 100 km and 150 km, respectively. Equation (6) below expresses the number of cars and buses in the scenarios:

Moreover, the Haber–Bosch process with 50% efficiency was used to obtain the green ammonia (NH3) potential. In the presence of an iron catalyzer and under an exothermic reaction (−92.4 kJ/mol), nitrogen captured from the air and hydrogen react at high temperatures (300–500 °C) and pressure (140–250 bar) to yield ammonia.

According to Rivarolo et al. [26], 177 kg of H2 and 823 kg of N2 are theoretically necessary to produce 1 ton of ammonia. Assuming that the hydrogen potential was fossil energy, the carbon dioxide that could be emitted was calculated using the IPCC method. This method was also used by Suryati et al. [27]. The CO2 reduction can be estimated using Equation (8) below.

3. Results

3.1. Crop Residue Potential in Côte d’Ivoire

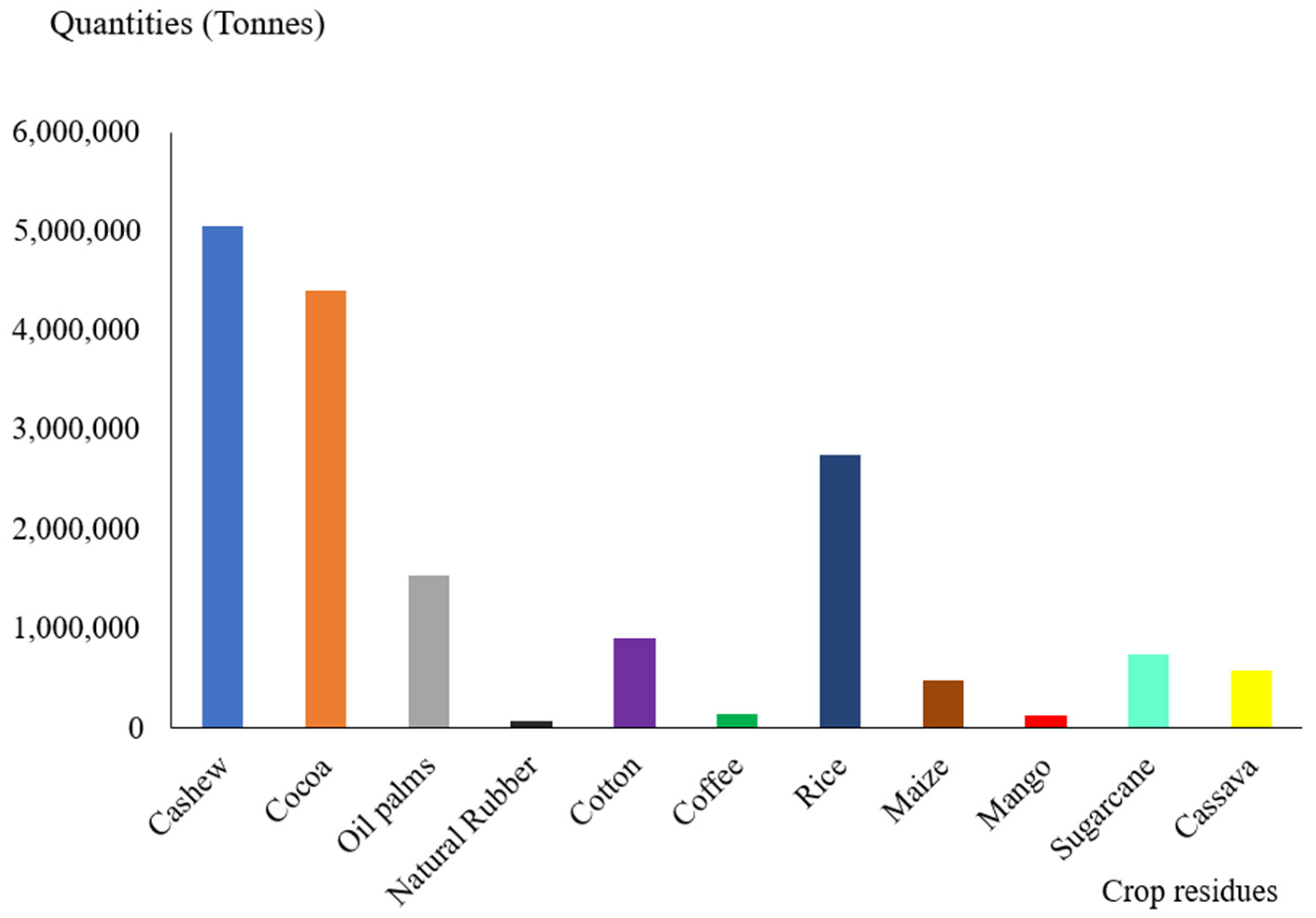

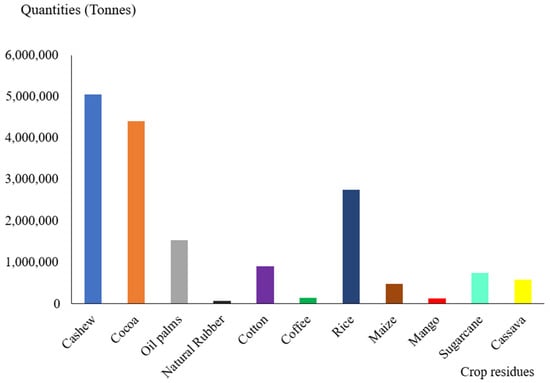

Côte d’Ivoire has achieved world records in agriculture thanks to its strong agricultural diversity. For instance, it is the world’s largest producer of cocoa and cashew nuts and the fifth-largest producer of palm oil, becoming the second-largest African producer. In addition, statistics have shown that the country is the world’s seventh-largest producer of natural rubber, ranking number one in Africa. According to the Organization for Economic Co-operation and Development [28], Côte d’Ivoire is the fourth African cotton producer and has a significant amount of crop residues, some of which are shown in Figure 2 below.

Figure 2.

Picture of some crop residues in Côte d’Ivoire.

The total amount of crop residues is evaluated at 16,801,306 tons. The cocoa sector has a huge potential for residues: cocoa production was estimated at 2.18 million tons in 2019–2020, and, as a result, Côte d’Ivoire generated approximately 15 million tons of wet pods, equivalent to 4.36 million tons of dry pods or 26.21% of all the crop residues considered in this study. Besides cocoa pods, there were also 43,760 tons of cocoa shells available in a few small local industries [29]. Regarding cashews, several residues are generated from this sector, with the apple unquestionably being the greatest portion of the fruit in terms of volume and mass, accounting for approximately 80% of the total weight. In 2019, the amount of cashew residues was estimated at 5,049,000 tons, including its apples (5,000,000 tons) and shells (49,000 tons), accounting for 30.05% of all residues. These values have widely increased, reaching an outstanding record. For instance, in 2022 alone, 1,028,172 tons of cashew nuts were recorded, and as Guehi et al. [30] have shown, cashew apples account for 9 to 10 times the weight of the nuts, about 9 to 10 million tons of cashew apples were generated.

Rice straw amounted to 2,118,610 tons, in addition to its husks and brans, measuring about 423,722 tons and 211,861 tons, respectively. It represented about 16.39% of all residues. Oil palm had residues like empty palm bunches, which accounted for 1,542,000 tons or 9.18% of the total residues. The cotton residues were estimated at 900,000 tons (5.36%), and sugarcane (740,000 tons, 4.40%), cassava (588,000 tons, 3.50%), and maize (480,000 tons, 2.86%) were small compared to the other residue types because they are partly used for direct combustion or animal feed (mainly cassava). Conversely, coffee, mango, and natural rubber had very low residues, with 146,353 tons (0.87%), 133,000 tons (0.79%), and 65,000 tons (0.39%), respectively, as they are only specifically grown in certain regions and produce relatively less residue during their treatment. Figure 3 shows the share of crop residues in 2019.

Figure 3.

Côte d’Ivoire’s estimated quantities of crop residues (tons) in 2019.

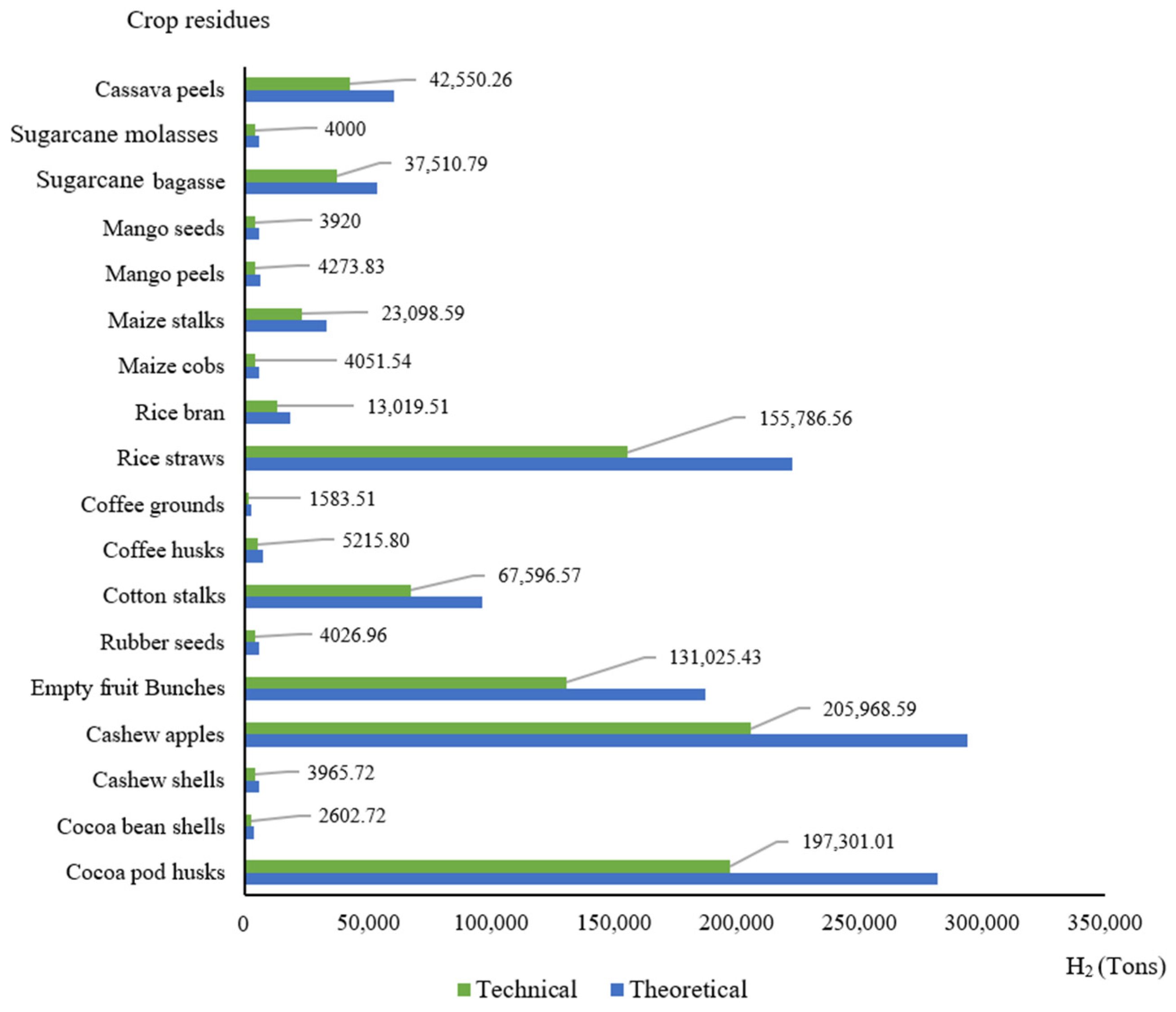

3.2. Hydrogen Potential

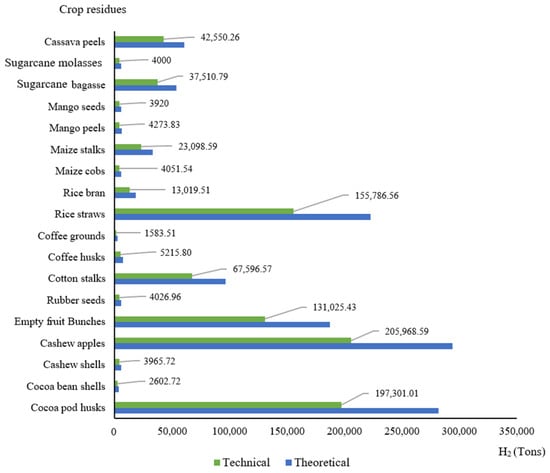

The various crop residue types used in this study presented huge hydrogen potential, estimated at 1,296,424.84 tons. Cashew apples had the greatest hydrogen potential, amounting to 294,240.84 tons, mainly because of the abundance of this underutilized resource in Côte d’Ivoire, coupled with the increase in cashew nut farms in recent years. Cocoa pod husks had 281,858.59 tons of hydrogen potential, while that of cashews or cocoa bean shells was substantially lower due to the country’s predominant practice of exporting crop products rather than processing them locally. The hydrogen potential of rice straw was 222,552.24 tons, slightly closer to that of cocoa pod husks and higher than that of palm oil’s empty fruit bunches, estimated at 187,179.19 tons. Furthermore, cotton stalks had a sizeable hydrogen potential of 96,566.52 tons, while cassava peels, sugarcane bagasse, and maize stalks contributed 60,786.08 tons, 53,586.84 tons, and 32,997.99 tons, respectively. Despite their small quantities, these crop residues remain valuable and can be used effectively. Meanwhile, other residues, such as sugarcane molasses, mango peels and seeds, maize cobs, rice bran, coffee grounds and husks, and rubber seeds, exhibited a much lower potential for hydrogen due to their limited quantity.

Considering a conversion efficiency of 70% for both gasification and dark fermentation [31], the technical hydrogen potential calculated from the above data stands at 907,497.39 tons, a figure that reflects a more feasible estimate than the theoretical potential. However, it is important to note that, in practical applications, this potential may be diminished due to various operational conditions, parameters, and losses incurred during the process. Figure 4 shows the theoretical and technical hydrogen potential of each crop residue.

Figure 4.

Technical and theoretical hydrogen potential from crop residues (tons).

4. Discussion

4.1. Strategy for Crop Residue Management

Currently, Côte d’Ivoire lacks an effective framework for managing crop leftovers. Several barriers prevent efficient waste management, including inadequate stakeholder participation, insufficient research on farm waste management, the absence of appropriate residue disposal sites, and a scarcity of knowledge and labor. Different stages are involved in the process of overcoming these problems and enabling the hydrogen-producing sectors to operate effectively at the time of implementation.

4.1.1. Stage 1: Stakeholder Engagement

The participation of various stakeholders such as rural communities, farmers, crop residue-processing industries, research institutions, the Ministry of Agriculture and Rural Development, the Ministry of Environment and Sustainable Development, and private sectors is essential. To effectively manage agricultural residues through an appropriate collection approach, all parties need to work together to emphasize the importance of adopting best practices. To guarantee stakeholders’ meaningful engagement, communication channels must be established, such as online platforms, surveys, forums, seminars, awareness campaigns, one-on-one meetings with farmers, radio and television advertisements, and information dissemination via social media. However, delegates should personally meet rural dwellers lacking regular access to communication tools such as the Internet and smartphones to promote awareness and provide the required communication facilities. This inclusive and transparent approach will promote collective accountability and the active participation of all stakeholders. It is also critical to encourage teamwork and build partnerships. Subsidies, including financial and technical support, should be made available to farmers and private organizations participating in residue-management projects.

4.1.2. Stage 2: Education and Training

To overcome the lack of information amongst most farmers, farmer education and training programs focused on proper crop-waste handling and collecting procedures, as well as the numerous advantages of residue collection, are vital. These programs should attempt to provide information on appropriate residue separation and packing processes to assure the quality and viability of the collected waste. It is also critical for trained persons (farmers, groups of people, etc.) to train others. The creation of mobile software applications that incorporate local dialects and French is critical to improving accessibility and convenience, as these programs would allow farmers to attend crop residue management courses on their smartphones at any time and from any location. Furthermore, to effectively reach a large audience, it is important to broadcast television programs on waste management hosted by specialists in the field in both French and the local dialects. Farmers should also be encouraged to learn how to use digital technologies such as drones, FarmLogs, ArcGIS, and QGIS, which could assist them in tracking and mapping agricultural waste generation, storage, and disposal sites.

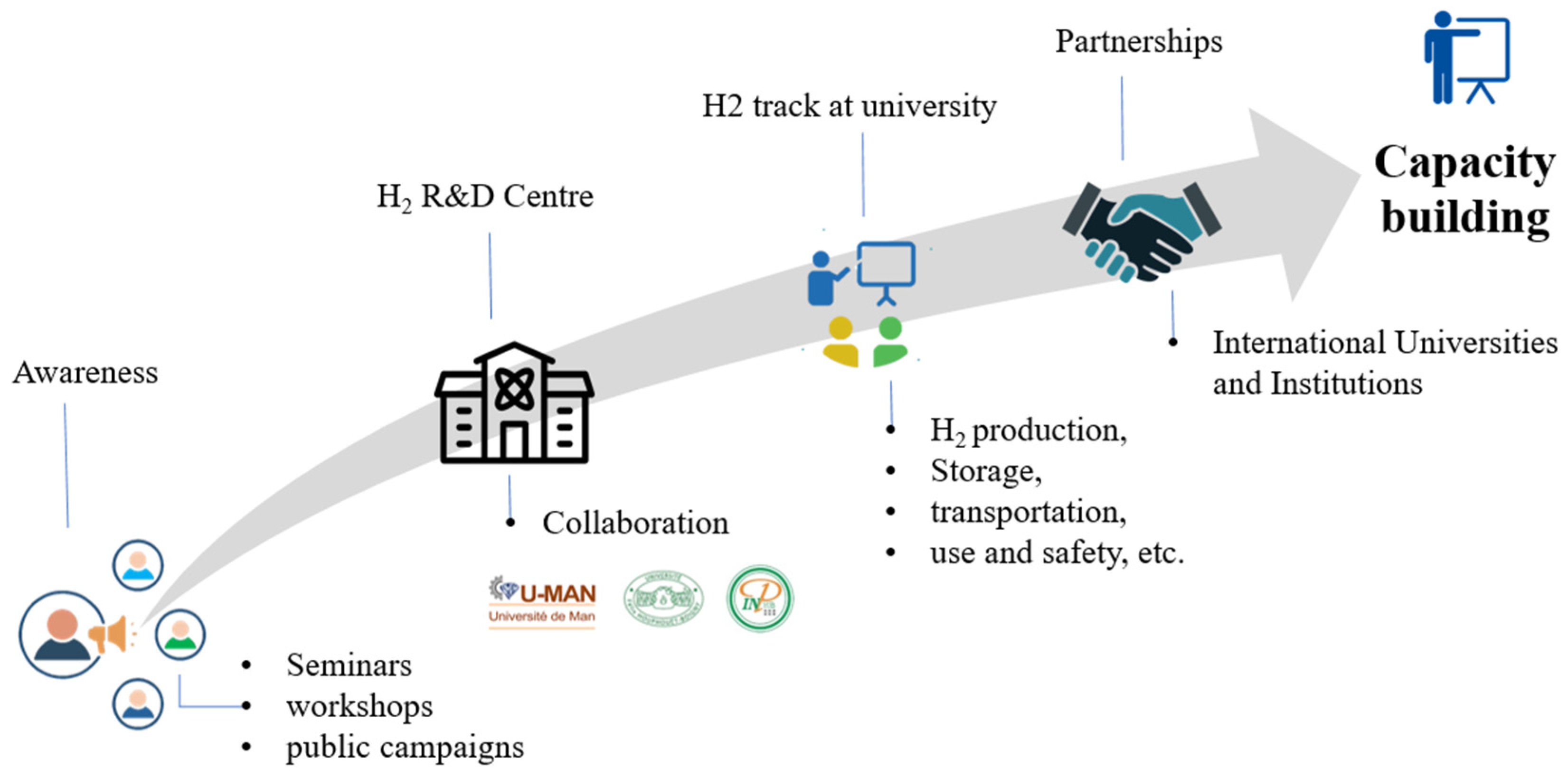

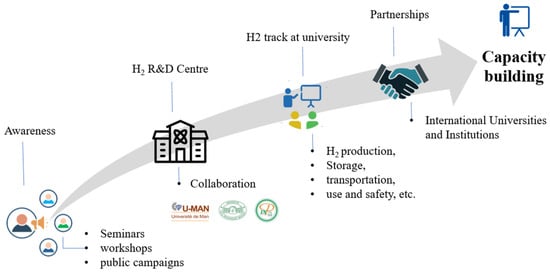

4.1.3. Stage 3: Capacity Building Strategy

Capacity development in the hydrogen field will address the lack of expertise and workforce in Côte d’Ivoire. To achieve this, it is first essential to promote awareness of hydrogen’s potential as an alternative energy carrier through seminars, workshops, and public campaigns. The public, educational institutions, NGOs, and industries must be mobilized to understand the importance of hydrogen and its applications, targeting high schools, colleges, universities, and energy companies. Afterward, the Hydrogen Research and Development Centre (HRDC) must be established to collaborate with universities such as the Félix Houphouet‒Boigny University in Abidjan, the University of Man, and many others. The Yamoussoukro Engineering School, which is implicated in scientific research and trains the country’s elites, must also be strongly involved. This would indeed encourage the development of hydrogen technologies. This center must also offer training programs and internships. By bridging the gap between academia and practical applications, industry experts could offer real-world insights and advice to students and researchers. Moreover, to facilitate the development of hydrogen, the universities mentioned must also integrate a specialized hydrogen track in their programs, thus ensuring that students receive comprehensive education and specific training on hydrogen technologies. This program should include courses on hydrogen production, storage, transportation, use, and safety. In addition, partnerships should be established between Ivorian universities and reputable institutions abroad, such as European, American, and Asian universities and industries that have expertise in hydrogen technologies. This collaboration will boost knowledge transfer and joint research projects, exposing students and researchers to international best practices and cutting-edge advances in the field. More importantly, the government must provide scholarships or funding opportunities for deserving students to pursue graduate studies or research in hydrogen-related disciplines abroad. This investment in human capacity would allow students to acquire in-depth knowledge and practical experience that they could bring back, contributing to the development of the hydrogen sector in Côte d’Ivoire (see Figure 5).

Figure 5.

Different steps for capacity building.

4.1.4. Stage 4: Development of the System for Collecting, Storing, and Transporting Crop Residues

The strategic location of an appropriate number of collection points near agricultural areas in some regions of Côte d’Ivoire will allow farmers to access these facilities easily to deposit crop residues. To prevent hazardous effects, appropriate collection equipment, such as personal protection equipment, must be provided. In addition, collection machines such as balers and forage harvesters are needed to efficiently gather and process crop residues by cutting, shredding, and baling them into manageable sizes, facilitating easier storage and transport. The construction of suitable storage facilities catering to the different crop residue types on-site is necessary. These facilities should be designed to maintain the residues’ quality while taking into account adequate ventilation, moisture control mechanisms, and fire-prevention measures during construction. After collecting and gathering the residues, a well-designed transportation system that effectively transports them from the collection point to the designated hydrogen plants must be established, minimizing transportation time and costs. Equipment such as loaders, conveyors, or trailers should be employed to safely and efficiently load, unload, and transport the residues from the field to the storage facilities or hydrogen-production sites.

4.2. Scenarios Based on Hydrogen Development in the Côte d’Ivoire

Scenarios are data-driven cases that help understand the implementation aspect of a strategy. Here, three different scenarios are explored, each considering the entire process, from hydrogen production to its end-use, in Côte d’Ivoire. The transport, industrial, agricultural, and electricity-generation sectors are specifically considered in these scenarios, and hydrogen allocation is determined based on product utilization as either energy or as chemical fertilizer.

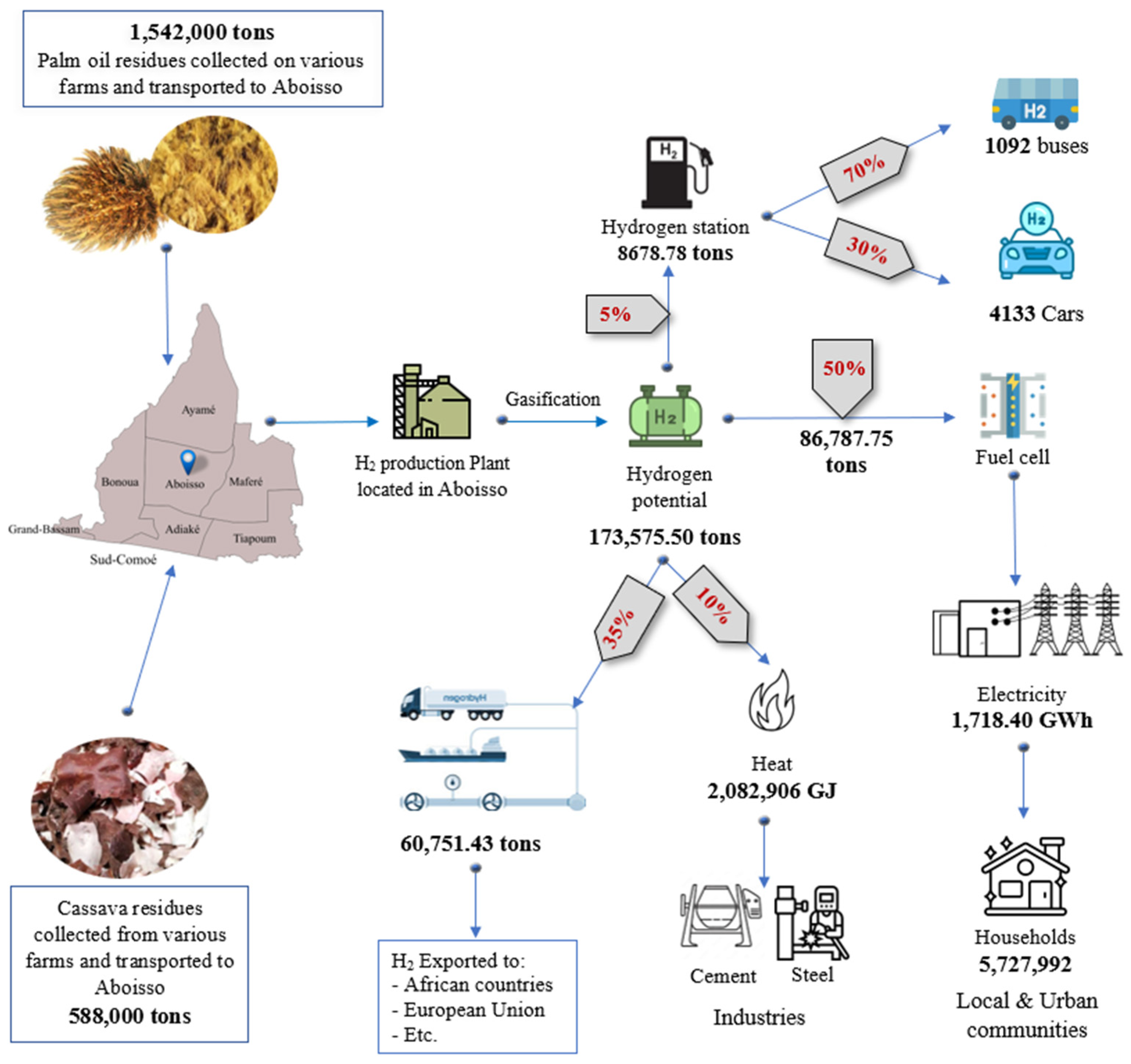

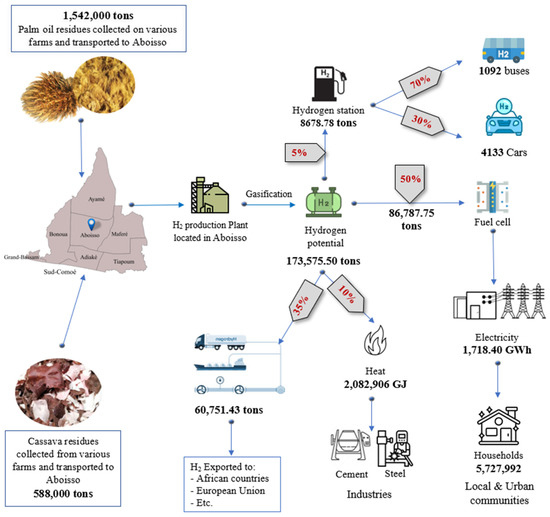

4.2.1. Scenario A: Hydrogen Production from Palm Oil and Cassava Residues

In this first scenario, 1,542,000 tons of palm-oil residues and 588,000 tons of cassava residues are collected from various farms and transported to Aboisso (A town in the south-east), in the Sud Comoé region, where the hydrogen plant is assumed to be located based on the availability of large quantities of palm oil residues. Through the gasification process, 173,575.50 tons of hydrogen is generated. A total of 5% of the total hydrogen produced is used in the transport sector, amounting to 8678.78 tons used in hydrogen stations to power 1092 buses and 4133 cars, a considerable amount considering the low percentage assigned to this sector. On the other hand, the electricity sector, receiving 50% (86,787.75 tons) of the available hydrogen, is supposed to supply 5,727,992 local and urban communities with 1718.40 gigawatt-hours over one year, allowing non-electrified areas in the country to have access to electricity. Furthermore, 2,082,906 gigajoules of heat are generated from 10% of the total hydrogen to power industries, therefore contributing to the decarbonization of the industrial sectors in Côte d’Ivoire. Various European nations and some African countries currently relying on Russian gas are grappling with the acute shortages stemming from the devastating conflict between Russia and Ukraine. Consequently, the exportation of 35% of the total hydrogen, encompassing an impressive 60,751.43 tons, would not only ameliorate this energy crisis but concurrently contribute to the substantial growth of Côte d’Ivoire’s gross domestic product (GDP). Hydrogen exportation can be effectively executed via various means, such as ships, pipelines, or extensive vehicular transport. A visual depiction of this scenario is provided in Figure 6.

Figure 6.

Schematic diagram of the different steps of scenario A.

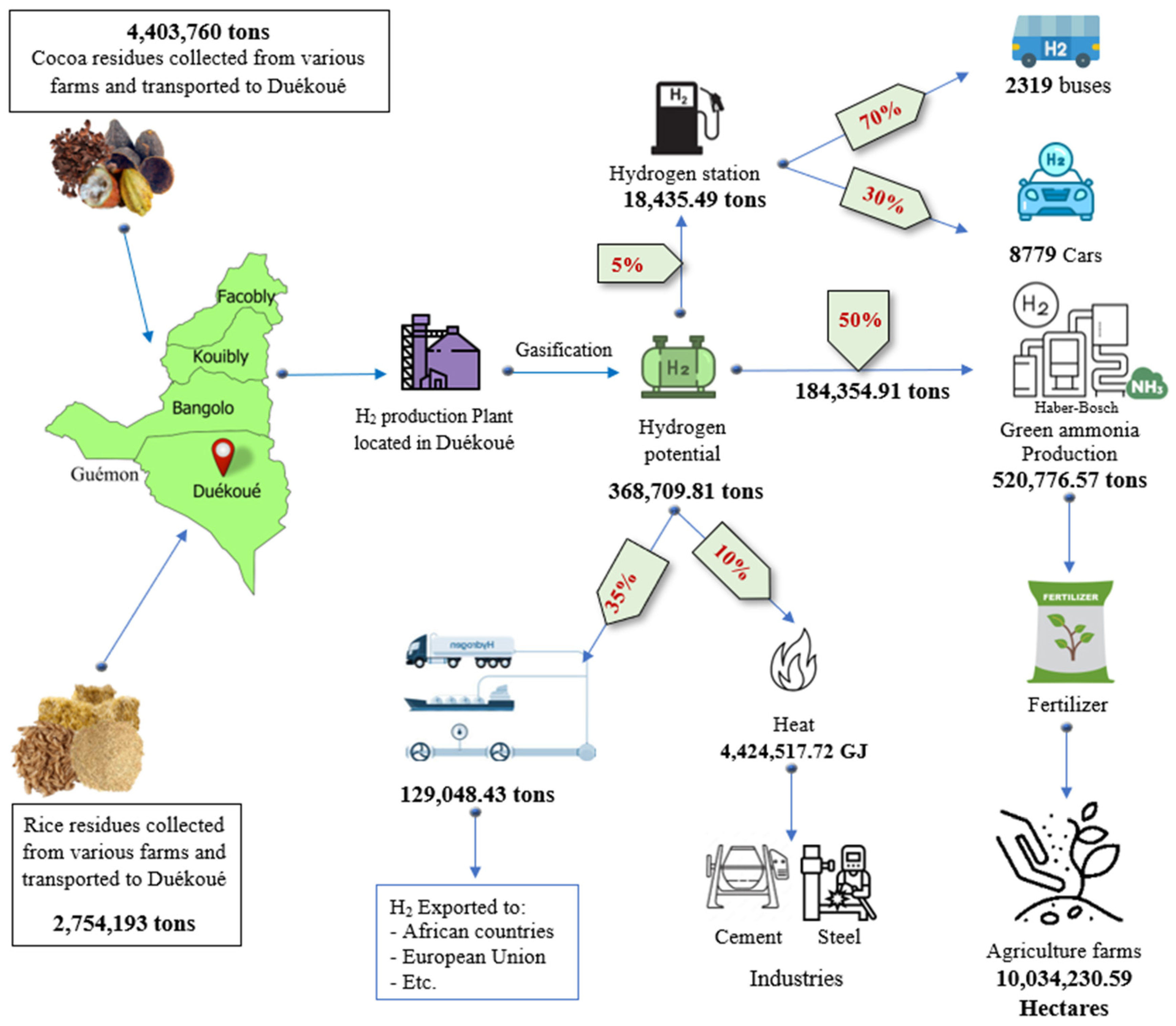

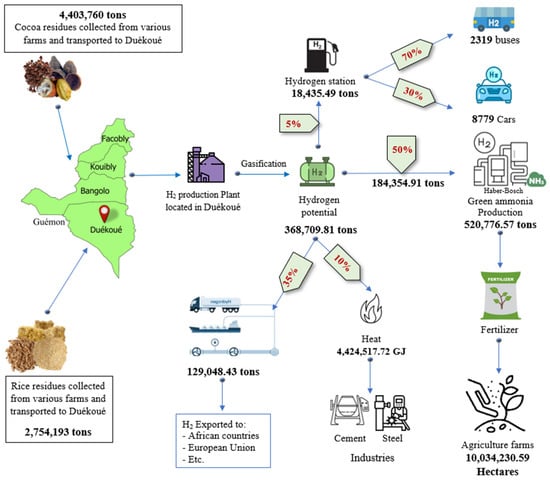

4.2.2. Scenario B: Hydrogen Production from Rice and Cocoa Residues

For this scenario (see Figure 7), 4,403,760 tons of cocoa residues and 2,754,193 tons of rice residues are procured from various agricultural farms and subsequently conveyed to Duékoué, a town situated within the Guémon region (Western) in Côte d’Ivoire, due to the huge amount of cassava and cocoa residues generated each year in this area. The application of the gasification process facilitates the generation of an impressive 368,709.81 tons of hydrogen, which is twice as high as in the first scenario. With a specific focus on the transportation sector, a mere 5% effectively energizes a fleet of 2319 buses and 8779 cars. Meanwhile, in terms of fertilizer provision, a significant portion of hydrogen resources (50%), amounting to 184,354.91 tons, is allocated to the agricultural sector, providing a remarkable 520,776.57 tons of green ammonia, with the potential to greatly benefit a large number of farms. Considering the utilization of fertilizers per unit of arable land (51.9 kg/hectare) in 2020, 10,034,230.59 hectares are estimated to have access in this scenario. Therefore, this could reduce Côte d’Ivoire’s dependence on imported chemical fertilizers from Russia, Morocco, etc. In addition, Côte d’Ivoire could become a fertilizer exporter nation in Africa. At the same time, up to 4,424,517.72 gigajoules of heat from 10% of hydrogen can be used in the industrial sector. As heat is an essential form of energy used in various industrial processes, such as manufacturing and refining, the availability of such an important heat source can provide numerous benefits to industries, including increased productivity and efficiency and reduced reliance on conventional energy sources. The amount of hydrogen that could be internationally exported is 129,048.43 tons—a significant quantity that could replace a large bulk of fossil energy. Hydrogen has gained attention in European nations as a clean and versatile energy carrier with various applications, including transportation, power generation, and industrial processes. The exportation of such a considerable quantity of hydrogen would enhance the transition to green energy. This scenario is the most promising of the three.

Figure 7.

Schematic diagram of the different steps of scenario B.

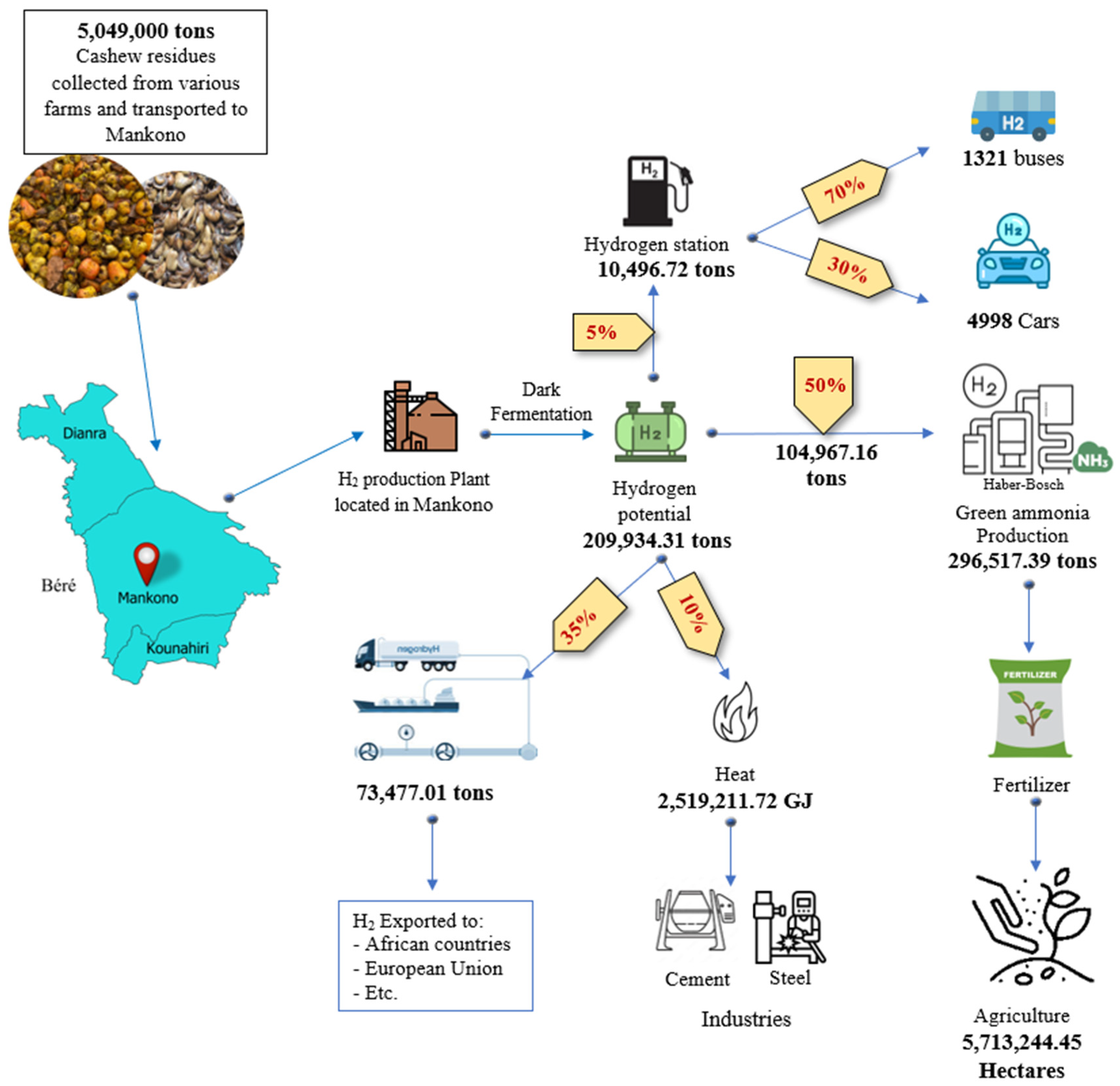

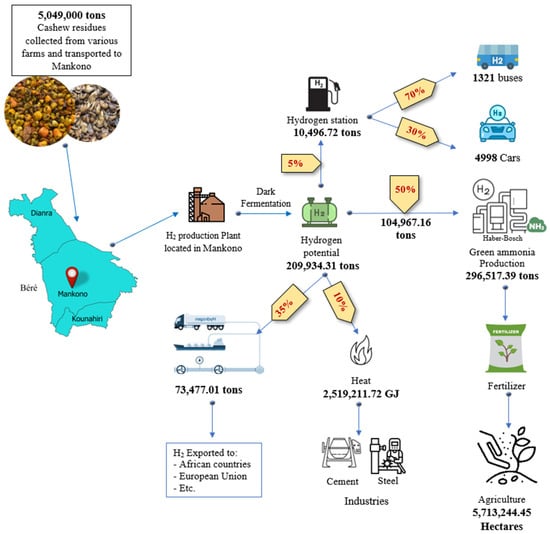

4.2.3. Scenario C: Hydrogen Production from Cashew Residues

Contrary to the two situations above, this scenario focuses on the use of wet biomass, particularly cashew apples, whereby the suitable conversion method is dark fermentation. In this scenario, we planned to establish a hydrogen factory near the farms in Mankono, located in the region of Béré, in the north of the country, where there is a huge potential for cashew nuts. Approximately 5,049,000 tons of cashew-nut residues will be transported from agricultural fields and local industries to the plant, as cashew apples are subject to rapid decomposition. This process has the potential to produce 209,934.31 tons of hydrogen. Fifty percent of this could provide 296,517.39 tons of green ammonia fertilizer and supply 5,713,244.45 hectares of arable land. Adding this yield to the second scenario will increase the fertilizer supply to 817,293.95 tons per year, supplying a considerable amount of arable land (15,747,475.04 hectares). Fertilization improves plant nutrition and crop quality, promotes plant growth, and ultimately maintains and even enhances soil fertility. Ammonia is extremely effective in providing nitrogen to the soil to improve crop yields. Additionally, in this scenario, 1321 buses and 4998 cars could benefit from 10,496.72 tons of hydrogen, while approximately 2,519,211.72 gigajoules of heat supply could be obtained from the 10% dedicated to the industrial sector. Moreover, under this scenario, a maximum of 73,477.01 tons of hydrogen could be exported internationally (see Figure 8). It is important to note that while these scenarios hold great opportunities, their implementation would require careful planning, coordination, and investment in infrastructure and technology. These considerations should include hydrogen storage, safety measures, and market demand, while environmental considerations and sustainability practices should be incorporated for long-term sustainability and positive impact.

Figure 8.

Schematic diagram of the different steps of scenario C.

4.3. Scenarios’ Impact

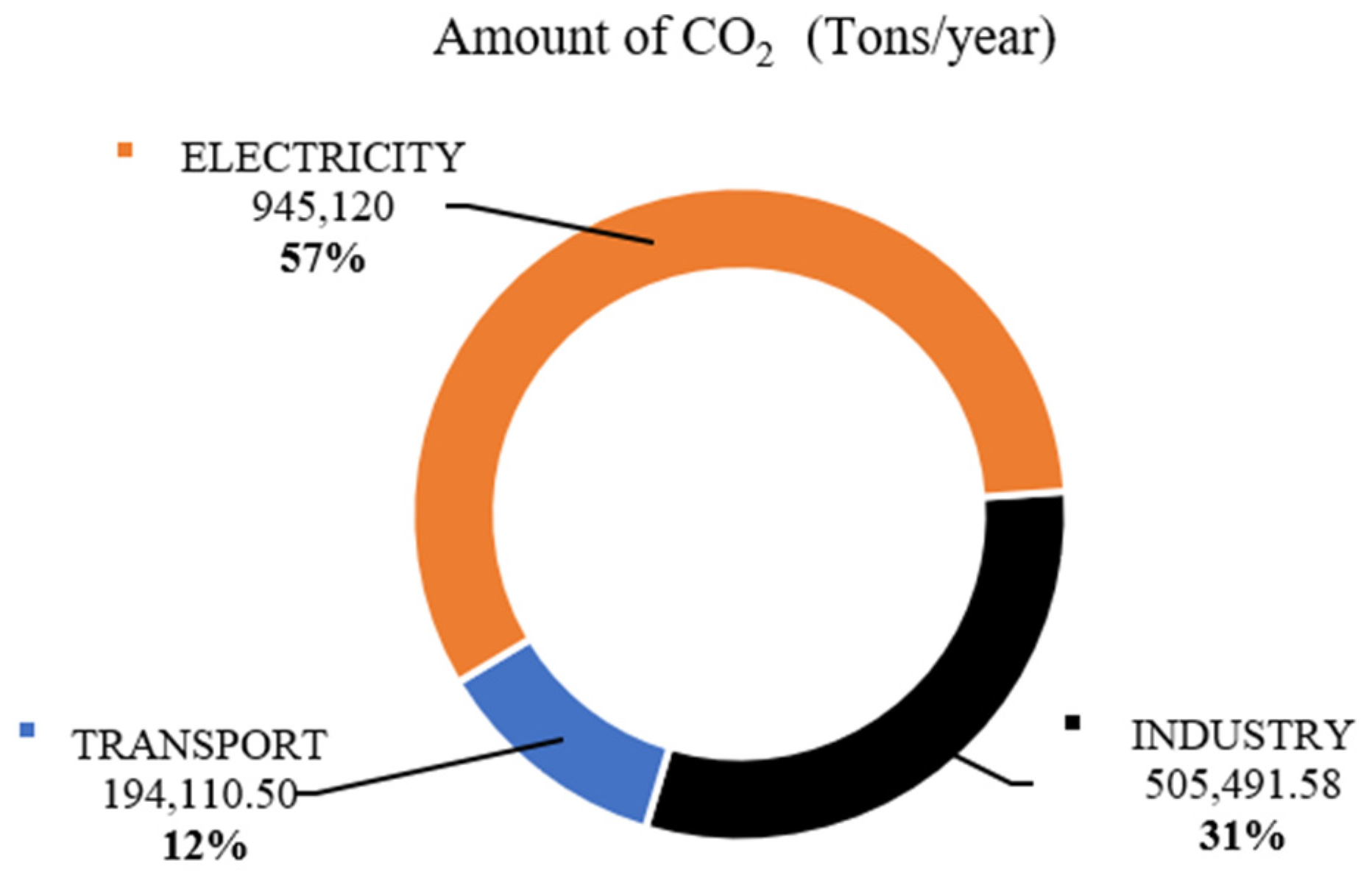

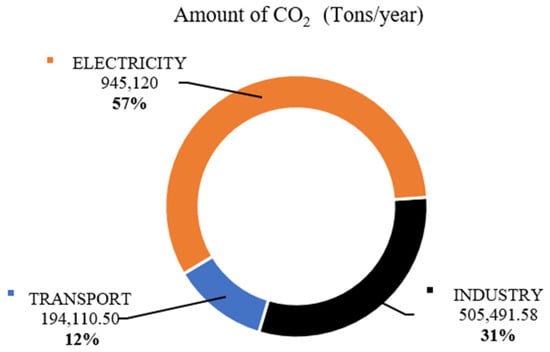

The three scenarios have a positive impact on the environment, the economy, and society. In Côte d’Ivoire, most vehicles are older than 10 years, thereby increasing greenhouse gas emissions and increasing air pollution because of incompletely burnt fuel [32]. Assuming the amount of hydrogen to be equivalent to gasoline (1 kg H2 equal to 2.8 kg gasoline) for small vehicles and diesel (1 kg H2 equal to 2.79 kg diesel) for buses [33], an overall 194,110.50 tons of CO2 emission could be reduced yearly, with the scenarios (A, B, and C) accounting for 44,794.47 tons, 95,133.56 tons, and 54,182.46 tons, respectively. This would decarbonize the transport sector by up to 12%, resulting in climate-change mitigation, air-quality improvement, public health enhancement, and environmental benefits. At the same time, CO2 emissions in the electricity sector will be greatly reduced, with the first scenario providing 50% of the total hydrogen produced, allowing for a yearly 945,120 tons CO2 reduction and, thus, 57% decarbonization. This will not only reduce dependence on fossil fuels but also boost renewable energy integration to 42.92% (if only 14% of electricity comes from hydrogen), nearing the government’s target of 45% by 2030. In addition, increasing hydrogen use in the electricity sector will increase income while decreasing poverty and improving education, thus promoting sustainable development.

The hard-to-debate industrial sector is positively impacted in the three scenarios. Indeed, supplying heat from hydrogen will replace fossil energy and mitigate up to 505,491.58 tons of CO2 emissions: 116,642.74 tons, 247,772.99 tons, and 141,075.86 tons for scenarios A, B, and C, respectively. This CO2 reduction will lead to 31% decarbonization. Considering that Côte d’Ivoire currently emits around 14.5 million tons of CO2, the implementation of this strategy would result in a substantial annual carbon-dioxide emission reduction of 11.34%, highlighting the significant impact that these measures can have on CO2 mitigation and the promotion of sustainable practices. Regarding the economic aspect, the production cost of renewable hydrogen in Africa is cheaper compared to Europe. Kalinci et al. [34] investigated three different gasifiers for hydrogen production, namely the downdraft, circulating fluidized bed, and plasma gasifiers. Their study reported production costs per unit mass of 1.16 USD/kg, 3.33 USD/kg, and 2.45 USD/kg, respectively. Considering circulating fluidized bed gasifiers’ cost, the production cost of scenarios A and B could be estimated at USD 578,006,415 and USD 1,227,803,667, respectively, meaning that hydrogen could be produced entirely in Côte d’Ivoire, with a lot of effort. Additionally, exporting hydrogen will stimulate the country’s economy. More importantly, according to the Ivorian Ministry of Economy and Finance, in 2021, the imported fertilizer cost was EUR 107 million for 357,179 tons. By comparing this with the green fertilizer production in the scenarios, up to 817,293.95 tons of fertilizers could be generated and, considering the local selling price (USD 22.33 per kilogram of fertilizer), up to USD 18,250,173.9 could be earned per year, making the country independent of imported fertilizers and increasing crop productivity. All these scenarios would provide many employment opportunities to the younger generation coping with unemployment. The diagram (see Figure 9) shows the carbon reduction in each sector’s electricity supply by source, following the scenarios:

Figure 9.

Possible reduction of carbon dioxide (CO2) emissions in three sectors under the scenarios.

5. Conclusions

In this work, strategies are illustrated for hydrogen development in Côte d’Ivoire. This study focused primarily on assessing crop residues’ potential and the amount of hydrogen that could be produced. Scenarios were developed to highlight the strategies needed to build hydrogen industries and the sectors that would have a high hydrogen demand.

The approach used in this study was theoretical. The results reveal that Côte d’Ivoire generated, in 2019, up to 16,801,306 tons of crop residues from 11 types of crops. This considerable amount has a theoretical hydrogen potential of 1,296,424.84 tons and could technically produce up to 907,497.39 tons of hydrogen per year. To achieve this, this study emphasized the adoption of a crop-waste-management strategy that comprised stakeholder involvement and farmer training, followed by a strategy for capacity building to gain a highly skilled workforce. The three proposed scenarios demonstrated a significant impact. In these scenarios, Ivorian industries could be supplied with 9,026,635 gigajoules of heat, and up to 17,910 cars and 4732 buses could run on hydrogen. The agricultural sector could receive up to 817,293.95 tons of green ammonia, which could be used on 15,747,475.04 hectares of arable land. In addition, the electricity sector could be positively impacted by supplying electricity to approximately 5,727,992 households, with an annual production of 1718.40 gigawatt-hours. Thus, up to 1,644,722.08 tons of CO2 could be reduced across various sectors, as follows: 12% in transport, 31% in industry, and 57% in the electricity sector. Additionally, there would be the possibility of exporting 263,276.87 tons of hydrogen to other countries.

This research highlights the benefits of valorizing crop residues and demonstrates the significant impact of hydrogen in various sectors. According to the findings of this study, there are potential crop residues that could be converted to hydrogen, offering a promising solution for the future. However, the lack of public awareness regarding residue use, funding for crop-residue management, and government policies and regulations presents a major challenge.

It is, therefore, imperative to conduct in-depth experimental studies to address key technical, economic, and political considerations and assess the feasibility and scalability of the results. By leveraging its abundant agricultural resources, Côte d’Ivoire can become a leader in the transition to a cleaner and more resilient energy future.

Author Contributions

Conceptualization, K.J.H.A. and S.N.; methodology, K.J.H.A. and V.S.; resources, K.J.H.A., Y.N., S.N. and V.S.; writing—original draft preparation, K.J.H.A.; writing—review and editing, K.J.H.A. and Y.N.; supervision, Y.N. and S.N.; and project administration, Y.N. and S.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry of Education and Research (BMBF) and West African Science Service Centre on Climate Change and Adapted Land Use (Wascal) under the funding number: 03SF0626D. Meanwhile, the publication was funded by the Regional Centre of Excellence for Electricity Management, Togo (CERME) with the funding number: IDA 6512-TG.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

New data for hydrogen potential was created from existing data.

Acknowledgments

We express our gratitude and thanks to WASCAL for launching this outstanding green hydrogen research project.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- IRENA. World Energy Transitions Outlook 2023: 1.5 °C Pathway; International Renewable Energy Agency: Masdar City, Abu Dhabi, 2023; Available online: https://www.irena.org/publications/2023/Jun/World-Energy-Transitions-Outlook-2023 (accessed on 1 July 2023).

- Dhakal, S.; Minx, J.C.; Toth, F.L.; Abdel-Aziz, A.; Meza, M.J.F.; Hubacek, K.; Jonckheere, I.G.C.; Kim, Y.-G.; Nemet, G.F.; Pachauri, S.; et al. Emissions Trends and Drivers. In IPCC, 2022: Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Abbass, K.; Qasim, M.Z.; Song, H.; Murshed, M.; Mahmood, H.; Younis, I. A Review of the Global Climate Change Impacts, Adaptation, and Sustainable Mitigation Measures. Environ. Sci. Pollut. Res. 2022, 29, 42539–42559. [Google Scholar] [CrossRef] [PubMed]

- Feliciano, D.; Recha, J.; Ambaw, G.; MacSween, K.; Solomon, D.; Wollenberg, E. Assessment of Agricultural Emissions, Climate Change Mitigation and Adaptation Practices in Ethiopia. Clim. Policy 2022, 22, 427–444. [Google Scholar] [CrossRef]

- Leal Filho, W.; Azeiteiro, U.M.; Balogun, A.-L.; Setti, A.F.F.; Mucova, S.A.R.; Ayal, D.; Totin, E.; Lydia, A.M.; Kalaba, F.K.; Oguge, N.O. The Influence of Ecosystems Services Depletion to Climate Change Adaptation Efforts in Africa. Sci. Total Environ. 2021, 779, 146414. [Google Scholar] [CrossRef] [PubMed]

- Riester, C.M.; García, G.; Alayo, N.; Tarancón, A.; Santos, D.M.F.; Torrell, M. Business Model Development for a High-Temperature (Co-)Electrolyser System. Fuels 2022, 3, 392–407. [Google Scholar] [CrossRef]

- IRENA. Energy-Transition Technology and Hydrogen Overview. 2022. Available online: https://www.irena.org/Energy-Transition/Technology/Hydrogen (accessed on 20 April 2023).

- Arcos, J.M.M.; Santos, D.M.F. The Hydrogen Color Spectrum: Techno-Economic Analysis of the Available Technologies for Hydrogen Production. Gases 2023, 3, 25–46. [Google Scholar] [CrossRef]

- H2 Atlas Africa. 2023. Available online: https://africa.h2atlas.de/ (accessed on 31 May 2024).

- Mukelabai, M.D.; Wijayantha, U.K.G.; Blanchard, R.E. Renewable Hydrogen Economy Outlook in Africa. Renew. Sustain. Energy Rev. 2022, 167, 112705. [Google Scholar] [CrossRef]

- Beaucamp, L.; Nforngwa, E. Green Hydrogen in Africa: Risks and Benefits. 2022. Available online: https://www.germanwatch.org/sites/default/files/germanwatch_green_hydrogen_in_africa_2022 (accessed on 4 June 2023).

- Klein, A.L. Mauritania: Africa’s Global Green Hydrogen Hub. 2023. Available online: https://energycapitalpower.com/mauritania-global-green-hydrogen-hub/ (accessed on 4 June 2023).

- Hollands, C. Top Green Hydrogen Projects Underway in Africa in 2023. 2023. Available online: https://energycapitalpower.com/top-green-hydrogen-projects-africa-in-2023/ (accessed on 5 June 2023).

- Kalak, T. Potential Use of Industrial Biomass Waste as a Sustainable Energy Source in the Future. Energies 2023, 16, 1783. [Google Scholar] [CrossRef]

- Zörb, C.; Lewandowski, I.; Kindervater, R.; Göttert, U.; Patzelt, D. Biobased Resources and Value Chains. In Bioeconomy; Lewandowski, I., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 75–95. [Google Scholar] [CrossRef]

- Kouassi, A.M.; Kouao, J.-M.; Kouakou, K.E. Caractérisation intra-annuelle de la variabilité climatique en Côte d’Ivoire. Bull. L’association Géographes Français. Géographies 2022, 99, 289–306. [Google Scholar] [CrossRef]

- Guero, M.; Drion, B.; Karsch, P. Study of the Biomass Potential in Côte d’Ivoire. 2021. Available online: https://www.rvo.nl/sites/default/files/2021/06/Study-of-the-biomass-potential-in-Cote-dIvoire.pdf (accessed on 19 July 2023).

- FAOSTAT. 2022. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 28 July 2023).

- Maitlo, G.; Ali, I.; Mangi, K.H.; Ali, S.; Maitlo, H.A.; Unar, I.N.; Pirzada, A.M. Thermochemical Conversion of Biomass for Syngas Production: Current Status and Future Trends. Sustainability 2022, 14, 2596. [Google Scholar] [CrossRef]

- Nelson, N.; Darkwa, J.; Calautit, J.; Worall, M.; Mokaya, R.; Adjei, E.; Kemausuor, F.; Ahiekpor, J. Potential of Bioenergy in Rural Ghana. Sustainability 2021, 13, 381. [Google Scholar] [CrossRef]

- Cárdenas, R.; Alfonso-Solar, D.; Peñalvo-López, E.; Vargas-Salgado, C.; Pérez-Navarro, A.; Chiñas-Palacios, C. Potential For Hydrogen Production from Biomass Residues in the Valencian Community. 2020. Available online: https://h2tools.org/bibliography/potential-hydrogen-production-biomass-residues-valencian-community-paper (accessed on 12 September 2023).

- Zagrodnik, R.; Seifert, K. Direct Fermentative Hydrogen Production from Cellulose and Starch with Mesophilic Bacterial Consortia. Pol. J. Microbiol. 2020, 69, 109–120. [Google Scholar] [CrossRef] [PubMed]

- Joode, D.; Johan, C. An Analysis of Energy Neutral Roads: A Case Study How to Produce Electricity and Hydrogen Using Thesurface Area of the A6 Highway in the Netherlands. 2022. Available online: https://www.diva-portal.org/smash/get/diva2:1694746/FULLTEXT01.pdf (accessed on 19 October 2023).

- US DOE. Hydrogen’s Role in Transportation. Available online: https://www.energy.gov/eere/vehicles/articles/hydrogens-role-transportation (accessed on 20 July 2023).

- Nekkers, R.; Ex, F.; van Beckhoven, J. Status Report 2BP. Hydrogen buses on theVeluwe. 2020. Available online: https://www.h2nodes.eu/images/docs/20200416_status_verslag_2BP_Hydrogen_buses_on_the_Veluwe_Eng_.pdf (accessed on 22 October 2023).

- Rivarolo, M.; Riveros-Godoy, G.; Magistri, L.; Massardo, A.F. Clean Hydrogen and Ammonia Synthesis in Paraguay from the Itaipu 14 GW Hydroelectric Plant. ChemEngineering 2019, 3, 87. [Google Scholar] [CrossRef]

- Suryati, I.; Hijriani, A.; Indrawan, I. Estimation of Greenhouse Gas Emission from Household Activities during the COVID-19 Pandemic in Binjai City, North Sumatera. IOP Conf. Ser. Earth Environ. Sci. 2021, 896, 012054. [Google Scholar] [CrossRef]

- OECD-FAO. OECD-FAO Agricultural Outlook 2022–2031; OECD-FAO Agricultural Outlook; OECD-FAO: Rome, Italy, 2022. [Google Scholar] [CrossRef]

- GIZ. Partnership Ready Côte d’Ivoire: Gestion et Recyclage des Déchets Organiques. 2020. Available online: https://www.giz.de/en/downloads/GBN_Sector%20Brief_CIV_Bioabfall_FR_Web.pdf (accessed on 30 October 2023).

- Guehi, M.S.; Abdoulaye, T.; Armel, F.Z.; Ahoussi, P.B.; Kouamé, R.N.; Naka, T.; Aka, F.K.; Ahmont, L.C.K.; Adama, C.G. Physicochemical and Nutritional Characterization of Flours from Cashew Apple, Kent Mango Peelings and Kernel Almonds Collected in Korhogo City (Northern Ivory Coast. GSC Biol. Pharm. Sci. 2023, 22, 048–055. [Google Scholar] [CrossRef]

- Holladay, J.D.; Hu, J.; King, D.L.; Wang, Y. An Overview of Hydrogen Production Technologies. Catal. Today 2009, 139, 244–260. [Google Scholar] [CrossRef]

- Doumbia, M.; Toure, N.; Silue, S.; Yoboue, V.; Diedhiou, A.; Hauhouot, C. Emissions from the Road Traffic of West African Cities: Assessment of Vehicle Fleet and Fuel Consumption. Energies 2018, 11, 2300. [Google Scholar] [CrossRef]

- Milojević, S. Reconstruction of Existing City Buses on Diesel Fuel for Drive on Hydrogen. 2016. Available online: https://www.researchgate.net/publication/313991475_RECONSTRUCTION_OF_EXISTING_CITY_BUSES_ON_DIESEL_FUEL_FOR_DRIVE_ON_HYDROGEN (accessed on 10 November 2023).

- Kalinci, Y.; Hepbasli, A.; Dincer, I. Exergoeconomic Analysis and Performance Assessment of Hydrogen and Power Production Using Different Gasification Systems. Fuel 2012, 102, 187–198. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).