Development of Poultry Sausages Utilizing Manually and Mechanically Deboned Meat from Spent Laying Quails

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Sausage Manufacturing

2.3. Physicochemical Analysis

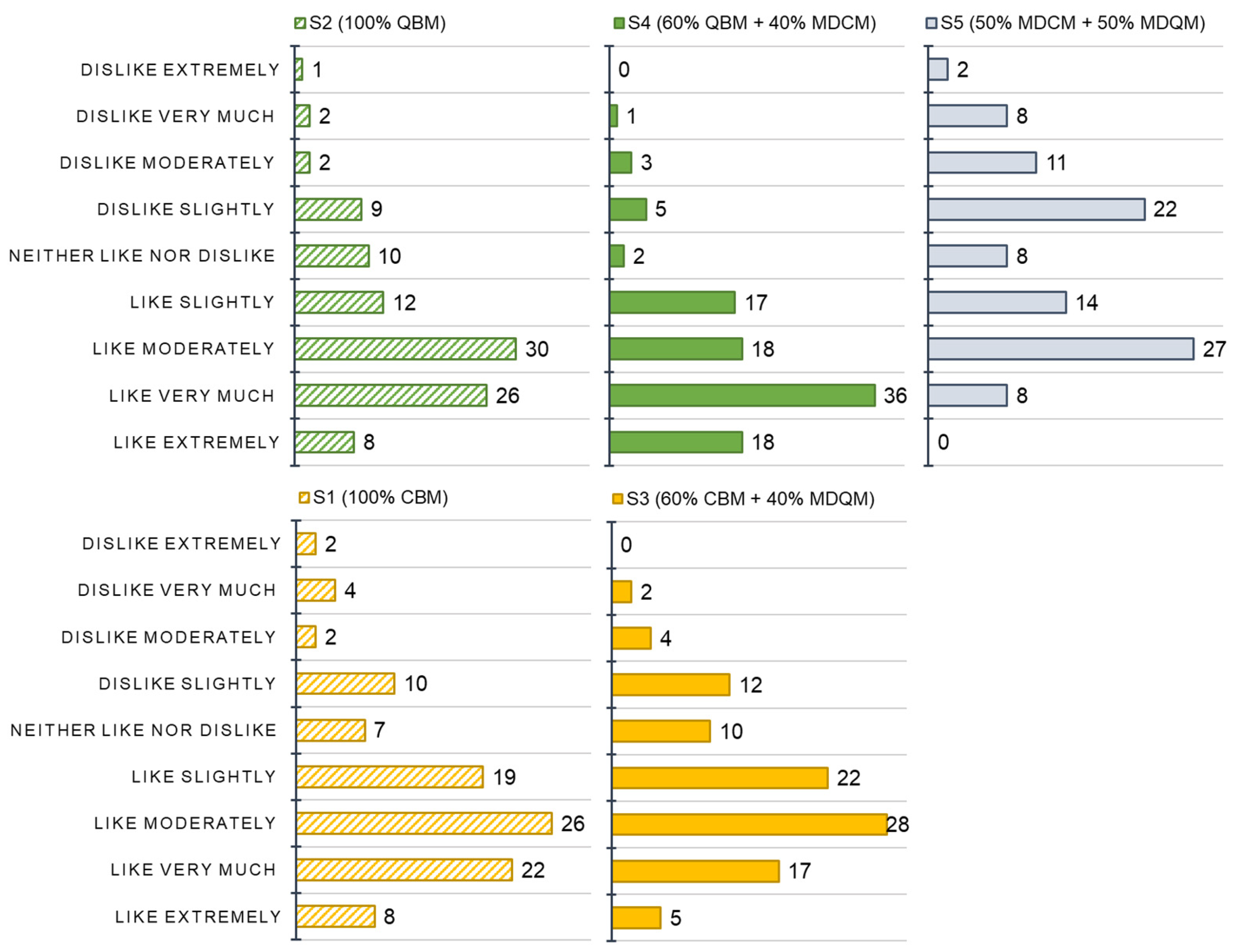

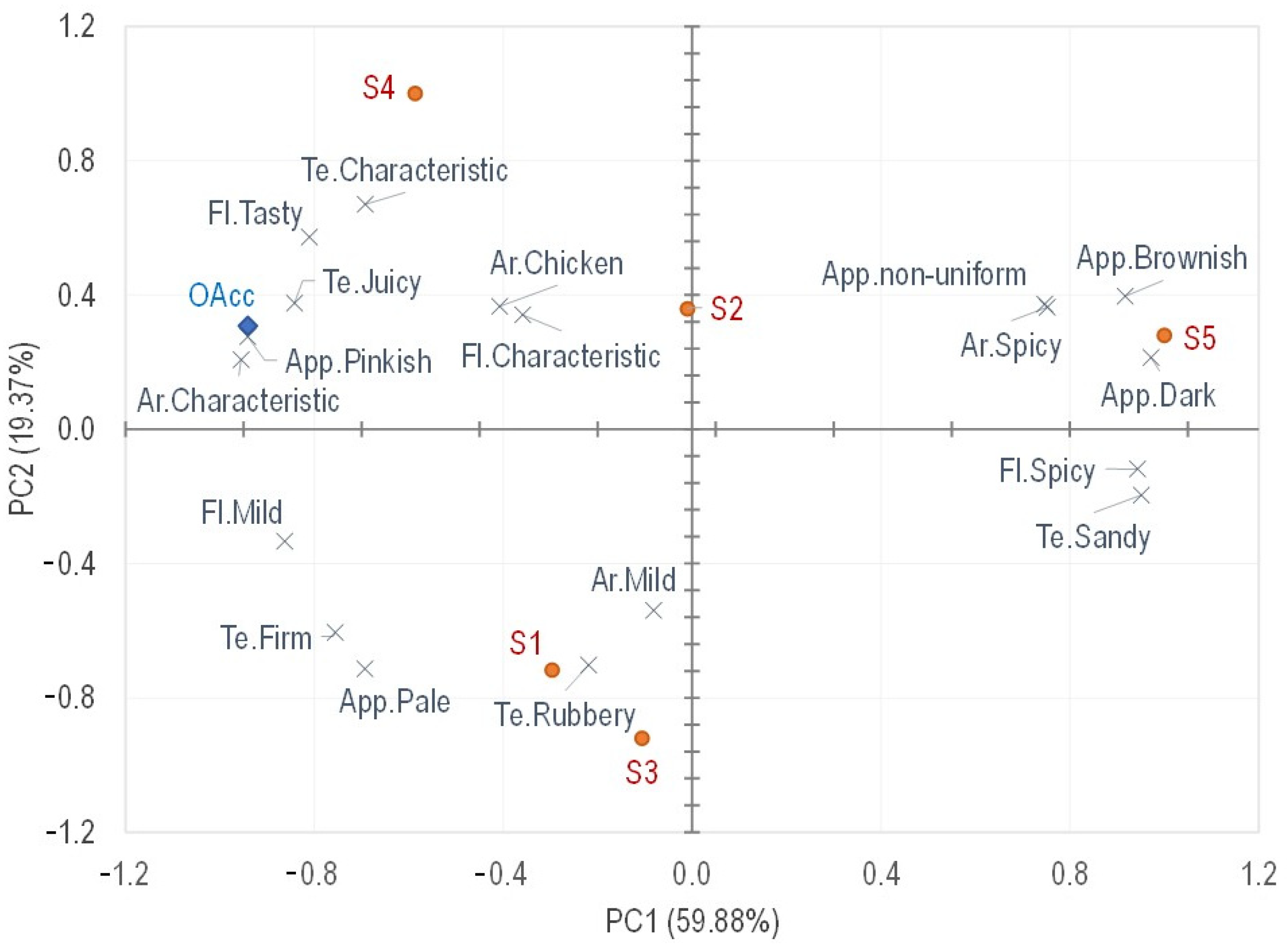

2.4. Sensorial Evaluation

2.5. Statistical Analysis

3. Results and Discussion

3.1. Raw Materials

3.2. Poultry Sausages

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bonafé, C.M. Evaluation of the Growth of Meat Quails Using Random Regression Models. Master’s Thesis, Master in Genetics and Breeding, Universidade Federal de Viçosa, Viçosa, Brazil, 2008. (In Portuguese). [Google Scholar]

- Furtado, D.A.; Braz, J.R.B.; Nascimento, J.W.B.d.; Lopes Neto, J.P.; Oliveira, D.L. Production and quality of Japanese quail eggs submitted to environments with different light spectrums. Eng. Agric. 2018, 38, 504–509. [Google Scholar] [CrossRef]

- Silva, J.H.V.; Costa, F.G.P. Table for Japanese and European Quails, 2nd ed.; FUNEP: Jaboticabal, Brazil, 2009. (In Portuguese) [Google Scholar]

- Silva, J.D.T.; Silva, V.K.; Silva, A.M.S.; Boiago, M.M.; Gravena, R.A.; Marques, R.H.; Dias, L.T.S.; Borba, H.; Moraes, V.M.B. Carcass yield and meat quality of male laying quails. Nucl. Anim. 2012, 4, 103–112. (In Portuguese) [Google Scholar] [CrossRef]

- IBGE. Municipal Livestock Production (PPM). Available online: https://www.ibge.gov.br/estatisticas/economicas/agricultura-e-pecuaria/9107-producao-da-pecuaria-municipal.html (accessed on 15 May 2024). (In Portuguese)

- Santos, W.M.d.; Santos, S.M.d.; Rebello, F.K.; Santos, M.A.S.d.; Soares, B.C.; Loureiro, J.P.B.d. Quail egg production situation in the State of Pará. Res. Soc. Dev. 2021, 10, e253101421873. [Google Scholar] [CrossRef]

- Grieser, D.O.; Oliveira, G.G.; Marcato, S.M.; Zancanela, V.; Melo, S.S.; Quevedo, P.S. Quail farming in Brazil: A promising activity for rural producers. ACSA 2024, 20, 35–39. (In Portuguese) [Google Scholar] [CrossRef]

- Santhi, D.; Kalaikannan, A. Japanese quail (Coturnix coturnix japonica) meat: Characteristics and value addition. World’s Poult. Sci. J. 2017, 73, 337–344. [Google Scholar] [CrossRef]

- Rezende, M.J.M.; Flauzina, L.P.; McManus, C.; Oliveira, L.Q.M. Productive performance and biometry of viscera of French quails fed different levels of metabolizable energy and crude protein. Acta Sci. Anim. Sci. 2008, 26, 353–358. (In Portuguese) [Google Scholar] [CrossRef]

- Trindade, M.A.; Felício, P.E.d.; Castillo, C.J.C. Mechanically separated meat of broiler breeder and white layer spent hens. Sci. Agric. 2004, 61, 234–239. [Google Scholar] [CrossRef]

- Pereira, A.G.T.; Ramos, E.M.; Teixeira, J.T.; Cardoso, G.P.; Ramos, A.L.S.; Fontes, P.R. Effects of the addition of mechanically deboned poultry meat and collagen fibers on quality characteristics of frankfurter-type sausages. Meat Sci. 2011, 89, 519–525. [Google Scholar] [CrossRef] [PubMed]

- Farag, M.; Abd-El-Aziz, N.A.; Ali, A. Preparing and evaluation of new nutritious products from quail meat. Food Nutr. Sci. 2021, 12, 889–898. [Google Scholar] [CrossRef]

- Purohit, A.S.; Reed, C.; Mohan, A. Development and evaluation of quail breakfast sausage. LWT Food Sci. Technol. 2016, 69, 447–453. [Google Scholar] [CrossRef]

- Ikhlas, B.; Huda, N.; Noryati, I. Chemical composition and physicochemical properties of meatballs prepared from mechanically deboned quail meat using various types of flour. Int. J. Poult. Sci. 2011, 10, 30–37. [Google Scholar] [CrossRef]

- Brasil. Normative Instruction No. 4: Approves the Technical Regulations on the Identity and Quality of Mechanically Separated Meat, Mortadella, Sausage and Emulsified Sausage; Ministério da Agricultura, Pecuária e Abastecimento (MAPA), Secretaria de Defesa Agropecuária (SDA): Brasília, DF, Brazil, 31 March 2000; Diário Oficial [da] República Federativa do Brasil, Section 66, Session 1; pp. 6–10. (In Portuguese) [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International, 19th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2012; p. 1298. [Google Scholar]

- Jorge, E.C.; Mendes, A.C.G.; Auriema, B.E.; Cazedey, H.P.; Fontes, P.R.; Ramos, A.L.S.; Ramos, E.M. Application of a check-all-that-apply question for evaluating and characterizing meat products. Meat Sci. 2015, 100, 124–133. [Google Scholar] [CrossRef] [PubMed]

- Ockerman, H.W.; Hansen, C.L. Animal by-Product Processing & Utilization; CRC Press: Boca Raton, FL, USA, 2000; p. 523. [Google Scholar]

- Ikhlas, B.; Huda, N.; Noryati, I. Comparison of meat quality characteristics between young and spent quails. Int. Food Res. J. 2010, 17, 661–666. [Google Scholar]

- Kokoszyński, D.; Żochowska-Kujawska, J.; Kotowicz, M.; Wegner, M.; Arpášová, H.; Włodarczyk, K.; Saleh, M.; Cebulska, A. Carcass characteristics, physicochemical traits, texture and microstructure of young and spent quails meat. Poult. Sci. 2024, 103, 103763. [Google Scholar] [CrossRef] [PubMed]

- Berri, C.; Wacrenier, N.; Millet, N.; Le Bihan-Duval, E. Effect of Selection for Improved Body Composition on Muscle and Meat Characteristics of Broilers from Experimental and Commercial Lines. Poult. Sci. 2001, 80, 833–838. [Google Scholar] [CrossRef] [PubMed]

- Barbut, S. Poultry Products Processing: An Industry Guide; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Pereira, A.G.T.; Cardoso, G.P.; Teixeira, J.T.; Ramos, E.M.; Ramos, A.L.S.; Fontes, P.R. Proximal composition, collagen content and sensory acceptance of sausages made with mechanically separated chicken meat and collagen fiber. Braz. J. Food Res. (REBRAPA) 2016, 7, 131–148. (In Portuguese) [Google Scholar] [CrossRef]

- Cardona, M.; Izquierdo, D.; Barat, J.M.; Fernández-Segovia, I. Intrinsic and extrinsic attributes that influence choice of meat and meat products: Techniques used in their identification. Eur. Food Res. Technol. 2023, 249, 2485–2514. [Google Scholar] [CrossRef]

| Ingredients (%) | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|

| Chicken breast (CBM) | 72 | - | 43 | - | - |

| Quail breast (QBM) | - | 72 | - | 43 | - |

| MDCM | - | - | - | 29 | 36 |

| MDQM | - | - | 29 | - | 36 |

| Vegetable fat | 7 | 7 | 7 | 7 | 7 |

| Ice (water) | 15 | 15 | 15 | 15 | 15 |

| Salt | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Soy protein isolate (SPI) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Cassava starch | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Sodium tripolyphosphate (TPP) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Curing salt (sodium nitrite) | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Antioxidant (sodium erythorbate) | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Monosodium glutamate (MSG) | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| Sausage seasoning | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 |

| Breast Meat | Mechanically Deboned Meat | ||||

|---|---|---|---|---|---|

| Characteristics | Quail | Chicken | Quail | Chicken | SEM |

| pH | 5.94 b | 5.87 b | 7.01 a | 6.96 a | 0.04 |

| Chemical composition (%) | |||||

| Moisture | 70.41 b | 73.87 a | 67.28 c | 66.29 d | 0.89 |

| Total Protein | 25.26 a | 22.33 b | 19.36 c | 16.38 d | 1.00 |

| Collagen | 0.49 b | 0.65 c | 1.23 a | 0.17 d | 0.12 |

| Fat | 2.60 c | 1.96 d | 9.57 b | 14.80 a | 1.60 |

| Ashes | 1.73 c | 1.84 c | 3.78 a | 2.51 b | 0.25 |

| Color indices | |||||

| Lightness (L*) | 43.13 c | 47.91 b | 46.23 cb | 59.93 a | 1.99 |

| Redness (a*) | 6.20 c | −0.70 d | 9.03 b | 25.39 a | 2.89 |

| Yellowness (b*) | 9.57 c | 3.70 d | 12.10 b | 22.65 a | 2.08 |

| Chroma (C*) | 11.40 c | 3.79 d | 15.11 b | 34.02 a | 3.37 |

| Hue angle (h, °) | 57.07 b | 101.83 a | 53.36 b | 41.74 c | 6.93 |

| Characteristics | S1 | S2 | S3 | S4 | S5 | SEM |

|---|---|---|---|---|---|---|

| pH | 6.30 c | 6.31 c | 6.47 b | 6.43 b | 6.62 a | 0.02 |

| Chemical composition (%) | ||||||

| Moisture | 67.19 a | 66.28 ab | 65.17 b | 64.50 bc | 63.09 c | 0.55 |

| Total Protein | 18.38 ab | 20.19 a | 17.52 bc | 17.91 bc | 15.17 c | 0.88 |

| Fat | 8.41 c | 8.87 c | 10.62 bc | 12.41 ab | 15.77 a | 0.95 |

| Ashes | 2.92 | 2.85 | 3.49 | 3.07 | 3.86 | 0.20 |

| Color indices | ||||||

| Lightness (L*) | 45.80 b | 44.10 c | 49.30 a | 49.70 a | 49.90 a | 0.81 |

| Redness (a*) | 5.90 ab | 6.10 a | 5.20 bc | 5.25 bc | 4.30 c | 0.21 |

| Yellowness (b*) | 8.90 b | 9.05 b | 9.25 ab | 9.45 ab | 10.10 a | 0.15 |

| Chroma (C*) | 10.68 | 10.91 | 10.77 | 10.81 | 10.98 | 0.06 |

| Hue angle (h, °) | 56.46 c | 56.00 c | 60.94 b | 60.92 b | 66.95 a | 1.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bueno, L.O.; Dinali, D.L.; Ramos, A.d.L.S.; Ramos, E.M. Development of Poultry Sausages Utilizing Manually and Mechanically Deboned Meat from Spent Laying Quails. Poultry 2025, 4, 5. https://doi.org/10.3390/poultry4010005

Bueno LO, Dinali DL, Ramos AdLS, Ramos EM. Development of Poultry Sausages Utilizing Manually and Mechanically Deboned Meat from Spent Laying Quails. Poultry. 2025; 4(1):5. https://doi.org/10.3390/poultry4010005

Chicago/Turabian StyleBueno, Lethícia Olimpio, Dalila Lima Dinali, Alcinéia de Lemos Souza Ramos, and Eduardo Mendes Ramos. 2025. "Development of Poultry Sausages Utilizing Manually and Mechanically Deboned Meat from Spent Laying Quails" Poultry 4, no. 1: 5. https://doi.org/10.3390/poultry4010005

APA StyleBueno, L. O., Dinali, D. L., Ramos, A. d. L. S., & Ramos, E. M. (2025). Development of Poultry Sausages Utilizing Manually and Mechanically Deboned Meat from Spent Laying Quails. Poultry, 4(1), 5. https://doi.org/10.3390/poultry4010005