Identification of the State of Electrical Appliances with the Use of a Pulse Signal Generator

Abstract

:1. Introduction

2. HF-GEN Method for Determining the Characteristics of EA

- the analysis covers impulse signals generated by the same source,

- the source of transients is a pulse signal generator connected to the tested power network,

- the pulse signal appears in a specific phase of the supply voltage,

- a pulse signal is produced at regular intervals,

- the maximum frequency of measured signals is 15 MHz.

2.1. Pulse Signal Generation

- the maximum value of the current pulse signal is 10 A,

- the rise time of the pulse is 60 μs,

- total pulse duration is less than 1 ms,

- interval between successive impulse triggers is less than 1 s.

2.2. Measurement Method

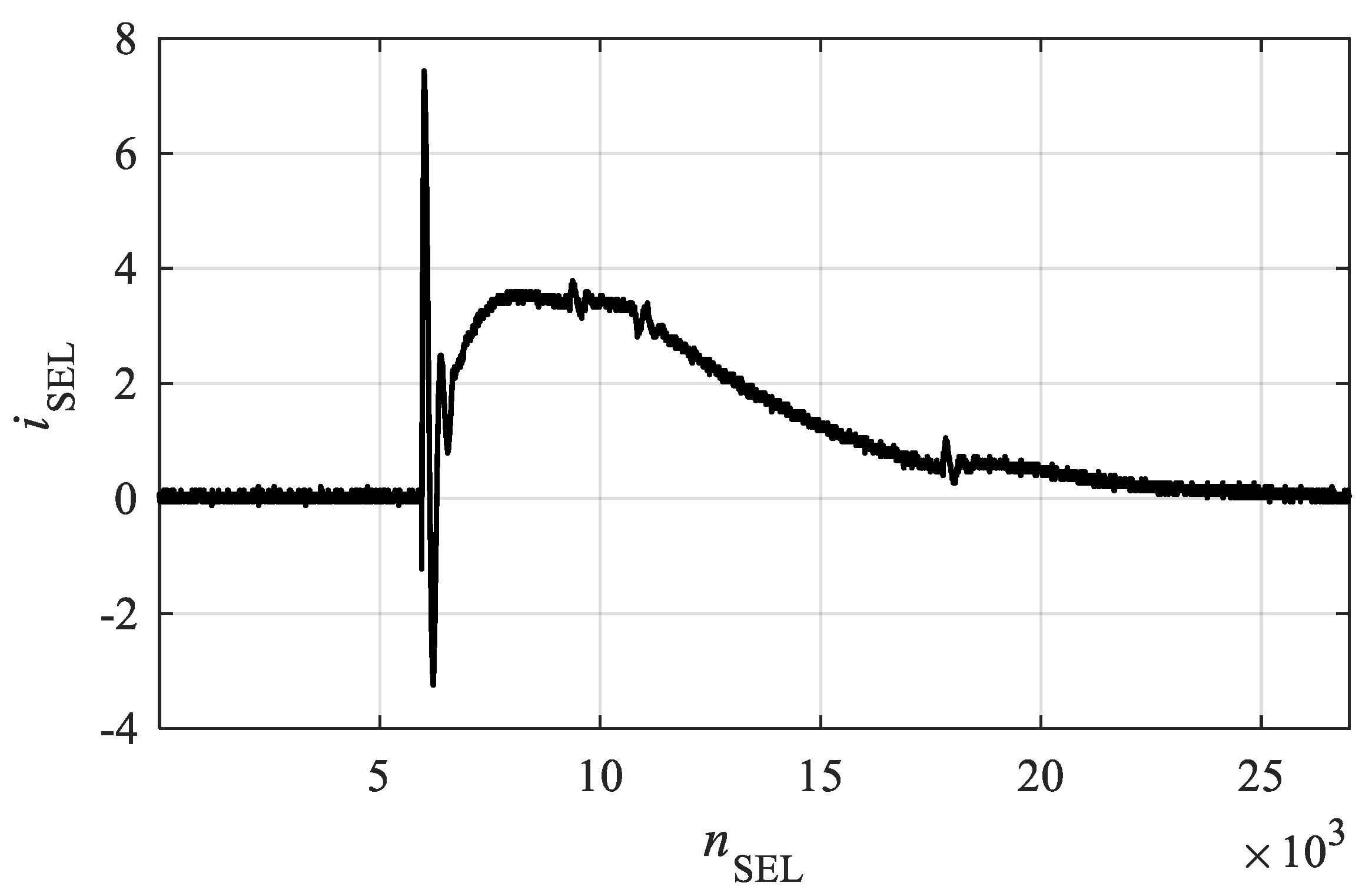

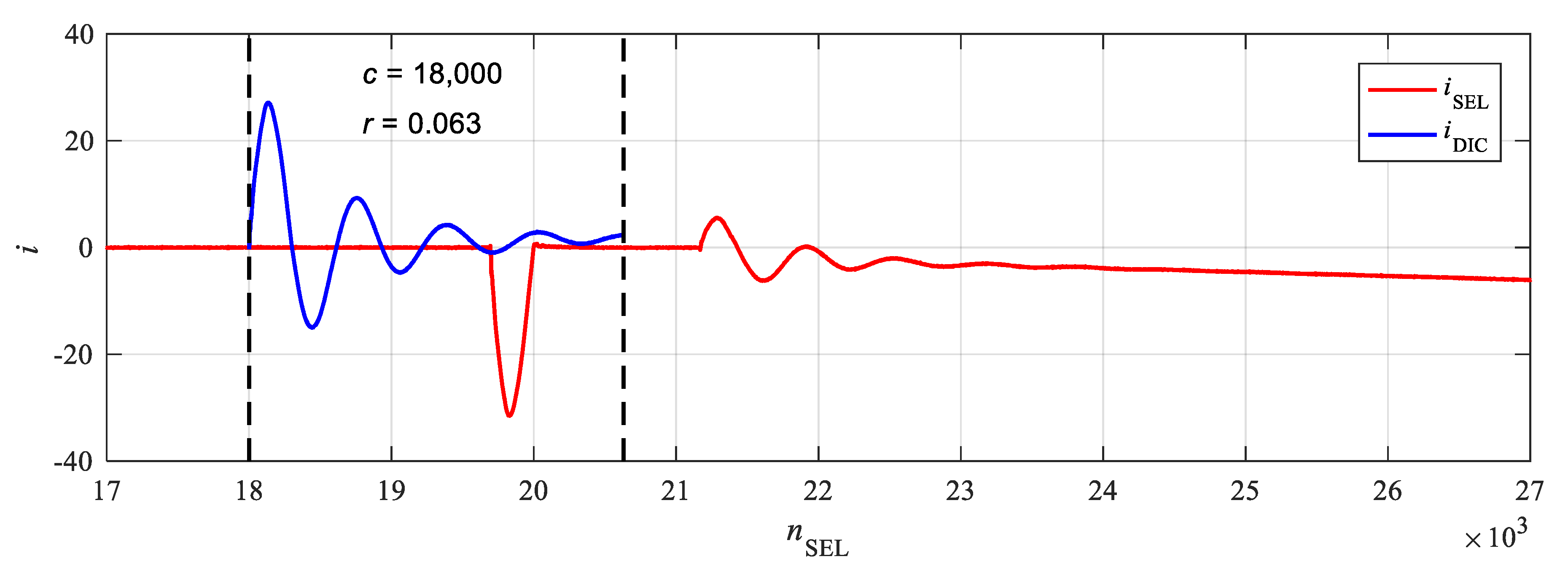

2.3. Selection of Current Samples

2.4. Preparation of a Dictionary of Transients

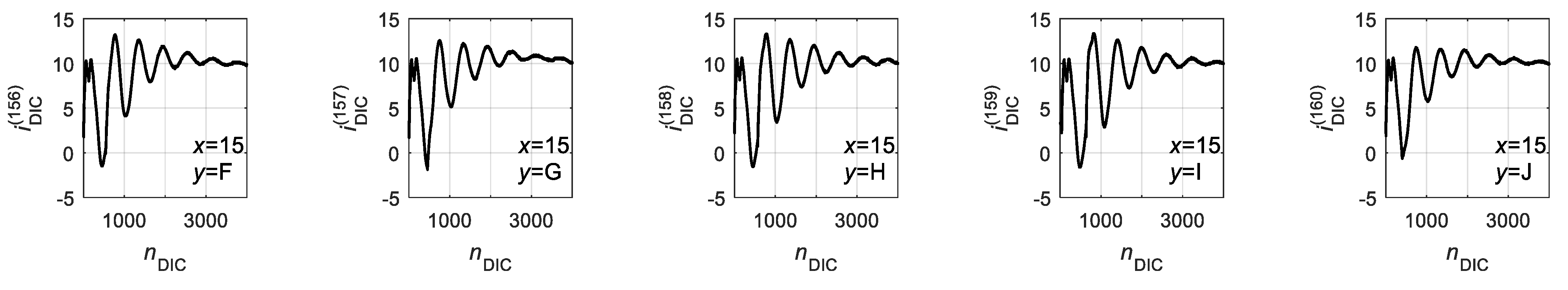

2.5. Determining the Cross-Correlation

2.6. Signature Calculation

3. Signature Quality Assessment Method

- Decision Tree (DT) representing rule-based decision systems,

- Artificial Neural Network (ANN) representing numerical decision-making systems,

- the k-Nearest Neighbors (kNN) classifier representing distance-based systems.

- actual appliances identifiers in the testing set—,

- category estimates based on ANN prediction—,

- category estimates based on DT prediction—,

- category estimates based on kNN prediction—.

3.1. Decision Tree

3.2. Neural Network

3.3. K-Nearest Neighbors

3.4. Classification Accuracy

4. Experimental Results

4.1. Laboratory Test Stand

4.2. Measurement Procedure

- Connecting to the power grid and switching on EA under test;

- Setting CS so that the GEN generates a pulse signal 150 times (in the case of its acquisition for quality evaluation) or at least 10 times (for the transients’ dictionary);

- Setting the SW to acquire all current pulses;

- Starting the impulse generation and acquisition process;

- Switching off the tested device.

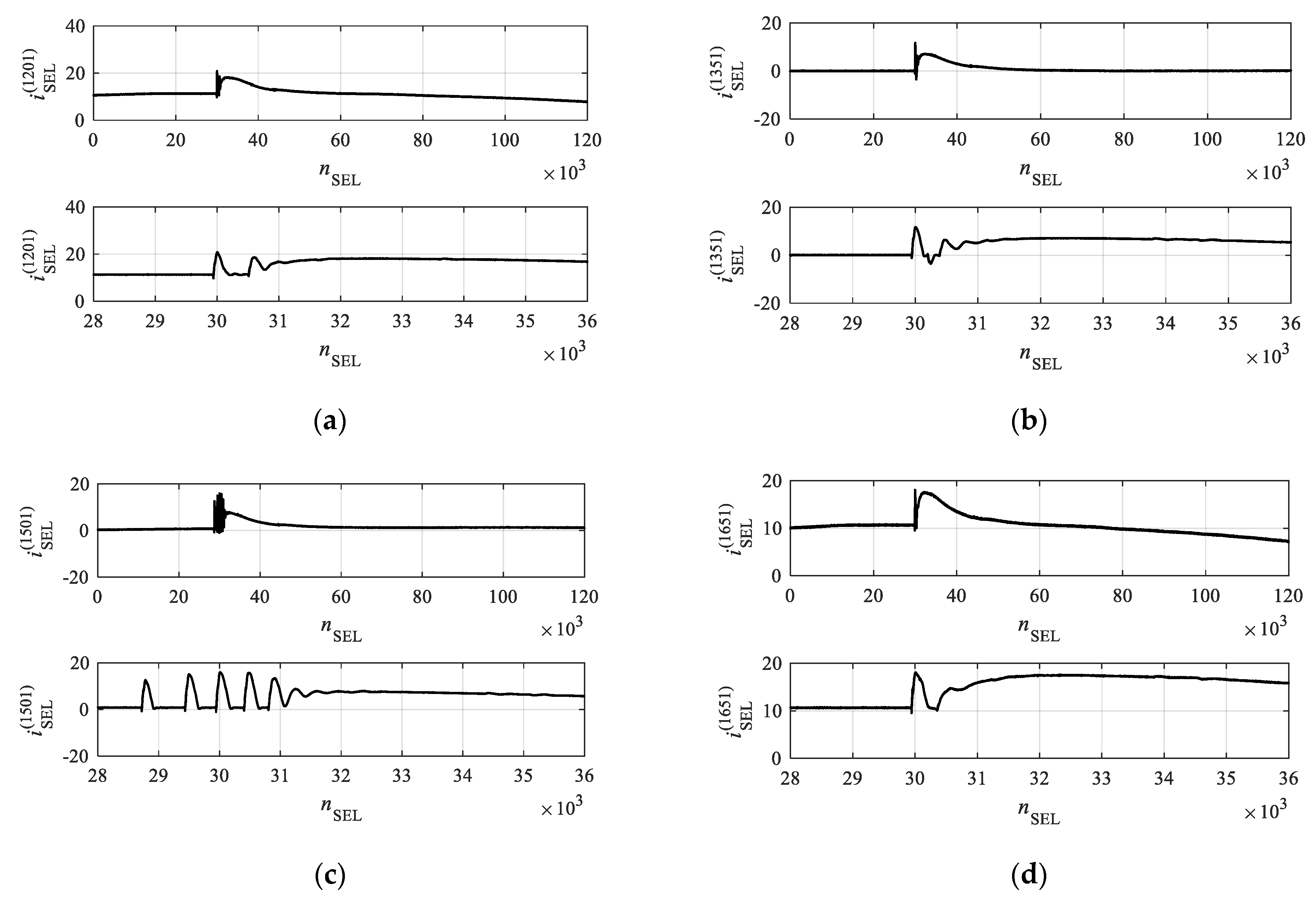

4.3. Analysis of Measured Current Vectors

4.4. Dictionary of Transients

4.5. Signature Parameters

4.6. Classification Results

4.6.1. Neural Network

4.6.2. Decision Tree

4.6.3. The kNN Algorithm

5. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hart, G.W. Nonintrusive Appliance Load Monitoring. Proc. IEEE 1992, 80, 1870–1891. [Google Scholar] [CrossRef]

- Tang, G.; Wu, K.; Lei, J. A Distributed and Scalable Approach to Semi-Intrusive Load Monitoring. IEEE Trans. Parallel Distrib. Syst. 2016, 27, 1553–1565. [Google Scholar] [CrossRef]

- Agyeman, K.A.; Han, S.; Han, S. Real-time recognition non-intrusive electrical appliance monitoring algorithm for a residential building energy management system. Energies 2015, 8, 9029–9048. [Google Scholar] [CrossRef]

- Carrie Armel, K.; Gupta, A.; Shrimali, G.; Albert, A. Is disaggregation the holy grail of energy efficiency? The case of electricity. Energy Policy 2013, 52, 213–234. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.K.; Azarkh, I.; Nicolle, B.; Jacquemod, G.; Dekneuvel, E. Applying NIALM technology to predictive maintenance for industrial machines. In Proceedings of the IEEE International Conference on Industrial Technology, Lyon, France, 20–22 February 2018; pp. 341–345. [Google Scholar]

- He, D.; Lin, W.; Liu, N.; Harley, R.G.; Habetler, T.G. Incorporating non-intrusive load monitoring into building level demand response. IEEE Trans. Smart Grid 2013, 4, 1870–1877. [Google Scholar]

- Zeifman, M.; Roth, K. Nonintrusive appliance load monitoring: Review and outlook. IEEE Trans. Consum. Electron. 2011, 57, 76–84. [Google Scholar] [CrossRef]

- Esa, N.F.; Abdullah, M.P.; Hassan, M.Y. A review disaggregation method in Non-intrusive Appliance Load Monitoring. Renew. Sustain. Energy Rev. 2016, 66, 163–173. [Google Scholar] [CrossRef]

- Liszewski, K.; Łukaszewski, R.; Kowalik, R.; Łukasz, N.; Winiecki, W. Different appliance identification methods in Non-Intrusive Appliance Load Monitoring. In Advanced Data Acquisition and Intelligent Data Processing; Haasz, V., Madani, K., Eds.; River Publishers: Aalborg, Denmark, 2014; pp. 31–58. [Google Scholar]

- Wong, Y.F.; Ahmet Sekercioglu, Y.; Drummond, T.; Wong, V.S. Recent approaches to non-intrusive load monitoring techniques in residential settings. In Proceedings of the IEEE Symposium on Computational Intelligence Applications in Smart Grid (CIASG), Singapore, 16–19 April 2013; pp. 73–79. [Google Scholar]

- Abubakar, I.; Khalis, S.N.; Mustafa, M.W.; Shareef, H.; Mustapha, M. An Overview of Non-Intrusive Load Monitoring Methodologies. In Proceedings of the IEEE Conference on Energy Conversion (CENCON), Johor Bahru, Malaysia, 9–20 October 2015; pp. 54–59. [Google Scholar]

- Gao, J.; Giri, S.; Kara, E.C.; Bergés, M. PLAID: A public dataset of high-resolution electrical appliance measurements for load identification research. In Proceedings of the BuildSys 2014—Proceedings of the 1st ACM Conference on Embedded Systems for Energy-Efficient Buildings, Memphis, Tennessee, 4–6 November 2014; Association for Computing Machinery: New York, NY, USA, 2014; pp. 198–199. [Google Scholar]

- Kelly, J.; Knottenbelt, W. The UK-DALE dataset, domestic appliance-level electricity demand and whole-house demand from five UK homes. Sci. Data 2015, 2, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Renaux, D.P.B.; Pottker, F.; Ancelmo, H.C.; Lazzaretti, A.E.; Lima, C.R.E.; Linhares, R.R.; Oroski, E.; da Silva Nolasco, L.; Lima, L.T.; Mulinari, B.M.; et al. A dataset for non-intrusive load monitoring: Design and implementation. Energies 2020, 13, 5371. [Google Scholar] [CrossRef]

- Pereira, L.; Nunes, N. Performance evaluation in non-intrusive load monitoring: Datasets, metrics, and tools—A review. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2018, 8, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Wójcik, A.; Łukaszewski, R.; Kowalik, R.; Winiecki, W. Nonintrusive appliance load monitoring: An overview, laboratory test results and research directions. Sensors 2019, 19, 3621. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mauch, L.; Yang, B. A new approach for supervised power disaggregation by using a deep recurrent LSTM network. In Proceedings of the 2015 IEEE Global Conference on Signal and Information Processing, Orlando, FL, USA, 14–16 December 2016; pp. 63–67. [Google Scholar]

- Koziy, K.; Gou, B.; Aslakson, J. A low-cost power-quality meter with series arc-fault detection capability for smart grid. IEEE Trans. Power Deliv. 2013, 28, 1584–1591. [Google Scholar] [CrossRef]

- Wang, Z.; Zheng, G. Residential appliances identification and monitoring by a nonintrusive method. IEEE Trans. Smart Grid 2012, 3, 80–92. [Google Scholar] [CrossRef]

- Zhao, B.; Stankovic, L.; Stankovic, V. On a Training-Less Solution for Non-Intrusive Appliance Load Monitoring Using Graph Signal Processing. IEEE Access 2016, 4, 1784–1799. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Dick, S. Whole-house Non-Intrusive Appliance Load Monitoring via multi-label classification. In Proceedings of the International Joint Conference on Neural Networks, Vancouver, BC, Canada, 24–29 July 2016; pp. 2749–2755. [Google Scholar]

- Henao, N.; Agbossou, K.; Kelouwani, S.; Dube, Y.; Fournier, M. Approach in Nonintrusive Type I Load Monitoring Using Subtractive Clustering. IEEE Trans. Smart Grid 2017, 8, 812–821. [Google Scholar] [CrossRef]

- Liu, B.; Luan, W.; Yu, Y. Dynamic time warping based non-intrusive load transient identification. Appl. Energy 2017, 195, 634–645. [Google Scholar] [CrossRef]

- Kong, W.; Dong, Z.; Xu, Y.; Hill, D. An Enhanced Bootstrap Filtering Method for Non- Intrusive Load Monitoring. In Proceedings of the 2016 IEEE Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016; pp. 1–5. [Google Scholar]

- Ducange, P.; Marcelloni, F.; Antonelli, M. A novel approach based on finite-state machines with fuzzy transitions for nonintrusive home appliance monitoring. IEEE Trans. Ind. Inform. 2014, 10, 1185–1197. [Google Scholar] [CrossRef]

- Sultanem, F. Using appliance signatures for monitoring residential loads at meter panel level. IEEE Trans. Power Deliv. 1991, 6, 1380–1385. [Google Scholar] [CrossRef]

- Reinhardt, A.; Burkhardt, D.; Zaheer, M.; Steinmetz, R. Electric appliance classification based on distributed high resolution current sensing. In Proceedings of the 37th Annual IEEE Conference on Local Computer Networks Workshops, Clearwater, FL, USA, 22–25 October 2012; pp. 999–1005. [Google Scholar]

- Yoshimoto, K.; Nakano, Y.; Amano, Y.; Kermanshahi, B. Non-intrusive appliances load monitoring system using neural networks. In Proceedings of the Proceedings ACEEE Summer Study on Energy Efficiency in Buildings; 2000; Volume 7, pp. 2–5. Available online: https://www.eceee.org/static/media/uploads/site-2/library/conference_proceedings/ACEEE_buildings/2000/Panel_7/p6_17/paper.pdf (accessed on 28 January 2021).

- Srinivasan, D.; Ng, W.S.; Liew, A.C. Neural-network-based signature recognition for harmonic source identification. IEEE Trans. Power Deliv. 2006, 21, 398–405. [Google Scholar] [CrossRef]

- Gupta, S.; Reynolds, M.S.; Patel, S.N. ElectriSense: Single-point sensing using EMI for electrical event detection and classification in the home. In Proceedings of the 12th ACM International Conference on Ubiquitous Computing, Copenhagen, Denmark, 26–29 September 2010; pp. 139–148. [Google Scholar]

- Torquato, R.; Acharya, J.R.; Xu, W. A Method to Determine Stray Voltage Sources—Part II: Verifications and Applications. IEEE Trans. Power Deliv. 2015, 30, 720–727. [Google Scholar] [CrossRef]

- Duarte, C.; Delmar, P.; Goossen, K.W.; Barner, K.; Gomez-Luna, E. Non-intrusive load monitoring based on switching voltage transients and wavelet transforms. In Proceedings of the 2012 Future of Instrumentation International Workshop, Gatlinburg, TN, USA, 8–9 October 2012; pp. 101–104. [Google Scholar]

- Duarte, C. Non-Intrusive Monitoring of Electrical Loads Based on Switching Transient Voltage Analysis: Signal Acquisition and Features Extraction; Univeristy of Delaware: Newark, DE, USA, 2013. [Google Scholar]

- Chang, H.H.; Lian, K.L.; Su, Y.C.; Lee, W.J. Power-spectrum-based wavelet transform for nonintrusive demand monitoring and load identification. IEEE Trans. Ind. Appl. 2014, 50, 2081–2089. [Google Scholar] [CrossRef]

- Wójcik, A.; Winiecki, W.; Łukaszewski, R.; Bilski, P. Analysis of Transient State Signatures in Electrical Household Appliances. In Proceedings of the 10th IEEE International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS), Metz, France, 18–21 September 2019; pp. 639–644. [Google Scholar]

- Lewis, J.P. Fast Normalized Cross-Correlation. Vis. Interface 2010, 120–123. [Google Scholar]

| Full Name | Acronym | |

|---|---|---|

| 1 | The highest value of the correlation module with example A of the EA dictionary with the category number 1 | COR_1_A |

| 2 | The highest value of the correlation module with example B of the EA dictionary with the category number 1 | COR_ 1_B |

| 3 | The highest value of the correlation module with example C of the EA dictionary with the category number 1 | COR_ 1_C |

| ⁞ | ⁞ | ⁞ |

| The highest value of the correlation module with the example J of the EA dictionary with the category number | COR_NEA_J |

| EA Name | Type | Nominal Power | ||

|---|---|---|---|---|

| 0 | no EA | - | - | 1…150 |

| 1 | vacuum cleaner | Zelmer ZVC425HT | 1000 W | 151…300 |

| 2 | slow juicer | Eldom PJ400 | 400 W | 301…450 |

| 3 | lamp with LED bulb “Osram” | Osram AB42758 | 11.5 W | 451…600 |

| 4 | lamp with LED bulb “Philips” | Philips 9290012345C | 13 W | 601…750 |

| 5 | lamp with LED bulb “Omega” | no data | 11 W | 751…900 |

| 6 | wall lamp with four LED bulbs “Lexman” | no data | 5 W | 901…1050 |

| 7 | laptop | Dell PP36L | 100–240 V ~1.6 A | 1051…1200 |

| 8 | iron | Philips GC 4410 | 2000–2400 W | 1201…1350 |

| 9 | sharpener | SilverCrest SEAS 20 B1 | 20 W | 1351…1500 |

| 10 | grinder | Makita GB801 | 550 W | 1501…1650 |

| 11 | kettle | Zelmer CK1004 | 1850–2200 W | 1651…1800 |

| 12 | jigsaw | Bosch GST 90 BE | 650 W | 1801…1950 |

| 13 | coffee machine | Saeco HD8917 | 1850 W | 1951…2100 |

| 14 | air conditioner | Cooper&Hunter CH-S09RX4 | 2700–2850 W | 2101…2250 |

| 15 | planer | Makita 2012NB | 1650 W | 2251…2400 |

| Category Number | Device Name | Signature Features Related to the Dictionary Examples | |

|---|---|---|---|

| 0 | no EA | 1…10 | COR_0_A…COR_0_J |

| 1 | vacuum cleaner | 11…20 | COR_1_A…COR_1_J |

| 2 | slow juicer | 21…30 | COR_2_A…COR_2_J |

| 3 | lamp with bulb “Osram” | 31…40 | COR_3_A…COR_3_J |

| 4 | lamp with bulb “Philips” | 41…50 | COR_4_A…COR_4_J |

| 5 | lamp with bulb “Omega” | 51…60 | COR_5_A…COR_5_J |

| 6 | wall lamp with five “Lexman” bulbs | 61…70 | COR_6_A…COR_6_J |

| 7 | Laptop | 71…80 | COR_7_A…COR_7_J |

| 8 | Iron | 81…90 | COR_8_A…COR_8_J |

| 9 | Sharpener | 91…100 | COR_9_A…COR_9_J |

| 10 | Grinder | 101…110 | COR_10_A…COR_10_J |

| 11 | Kettle | 111…120 | COR_11_A…COR_11_J |

| 12 | Jigsaw | 121…130 | COR_12_A…COR_12_J |

| 13 | coffee machine | 131…140 | COR_13_A…COR_13_J |

| 14 | air conditioner | 141…150 | COR_14_A…COR_14_J |

| 15 | Planer | 151…160 | COR_15_A…COR_15_J |

| Assigned Category | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |||

| True Category | 0 | 89 | 0 | 0 | 14 | 0 | 0 | 15 | 0 | 2 | 20 | 9 | 0 | 0 | 0 | 1 | 0 | 59% |

| 1 | 0 | 147 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 98% | |

| 2 | 0 | 3 | 146 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 97% | |

| 3 | 40 | 0 | 0 | 42 | 0 | 0 | 6 | 1 | 0 | 30 | 31 | 0 | 0 | 0 | 0 | 0 | 28% | |

| 4 | 0 | 0 | 0 | 0 | 73 | 76 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 49% | |

| 5 | 0 | 0 | 0 | 0 | 32 | 117 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 78% | |

| 6 | 31 | 0 | 0 | 8 | 0 | 1 | 106 | 0 | 0 | 3 | 1 | 0 | 0 | 0 | 0 | 0 | 71% | |

| 7 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 148 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 99% | |

| 8 | 0 | 0 | 0 | 0 | 4 | 2 | 0 | 0 | 142 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 95% | |

| 9 | 21 | 0 | 0 | 30 | 0 | 0 | 5 | 1 | 1 | 36 | 56 | 0 | 0 | 0 | 0 | 0 | 24% | |

| 10 | 11 | 0 | 0 | 13 | 0 | 0 | 2 | 0 | 0 | 31 | 93 | 0 | 0 | 0 | 0 | 0 | 62% | |

| 11 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 149 | 0 | 0 | 0 | 0 | 99% | |

| 12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 150 | 0 | 0 | 0 | 100% | |

| 13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 150 | 0 | 0 | 100% | |

| 14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 150 | 0 | 100% | |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 149 | 99% | |

| Assigned Category | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |||

| True Category | 0 | 60 | 0 | 0 | 25 | 3 | 1 | 28 | 1 | 3 | 25 | 4 | 0 | 0 | 0 | 0 | 0 | 40% |

| 1 | 0 | 143 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 95% | |

| 2 | 0 | 5 | 140 | 0 | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 93% | |

| 3 | 29 | 0 | 0 | 44 | 0 | 0 | 14 | 1 | 0 | 36 | 26 | 0 | 0 | 0 | 0 | 0 | 29% | |

| 4 | 0 | 0 | 0 | 0 | 111 | 33 | 2 | 2 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 74% | |

| 5 | 1 | 0 | 0 | 0 | 39 | 105 | 2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 70% | |

| 6 | 23 | 0 | 0 | 11 | 2 | 1 | 100 | 2 | 0 | 9 | 2 | 0 | 0 | 0 | 0 | 0 | 67% | |

| 7 | 2 | 0 | 2 | 0 | 0 | 0 | 1 | 136 | 3 | 2 | 3 | 0 | 0 | 1 | 0 | 0 | 91% | |

| 8 | 2 | 0 | 2 | 1 | 4 | 1 | 0 | 0 | 134 | 1 | 0 | 3 | 0 | 0 | 2 | 0 | 89% | |

| 9 | 25 | 0 | 0 | 33 | 1 | 1 | 7 | 2 | 2 | 57 | 22 | 0 | 0 | 0 | 0 | 0 | 38% | |

| 10 | 8 | 0 | 0 | 30 | 0 | 0 | 6 | 0 | 0 | 28 | 78 | 0 | 0 | 0 | 0 | 0 | 52% | |

| 11 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 3 | 5 | 0 | 0 | 139 | 1 | 0 | 0 | 0 | 93% | |

| 12 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 145 | 0 | 2 | 1 | 97% | |

| 13 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 146 | 0 | 0 | 97% | |

| 14 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 1 | 0 | 0 | 0 | 0 | 145 | 0 | 97% | |

| 15 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 146 | 97% | |

| Assigned Category | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |||

| True Category | 0 | 70 | 0 | 0 | 38 | 0 | 1 | 14 | 2 | 1 | 17 | 7 | 0 | 0 | 0 | 0 | 0 | 47% |

| 1 | 0 | 149 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 99% | |

| 2 | 0 | 3 | 147 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 98% | |

| 3 | 38 | 0 | 0 | 65 | 0 | 0 | 3 | 0 | 1 | 21 | 22 | 0 | 0 | 0 | 0 | 0 | 43% | |

| 4 | 1 | 0 | 0 | 0 | 120 | 29 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 80% | |

| 5 | 3 | 0 | 0 | 0 | 31 | 113 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 75% | |

| 6 | 19 | 0 | 0 | 11 | 1 | 0 | 107 | 1 | 0 | 7 | 4 | 0 | 0 | 0 | 0 | 0 | 71% | |

| 7 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 145 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 97% | |

| 8 | 0 | 0 | 0 | 1 | 0 | 2 | 0 | 0 | 145 | 1 | 0 | 0 | 0 | 0 | 1 | 0 | 97% | |

| 9 | 25 | 0 | 0 | 26 | 0 | 0 | 6 | 0 | 3 | 59 | 31 | 0 | 0 | 0 | 0 | 0 | 39% | |

| 10 | 10 | 0 | 0 | 29 | 0 | 0 | 1 | 0 | 0 | 25 | 85 | 0 | 0 | 0 | 0 | 0 | 57% | |

| 11 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 149 | 0 | 0 | 0 | 0 | 99% | |

| 12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 150 | 0 | 0 | 0 | 100% | |

| 13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 150 | 0 | 0 | 100% | |

| 14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 150 | 0 | 100% | |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 150 | 100% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wójcik, A.; Bilski, P.; Łukaszewski, R.; Dowalla, K.; Kowalik, R. Identification of the State of Electrical Appliances with the Use of a Pulse Signal Generator. Energies 2021, 14, 673. https://doi.org/10.3390/en14030673

Wójcik A, Bilski P, Łukaszewski R, Dowalla K, Kowalik R. Identification of the State of Electrical Appliances with the Use of a Pulse Signal Generator. Energies. 2021; 14(3):673. https://doi.org/10.3390/en14030673

Chicago/Turabian StyleWójcik, Augustyn, Piotr Bilski, Robert Łukaszewski, Krzysztof Dowalla, and Ryszard Kowalik. 2021. "Identification of the State of Electrical Appliances with the Use of a Pulse Signal Generator" Energies 14, no. 3: 673. https://doi.org/10.3390/en14030673