A Study on Soot and Ash Accumulation Characteristics of Diesel Particulate Filter Substrate Using Nondestructive Computed Radiography X-ray Imaging Technique

Abstract

:1. Introduction

2. Testing Device and Method

2.1. Testing Device

2.1.1. X-ray System

- Tube voltage: Tube voltage refers to a high voltage applied to the anode to generate X-rays in the X-ray tube, and its size determines the size of photon energy of the X-rays. Therefore, in case the tube voltage is low, it cannot sufficiently transmit an object, deteriorating the image quality. Conversely, a high tube voltage leads to an excessive amount of X-ray penetrating the object, reducing the contrast of the produced image. Therefore, an adequate level of tube voltage should be determined according to the type of object in use.

- Tube current: Tube current means a current flowing from anode to cathode, and its size determines the number of photons. The quantity of tube current is expressed in the unit mAs, which is generated by multiplying the tube current (mA) by the exposure time (s). Depending on the type of object, an appropriate level of tube current should be set to reduce the noise in images.

2.1.2. IP

2.1.3. CR Reader

2.1.4. Image J

2.2. Testing Method

3. Test Results and Observations

3.1. Accumulation of Carbon Powder and Ash Powder

3.1.1. Results from Images of Substrate with Accumulated Carbon Powder

- New substrate (0 g): The new substrate has nothing accumulated inside.

- Accumulation 12.5 g: 50% of the maximum accumulated quantity is accumulated in the substrate.

- Accumulation 25 g: The maximum accumulated quantity of substrate.

- Accumulation 62.5 g, 100 g, and 125 g: Excessively accumulated quantity setting for better visual observation.

3.1.2. Analysis of Images of Substrate with Accumulated Carbon Powder

3.1.3. Results from Images of Substrate with Accumulated Ash Powder

3.1.4. Analysis of Images of Substrate with Accumulated Ash Powder

3.2. Comparison between Pixel Values of Carbon Powder and Ash Powder

3.3. Summary of Verification Results and Observations

4. Conclusions

- This study assessed whether it is possible to quantitatively evaluate the accumulation status of soot and ash utilizing the CR X-ray imaging technique and Image J. Respective X-ray images were taken after cumulating carbon powder, similar to soot, on the DPF substrate, in quantities of 12.5 g, 25 g, 62.5 g, 100 g, and 125 g. Later, X-ray images were filmed after placing 12.5 g, 25 g, 100 g, and 125 g of ash powder in a new substrate to conduct a comparative analysis of the produced images.

- As the accumulated carbon powder and ash powder increased in quantity, the images of carbon powder accumulation showed the upper part of the plug of the substrate being colored paler white, whereas those of ash powder displayed deeper white color. An analysis of the pixel values using the histogram and ROI features of Image J confirmed that ash powder had a higher pixel value than carbon powder did. As ash demonstrates a higher density than that of carbon powder due to their composition of components deriving mainly from engine oil, it leads to a lower X-ray transmittance, which is presumed to make the images appear whiter.

- This study confirms that it is possible to identify the accumulation status of soot and ash on the DPF substrate. However, although the qualitative evaluation was verified, additional uncertainty studies are needed to verify the quantitative evaluation. In addition, further research is required on the accumulation analysis of soot and ash on the DPF of an in-use vehicle with canister and verification activities on the economic aspects and safety.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DPF | Diesel Particulate Filter |

| PM | Particulate Matter |

| OBD | On-Board Diagnostics |

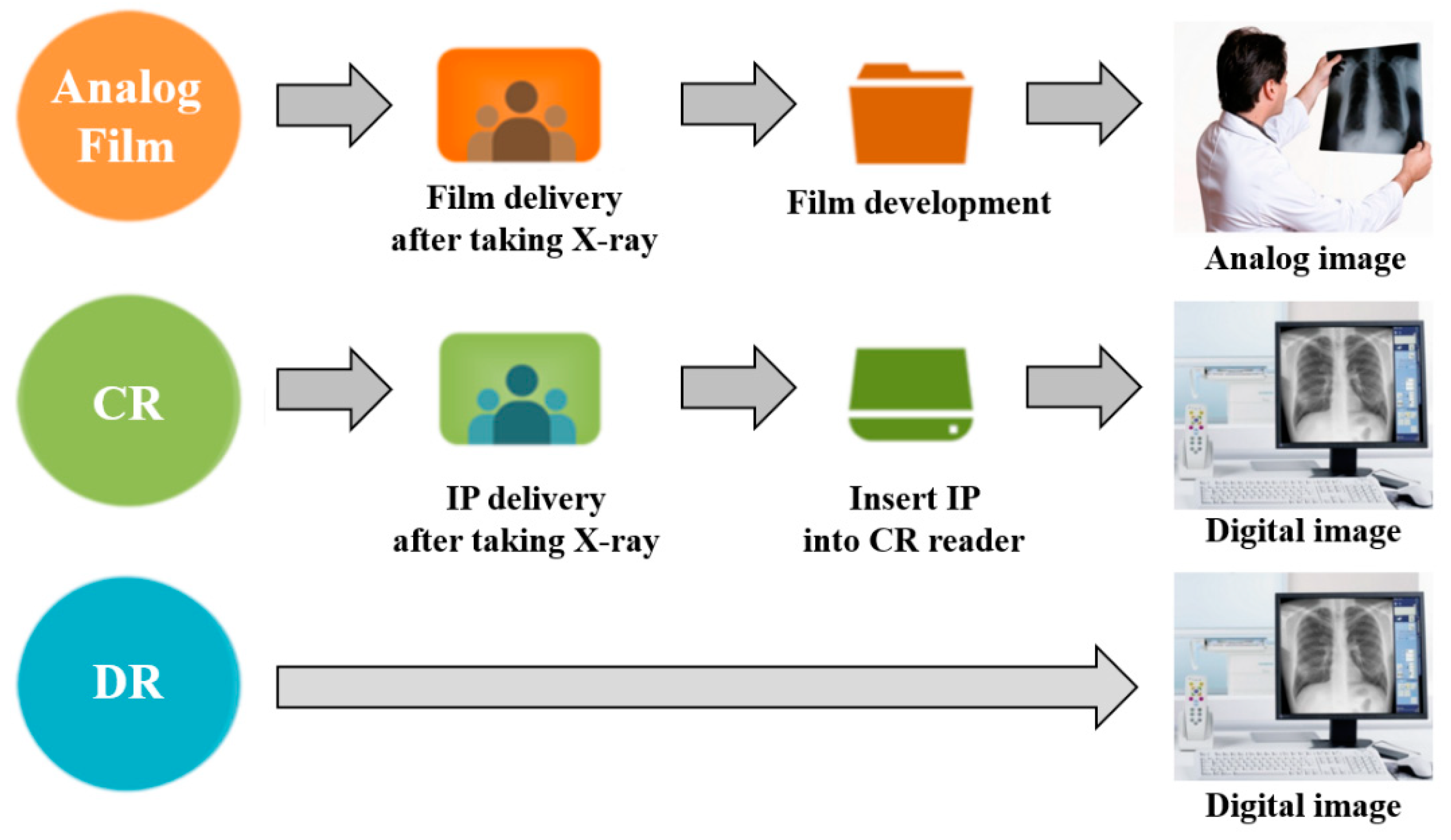

| DR | Digital Radiography |

| FPD | Flat Panel Detector |

| CR | Computed Radiography |

| IP | Imaging Plate |

| CT | Computed Tomography |

| CPSI | Cells per Square Inch |

| A/D | Analog to Digital |

| ROI | Region of Interest |

References

- Sin, D.C.; Song, S.S. A data book on the debate forum of automotive particulate matter reduction for the spread of eco-friendly transportation culture. In Proceedings of the 2018 Debate Forum on Automotive Particulate Matter Reduction, The National Assembly, Seoul, Korea, 18 April 2018; p. 42. Available online: https://ampos.nanet.go.kr:7443/materialSeminarDetail.do?control_no=PAMP1000056519 (accessed on 13 January 2021).

- Kim, W.S.; Kim, J.A. Policy Option to Manage High-Pollution On-Road Diesel Vehicles Based on Excessive Emission Grades in Seoul; The Seoul Institute: Seoul, Korea, 2015; pp. 21–27. Available online: https://www.si.re.kr/taxonomy/term/21583 (accessed on 13 January 2021).

- Kwon, M.J.; Park, G.Y.; Lim, H.J.; Kim, J.J.; Kim, K.H.; Song, H.Y.; Lee, S.W. A study on the performance deterioration of SCR for heavy-duty diesel vehicles. SAE Pap. 2019, 1, 2235. [Google Scholar]

- Korea Ministry of Environment (MOE). Comprehensive Plan Report of Measures for Particulate Matter Management. 2019. Available online: http://www.me.go.kr/home/web/policy_data/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=title&searchValue=%EB%AF%B8%EC%84%B8%EB%A8%BC%EC%A7%80&menuId=10259&orgCd=&condition.deleteYn=N&seq=7399 (accessed on 13 January 2021).

- Merkel, G.A.; Cutler, W.A.; Warren, C.J. Thermal durability of wall-flow ceramic diesel particulate filters. SAE Pap. 2001, 1, 190. [Google Scholar]

- Rah, W.Y. PM reduction efficiency using metal type DPF. Trans. Korean Soc. Automot. Eng. 2013, 21, 176–180. [Google Scholar]

- Zhang, X.; Tennison, P.; Schram, T. 3D Numerical study of pressure loss characteristics and Soot leakage through a damaged DPF. SAE Pap. 2009, 1, 1267. [Google Scholar] [CrossRef]

- Calzada, E.; Schillinger, B.; Grunauer, F. Construction and assembly of the neutron radiography and tomography facility ANTARES at FRM II. Nucl. Instrum. Methods Phys. Res. A 2005, 542, 38–44. [Google Scholar] [CrossRef]

- Ismail, B.; Ewing, D.; Chang, J.; Cotton, J. Development of a non-destructive neutron radiography technique to measure the three dimensional Soot deposition profiles in diesel engine exhaust systems. J. Aerosol Sci. 2004, 35, 1275–1288. [Google Scholar] [CrossRef]

- Zandhuis, J.A.; Funney, C.E.A.; Toops, T.J.; Partridge, W.P.; Daw, C.S.; Fox, T. Nondestructive X-ray inspection of thermal damage, Soot and Ash distribution in diesel particulate filters. SAE Pap. 2009, 1, 289. [Google Scholar]

- Matsuno, M.; Kitamura, T.; Usui, Y.; Kusaka, J.; Fukuma, T.; Takeda, Y.; Kinoshita, K. Ash accumulation and transport in diesel particulate filters (Second report) –Impact of active Regeneration frequency on Ash distribution. Trans. Soc. Automot. Eng. Jpn. 2018, 49, 1199–1204. [Google Scholar]

- Usui, Y.; Ohashi, Y.; Morimoto, K.; Kusaka, J.; Fukuma, T.; Kitamura, T.; Matsuno, M.; Takeda, Y.; Kinoshita, K. Ash accumulation and transport in diesel particulate filters (First report)–quantification of Ash accumulation density distribution by X-ray CT Imaging–. Trans. Soc. Automot. Eng. Jpn. 2018, 49, 1193–1198. [Google Scholar]

- Jin, D.Y.; Myung, C.L.; Kim, J.H.; Park, S.S. Physicochemical analysis of two aged diesel particulate filters placed at close coupled and under floor positions of the vehicles. Int. J. Automot. Technol. 2019, 20, 327–335. [Google Scholar] [CrossRef]

- Kwon, M.J.; Park, G.Y.; Kim, S.J.; Han, T.H.; Kim, J.M.; Lee, S.W. Feasibility study on nondestructive measurement of damaged DPF using CR X-ray imaging technique. Trans. Korean Soc. Automot. Eng. 2019, 27, 795–801. [Google Scholar]

- Abramoff, M.D.; Magalhães, P.J.; Ram, S.J. Image processing with ImageJ. Biophotonics Int. 2003, 11, 36–42. [Google Scholar]

- Sappok, A.; Wong, V. Ash effects on diesel particulate filter pressure drop sensitivity to Soot and implications for Regeneration frequency and DPF control. SAE Pap. 2010, 1, 811. [Google Scholar] [CrossRef]

- Roshani, M.; Phan, G.; Roshani, G.H.; Hanus, R.; Nazemi, B.; Corniani, E.; Nazemi, E. Combination of X-ray tube and GMDH neural network as a nondestructive and potential technique for measuring characteristics of gas-oil–water three phase flows. Measurement 2021, 168, 108427. [Google Scholar] [CrossRef]

- Tomaru, R.; Done, C.; Ohsuga, K.; Odaka, H.; Takahashi, T. The thermal-radiative wind in low-mass X-ray binary H1743− 322–II. Iron line predictions from Monte Carlo radiation transfer. Mon. Not. R. Astron. Soc. 2020, 494, 3413–3421. [Google Scholar] [CrossRef]

- Roshani, M.; Phan, G.; Jammal, P.; Ali, M.; Roshani, G.H.; Hanus, R.; Duong, T.; Corniani, E.; Nazemi, E.; Kalmoun, E.M. Evaluation of flow pattern recognition and void fraction measurement in two phase flow independent of oil pipeline’s scale layer thickness. Alex. Eng. J. 2021, 60, 1955–1966. [Google Scholar] [CrossRef]

- Salgado, W.L.; Dam, R.S.D.F.; Teixeira, T.P.; Conti, C.C.; Salgado, C.M. Application of artificial intelligence in scale thickness prediction on offshore petroleum using a gamma-ray densitometer. Radiat. Phys. Chem. 2020, 168, 108549. [Google Scholar] [CrossRef]

| Analog Film | CR | DR | |

|---|---|---|---|

| Image acquisition time | Slow | Normal | Fast |

| Image processing | Impossible | Possible | Possible |

| Dynamic range | Low | High | High |

| Cost (investment) | Low | Normal | High |

| Cost (using) | High (film, developer, etc.) | Normal (IP replacement, etc.) | Low |

| Number of reuses | 1 | 10,000 | 1,000,000 |

| System Model | GXR-S |

|---|---|

| Output rating | 52 kW |

| kV range | 40~150 kV, 1 kV step |

| mA range | 10–640 mA |

| Timer range | 0.001–10 s, 38 steps |

| mAs range | 0.1–500 mAs |

| System Model | Regius Model 110 |

|---|---|

| Sampling pitch | 2 Types 87.5/175 μm |

| Maximum resolution | 4020 × 4892 |

| Digital gradation level | 4096 levels (12 bit) |

| Processing capacity | approx. 61~80 plates/h |

| Item | Condition |

|---|---|

| Tube Voltage | 50 kV |

| Tube current | 10 mAs |

| Irradiation distance | 1 m |

| Sampling pitch (low scan mode) | 175 μm |

| Type of DPF substrate | Wall-flow |

| Substrate material | Cordierite |

| (a) 0 g Accumulation | (b) 12.5 g Accumulation | (c) 25 g Accumulation |

|  |  |

| (d) 62.5 g Accumulation | (e) 100 g Accumulation | (f) 125 g Accumulation |

|  |  |

| Carbon Powder Accumulation (g) | Mean Pixel Value | Standard Deviation |

|---|---|---|

| 0 | 158.887 | 1.420 |

| 12.5 | 167.390 | 3.273 |

| 25 | 172.388 | 2.050 |

| 62.5 | 178.212 | 1.781 |

| 100 | 179.967 | 1.630 |

| 125 | 183.624 | 1.623 |

| (a) 12.5 g Accumulation | (b) 25 g Accumulation | (c) 100 g Accumulation | (d) 125 g Accumulation |

|  |  |  |

| Ash Powder Accumulation (g) | Mean Pixel Value | Standard Deviation |

|---|---|---|

| 0 | 158.180 | 1.301 |

| 12.5 | 177.178 | 7.730 |

| 25 | 192.931 | 5.981 |

| 100 | 242.537 | 2.890 |

| 125 | 244.057 | 3.337 |

| Carbon Powder Accumulation 25 g | Ash Powder Accumulation 25 g |

|  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, G.; Ryu, H.; Kwon, M.; Lee, S. A Study on Soot and Ash Accumulation Characteristics of Diesel Particulate Filter Substrate Using Nondestructive Computed Radiography X-ray Imaging Technique. Appl. Sci. 2021, 11, 9483. https://doi.org/10.3390/app11209483

Park G, Ryu H, Kwon M, Lee S. A Study on Soot and Ash Accumulation Characteristics of Diesel Particulate Filter Substrate Using Nondestructive Computed Radiography X-ray Imaging Technique. Applied Sciences. 2021; 11(20):9483. https://doi.org/10.3390/app11209483

Chicago/Turabian StylePark, Giyoung, Hoyoung Ryu, Manjae Kwon, and Seangwock Lee. 2021. "A Study on Soot and Ash Accumulation Characteristics of Diesel Particulate Filter Substrate Using Nondestructive Computed Radiography X-ray Imaging Technique" Applied Sciences 11, no. 20: 9483. https://doi.org/10.3390/app11209483

APA StylePark, G., Ryu, H., Kwon, M., & Lee, S. (2021). A Study on Soot and Ash Accumulation Characteristics of Diesel Particulate Filter Substrate Using Nondestructive Computed Radiography X-ray Imaging Technique. Applied Sciences, 11(20), 9483. https://doi.org/10.3390/app11209483