Architecture Design and Application of a Compound Robot Control System with Movement–Process Collaboration †

Abstract

:1. Introduction

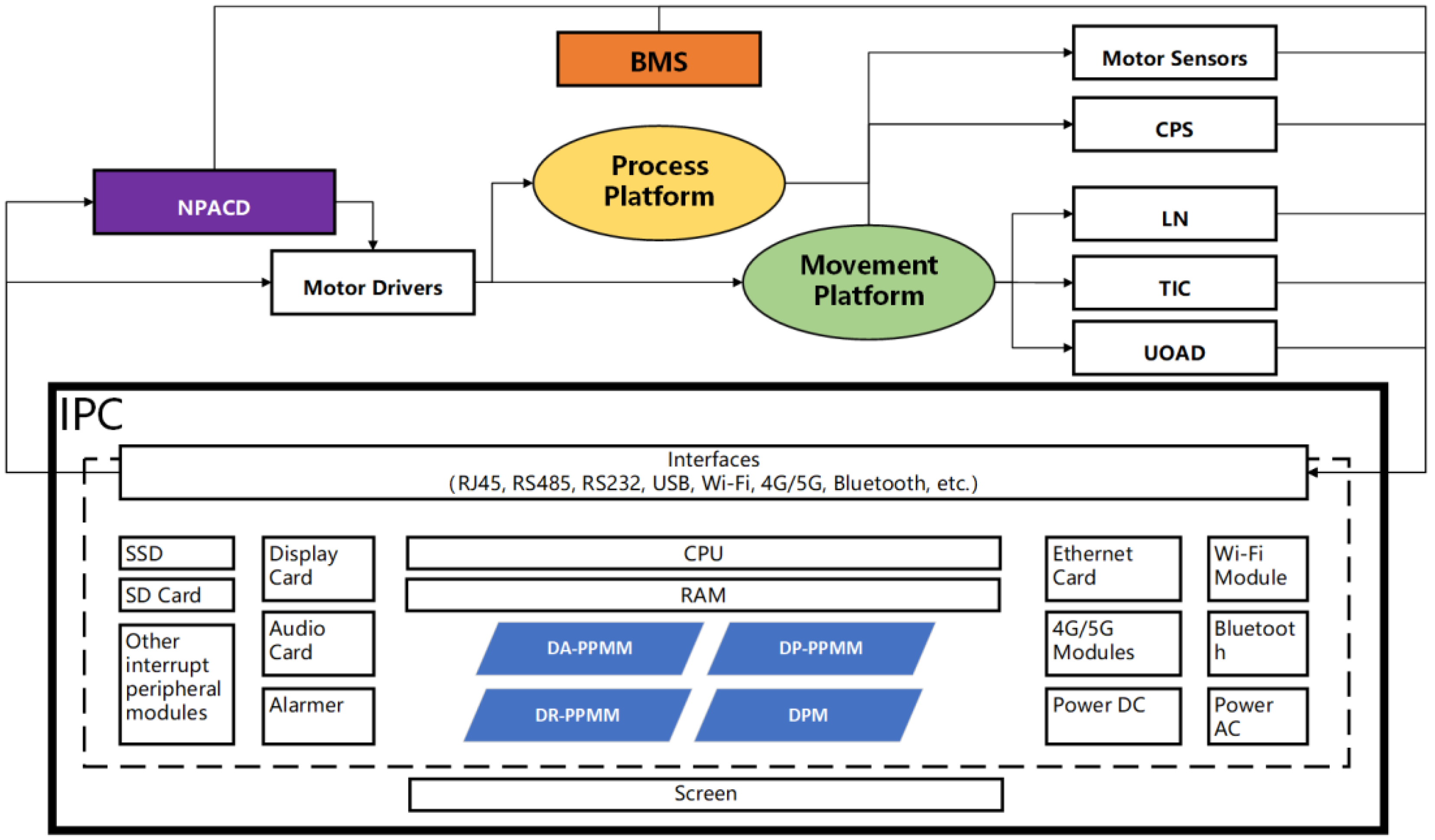

2. The Hardware Part of the MPCCR Control System

3. The Software Part of the MPCCR Control System

4. The Applications

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wagner, T.; Herrmann, C.; Thiede, S. Industry 4.0 Impacts on Lean Production Systems. Procedia CIRP 2017, 63, 125–131. [Google Scholar] [CrossRef]

- Kehoe, B.; Patil, S.; Abbeel, P.; Goldberg, K. A survey of research on cloud robotics and automation. Autom. Sci. Eng. 2015, 12, 398–409. [Google Scholar] [CrossRef]

- Yao, F.; Keller, A.; Ahmad, M.; Ahmad, B.; Harrison, R.; Colombo, A.W. Optimizing the Scheduling of Autonomous Guided Vehicle in a Manufacturing Process. In Proceedings of the IEEE 16th International Conference on Industrial Informatics (INDIN), Porto, Portugal, 18–20 July 2018; pp. 264–269. [Google Scholar]

- Sanneman, L.; Fourie, C.; Shah, J.A. The State of Industrial Robotics: Emerging Technologies, Challenges, and Key Research Directions. Found. Trends® Robot. 2021, 8, 225–306. [Google Scholar] [CrossRef]

| Hardware Parts | Description |

|---|---|

| Laser Navigator (LN) | The LN is used for MPCCR movement navigation, real-time locating, and map construction (simultaneous localization and mapping, SLAM), is connected to an IPC, and provides environmental scanning data. In the teaching mode, the IPC reads the point cloud data from the LN to build a spatial map. In the actual logistics and transportation process, the IPC reads the point cloud data from the LN to complete the current spatial positioning of the MPCCR. |

| Thermal Imaging Camera (TIC) | The TIC is used for all-weather intelligent obstacle avoidance, intelligent inspection, intelligent violation operation recognition, security alarms and other functions, connected to an IPC and providing infrared video data. Based on thermal imaging data processing, the IPC can intelligently recognize human posture, achieve functions such as personnel intrusion detection, personal collision prevention, personnel status, and wear compliance inspection, and identify whether sparks or smoke are generated, and timely carry out fire warnings and alarms. When inspection tasks need to be carried out, pickups, temperature and humidity sensors, etc., can also be installed to enhance their environmental perception ability. |

| Ultrasonic Obstacle Avoidance Device (UOAD) | The UOAD is used for MPCCR conventional obstacle avoidance, distance measurement, and other functions, is connected to an IPC, and provides ultrasonic distance measurement data. Ultrasonic obstacle avoidance can find obstacles around the robot, and distance measurement can calculate the best braking and deceleration time to realize the energy-saving operation of the robot. |

| Contact Pressure Sensor (CPS) | The CPS is used to implement the functions of emergency stops, alarms, and other response actions after MPCCR impacts. It is connected to an IPC and provides pressure data on key parts of the car body. The key parts include the central position of the front, rear, left, and right baffles of the movement platform, the central position of the upper and lower baffles of the car body, and the central position outside the joint axes of the process platform, so that the position where the MPCCR is hit can be basically captured, and possible faults or potential safety hazards can be found. |

| Non-standard Process Action Control Device (NPACD) | The NPACD includes PLC, intelligent board or dedicated controller with motion control function, as an extension device of the IPC, can be externally connected to the servo or frequency converter drive motor to achieve non-standard multi-axis motion control, and at the same time, control data and action execution data are received back to the IPC. The IPC has built-in motion control modules for standard serial and parallel robots, but for non-standard heterogeneous robotic arms, it is still necessary to expand and connect third-party control devices to complete various customized process action control. The IPC supports mainstream fieldbus and free communication protocols to connect with third-party control devices. |

| Battery Management System (BMS) | The BMS is relatively independent, mainly transmitting energy data such as the robot’s current power, output voltage, and current to the IPC. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, L.; Li, Q.; Chen, Z. Architecture Design and Application of a Compound Robot Control System with Movement–Process Collaboration. Comput. Sci. Math. Forum 2023, 8, 59. https://doi.org/10.3390/cmsf2023008059

Xiao L, Li Q, Chen Z. Architecture Design and Application of a Compound Robot Control System with Movement–Process Collaboration. Computer Sciences & Mathematics Forum. 2023; 8(1):59. https://doi.org/10.3390/cmsf2023008059

Chicago/Turabian StyleXiao, Le, Qiang Li, and Zhicheng Chen. 2023. "Architecture Design and Application of a Compound Robot Control System with Movement–Process Collaboration" Computer Sciences & Mathematics Forum 8, no. 1: 59. https://doi.org/10.3390/cmsf2023008059