Design and Analysis of a Novel Axial-Radial Flux Permanent Magnet Machine with Halbach-Array Permanent Magnets

Abstract

:1. Introduction

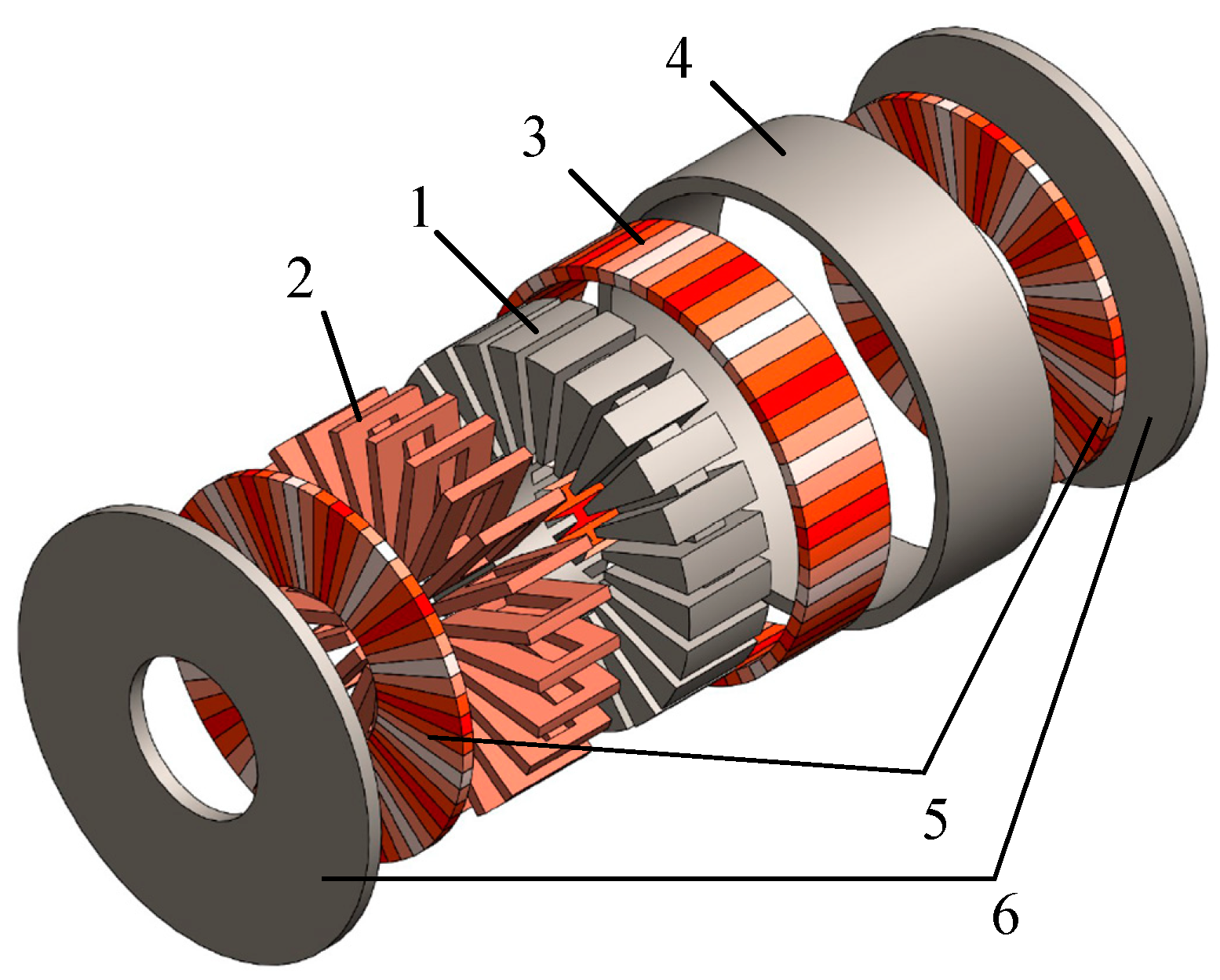

2. Structure and Operational Principle

2.1. Structure of Axial-Radial Flux Permanent Magnet (ARFPM) Machine

2.2. Operational Principle of ARFPM Machine

3. Parametric Study of ARFPM Machine

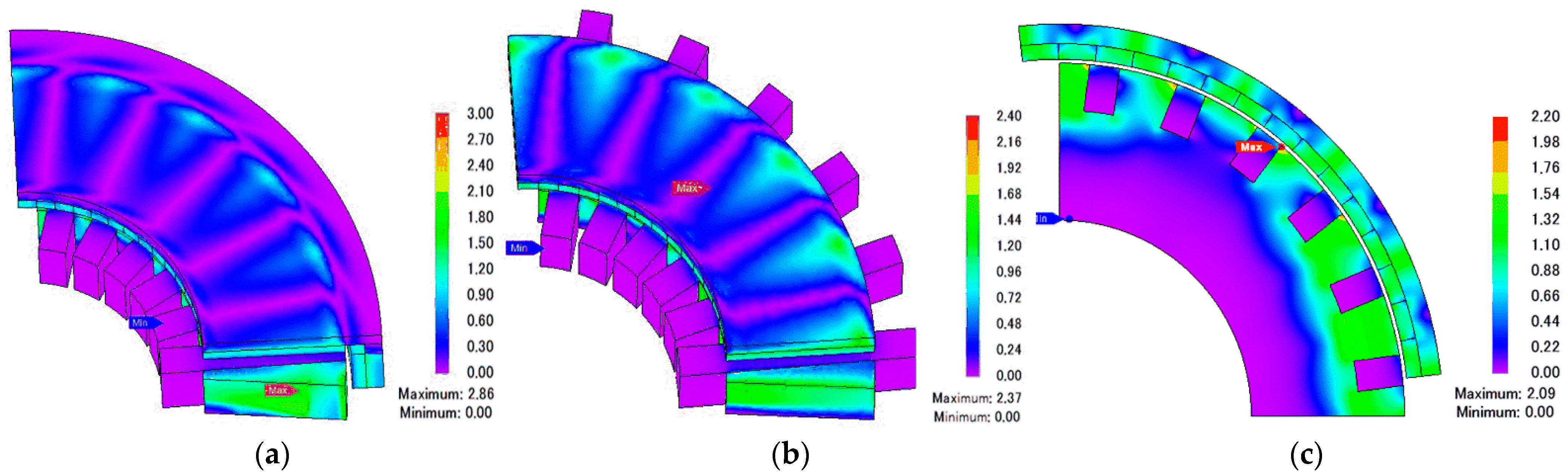

3.1. Study on Air-Gap Flux Density and Back Electromotive Force (EMF)

3.1.1. Impact of Permanent Magnet (PM) Arrangement

3.1.2. Impact of Air-Gap Depth

3.2. Study of Axial Force

3.3. Study of Electromagnetic Torque

4. Comparative Analysis of ARFPM Machine

4.1. Air-Gap Magnetic Flux Density

4.2. No-Load Back EMF

4.3. Electromagnetic Torque

4.4. Cogging Torque

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zhao, H.; Liu, C.; Song, Z.; Wang, W. Analytical Modeling of a Double-Rotor Multiwinding Machine for Hybrid Aircraft Propulsion. IEEE Trans. Transp. Electrif. 2020, 6, 1537–1550. [Google Scholar] [CrossRef]

- Wang, D.; Peng, C.; Xue, D.; Zhang, D.; Wang, X. Performance Assessment and Comparative Study of a Permanent Magnet Machine with Axial Flux Regulator. IEEE Trans. Energy Convers. 2019, 34, 1522–1531. [Google Scholar] [CrossRef]

- Yu, J.; Liu, C.; Song, Z.; Zhao, H. Permeance and Inductance Modeling of a Double-Stator Hybrid-Excited Flux-Switching Permanent-Magnet Machine. IEEE Trans. Transp. Electrif. 2020, 6, 1134–1145. [Google Scholar] [CrossRef]

- Liu, C.; Chau, K.T.; Lee, C.H.T.; Song, Z. A Critical Review of Advanced Electric Machines and Control Strategies for Electric Vehicles. Inst. Electr. Electron. Eng. 2020, 109, 1004–1028. [Google Scholar] [CrossRef]

- Tong, C.; Song, Z.; Bai, J.; Liu, J.; Zheng, P. Analytical Investigation of the Magnetic-Field Distribution in an Axial Magnetic-Field-Modulated Brushless Double-Rotor Machine. Energies 2016, 9, 589. [Google Scholar] [CrossRef] [Green Version]

- Song, Z.; Liu, C.; Zhao, H. Investigation on Magnetic Force of a Flux-Modulated Double-Rotor Permanent Magnet Synchronous Machine for Hybrid Electric Vehicle. IEEE Trans. Transp. Electrif. 2019, 5, 1383–1394. [Google Scholar] [CrossRef]

- Aydin, M.; Surong, H.; Lipo, T.A. Torque quality and comparison of internal and external rotor axial flux surface-magnet disc machines. IEEE Trans. Ind. Electron. 2006, 53, 822–830. [Google Scholar] [CrossRef]

- Khatab, M.F.H.; Zhu, Z.Q.; Li, H.Y.; Liu, Y. Comparative study of novel axial flux magnetically geared and conventional axial flux permanent magnet machines. CES Trans. Electr. Mach. Syst. 2018, 2, 392–398. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Kahourzade, S.; Rahim, N.A.; Hew, W.P.; Uddin, M.N. Design, Analysis, and Prototyping of a Novel-Structured Solid-Rotor-Ringed Line-Start Axial-Flux Permanent-Magnet Motor. IEEE Trans. Ind. Electron. 2014, 61, 1722–1734. [Google Scholar] [CrossRef]

- Trong Duy, N.; King-Jet, T.; Shao, Z.; Hoan Thong, N. A Novel Axial Flux Permanent-Magnet Machine for Flywheel Energy Storage System: Design and Analysis. IEEE Trans. Ind. Electron. 2011, 58, 3784–3794. [Google Scholar] [CrossRef]

- Fawzal, A.S.; Cirstea, R.M.; Gyftakis, K.N.; Woolmer, T.J.; Dickison, M.; Blundell, M. Fan Performance Analysis for Rotor Cooling of Axial Flux Permanent Magnet Machines. IEEE Trans. Ind. Appl. 2017, 53, 3295–3304. [Google Scholar] [CrossRef]

- Dwivedi, A.; kumar Singh, S.; Srivastava, R.K. Analysis and Performance Evaluation of Axial Flux Permanent Magnet Motors. IEEE Trans. Ind. Appl. 2018, 54, 1765–1772. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.; Qu, R.; Li, D. Analysis and Design of Triple-Rotor Axial-Flux Spoke-Array Vernier Permanent Magnet Machines. IEEE Trans. Ind. Appl. 2018, 54, 244–253. [Google Scholar] [CrossRef]

- Geng, W.W.; Zhang, Z.R. Analysis and Implementation of New Ironless Stator Axial-Flux Permanent Magnet Machine with Concentrated Nonoverlapping Windings. IEEE Trans. Energy Convers. 2018, 33, 1274–1284. [Google Scholar] [CrossRef]

- Vansompel, H.; Sergeant, P.; Dupre, L.; Bossche, A. A Combined Wye-Delta Connection to Increase the Performance of Axial-Flux PM Machines with Concentrated Windings. IEEE Trans. Energy Convers. 2012, 27, 403–410. [Google Scholar] [CrossRef]

- Pranjic, F.; Virtic, P. Designing Rotor Disks of a Coreless Axial Flux Permanent Magnet Machines by Using Simplified FEM and an Approximation Method. IEEE Trans. Energy Convers. 2020, 35, 1505–1512. [Google Scholar] [CrossRef]

- Kim, J.; Choi, W.; Sarlioglu, B. Closed-form Solution for Axial Flux Permanent Magnet Machines with a Traction Application Study. IEEE Trans. Ind. Appl. 2015, 52, 1775–1784. [Google Scholar] [CrossRef]

- Virtic, P.; Vrazic, M.; Papa, G. Design of an Axial Flux Permanent Magnet Synchronous Machine Using Analytical Method and Evolutionary Optimization. IEEE Trans. Energy Convers. 2016, 31, 150–158. [Google Scholar] [CrossRef]

- Di Gerlando, A.; Foglia, G.M.; Iacchetti, M.F.; Perini, R. Parasitic Currents in Stray Paths of Some Topologies of YASA AFPM Machines: Trend with Machine Size. IEEE Trans. Ind. Electron. 2016, 63, 2746–2756. [Google Scholar] [CrossRef] [Green Version]

- Winterborne, D.; Stannard, N.; Sjoberg, L.; Atkinson, G. An Air-Cooled YASA Motor for in-Wheel Electric Vehicle Applications. IEEE Trans. Ind. Appl. 2020, 56, 6448–6455. [Google Scholar] [CrossRef]

- Taran, N.; Rallabandi, V.; Heins, G.; Ionel, D.M. Coreless and Conventional Axial Flux Permanent Magnet Motors for Solar Cars. IEEE Trans. Ind. Appl. 2018, 54, 5907–5917. [Google Scholar] [CrossRef]

- Mirimani, S.M.; Vahedi, A.; Marignetti, F.; de Santis, E. Static Eccentricity Fault Detection in Single-Stator–Single-Rotor Axial-Flux Permanent-Magnet Machines. IEEE Trans. Ind. Appl. 2012, 48, 1838–1845. [Google Scholar] [CrossRef]

- Ajily, E.; Ardebili, M.; Abbaszadeh, K. Magnet Defect and Rotor Eccentricity Modeling in Axial-Flux Permanent-Magnet Machines via 3-D Field Reconstruction Method. IEEE Trans. Energy Convers. 2016, 31, 486–495. [Google Scholar] [CrossRef]

- Aydin, M.; Gulec, M. A New Coreless Axial Flux Interior Permanent Magnet Synchronous Motor with Sinusoidal Rotor Segments. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- De Donato, G.; Capponi, F.G.; Rivellini, A.; Caricchi, F. Integer-Slot vs Fractional-Slot Concentrated-Winding Axial-Flux Permanent Magnet Machines: Comparative Design, FEA and Experimental Tests. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 17–22 September 2011; pp. 3120–3127. [Google Scholar]

- De Donato, G.; Giulii Capponi, F.; Caricchi, F. Fractional-Slot Concentrated-Winding Axial-Flux Permanent-Magnet Machine with Core-Wound Coils. IEEE Trans. Ind. Appl. 2012, 48, 630–641. [Google Scholar] [CrossRef]

- Song, Z.; Liu, C.; Feng, K.; Zhao, H.; Yu, J. Field Prediction and Validation of a Slotless Segmented-Halbach Permanent Magnet Synchronous Machine for More Electric Aircraft. IEEE Trans. Transp. Electrif. 2020, 6, 1577–1591. [Google Scholar] [CrossRef]

- Jin, P.; Yuan, Y.; Xu, Q.; Fang, S.; Lin, H.; Ho, S.L. Analysis of Axial-Flux Halbach Permanent-Magnet Machine. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Tang, R. Modern Permanent Magnet Machines: Theory and Design, 1st ed.; China Machine Press: Beijing, China, 2015; Volume 9. [Google Scholar]

- Xiao, L.; Li, J.; Qu, R.; Lu, Y.; Zhang, R.; Li, D. Cogging Torque Analysis and Minimization of Axial Flux PM Machines with Combined Rectangle-Shaped Magnet. IEEE Trans. Ind. Appl. 2017, 53, 1018–1027. [Google Scholar] [CrossRef]

- Wanjiku, J.; Khan, M.A.; Barendse, P.S.; Pillay, P. Influence of Slot Openings and Tooth Profile on Cogging Torque in Axial-Flux PM Machines. IEEE Trans. Ind. Electron. 2015, 62, 7578–7589. [Google Scholar] [CrossRef]

| Parameter | ARFPM Machine | AFPM Machine | RFPM Machine |

|---|---|---|---|

| Pole pairs | 10 | 10 | 10 |

| Slot number | 24 | 24 | 24 |

| Outer diameter of the machine | 200 mm | 200 mm (include length of ends) | 200 mm |

| Inner diameter of the machine | 100 mm | 100 mm | 100 mm |

| Width of slot | 7.86 mm | 7.86 mm | 7.86 mm |

| Depth of slot | 12 mm | 12 mm | 12 mm |

| Thickness of PM | 4 mm | 4 mm | 4 mm |

| Axial length of the machine | 60 mm | 60 mm | 60 mm (include length of ends) |

| Air-gap depth | 1 mm | 1 mm | 1 mm |

| Turns in every slot | 65 | 65 | 65 |

| Current density | 5 A/mm2 | 5 A/mm2 | 5 A/mm2 |

| Rotary speed | 600 rpm | 600 rpm | 600 rpm |

| Performance | ARFPM Machine | AFPM Machine | RFPM Machine |

|---|---|---|---|

| Back EMF | 256 V | 161 V | 105 V |

| THD of back EMF | 9.47% | 1.32% | 1.90% |

| Electromagnetic torque | 39.93 Nm | 27.33 Nm | 17.74 Nm |

| Torque-to-PM volume | 170.47 Nm/L | 194.18 Nm/L | 189.75 Nm/L |

| Torque ripple | 14.3% | 5.0% | 17.8% |

| Cogging torque | 3.60 Nm | 0.83 Nm | 3.18 Nm |

| Current density | 5 A/mm2 | 5 A/mm2 | 5 A/mm2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, R.; Liu, C.; Song, Z.; Zhao, H. Design and Analysis of a Novel Axial-Radial Flux Permanent Magnet Machine with Halbach-Array Permanent Magnets. Energies 2021, 14, 3639. https://doi.org/10.3390/en14123639

Huang R, Liu C, Song Z, Zhao H. Design and Analysis of a Novel Axial-Radial Flux Permanent Magnet Machine with Halbach-Array Permanent Magnets. Energies. 2021; 14(12):3639. https://doi.org/10.3390/en14123639

Chicago/Turabian StyleHuang, Rundong, Chunhua Liu, Zaixin Song, and Hang Zhao. 2021. "Design and Analysis of a Novel Axial-Radial Flux Permanent Magnet Machine with Halbach-Array Permanent Magnets" Energies 14, no. 12: 3639. https://doi.org/10.3390/en14123639

APA StyleHuang, R., Liu, C., Song, Z., & Zhao, H. (2021). Design and Analysis of a Novel Axial-Radial Flux Permanent Magnet Machine with Halbach-Array Permanent Magnets. Energies, 14(12), 3639. https://doi.org/10.3390/en14123639