Estimating Economic and Environmental Impacts of Red-Wine-Making Processes in the USA

Abstract

:1. Introduction

2. Materials and Methods

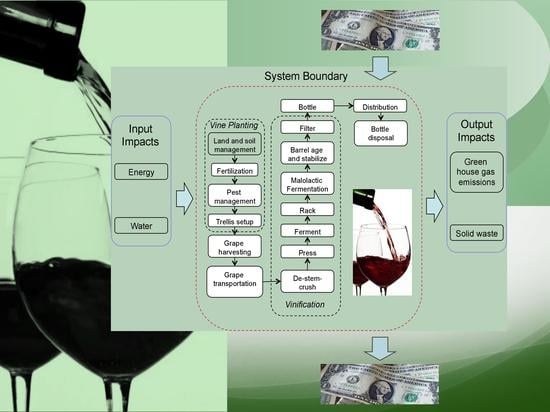

2.1. Life-Cycle Assessment (LCA)

2.2. Techno-Economic Analysis (TEA)

3. Results and Discussion

3.1. Life-Cycle Assessment (LCA)

3.2. Techno-Economic Analysis (TEA)

3.3. Implications

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- World Health Organization. Global Status Report on Alcohol and Health; World Health Organization: Geneva, Switzerland, 2011; ISBN 9789241574151. [Google Scholar]

- Johnson, H. Vintage: The Story of Wine; Simon and Schuster: New York, NY, USA, 1989. [Google Scholar]

- Berkowitz, M. World’s earliest wine. Archaeology 1996, 49, 5. [Google Scholar]

- Keys, D. Now that’s What You Call a Real Vintage: Professor Unearths 8,000-Year-Old Wine; The Independent: London, UK, 28 December 2003. [Google Scholar]

- Viegas, J. Ancient mashed grapes found in Greece. Discovery News, 22 April 2007. [Google Scholar]

- Owen, J. Earliest known winery found in Armenian cave. National Geographic News, 12 January 2011. [Google Scholar]

- Considine, J.; Frankish, E. Complete Guide to Quality in Small-Scale Wine Making; Elsevier: Waltham, MA, USA, 2013. [Google Scholar]

- Sacchi, K.L.; Bisson, L.F.; Adams, D.O. A review of the effect of winemaking techniques on phenolic extraction in red wines. Am. J. Enol. Vitic. 2005, 56, 197–206. [Google Scholar]

- Klopffer, W. Life cycle assessment: From beginning to the current state. Environ. Sci. Pollut. Res. 1997, 4, 223–228. [Google Scholar] [CrossRef] [PubMed]

- Hunt, R.; Franklin, W.E. LCA-how it came about-personal reflections on the origin and the development of LCA in the USA. Int. J. LCA 1996, 1, 4–7. [Google Scholar] [CrossRef]

- International Organization for Standardization. Environmental Management-Life Cycle Assessment-Principles and Framework; International Standard Organization: Geneva, Switzerland, 2006. [Google Scholar]

- Fusi, A.; Guidetti, R.; Benedetto, G. Delving into the environmental aspect of a Sardinian white wine: From partial to total life cycle assessment. Sci. Total Environ. 2014, 472, 989–1000. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neto, B.; Dias, A.C.; Machado, M. Life cycle assessment of the supply chain of a Portuguese wine: From viticulture to distribution. Int. J. Life Cycle Assess 2013, 18, 590–602. [Google Scholar] [CrossRef]

- Point, E.; Tyedmers, P.; Naugler, C. Life cycle environmental impacts of wine production and consumption in Nova Scotia, Canada. J. Clean Prod. 2012, 27, 11–20. [Google Scholar] [CrossRef]

- Benedetto, G. The environmental impact of a Sardinian wine by partial life cycle assessment. Wine Econ. Policy 2013, 2, 33–41. [Google Scholar] [CrossRef]

- Bosco, S.; Di Bene, C.; Galli, M.; Remorini, D.; Massai, R.; Bonari, E. Greenhouse gas emissions in the agricultural phase of wine production in the Maremma rural district in Tuscany. Italy. Ital. J. Agron. 2011, 6, 93–100. [Google Scholar] [CrossRef]

- Vazquez-Rowe, I.; Villanueva-Rey, P.; Moreira, M.T.; Feijoo, G. Environmental analysis of Ribeiro wine from a timeline perspective: Harvest year matters when reporting environmental impacts. J. Environ. Manag. 2012, 98, 73–83. [Google Scholar] [CrossRef] [PubMed]

- Marouli, A.Z.; Maroulis, Z.B. Cost data analysis for the food industry. J. Food Eng. 2005, 67, 289–299. [Google Scholar] [CrossRef]

- Ruiz, F.A.; Castel, J.M.; Mena, Y.; Camunez, J.; Gonzalez-Redondo, P. Application of the Techno-economic analysis for characterizing, making diagnoses and improving pastoral dairy goat systems in Andalusia (Spain). Small Rumin. Res. 2008, 77, 208–220. [Google Scholar] [CrossRef]

- Dillon, C.R.; Morris, J.R.; Price, C.; Ward, D.; Metz, D. Economic considerations for small-sized to medium-sized wineries. Wine East Buyers’ Guide 6–23.

- Dillon, C.R.; Morris, J.R.; Price, C. Effects of grape and other raw material price on winery profitability. Arkansas State Hort. Ass. Ann. 1993. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.202.4433&rep=rep1&type=pdf (accessed on 25 August 2019).

- Sellers-Rubio, R. Evaluation the economic performance of Spanish wineries. Int. J. Wine Bus. Res. 2010, 22, 73–84. [Google Scholar] [CrossRef]

- EIOLCA. Available online: http://www.eiolca.net (accessed on 1 July 2018).

- Alibaba. Available online: http://www.alibaba.com (accessed on 1 July 2018).

- Novak, P.; Burg, P. Evaluation of harvest losses within a full mechanized grape harvest. ACTA Univ. Agric. Silvic. Mendel. Brun. 2013, 61, 751–756. [Google Scholar] [CrossRef]

- The Vintner’s Vault. Available online: http://www.thevintnervault.com (accessed on 1 July 2018).

| Vine Planting | Wine Making | Bottle Manufacture | Distribution | |

|---|---|---|---|---|

| Energy (kJ) * | 10.0 | 26.8 | 8.9 | 6.4 |

| Water (gal) ** | 7.4 | 34.5 | 11.7 | 6.5 |

| GHG * | Vine Planting | Wine Making | Bottle Manufacture | Distribution |

|---|---|---|---|---|

| CO2 | 24.1 | 28.3 | 40.7 | 33.6 |

| CH4 | 0 | 0 | 0 | 0 |

| N2O | 37.9 | 0 | 0 | 0 |

| HFC/PFCS | 0 | 0 | 0 | 0 |

| Total (g CO2eq) | 62 | 28.3 | 40.7 | 33.6 |

| Constituent | Vine Planting | Wine Making | Bottle Manufacture | Distribution |

|---|---|---|---|---|

| Nitrate | 0.48 | 0 | 0 | 0 |

| Sulfur | 2.21 | 0 | 0 | 0 |

| Glyphosate | 0.17 | 0 | 0 | 0 |

| Mancozeb | 0.24 | 0 | 0 | 0 |

| Dimethomorph | 43.13 | 0 | 0 | 0 |

| Metiram | 0.24 | 0 | 0 | 0 |

| Copper oxychloride | 0.23 | 0 | 0 | 0 |

| Marc and lees | 0 | 270 | 0 | 0 |

| Stalks | 0 | 50 | 0 | 0 |

| Glass | 0 | 0 | 170 | 0 |

| Total | 46.7 | 320 | 170 | 0 |

| Scale | Small (5000 gal/year) | Medium (50,000 gal/year) | Large (500,000 gal/year) | |

|---|---|---|---|---|

| Land (acre) | 7 | 70 | 700 | |

| Grape output (ton) | 42 | 420 | 4200 | |

| Tillage * | Amount of machine | 1 | 5 | 20 |

| Machine work time (h) | 47.2 | 95 | 236 | |

| Fuel consumption (gallon/h) | 0.25 | 1.25 | 5 | |

| Work efficiency (m2/h) | 600 | 3000 | 12,000 | |

| Machine cost ($/machine) | 500 | 500 | 500 | |

| Fertilizer * | Amount of fertilizer (lb) | 105 | 1050 | 10,500 |

| Fertilizer cost ($/ton) | 300 | 300 | 300 | |

| Harvester ** | Amount of machine | 1 | 1 | 1 |

| Machine work time (h) | 3 | 30 | 300 | |

| Fuel consumption (gallon/h) | 4.8 | 4.8 | 4.8 | |

| Work efficiency (ton/h) | 14 | 14 | 14 | |

| Machine cost ($/machine) | 170,000 | 170,000 | 170,000 | |

| Fermentation tank cost ($) * | 40,000 | 230,000 | 900,000 | |

| Oak barrel *** | Unit cost ($/gallon) | 15 | 15 | 15 |

| Total cost ($) | 75,600 | 756,000 | 7,560,000 | |

| Bottling equipment cost ($) **** | 7000 | 130000 | 500,000 | |

| Bottle cost *** | Unit cost ($/750-mL bottle) | 0.5 | 0.5 | 0.5 |

| Total cost ($) | 12,700 | 127,000 | 1,270,000 | |

| Crush, press, rack, filter equipment cost (dollar) **** | 15,000 | 80,000 | 500,000 | |

| Full time employee or wine making process (person) **** | 2 | 3 | 22 |

| Scale | Small (5000 gal/year) | Medium (50,000 gal/year) | Large (500,000 gal/year) | |

|---|---|---|---|---|

| Grape vine | Recycle | 0 | 0 | 0 |

| Tillage ($/year) | Labor | 472 | 950 | 2360 |

| Machine | 33 | 167 | 700 | |

| Energy | 36 | 360 | 3600 | |

| Fertilizer ($/year) | 14 | 140 | 1400 | |

| Harvest ($/year) | Labor | 30 | 300 | 3000 |

| Machine | 12,000 | 12,000 | 12,000 | |

| Energy | 43.2 | 432 | 4320 | |

| Fermentation tank ($/year) | 2700 | 15,500 | 60,000 | |

| Oak barrel ($/year) | 5040 | 50,400 | 504,000 | |

| Bottling equipment ($/year) | 470 | 8700 | 35,000 | |

| Bottle ($/year) | 12,700 | 127,000 | 1,270,000 | |

| Crush, press, rack, filter equipment ($/year) | 1000 | 5400 | 35,000 | |

| Labor cost for full time employee ($/year) | 80,000 | 120,000 | 880,000 | |

| Cost of equipment and material ($/year) | 21,336 | 93,099 | 656,020 | |

| Cost of labor ($/year) | 80,502 | 121,250 | 885,360 | |

| Cost of bottle ($/year) | 12,700 | 127,000 | 1,270,000 | |

| Total cost ($/year) | 114,587 | 341,839 | 2,816,280 | |

| Revenue ($/year) | 252,360 | 2,523,600 | 25,236,000 | |

| Net profit ($/year) | 137,773 | 2,181,761 | 22,419,720 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Rosentrater, K.A. Estimating Economic and Environmental Impacts of Red-Wine-Making Processes in the USA. Fermentation 2019, 5, 77. https://doi.org/10.3390/fermentation5030077

Zhang C, Rosentrater KA. Estimating Economic and Environmental Impacts of Red-Wine-Making Processes in the USA. Fermentation. 2019; 5(3):77. https://doi.org/10.3390/fermentation5030077

Chicago/Turabian StyleZhang, Congmu, and Kurt A. Rosentrater. 2019. "Estimating Economic and Environmental Impacts of Red-Wine-Making Processes in the USA" Fermentation 5, no. 3: 77. https://doi.org/10.3390/fermentation5030077

APA StyleZhang, C., & Rosentrater, K. A. (2019). Estimating Economic and Environmental Impacts of Red-Wine-Making Processes in the USA. Fermentation, 5(3), 77. https://doi.org/10.3390/fermentation5030077