Review of Industrialization Development of Nanoimprint Lithography Technology

Abstract

:1. Introduction

2. Advantages of Nanoimprint Lithography Technology

2.1. Low Cost

2.2. High Resolution

2.3. Non-Developing Process

2.4. Not Affected by the Standing Wave Effect

3. Challenges of Nanoimprint Lithography Technology

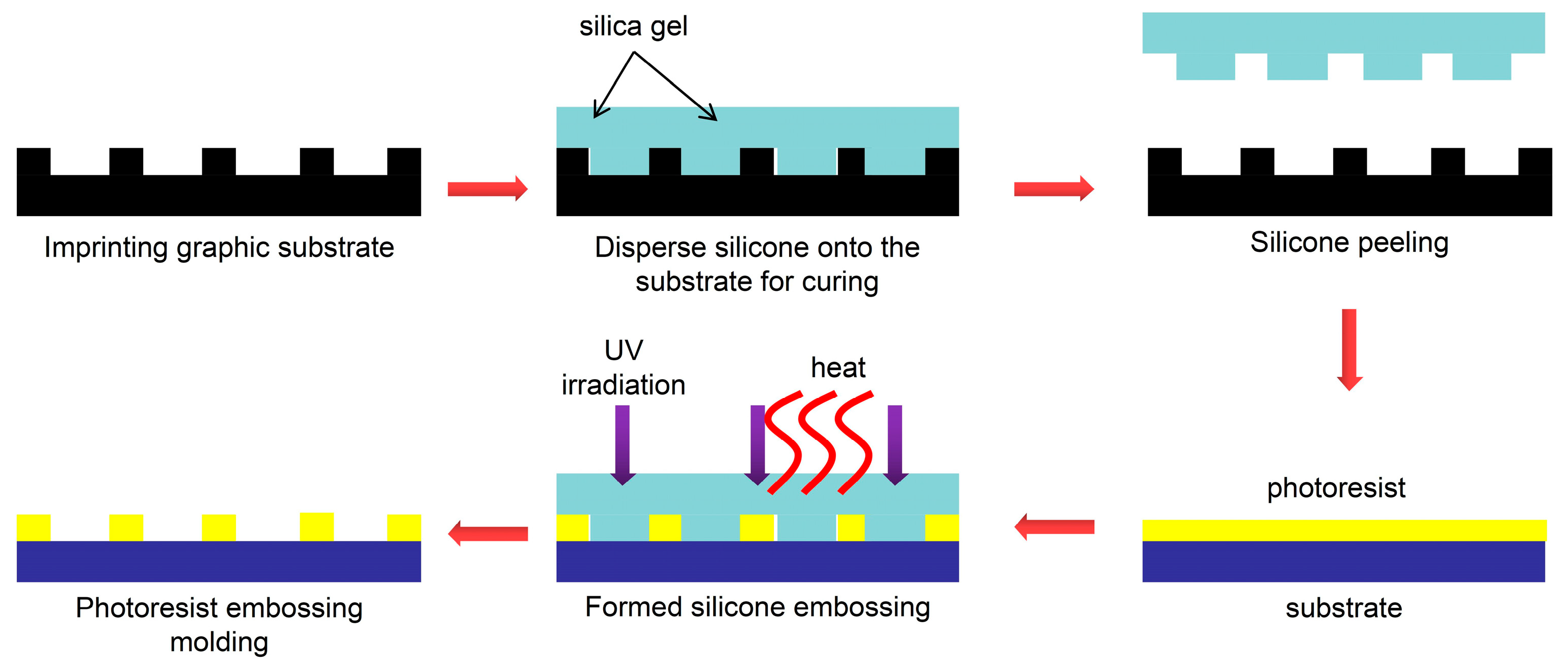

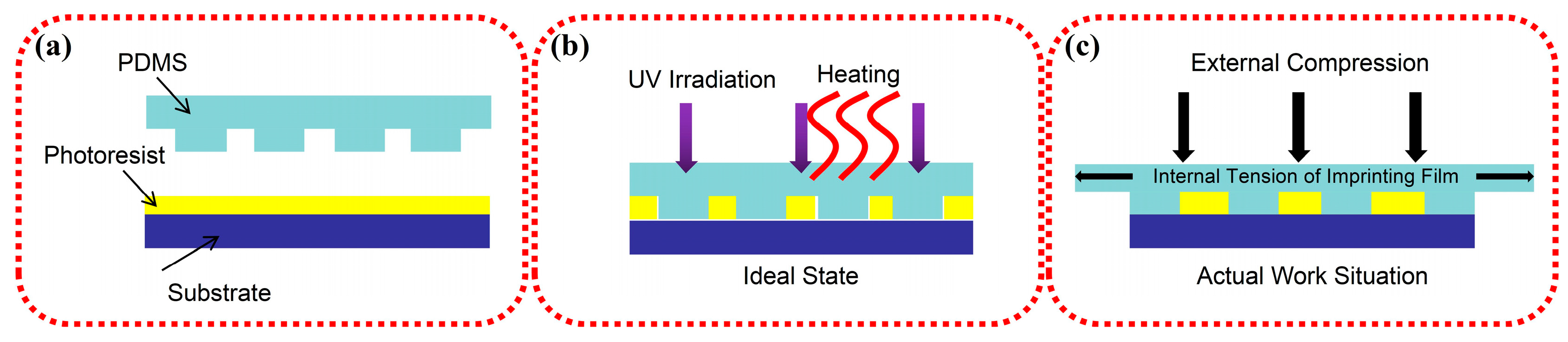

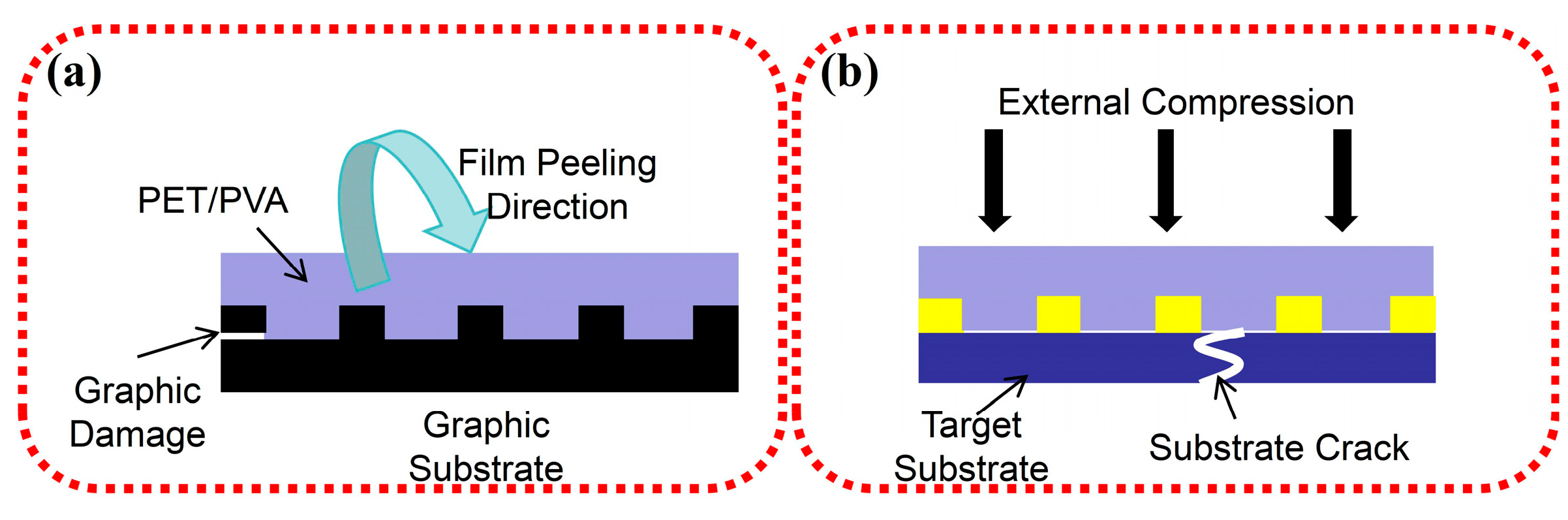

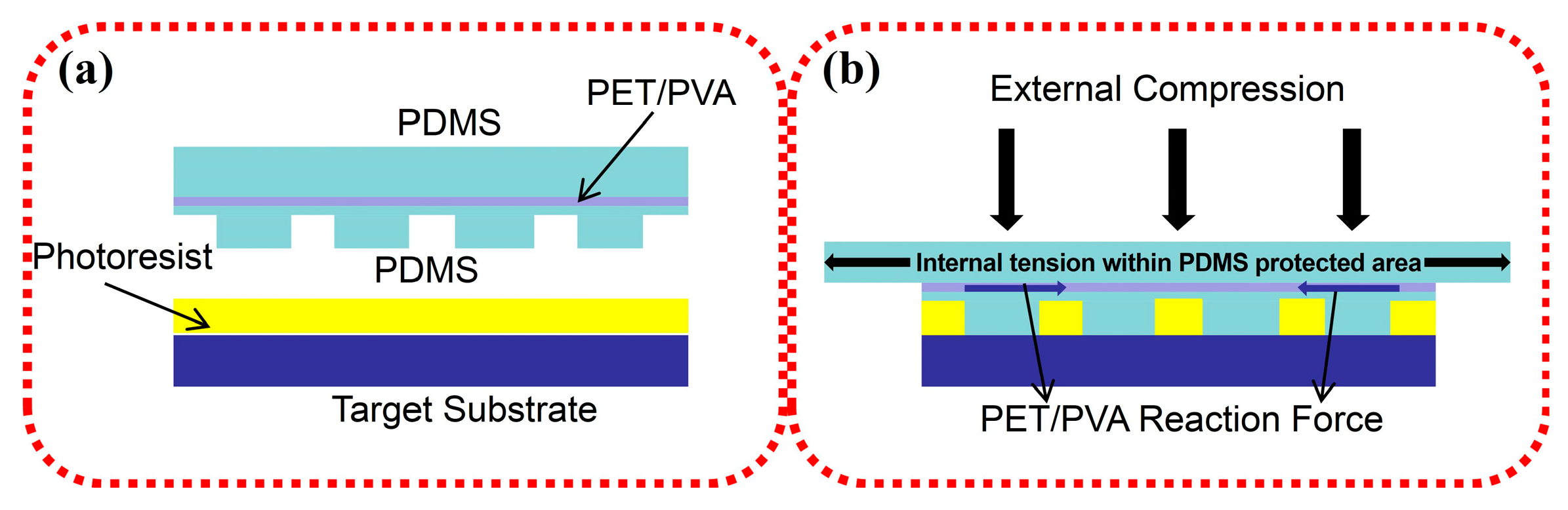

3.1. Thin Film Characteristic Issues

3.2. Application Limitations in Precision Chip Manufacturing

4. Application of Nanoimprint Lithography in Different Industries

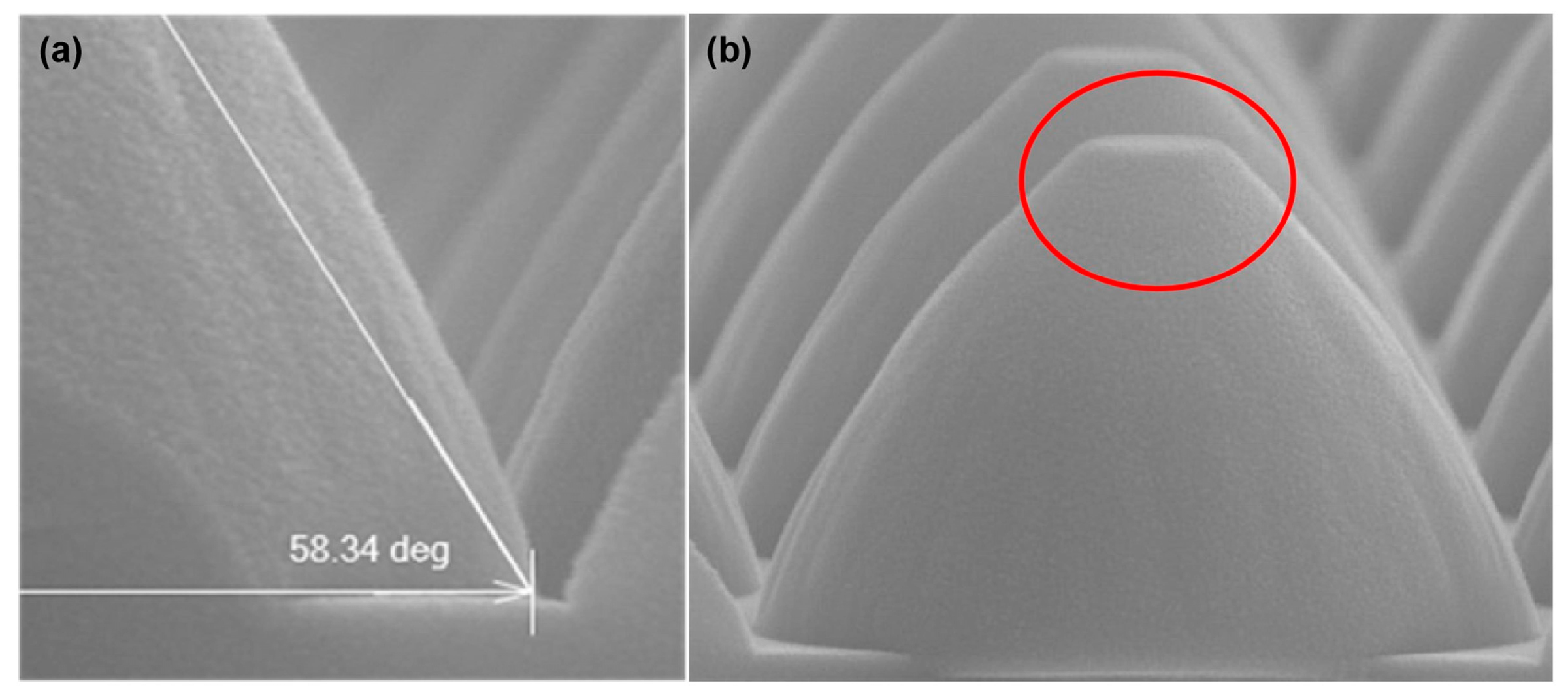

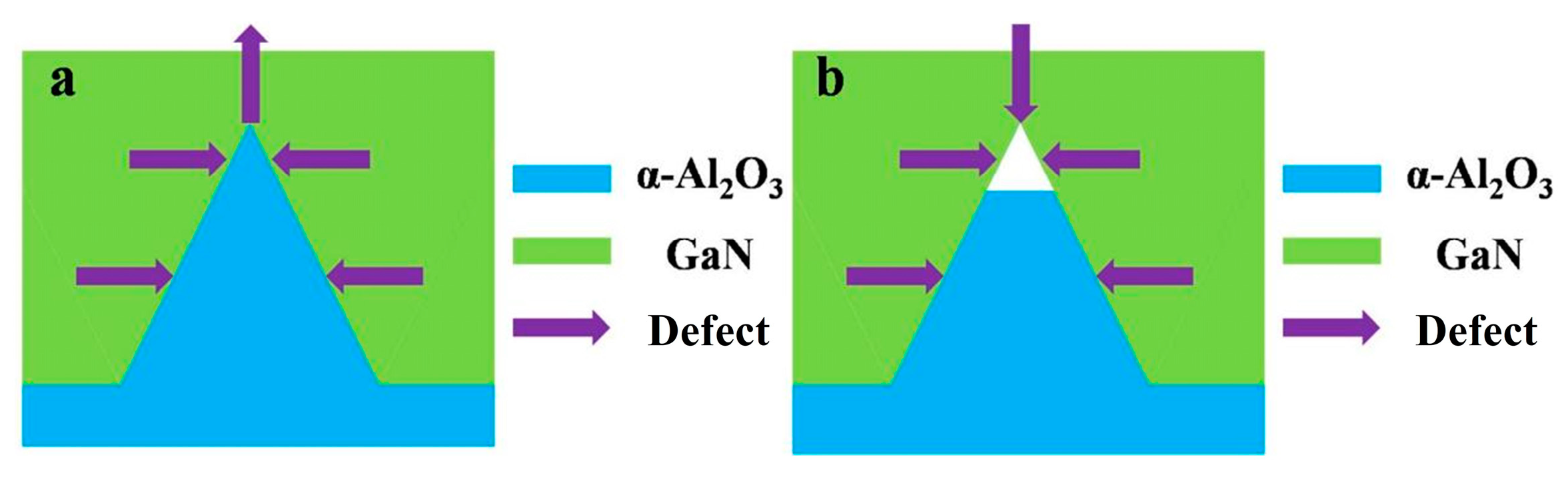

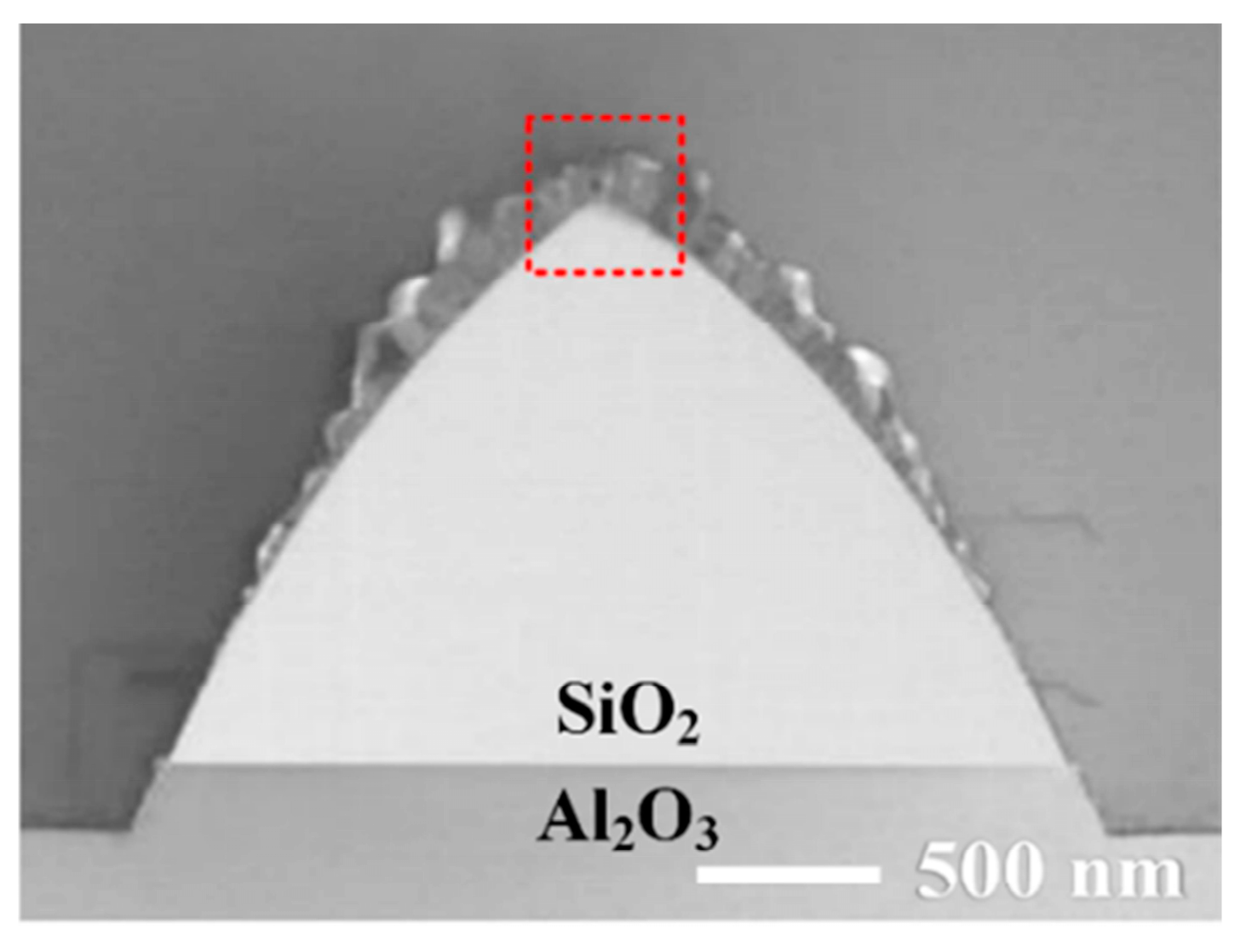

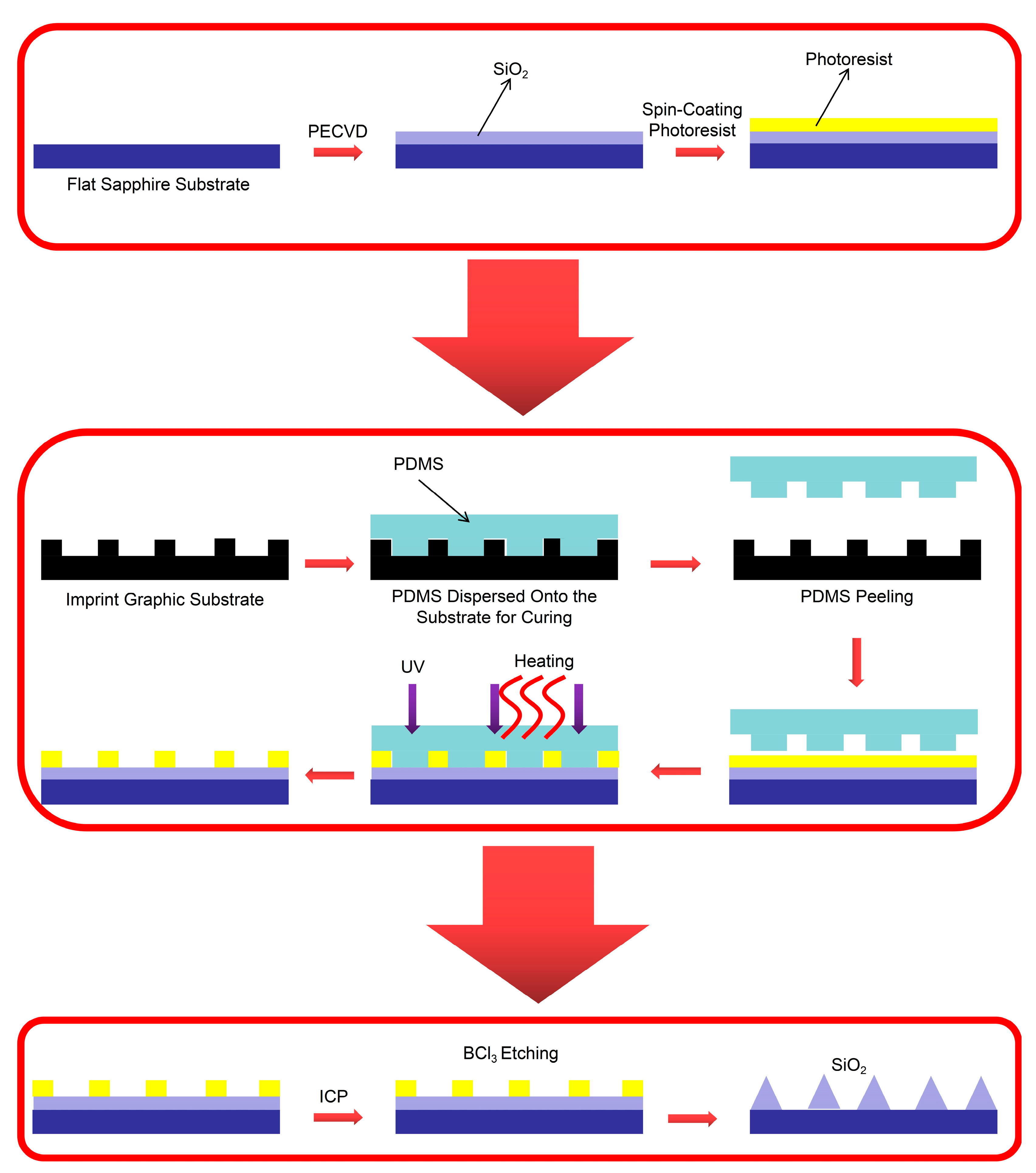

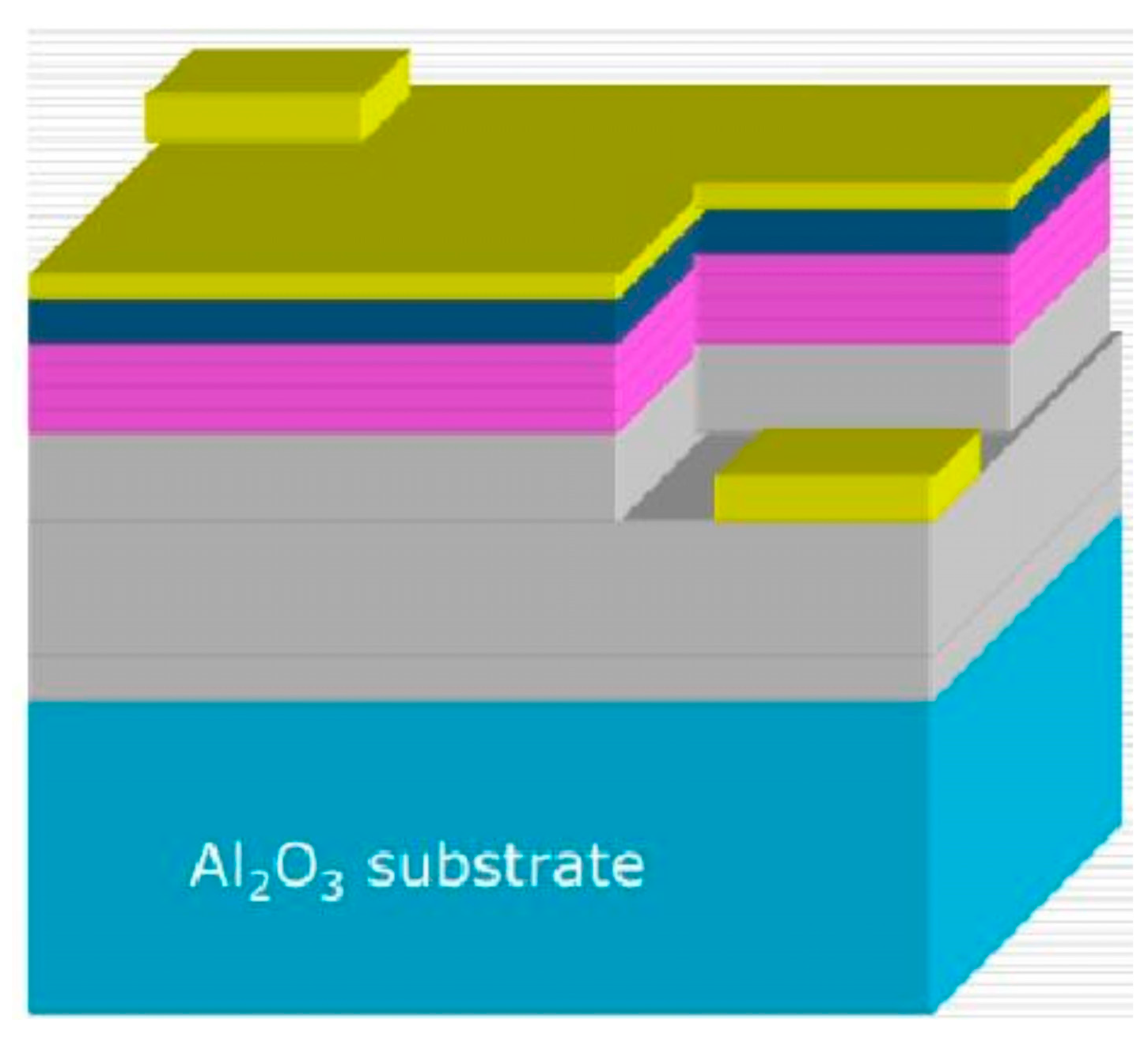

4.1. Patterned Sapphire Substrates

4.2. LED Chip Manufacturing

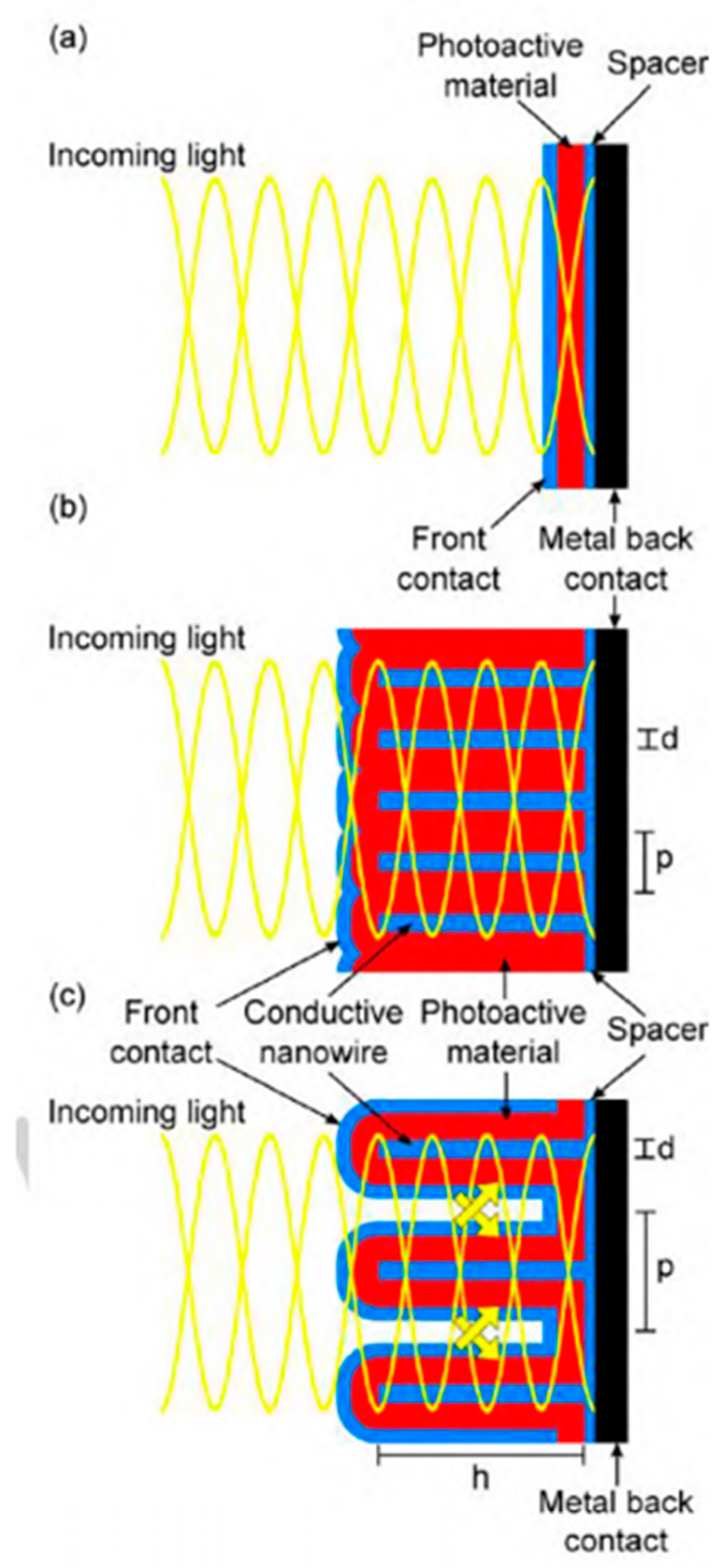

4.3. Photovoltaic Cell Manufacturing

4.4. Applications in Other Fields

5. Cost Analysis of Nanoimprint Lithography

6. The Industrialization Prospects of Nanoimprint Lithography

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| NIL | Nanoimprint Lithography |

| PSSs | patterned sapphire substrates |

| EUV | extreme ultraviolet |

| DUV | deep ultraviolet |

| PSC | patterned sapphire composite substrate |

| LED | Light-Emitting Diode |

References

- Singh, N.H.; Moirangthem, R.S.; Meitei, S.R.; Singh, N.M. Fabrication and Characterization of Zinc oxide nanorods-Modified Electrodes using Nanoimprint Lithography for electrochemical sensing of heavy metal ions. Thin Solid Film. 2024, 807, 140550. [Google Scholar] [CrossRef]

- Zhu, K.; Wen, C.; Aljarb, A.A.; Xue, F.; Xu, X.; Tung, V.; Zhang, X.; Alshareef, H.N.; Lanza, M. The development of integrated circuits based on two-dimensional materials. Nat. Electron. 2021, 4, 775–785. [Google Scholar] [CrossRef]

- Ha, D.; Fang, Z.; Zhitenev, N.B. Paper in electronic and optoelectronic devices. Adv. Electron. Mater. 2018, 4, 1700593. [Google Scholar] [CrossRef]

- Cai, Y.; Qin, A.; Tang, B.Z. Siloles in optoelectronic devices. J. Mater. Chem. C 2017, 5, 7375–7389. [Google Scholar] [CrossRef]

- Bodnariuk, M.; Melentiev, R. Bibliometric analysis of micro-nano manufacturing technologies. Nanotechnol. Precis. Eng. 2019, 2, 61–70. [Google Scholar] [CrossRef]

- Fidan, I.; Ali, M.A.; Naikwadi, V.; Gudavasov, S.; Mahmudov, M.; Mohammadizadeh, M.; Zhang, Z.; Sharma, A. Nano-Level Additive Manufacturing: Condensed Review of Processes, Materials, and Industrial Applications. Technologies 2024, 12, 117. [Google Scholar] [CrossRef]

- Huang, X.; Qi, Y.; Bu, T.; Li, X.; Liu, G.; Zeng, J.; Fan, B.; Zhang, C. Overview of advanced micro-nano manufacturing technologies for triboelectric nanogenerators. Nanoenergy Adv. 2022, 2, 316–343. [Google Scholar] [CrossRef]

- Wu, Q.; Li, Y.; Zhao, Y. The evolution of photolithography technology, process standards, and future outlook. In Proceedings of the 2020 IEEE 15th International Conference on Solid-State & Integrated Circuit Technology (ICSICT), Kunming, China, 3–6 November 2020. [Google Scholar]

- Ji, T.; Jin, S.; Zhang, H.; Chen, S.; Sun, X. Full color quantum dot light-emitting diodes patterned by photolithography technology. J. Soc. Inf. Disp. 2018, 26, 121–127. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Y.; Man, Z.; Tang, A. Research progress of quantum dot photolithography patterning and direct photolithography application. Nano Res. 2024, 17, 10386–10411. [Google Scholar] [CrossRef]

- Kazazis, D.; Santaclara, J.G.; van Schoot, J.; Mochi, I.; Ekinci, Y. Extreme ultraviolet lithography. Nat. Rev. Methods Primers 2024, 4, 84. [Google Scholar] [CrossRef]

- Fomenkov, I.; Brandt, D.; Ershov, A.; Schafgans, A.; Tao, Y.; Vaschenko, G.; Rokitski, S.; Kats, M.; Vargas, M.; Purvis, M.; et al. Light sources for high-volume manufacturing EUV lithography: Technology, performance, and power scaling. Adv. Opt. Technol. 2017, 6, 173–186. [Google Scholar] [CrossRef]

- Miyazaki, J.; Yen, A. EUV lithography technology for high-volume production of semiconductor devices. J. Photopolym. Sci. Technol. 2019, 32, 195–201. [Google Scholar] [CrossRef]

- van de Kerkhof, M.; Liu, F.; Meeuwissen, M.; Zhang, X.; Bayraktar, M.; de Kruif, R.; Davydova, N. High-power EUV lithography: Spectral purity and imaging performance. J. Micro/Nanolithogr. MEMS MOEMS 2020, 19, 033801. [Google Scholar] [CrossRef]

- Taguchi, A.; Nakayama, A.; Oketani, R.; Kawata, S.; Fujita, K. Multiphoton-excited deep-ultraviolet photolithography for 3D nanofabrication. ACS Appl. Nano Mater. 2020, 3, 11434–11441. [Google Scholar] [CrossRef]

- Rice, B.J. Extreme ultraviolet (EUV) lithography. In Nanolithography; Woodhead Publishing: Cambridge, UK, 2014; pp. 42–79. [Google Scholar]

- Mack, C.A. Reducing roughness in extreme ultraviolet lithography. J. Micro/Nanolithogr. MEMS MOEMS 2018, 17, 041006. [Google Scholar] [CrossRef]

- Itani, T.; Kozawa, T. Resist materials and processes for extreme ultraviolet lithography. Jpn. J. Appl. Phys. 2012, 52, 010002. [Google Scholar] [CrossRef]

- Ober, C.K.; Käfer, F.; Yuan, C. Recent developments in photoresists for extreme-ultraviolet lithography. Polymer 2023, 280, 126020. [Google Scholar] [CrossRef]

- Wang, X.; Tao, P.; Wang, Q.; Zhao, R.; Liu, T.; Hu, Y.; Hu, Z.; Wang, Y.; Wang, J.; Tang, Y.; et al. Trends in photoresist materials for extreme ultraviolet lithography: A review. Mater. Today 2023, 67, 299–319. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, Y.; Choi, C.L.R.; Zhang, P.; Wu, T.; Chan, Y.K. Continuous roller nanoimprinting: Next generation lithography. Nanoscale 2023, 15, 11403–11421. [Google Scholar] [CrossRef]

- Cui, S.; Sun, K.; Liao, Z.; Zhou, Q.; Jin, L.; Jin, C.; Hu, J.; Wen, K.-S.; Liu, S.; Zhou, S. Flexible nanoimprint lithography enables high-throughput manufacturing of bioinspired microstructures on warped substrates for efficient III-nitride optoelectronic devices. Sci. Bull. 2024, 69, 2080–2088. [Google Scholar] [CrossRef]

- Takeishi, H.; Sreenivasan, S.V. Nanoimprint system development and status for high volume semiconductor manufacturing. In Proceedings of the Alternative Lithographic Technologies VII, SPIE Advanced Lithography, San Jose, CA, USA, 22–26 February 2015; Volume 9423, pp. 49–57. [Google Scholar]

- Chou, S.Y.; Krauss, P.R.; Zhang, W.; Guo, L.; Zhuang, L. Sub-10 nm imprint lithography and applications. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1997, 15, 2897–2904. [Google Scholar] [CrossRef]

- Shao, J.; Chen, X.; Li, X.; Tian, H.; Wang, C.; Lu, B. Nanoimprint lithography for the manufacturing of flexible electronics. Sci. China Technol. Sci. 2019, 62, 175–198. [Google Scholar] [CrossRef]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Modaresialam, M.; Chehadi, Z.; Bottein, T.; Abbarchi, M.; Grosso, D. Nanoimprint Lithography Processing of Inorganic-Based Materials. Chem. Mater. 2021, 33, 5464–5482. [Google Scholar] [CrossRef]

- Shao, J.; Chen, X.; Li, X.; Tian, H.; Wang, C.; Lu, B. A versatile pattern inversion process based on thermal and soft UV nanoimprint lithography techniques. Microelectron. Eng. 2010, 87, 899–903. [Google Scholar]

- Park, T.W.; Kang, Y.L.; Kang, E.B.; Kim, S.; Kim, Y.N.; Park, W.I. Formation of Multiscale Pattern Structures by Combined Patterning of Nanotransfer Printing and Laser Micromachining. Nanomaterials 2023, 13, 2327. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X. Nanostructures: Fabrication and applications. In Nanolithography; Woodhead Publishing: Cambridge, UK, 2014; pp. 348–375. [Google Scholar]

- Yao, X.; Peng, R.; Ding, J. Cell–material interactions revealed via material techniques of surface patterning. Adv. Mater. 2013, 25, 5257–5286. [Google Scholar] [CrossRef]

- Luo, X. Fabrication techniques. In Engineering Optics 2.0: A Revolution in Optical Theories, Materials, Devices and Systems; Springer: Singapore, 2019; pp. 179–242. [Google Scholar]

- Cui, Z. Nanoimprint Lithography. In Nanofabrication: Principles, Capabilities and Limits; Springer International Publishing: Cham, Switzerland, 2024; pp. 201–255. [Google Scholar]

- Sharma, E.; Rathi, R.; Misharwal, J.; Sinhmar, B.; Kumari, S.; Dalal, J.; Kumar, A. Evolution in lithography techniques: Microlithography to nanolithography. Nanomaterials 2022, 12, 2754. [Google Scholar] [CrossRef]

- Cojocaru, C.V.; Cicoira, F.; Rosei, F. Alternative Nanofabrication Approaches for non-CMOS Applications. In Nanofabrication Fundamentals and Applications; World Scientific Publishing Co.: Singapore, 2008; pp. 499–542. [Google Scholar]

- Sun, H.; Li, L.; Gu, L.; Wang, J.; Zhang, L.; Gu, Y.; Bao, X. Nanoimprint Lithography for Solar Cell Applications. J. Nanoelectron. Optoelectron. 2024, 19, 1075–1097. [Google Scholar] [CrossRef]

- Ma, R.; Zhang, X.; Sutherland, D.; Bochenkov, V.; Deng, S. Nanofabrication of nanostructure lattices: From high-quality large patterns to precise hybrid units. Int. J. Extrem. Manuf. 2024, 6, 062004. [Google Scholar] [CrossRef]

- Boltasseva, A.; Shalaev, V.M. Fabrication of optical negative-index metamaterials: Recent advances and outlook. Metamaterials 2008, 2, 1–17. [Google Scholar] [CrossRef]

- Dumond, J.J.; Low, H.Y. Recent developments and design challenges in continuous roller micro-and nanoimprinting. J. Vac. Sci. Technol. B 2012, 30, 010801. [Google Scholar] [CrossRef]

- Wisser, F.M.; Schumm, B.; Mondin, G.; Grothe, J.; Kaskel, S. Precursor strategies for metallic nano-and micropatterns using soft lithography. J. Mater. Chem. C 2015, 3, 2717–2731. [Google Scholar] [CrossRef]

- Ooi, Y.K.; Zhang, J. Light extraction efficiency analysis of flip-chip ultraviolet light-emitting diodes with patterned sapphire substrate. IEEE Photonics J. 2018, 10, 1–13. [Google Scholar] [CrossRef]

- Hsiang, E.L.; He, Z.; Huang, Y.; Gou, F.; Lan, Y.F.; Wu, S.T. Improving the power efficiency of micro-LED displays with optimized LED chip sizes. Crystals 2020, 10, 494. [Google Scholar] [CrossRef]

- Nayak, P.K.; Mahesh, S.; Snaith, H.J.; Cahen, D. Photovoltaic solar cell technologies: Analysing the state of the art. Nat. Rev. Mater. 2019, 4, 269–285. [Google Scholar] [CrossRef]

- Guo, X.; Hu, J.; Zhuang, Z.; Deng, M.; Wu, F.; Li, X.; Liu, B.; Yuan, C.; Ge, H.; Li, F.; et al. Fabrication of wafer-scale nanopatterned sapphire substrate by hybrid nanoimprint lithography. J. Vac. Sci. Technol. B 2014, 32, 06FG06. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, X.; Du, P.; Zhang, Z.; Liu, X.; Liu, S.; Guo, L.J. Application of patterned sapphire substrate for III-nitride light-emitting diodes. Nanoscale 2022, 14, 4887–4907. [Google Scholar] [CrossRef]

- Chen, D.; Chen, Y.C.; Zeng, G.; Zhang, D.W.; Lu, H.L. Integration technology of micro-LED for next-generation display. Research 2023, 6, 0047. [Google Scholar] [CrossRef]

- Yu, B.; Li, Y.; Li, J.; Ding, X.; Li, Z. Challenges of high-yield manufacture in micro-light-emitting diodes displays: Chip fabrication, mass transfer, and detection. J. Phys. D Appl. Phys. 2024, 57, 463001. [Google Scholar] [CrossRef]

- Lee, T.Y.; Chen, L.Y.; Lo, Y.Y.; Swayamprabha, S.S.; Kumar, A.; Huang, Y.M.; Chen, S.C.; Zan, H.W.; Chen, F.C.; Horng, R.H.; et al. Technology and applications of micro-LEDs: Their characteristics, fabrication, advancement, and challenges. ACS Photonics 2022, 9, 2905–2930. [Google Scholar] [CrossRef]

- Gong, Y.; Gong, Z. Laser-Based Micro/Nano-Processing Techniques for Microscale LEDs and Full-Color Displays. Adv. Mater. Technol. 2023, 8, 2200949. [Google Scholar] [CrossRef]

- Wang, W.; Qi, L. Light management with patterned micro- and nanostructure arrays for photocatalysis, photovoltaics, and optoelectronic and optical devices. Adv. Funct. Mater. 2019, 29, 1807275. [Google Scholar] [CrossRef]

- Violas, A.F.; Oliveira, A.J.N.; Yakovleva, E.; Sieira, B.L.; Pinto, F.; Rocha, B.; Ribeiro, E.J.; Pinheiro, X.L.; Bondarchuk, O.; Capitão, J.; et al. One-Step Lithography Nanostructured Au Encapsulation for Light Management in Ultrathin ACIGS Solar Cells. Sol. RRL 2025, 9, 2400837. [Google Scholar] [CrossRef]

- Jeong, B.; Han, H.; Park, C. Micro- and nanopatterning of halide perovskites where crystal engineering for emerging photoelectronics meets integrated device array technology. Adv. Mater. 2020, 32, e2000597. [Google Scholar] [CrossRef] [PubMed]

- Pimpin, A.; Srituravanich, W. Review on micro-and nanolithography techniques and their applications. Eng. J. 2012, 16, 37–56. [Google Scholar] [CrossRef]

- Resnick, D.J.; Choi, J. A review of nanoimprint lithography for high-volume semiconductor device manufacturing. Adv. Opt. Technol. 2017, 6, 229–241. [Google Scholar] [CrossRef]

- Nagarjuna, R.; Thakur, A.; Balapure, A.; Saifullah, M.S.M.; Dutta, J.R.; Ganesan, R. Chemically amplified molecular resins for shrinkage-controlled direct nanoimprint lithography of functional oxides: An application towards dark-light dual-mode antibacterial surfaces. Mater. Adv. 2024, 5, 593–607. [Google Scholar] [CrossRef]

- Sun, Y.L.; Jevasuwan, W.; Fukata, N. Top-down fabrication of Ge nanowire arrays by nanoimprint lithography and hole gas accumulation in Ge/Si core-shell nanowires. Appl. Surf. Sci. 2024, 643, 158656. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, H.; Wang, Y.; Li, Y.; Song, B.; Bratkovsk, A.; Wang, S.Y.; Wu, W. Nanoimprint lithography: An enabling technology for nanophotonics. Appl. Phys. A 2015, 121, 327–333. [Google Scholar] [CrossRef]

- Wu, D.; Nitul, S.R.; Luo, X. Nanoimprint lithography-the past, the present and the future. Curr. Nanosci. 2016, 12, 712–724. [Google Scholar] [CrossRef]

- Thielsch, R. Optical coatings for the DUV/VUV. In Optical Interference Coatings; Springer: Berlin/Heidelberg, Germany, 2003; pp. 257–279. [Google Scholar]

- Banine, V.; Moors, R. Plasma sources for EUV lithography exposure tools. J. Phys. D Appl. Phys. 2004, 37, 3207. [Google Scholar] [CrossRef]

- Alnakhli, Z.; Liu, Z.; AlQatari, F.; Cao, H.; Li, X. UV-assisted nanoimprint lithography: The impact of the loading effect in silicon on nanoscale patterns of metalens. Nanoscale Adv. 2024, 6, 2954–2967. [Google Scholar] [CrossRef]

- Byrne, G.; Dimitrov, D.; Monostori, L.; Teti, R.; van Houten, F.; Wertheim, R. Biologicalisation: Biological transformation in manufacturing. CIRP J. Manuf. Sci. Technol. 2018, 21, 1–32. [Google Scholar] [CrossRef]

- Barcelo, S.; Li, Z. Nanoimprint lithography for nanodevice fabrication. Nano Converg. 2016, 3, 21. [Google Scholar] [CrossRef]

- Yu, C.C.; Chen, H.-L. Nanoimprint technology for patterning functional materials and its applications. Microelectron. Eng. 2015, 132, 98–119. [Google Scholar] [CrossRef]

- Lee, Y.C.; Chen, H.L.; Lu, C.Y.; Wu, H.S.; Chou, Y.F.; Chen, S.H. Using nanoimprint lithography to improve the light extraction efficiency and color rendering of dichromatic white light-emitting diodes. Nanoscale 2015, 7, 16312–16320. [Google Scholar] [CrossRef]

- Ding, T.; Sigle, D.O.; Herrmann, L.O.; Wolverson, D.; Baumberg, J.J. Nanoimprint lithography of Al nanovoids for deep-UV SERS. ACS Appl. Mater. Interfaces 2014, 6, 17358–17363. [Google Scholar] [CrossRef]

- Lan, H. Large-area nanoimprint lithography and applications. In Micro/Nanolithography—A Heuristic Aspect on the Enduring Technology; IntechOpen: Rijeka, Croatia, 2018; pp. 43–68. [Google Scholar]

- del Barrio, J.; Somolinos, C.S. Light to shape the future: From photolithography to 4D printing. Adv. Opt. Mater. 2019, 7, 1900598. [Google Scholar] [CrossRef]

- Sreenivasan, S.V. Nanoimprint lithography steppers for volume fabrication of leading-edge semiconductor integrated circuits. Microsyst. Nanoeng. 2017, 3, 17075. [Google Scholar] [CrossRef]

- Pease, R.F.; Chou, S.Y. Lithography and other patterning techniques for future electronics. Proc. IEEE 2008, 96, 248–270. [Google Scholar] [CrossRef]

- Sanders, D.P. Advances in patterning materials for 193 nm immersion lithography. Chem. Rev. 2010, 110, 321–360. [Google Scholar] [CrossRef] [PubMed]

- Jacob, A.P.; Xie, R.; Sung, M.G.; Liebmann, L.; Lee, R.T.P.; Taylor, B. Scaling challenges for advanced CMOS devices. Int. J. High Speed Electron. Syst. 2017, 26, 1740001. [Google Scholar] [CrossRef]

- Fabrizio, E.D.; Schlücker, S.; Wenger, J.; Regmi, R.; Rigneault, H.; Calafiore, G.; West, M.; Cabrini, S.; Fleischer, M.; van Hulst, N.F. Roadmap on biosensing and photonics with advanced nano-optical methods. J. Opt. 2016, 18, 063003. [Google Scholar] [CrossRef]

- Cox, L.M.; Martinez, A.M.; Blevins, A.K.; Sowan, N.; Ding, Y.; Bowman, C.N. Nanoimprint lithography: Emergent materials and methods of actuation. Nano Today 2020, 31, 100838. [Google Scholar] [CrossRef]

- Zaouk, R.; Par, B.Y.; Madou, M.J. Introduction to microfabrication techniques. In Microfluidic Techniques: Reviews and Protocols; Humana: Totowa, NJ, USA, 2006; pp. 5–15. [Google Scholar]

- Sorribas, H.; Padeste, C.; Tiefenauer, L. Photolithographic generation of protein micropatterns for neuron culture applications. Biomaterials 2002, 23, 893–900. [Google Scholar] [CrossRef] [PubMed]

- Tsai, I.Y.; Crosby, A.J.; Russell, T.P. Surface patterning. Methods Cell Biol. 2007, 83, 67–87. [Google Scholar]

- Smith, B.W. Photoresist and Materials Processing. In Microlithography; CRC Press: Boca Raton, FL, USA, 2020; pp. 419–492. [Google Scholar]

- Bramsiepe, C.; Sievers, S.; Seifert, T.; Stefanidis, G.D.; Vlachos, D.G.; Schnitzer, H.; Muster, B.; Brunner, C.; Sanders, J.P.M.; Bruins, M.E.; et al. Low-cost small scale processing technologies for production applications in various environments—Mass produced factories. Chem. Eng. Process. Process Intensif. 2012, 51, 32–52. [Google Scholar] [CrossRef]

- Wang, C.; Jones, R.L.; Lin, E.K.; Wu, W.L.; Leu, J. Small angle x-ray scattering measurements of lithographic patterns with sidewall roughness from vertical standing waves. Appl. Phys. Lett. 2007, 90, 193122. [Google Scholar] [CrossRef]

- Xie, Q.; Hong, M.; Tan, H.; Chen, G.; Shi, L.; Chong, T. Fabrication of nanostructures with laser interference lithography. J. Alloy. Compd. 2008, 449, 261–264. [Google Scholar] [CrossRef]

- Bernard, D.A.; Urbach, H.P. Thin-film interference effects in photolithography for finite numerical apertures. J. Opt. Soc. Am. A 1991, 8, 123–133. [Google Scholar] [CrossRef]

- Stokes, K.; Clark, K.; Odetade, D.; Hardy, M.; Oppenheimer, P.G. Advances in lithographic techniques for precision nanostructure fabrication in biomedical applications. Discov. Nano 2023, 18, 153. [Google Scholar] [CrossRef] [PubMed]

- Wolferen, H.A.G.M.; Abelmann, L. Laser interference lithography. In Lithography: Principles, Processes and Materials; Nova Publishers: New York, NY, USA, 2011; pp. 133–148. [Google Scholar]

- Wathuthanthri, I.; Liu, Y.; Du, K.; Xu, W.; Choi, C.H. Simple Holographic Patterning for High-Aspect-Ratio Three-Dimensional Nanostructures with Large Coverage Area. Adv. Funct. Mater. 2013, 23, 608–618. [Google Scholar] [CrossRef]

- Luo, X.; Tsai, D.P.; Gu, M.; Hong, M. Subwavelength interference of light on structured surfaces. Adv. Opt. Photonics 2018, 10, 757–842. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Z.F. Standing wave effect and fractal structure in dislocation evolution. Sci. Rep. 2017, 7, 4062. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Origin of laser-induced near-subwavelength ripples: Interference between surface plasmons and incident laser. ACS Nano 2009, 3, 4062–4070. [Google Scholar] [CrossRef]

- Brown, R.H.; Twiss, R.Q. Interferometry of the intensity fluctuations in light-I. Basic theory: The correlation between photons in coherent beams of radiation. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1957, 242, 300–324. [Google Scholar]

- Moreau, W.M.; Moreau, W.M. Optical Exposure. In Semiconductor Lithography: Principles, Practices, and Materials; Plenum Press: New York, NY, USA, 1988; pp. 355–408. [Google Scholar]

- Gan, Z.; Feng, H.; Chen, L.; Min, S.; Liang, C.; Xu, M.; Jiang, Z.; Sun, Z.; Sun, C.; Cui, D.; et al. Spatial modulation of nanopattern dimensions by combining interference lithography and grayscale-patterned secondary exposure. Light. Sci. Appl. 2022, 11, 89. [Google Scholar] [CrossRef]

- Aliu, S.O. High Resolution Electron Beam Lithography with Application to RF Transistor Fabrication. Ph.D. Thesis, The University of Manchester, Manchester, UK, 1976. [Google Scholar]

- Heintzmann, R.; Huser, T. Super-resolution structured illumination microscopy. Chem. Rev. 2017, 117, 13890–13908. [Google Scholar] [CrossRef]

- Guo, L.J. Nanoimprint lithography: Methods and material requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef]

- Kumar, N.; Kennedy, K.; Gildersleeve, K.; Abelson, R.; Mastrangelo, C.M.; Montgomery, D.C. A review of yield modelling techniques for semiconductor manufacturing. Int. J. Prod. Res. 2006, 44, 5019–5036. [Google Scholar] [CrossRef]

- Cao, H.; Eliezer, Y. Harnessing disorder for photonic device applications. Appl. Phys. Rev. 2022, 9, 011309. [Google Scholar] [CrossRef]

- Ren, K.; Zhou, J.; Wu, H. Materials for microfluidic chip fabrication. Acc. Chem. Res. 2013, 46, 2396–2406. [Google Scholar] [CrossRef]

- Yang, Z.; Abas, A. Preparation and Application of Novel Power Semiconductor Chips. J. Eng. 2024, 2024, 5589976. [Google Scholar] [CrossRef]

- Pattanayak, P.; Singh, S.K.; Gulati, M.; Vishwas, S.; Kapoor, B.; Chellappan, D.K.; Anand, K.; Gupta, G.; Jha, N.K.; Gupta, P.K.; et al. Microfluidic chips: Recent advances, critical strategies in design, applications and future perspectives. Microfluid. Nanofluid. 2021, 25, 1–28. [Google Scholar] [CrossRef]

- Han, K.N.; Li, C.A.; Seong, G.H. Microfluidic chips for immunoassays. Annu. Rev. Anal. Chem. 2013, 6, 119–141. [Google Scholar] [CrossRef]

- Tucher, N.; Höhn, O.; Hauser, H.; Müller, C.; Bläsi, B. Characterizing the degradation of PDMS stamps in nanoimprint lithography. Microelectron. Eng. 2017, 180, 40–44. [Google Scholar] [CrossRef]

- Choi, P.; Fu, P.-F.; Guo, L.J. Siloxane copolymers for nanoimprint lithography. Adv. Funct. Mater. 2007, 17, 65–70. [Google Scholar] [CrossRef]

- Zhou, W.; Min, G.; Zhang, J.; Liu, Y.; Wang, J.; Zhang, Y.; Sun, F. Nanoimprint lithography: A processing technique for nanofabrication advancement. Nano-Micro Lett. 2011, 3, 135–140. [Google Scholar] [CrossRef]

- Lee, J.J.; Park, S.Y.; Choi, K.B.; Kim, G.H. Nano-scale patterning using the roll typed UV-nanoimprint lithography tool. Microelectron. Eng. 2008, 85, 861–865. [Google Scholar] [CrossRef]

- Bhingardive, V.; Menahem, L.; Schvartzman, M. Soft thermal nanoimprint lithography using a nanocomposite mold. Nano Res. 2017, 11, 2705–2714. [Google Scholar] [CrossRef]

- Lee, J.H.; Yang, K.; Hong, S.H.; Lee, H.; Choi, K.W. Fabrication of 70 nm narrow metal nanowire structure on flexible PET film by nanoimprint lithography. Microelectron. Eng. 2008, 85, 710–713. [Google Scholar] [CrossRef]

- Shin, J.H.; Lee, S.H.; Byeon, K.J.; Han, K.S.; Lee, H.; Tsunozaki, K. Fabrication of flexible UV nanoimprint mold with fluorinated polymer-coated PET film. Nanoscale Res. Lett. 2011, 6, 1–5. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, Y.; Wang, D.; He, F.; Rotello, V.M.; Carter, K.R.; Watkins, J.J.; Nugen, S.R. UV-nanoimprint lithography as a tool to develop flexible microfluidic devices for electrochemical detection. Lab Chip 2015, 15, 3086–3094. [Google Scholar] [CrossRef]

- Choi, H.; Kim, J.; Kim, W.; Seong, J.; Park, C.; Choi, M.; Kim, N.; Ha, J.; Qiu, C.W.; Rho, J.; et al. Realization of high aspect ratio metalenses by facile nanoimprint lithography using water-soluble stamps. PhotoniX 2023, 4, 18. [Google Scholar] [CrossRef]

- Lee, H.; Yang, K.Y.; Hong, S.H.; Schaper, C.D.; Jung, G.Y. Nano-imprint Lithography of 100nm sized patterns using water soluble PVA, poly (vinyl alcohol), template. Solid State Phenom. 2007, 121, 661–664. [Google Scholar] [CrossRef]

- Lan, H.; Liu, H. UV-nanoimprint lithography: Structure, materials and fabrication of flexible molds. J. Nanosci. Nanotechnol. 2013, 13, 3145–3172. [Google Scholar] [CrossRef]

- Schift, H.; Kristensen, A. Nanoimprint lithography. In Springer Handbook of Nanotechnology; Springer: Berlin/Heidelberg, Germany, 2017; pp. 113–142. [Google Scholar]

- Kwon, B.; Kim, J.H. Importance of molds for nanoimprint lithography: Hard, soft, and hybrid molds. J. Nanosci. 2016, 2016, 6571297. [Google Scholar] [CrossRef]

- Park, S.; Song, Z.; Brumfield, L.; Amirsadeghi, A.; Lee, J. Demolding temperature in thermal nanoimprint lithography. Appl. Phys. A 2009, 97, 395–402. [Google Scholar] [CrossRef]

- Lan, H.B.; Ding, Y.C.; Liu, H.Z.; Que, Y.R.; Tao, W.W.; Li, H.S.; Lu, B.H. Mold deformation in soft UV-nanoimprint lithography. Sci. China Ser. E Technol. Sci. 2009, 52, 294–302. [Google Scholar] [CrossRef]

- Taha, B.A.; Addie, A.J.; Kadhim, A.C.; Azzahrani, A.S.; Ahmed, N.M.; Haider, A.J.; Chaudhary, V.; Arsad, N. Plasmonic-Enabled Nanostructures for Designing the Next Generation of Silicon Photodetectors: Trends, Engineering and Opportunities. Surf. Interfaces 2024, 48, 104334. [Google Scholar] [CrossRef]

- Li, G.; Wang, W.; Yang, W.; Lin, Y.; Wang, H.; Lin, Z.; Zhou, S. GaN-based light-emitting diodes on various substrates: A critical review. Rep. Prog. Phys. 2016, 79, 056501. [Google Scholar] [CrossRef] [PubMed]

- Song, L.; Yong, X.; Zhang, P.; Song, S.; Chen, K.; Yan, H.; Sun, T.; Lu, Q.; Shi, H.; Chen, Y.; et al. Recent progress of laser processing technology in micro-LED display manufacturing: A review. Opt. Laser Technol. 2025, 181, 111710. [Google Scholar] [CrossRef]

- Ryou, J.H.; Lee, W. GaN on sapphire substrates for visible light-emitting diodes. In Nitride Semiconductor Light-Emitting Diodes (LEDs); Woodhead Publishing: Cambridge, UK, 2018; pp. 43–78. [Google Scholar]

- Nagasawa, Y.; Hirano, A. A review of AlGaN-based deep-ultraviolet light-emitting diodes on sapphire. Appl. Sci. 2018, 8, 1264. [Google Scholar] [CrossRef]

- Tsai, Y.L.; Lai, K.Y.; Lee, M.J.; Liao, Y.K.; Ooi, B.S.; Kuo, H.C.; He, J.H. Photon management of GaN-based optoelectronic devices via nanoscaled phenomena. Prog. Quantum Electron. 2016, 49, 1–25. [Google Scholar] [CrossRef]

- Peng, R.; Hao, Y.; Meng, X.; Xu, S.; Zhang, J.; Li, P.; Huang, J.; Du, J.; Zhao, Y.; Fan, X. Study on dislocation annihilation mechanism of the high-quality GaN grown on sputtered AlN/PSS and its application in green light-emitting diodes. IEEE Trans. Electron Devices 2019, 66, 2243–2248. [Google Scholar] [CrossRef]

- Byeon, K.J.; Lee, H. Recent progress in direct patterning technologies based on nano-imprint lithography. Eur. Phys. J. Appl. Phys. 2012, 59, 10001. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, F.; Wang, J.; He, C.; Guo, W.; Wang, M.; Sheng, B.; Lu, L.; Qin, Z.; Wang, X.; et al. High-quality AlN epitaxy on nano-patterned sapphire substrates prepared by nano-imprint lithography. Sci. Rep. 2016, 6, 35934. [Google Scholar] [CrossRef]

- Chao, S.H.; Yeh, L.H.; Wu, R.T.; Kawagishi, K.; Hsu, S.C. Novel patterned sapphire substrates for enhancing the efficiency of GaN-based light-emitting diodes. RSC Adv. 2020, 10, 16284–16290. [Google Scholar] [CrossRef]

- Li, Z.T.; Li, J.X.; Li, J.S.; Du, X.W.; Song, C.J.; Tang, Y. Thermal impact of LED chips on quantum dots in remote-chip and on-chip packaging structures. IEEE Trans. Electron Devices 2019, 66, 4817–4822. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, X.; Guo, C.; Xu, J.; Wu, M.; Su, Q. Three-band white light from InGaN-based blue LED chip precoated with green/red phosphors. IEEE Photonics Technol. Lett. 2005, 17, 1160–1162. [Google Scholar] [CrossRef]

- Jang, H.; Lee, J.H.; Byon, C.; Lee, B.J. Innovative analytic and experimental methods for thermal management of SMD-type LED chips. Int. J. Heat Mass Transf. 2018, 124, 36–45. [Google Scholar] [CrossRef]

- Nomoto, J.I.; Hirano, T.; Miyata, T.; Minami, T. Preparation of Al-doped ZnO transparent electrodes suitable for thin-film solar cell applications by various types of magnetron sputtering depositions. Thin Solid Film. 2011, 520, 1400–1406. [Google Scholar] [CrossRef]

- Huang, H.W.; Lin, C.H.; Yu, C.C.; Lee, B.D.; Chiu, C.H.; Lai, C.F.; Kuo, H.C.; Leung, K.M.; Lu, T.C.; Wang, S.C. Enhanced light output from a nitride-based power chip of green light-emitting diodes withnano-rough surface using nanoimprint lithography. Nanotechnology 2008, 19, 185301. [Google Scholar] [CrossRef]

- Harwell, J.; Samuel, I.D.W. Nanoimprint lithography as a route to nanoscale back-contact perovskite solar cells. ACS Appl. Nano Mater. 2023, 6, 14940–14947. [Google Scholar] [CrossRef] [PubMed]

- Marín, J.M.R.; Rasmussen, H.K.; Hassager, O. 3D simulation of nano-imprint lithography. Nanoscale Res. Lett. 2010, 5, 274–278. [Google Scholar] [CrossRef]

- Khaleque, T.; Svavarsson, H.G.; Magnusson, R. Fabrication of resonant patterns using thermal nano-imprint lithography for thin-film photovoltaic applications. Opt. Express 2013, 21, A631–A641. [Google Scholar] [CrossRef]

- Han, K.S.; Shin, J.H.; Yoon, W.Y.; Lee, H. Enhanced performance of solar cells with anti-reflection layer fabricated by nano-imprint lithography. Sol. Energy Mater. Sol. Cells 2011, 95, 288–291. [Google Scholar] [CrossRef]

- Battaglia, C.; Escarré, J.; Söderström, K.; Erni, L.; Ding, L.; Bugnon, G.; Billet, A.; Boccard, M.; Barraud, L.; Wolf, S.D.; et al. Nanoimprint lithography for high-efficiency thin-film silicon solar cells. Nano Lett. 2011, 11, 661–665. [Google Scholar] [CrossRef]

- Hauser, H.; Tucher, N.; Tokai, K.; Schneider, P.; Wellens, C.; Volk, A.; Seitz, S.; Benick, J.; Barke, S. Development of nanoimprint processes for photovoltaic applications. J. Micro/Nanolithogr. MEMS MOEMS 2015, 14, 031210. [Google Scholar] [CrossRef]

- Gu, Y.; Xu, J.; Lin, J.; Ma, H.; Zhao, H.; Zhang, Y.; Sun, B. The fabrication of anti-reflection grating structures film for solar cells using vibration-assisted UV nanoimprint lithography. Sol. Energy 2022, 241, 172–183. [Google Scholar] [CrossRef]

- Lan, W.; Yang, Z.; Zhang, Y.; Wei, Y.; Wang, P.; Abas, A.; Tang, G.; Zhang, X.; Wang, J.; Xie, E. Novel transparent high-performance AgNWs/ZnO electrodes prepared on unconventional substrates with 3D structured surfaces. Appl. Surf. Sci. 2018, 433, 821–828. [Google Scholar] [CrossRef]

- McClung, A.; Torfeh, M.; Einck, V.J.; Watkins, J.J.; Arbab, i.A. Visible metalenses with high focusing efficiency fabricated using nanoimprint lithography. Adv. Opt. Mater. 2023, 12, 2301865. [Google Scholar] [CrossRef]

- Chehadi, Z.; Montanari, M.; Granchi, N.; Modaresialam, M.; Koudia, M.; Abel, M.; Putero, M.; Grosso, D.; Intonti, F.; Abbarchi, M. Soft Nano-Imprint Lithography of Rare-Earth-Doped Light-Emitting Photonic Metasurface. Adv. Opt. Mater. 2022, 10, 2201618. [Google Scholar] [CrossRef]

- Modaresialam, M.; Granchi, N.; Stehlik, M.; Petite, C.; Delegeanu, S.; Gourdin, A.; Bouabdellaoui, M.; Intonti, F.; Kerzabi, B.; Grosso, D.; et al. Nano-imprint lithography of broad-band and wide-angle antireflective structures for high-power lasers. Opt. Express 2024, 32, 12967–12981. [Google Scholar] [CrossRef]

- Chehadi, Z.; Bouabdellaoui, M.; Modaresialam, M.; Bottein, T.; Salvalaglio, M.; Bollani, M.; Grosso, D.; Abbarchi, M. Scalable disordered hyperuniform architectures via nanoimprint lithography of metal oxides. ACS Appl. Mater. Interfaces 2021, 13, 37761–37774. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.; Ma, D.; Li, H.; Cui, G.; Zhang, J.; Yang, Z. Review of Industrialization Development of Nanoimprint Lithography Technology. Chips 2025, 4, 10. https://doi.org/10.3390/chips4010010

Cao Y, Ma D, Li H, Cui G, Zhang J, Yang Z. Review of Industrialization Development of Nanoimprint Lithography Technology. Chips. 2025; 4(1):10. https://doi.org/10.3390/chips4010010

Chicago/Turabian StyleCao, Yuanxun, Dayong Ma, Haiming Li, Guangxu Cui, Jie Zhang, and Zhiwei Yang. 2025. "Review of Industrialization Development of Nanoimprint Lithography Technology" Chips 4, no. 1: 10. https://doi.org/10.3390/chips4010010

APA StyleCao, Y., Ma, D., Li, H., Cui, G., Zhang, J., & Yang, Z. (2025). Review of Industrialization Development of Nanoimprint Lithography Technology. Chips, 4(1), 10. https://doi.org/10.3390/chips4010010