Novel Flours from Neltuma affinis Fruit for Improving the Technological Quality and Alveolar Structure of Gluten-Free Bread †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

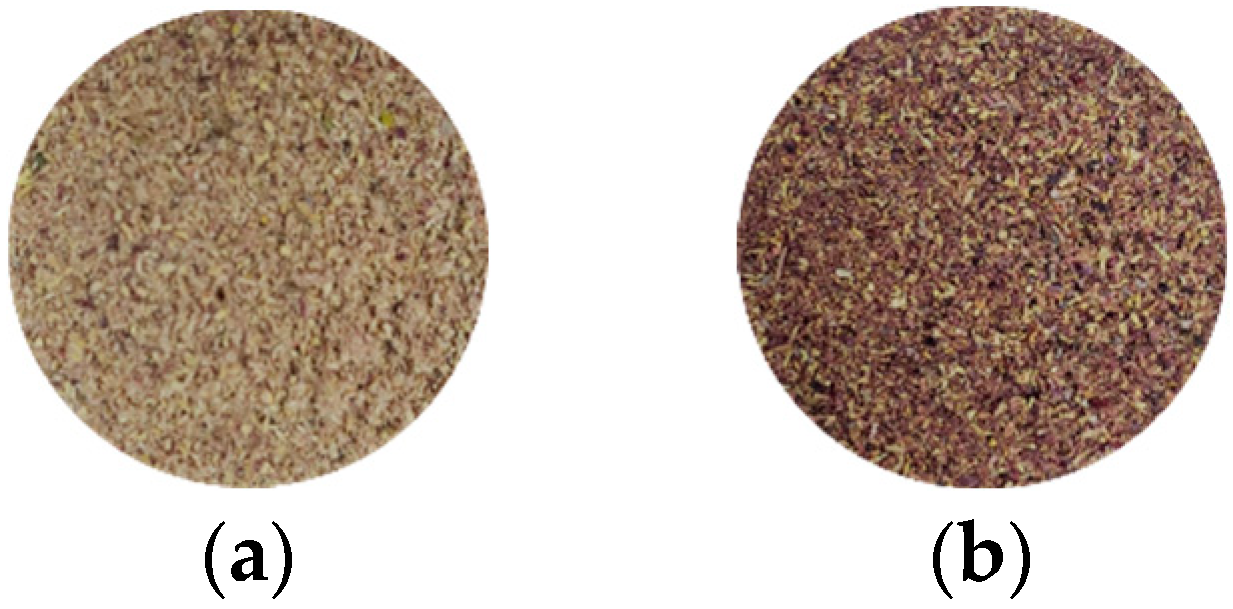

2.2. Obtaining Flour from the Fruit of Neltuma affinis

2.3. Process of Making GF Breads

2.4. Determination of Optimum Fermentation Times (OFT)

2.5. Physicochemical Characterization of GF Breads

2.6. Experimental Design and Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Circular Economy. 2020. Available online: https://www.un.org/sustainabledevelopment/sustainable-consumption-production/ (accessed on 24 April 2022).

- Ojeda, L.; Genevois, C.E.; Busch, V. Novel flours from leguminosae (Neltuma ruscifolia) pods for technological improvement and nutritional enrichment of wheat bread. Heliyon 2023, 9, e17774. [Google Scholar] [CrossRef] [PubMed]

- Genevois, C.E.; de Escalada Pla, M.F. Soybean by-products and modified cassava starch for improving alveolar structure and quality characteristics of gluten-free bread. Eur. Food Res. Technol. 2021, 247, 1477–1488. [Google Scholar] [CrossRef]

- Ammar, I.; Sebii, H.; Aloui, T.; Attia, H.; Hadrich, B.; Felfoul, I. Optimization of a novel. gluten-free bread’s formulation based on chickpea. carob and rice flours using response surface design. Heliyon 2022, 8, e12164. [Google Scholar] [CrossRef] [PubMed]

- Tsatsaragkou, K.; Gounaropoulos, G.; Mandala, I. Development of gluten free bread containing carob flour and resistant starch. LWT 2014, 58, 124–129. [Google Scholar] [CrossRef]

| Systems | Independent Variables | Dependent Variables | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ES 1 | EM 2 | WH 3 | L 4 | a* 5 | b* 6 | pH | CS 7 | CD 8 | |

| 1 * | 10 | 10 | 115 | 44.31 ± 0.57 d | 16.33 ± 0.36 fg | 11.52 ± 0.28 f | 4.21 ± 0.02 abc | 0.81 ± 0.07 cde | 0.16 ± 0.01 bc |

| 2 | 20 | 0 | 115 | 52.81 ± 0.59 g | 9.43 ± 0.81 c | 20.05 ± 0.70 i | 4.39 ± 0.02 cd | 0.87 ± 0.11 e | 0.08 ± 0.01 a |

| 3 | 0 | 10 | 160 | 46.65 ± 0.75 ef | 13.43 ± 0.35 d | 7.63 ± 0.25 abc | 4.31 ± 0.02 bc | 0.77 ± 0.01 cde | 0.07 ± 0.03 ab |

| 4 | 20 | 10 | 160 | 44.34 ± 1.14 d | 17.37 ± 0.16 h | 13.05 ± 0.43 g | 4.10 ± 0.00 abc | 0.72 ± 0.04 bcd | 0.15 ± 0.05 bc |

| 5 | 10 | 20 | 160 | 36.48 ± 1.06 ab | 19.57 ± 0.80 i | 8.17 ± 0.55 bcd | 4.03 ± 0.06 ab | 0.69 ± 0.03 bc | 0.14 ± 0.01 abc |

| 6 | 10 | 0 | 160 | 65.05 ± 0.02 h | 4.97 ± 0.13 b | 18.14 ± 0.23 h | 4.81 ± 0.02 e | 0.85 ± 0.02 de | 0.12 ± 0.03 abc |

| 7 * | 10 | 10 | 115 | 44.12 ± 0.43 d | 16.15 ± 0.31 fg | 11.24 ± 0.54 f | 4.20 ± 0.00 abc | 0.77 ± 0.10 cde | 0.14 ± 0.04 abc |

| 8 | 0 | 20 | 115 | 36.72 ± 0.79 b | 19.90 ± 0.28 i | 6.83 ± 0.25 a | 4.08 ± 0.02 c | 0.63 ± 0.04 b | 0.15 ± 0.01 abc |

| 9 | 20 | 20 | 115 | 33.83 ± 0.77 a | 19.64 ± 0.40 i | 10.04 ± 0.44 e | 3.99 ± 0.02 a | 0.71 ± 0.08 bc | 0.18 ± 0.02 c |

| 10 | 10 | 20 | 70 | 41.60 ± 0.34 c | 16.54 ± 0.17 g | 8.41 ± 0.25 cd | 4.03 ± 0.06 ab | 0.25 ± 0.09 a | 1.26 ± 0.06 f |

| 11 | 0 | 10 | 70 | 48.74 ± 0.67 f | 13.69 ± 0.25 d | 8.72 ± 0.10 d | 4.31 ± 0.04 bc | 0.27 ± 0.01 b | 1.16 ± 0.10 e |

| 12 | 10 | 0 | 70 | 68.82 ± 0.01 i | 4.99 ± 0.32 b | 19.44 ± 0.33 i | 4.82 ± 0.04 e | 0.21 ± 0.01 a | 1.23 ± 0.03 f |

| 13 | 0 | 0 | 115 | 77.16 ± 2.39 j | -1.38 ± 0.05 a | 7.43 ± 0.55 ab | 5.29 ± 0.02 f | 0.62 ± 0.11 b | 0.13 ± 0.02 abc |

| 14 | 20 | 10 | 70 | 45.90 ± 0.54 d | 15.17 ± 1.05 e | 13.28 ± 0.69 g | 4.18 ± 0.04 abc | 0.27 ± 0.02 a | 1.06 ± 0.05 d |

| 15 * | 10 | 10 | 115 | 49.95± 0.96 d | 15.66 ± 0.26 ef | 10.98 ± 0.63 f | 4.40 ± 0.28 de | 0.72 ± 0.09 bcd | 0.13 ± 0.02 abc |

| Regression Coefficients | ||||||

|---|---|---|---|---|---|---|

| L | a* | b* | pH | CS | CD | |

| Constants | 12,807.6000 | −3.1608 | 17.7197 | 4.9975 | −1.6697 | 4.9270 |

| A: ES | −237.9520 * | 0.3975 * | 0.8113 * | −0.0289 | 0.0162 | −0.0054 |

| B:EM | 9.4891 * | 1.5690 * | −0.5028 * | −0.0978 * | 0.0203 | −0.0061 |

| C: WC | −208.0390 * | 0.0688 * | −0.1251 | 0.0035 | 0.0335 * | −0.0705 * |

| AA | −6.5632 * | −0.0038 | −0.0153 * | −0.0001 | −0.0002 | −0.0004 * |

| AB | 0.0779 * | −0.0277 * | −0.0235 * | 0.0020 | −0.0004 | 0.0002 |

| AC | 2.6773 * | 0.0013 | 0.0004 | −0.0001 | −0.0001 | 0.0001 * |

| BB | 6.6280 * | −0.0381 * | 0.0137 * | 0.0018 | −0.0003 | 0.0003 * |

| BC | −1.5656 * | 0.0016 * | 0.0005 | 0.0001 | −0.0001 | −0.0001 |

| CC | 0.9190 * | −0.0003 | 0.0004 * | −0.0001 | −0.0001 * | 0.0002 * |

| R2 | 49.9705 | 98.6595 | 93.3162 | 95.7408 | 96.8661 | 99.7637 |

| R2adj | 0.0000 | 96.2467 | 81.2853 | 88.0742 | 91.2250 | 99.3383 |

| Lack of fit | 0.0000 | 0.0489 | 0.0120 | 0.4393 | 0.2394 | 0.0900 |

| DW | 2.5591 | 2.3528 | 2.4612 | 1.3950 | 1.8717 | 2.1902 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esposito, N.; Irigoytía, K.; Busch, V.; Castagnini, J.M.; Buera, P.; Genevois, C. Novel Flours from Neltuma affinis Fruit for Improving the Technological Quality and Alveolar Structure of Gluten-Free Bread. Biol. Life Sci. Forum 2023, 26, 119. https://doi.org/10.3390/Foods2023-15516

Esposito N, Irigoytía K, Busch V, Castagnini JM, Buera P, Genevois C. Novel Flours from Neltuma affinis Fruit for Improving the Technological Quality and Alveolar Structure of Gluten-Free Bread. Biology and Life Sciences Forum. 2023; 26(1):119. https://doi.org/10.3390/Foods2023-15516

Chicago/Turabian StyleEsposito, Nancy, Karen Irigoytía, Verónica Busch, Juan Manuel Castagnini, Pilar Buera, and Carolina Genevois. 2023. "Novel Flours from Neltuma affinis Fruit for Improving the Technological Quality and Alveolar Structure of Gluten-Free Bread" Biology and Life Sciences Forum 26, no. 1: 119. https://doi.org/10.3390/Foods2023-15516

APA StyleEsposito, N., Irigoytía, K., Busch, V., Castagnini, J. M., Buera, P., & Genevois, C. (2023). Novel Flours from Neltuma affinis Fruit for Improving the Technological Quality and Alveolar Structure of Gluten-Free Bread. Biology and Life Sciences Forum, 26(1), 119. https://doi.org/10.3390/Foods2023-15516