The Diffusion of Bioplastics: What Can We Learn from Poly(Lactic Acid)?

Abstract

:1. Introduction

2. Methodology

3. An Overview of Bioplastics

4. The Properties of PLA

5. PLA: A Timeline of the Main Advances, Players, and Drivers Impacting Its Diffusion

5.1. Invention and Decades of Limited Diffusion (from 1932 to the Early 1980s)

5.2. Renewed Interest Due to Environmental Concerns (from the Late 1980s to around 2002)

5.2.1. Environmental Concerns on Plastics

5.2.2. The New PLA Producers

5.2.3. Initial Properties of PLA and Applications

5.3. Slow Growth and the Achievement of an Apparent Tipping Point (from around 2002 to the Present)

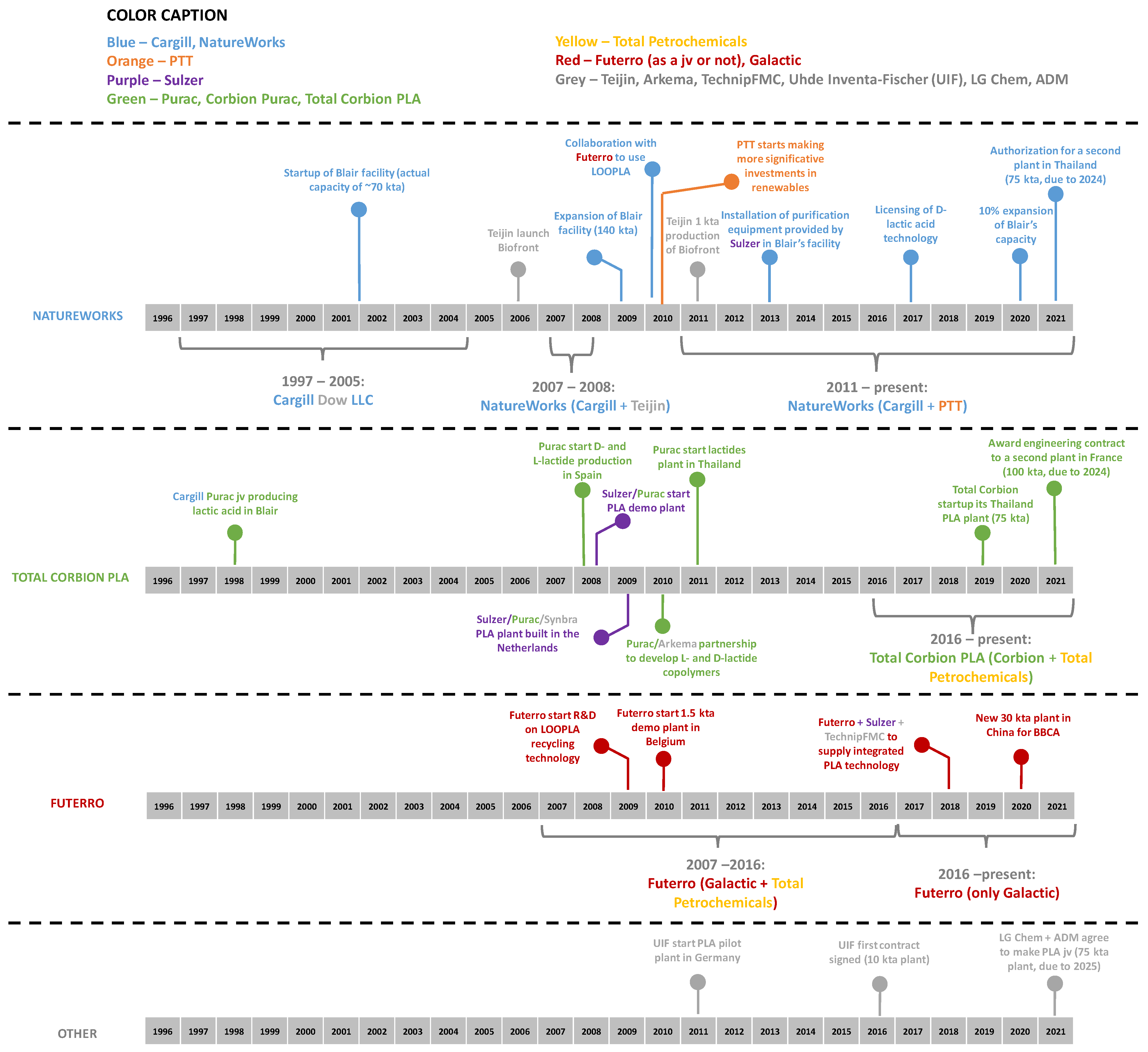

5.3.1. New Entries and Exit of Producers

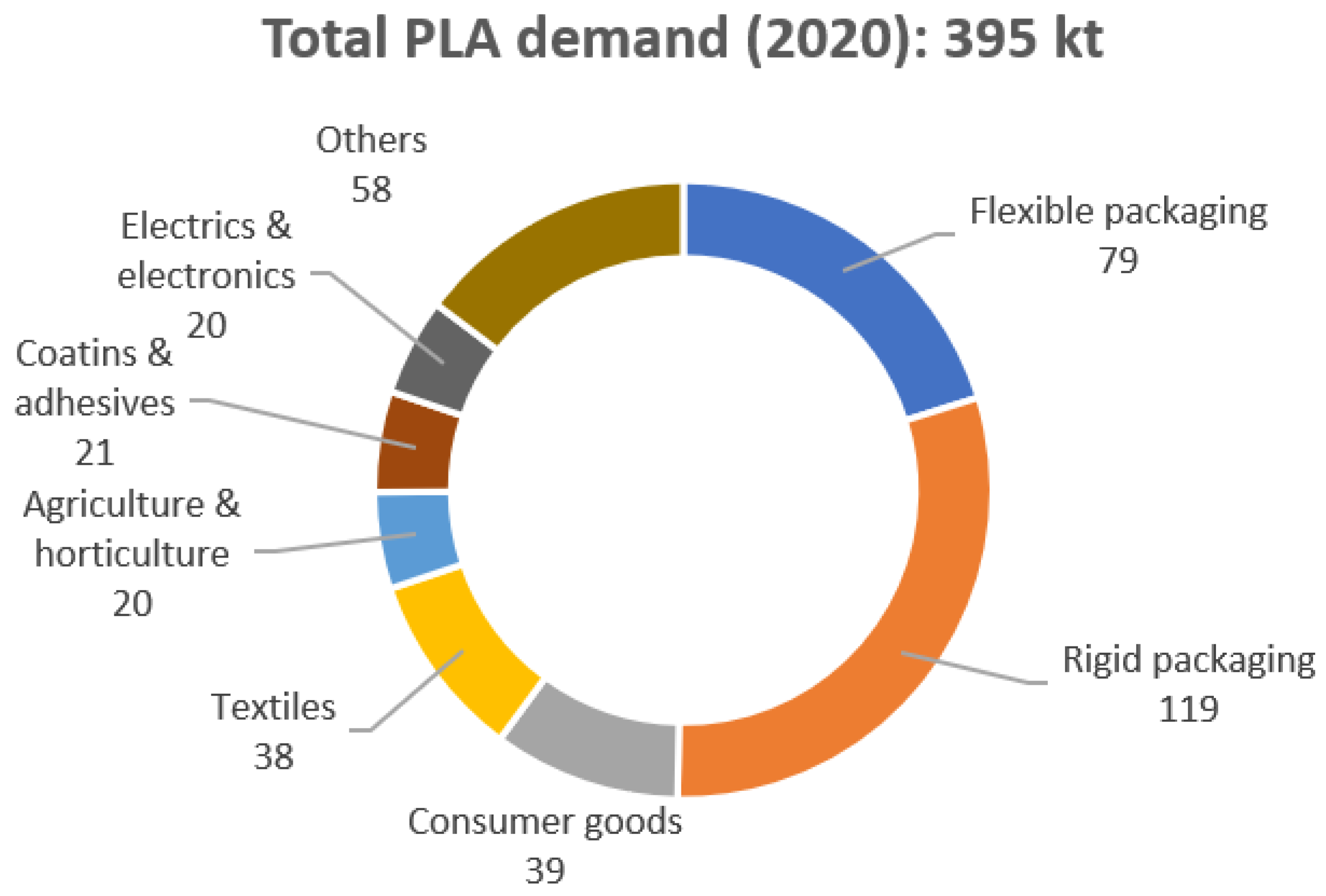

5.3.2. Main PLA Markets and Capacity Build-up

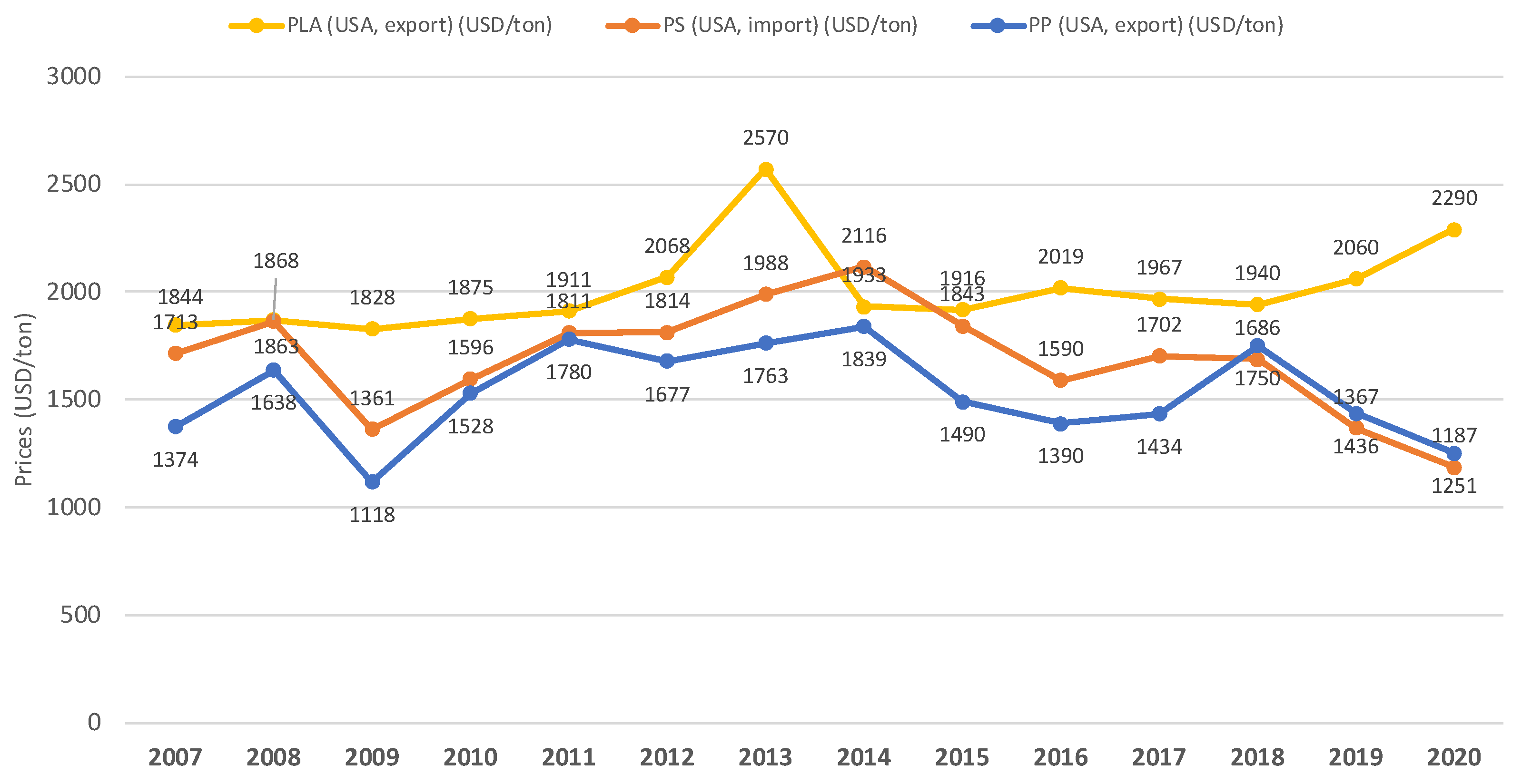

5.3.3. Prices, Properties, and Processability of PLA

5.3.4. PLA Applications

5.3.5. Sustainability Aspects of PLA Production and EOL Alternatives

5.3.6. Demand Drivers

6. Stylized Facts of the Diffusion of Bioplastics

6.1. Stylized Fact 1: The Prevalence of Petrochemical Plastics Restricted the Increase in the Capabilities of Bioplastics

6.2. Stylized Fact 2: Plastics Generally Present Property Issues When They Are Introduced

6.3. Stylized Fact 3: Plastic Pollution Was a Key Trigger of Bioplastics Diffusion

6.4. Stylized Fact 4: Bioplastics Experienced Lower-than-Expected Market Growth, Which Compromised Corporate Commitment

6.5. Stylized Fact 5: Co-Operation Is Key to Promoting Bioplastics

6.6. Stylized Fact 6: Sustainability Scrutiny Simultaneously Propels and Hinders Bioplastics

7. The Lessons from PLA and Insights into Diffusion of Bioplastics

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options, 1st ed.; Organisation for Economic Co-operation and Development: Paris, France, 2022; Available online: https://www.oecd-ilibrary.org/environment/global-plastics-outlook_de747aef-en (accessed on 10 April 2022).

- World Economic Forum. The New Plastics Economy: Rethinking the Future of Plastics; McKinsey: Geneva, Switzerland, 2016; Available online: https://www.mckinsey.com/~/media/McKinsey/dotcom/client_service/Sustainability/PDFs/The%20New%20Plastics%20Economy.ashx (accessed on 20 March 2022).

- UNEP. Plastic Pollution is an Environmental Injustice to Vulnerable Communities—New Report; UN Environment: Nairobi, Kenya, 2021; Available online: http://www.unep.org/news-and-stories/press-release/plastic-pollution-environmental-injustice-vulnerable-communities-new (accessed on 22 February 2023).

- OECD. Plastic Pollution is Growing Relentlessly as Waste Management and Recycling Fall Short, Says OECD; Newsroom: Paris, France, 2022; Available online: https://www.oecd.org/newsroom/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm (accessed on 10 July 2022).

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef] [PubMed]

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Bailey, G.; Chitalia, A. Can Bioplastics Make the Chemicals Industry Greener? Wood Mackenzie: Edinburgh, UK, 2020; Available online: https://www.woodmac.com/news/opinion/can-bioplastics-make-the-chemicals-industry-greener/ (accessed on 20 March 2022).

- De Smet, M.; Linder, M.; Koopmans, R.; Doorsselaer, K.; van Velis, C.; De Wilde, B.; Ritschkoff, A.-C.; Crippa, M.; Leyssens, J.; Wagner, M.; et al. A Circular Economy for Plastics: Insights from Research and Innovation to Inform Policy and Funding Decisions—Directorate-General for Research and Innovation (European Commission); Publications Office of the European Union: Luxembourg, 2019; Available online: https://data.europa.eu/doi/10.2777/269031 (accessed on 10 July 2022).

- Fuentes-Saguar, P.D.; Mainar-Causapé, A.J.; Ferrari, E. The Role of Bioeconomy Sectors and Natural Resources in EU Economies: A Social Accounting Matrix-Based Analysis Approach. Sustainability 2017, 9, 2383. [Google Scholar] [CrossRef] [Green Version]

- Diaz-Chavez, R.; Mortensen, S.; Wikman, A. Bioeconomy: Tapping Natural and Human Resources to Achieve Sustainability; Stockholm Environmental Institute: Stockholm, Sweden, 2019; Available online: https://www.sei.org/wp-content/uploads/2020/01/sei-report-2020-bioeconomy-diaz-chavez.pdf (accessed on 22 February 2023).

- Edgington, T. Plastic or Paper: Which Bag is Greener? BBC News. 2019. Available online: https://www.bbc.com/news/business-47027792 (accessed on 20 March 2022).

- Calabia, B.P.; Tokiwa, Y.; Ugwu, C.U.; Aiba, S. Biodegradation. In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 423–430. [Google Scholar]

- European Bioplastics. Bioplastic Materials; European Bioplastics: Berlin, Germany, 2021; Available online: https://www.european-bioplastics.org/bioplastics/materials/ (accessed on 26 October 2021).

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.-A.T. Environmental impact of bioplastic use: A review. Heliyon 2021, 7, e07918. [Google Scholar] [CrossRef]

- Tullo, A. Plastic Found at the End of the Maize. Chemical & Engineering News, 2000. Available online: https://pubs.acs.org/doi/pdf/10.1021/cen-v078n003.p013(accessed on 22 October 2021).

- Pacitti, S. Thailand PLA Plant Makes Progress. Plastics in Packaging, 2021. Available online: https://plasticsinpackaging.com/thailand-pla-plant-makes-progress/(accessed on 14 September 2021).

- European Bioplastics. Bioplastics Market Development Update 2022; European Bioplastics: Berlin, Germany, 2022; Available online: https://docs.european-bioplastics.org/publications/market_data/2022/Report_Bioplastics_Market_Data_2022_short_version.pdf (accessed on 21 December 2022).

- Kawaguchi, H.; Takada, K.; Elkasaby, T.; Pangestu, R.; Toyoshima, M.; Kahar, P.; Ogino, C.; Kaneko, T.; Kondo, A. Recent advances in lignocellulosic biomass white biotechnology for bioplastics. Bioresour. Technol. 2021, 344, 126165. [Google Scholar] [CrossRef]

- Nanda, S.; Patra, B.R.; Patel, R.; Bakos, J.; Dalai, A.K. Innovations in applications and prospects of bioplastics and biopolymers: A review. Environ. Chem. Lett. 2021, 20, 379–395. [Google Scholar] [CrossRef]

- Jem, K.J.; Tan, B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv. Ind. Eng. Polym. Res. 2020, 3, 60–70. [Google Scholar] [CrossRef]

- Narancic, T.; Cerrone, F.; Beagan, N.; O’Connor, K.E. Recent Advances in Bioplastics: Application and Biodegradation. Polymers 2020, 12, 920. [Google Scholar] [CrossRef] [Green Version]

- Adner, R.; Kapoor, R. Value creation in innovation ecosystems: How the structure of technological interdependence affects firm performance in new technology generations. Strat. Manag. J. 2010, 31, 306–333. [Google Scholar] [CrossRef]

- Ortt, J. Understanding the Pre-diffusion Phases. In Gaining Momentum—Managing the Diffusion of Innovations, 1st ed.; Tidd, J., Ed.; Imperial College Press: London, UK, 2010; pp. 47–80. [Google Scholar]

- Rogers, E.M. Diffusion of Innovations, 5th ed.; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Rosenberg, N. Factors affecting the diffusion of technology. Explor. Econ. Hist. 1972, 10, 3–33. [Google Scholar] [CrossRef]

- Tidd, J. From Models to the Management of Diffusion. In Gaining Momentum—Managing the Diffusion of Innovations, 1st ed.; Tidd, J., Ed.; Imperial College Press: London, UK, 2010; pp. 3–45. [Google Scholar]

- Döhler, N.; Wellenreuther, C.; Wolf, A. Market dynamics of biodegradable bio-based plastics: Projections and linkages to European policies. EFB Bioecon. J. 2022, 2, 100028. [Google Scholar] [CrossRef]

- De Almeida Oroski, F.; Alves, F.C.; Bomtempo, J.V. Bioplastics Tipping Point: Drop-in or non-drop-in? J. Bus. Chem. 2014, 11, 43–50. [Google Scholar]

- Helfat, C.E. Stylized facts, empirical research and theory development in management. Strat. Organ. 2007, 5, 185–192. [Google Scholar] [CrossRef]

- Gruber, P.R. Cargill Dow LLC. J. Ind. Ecol. 2003, 3–4, 209–213. [Google Scholar] [CrossRef]

- C&EN. C&EN Archives. 2018. Available online: https://pubs.acs.org/loi/cgeabj/group/d2010.y2018 (accessed on 2 January 2019).

- Plastics Technology. Archive Issues. Issues. 2022. Available online: https://www.ptonline.com/articles/issues (accessed on 23 November 2022).

- Hirschman, D. Stylized Facts in the Social Sciences. Sociol. Sci. 2016, 3, 604–626. [Google Scholar] [CrossRef] [Green Version]

- EU. Roadmap for the Chemical Industry in Europe towards a Bioeconomy. In Europe: E4tech, Nova-Institute, BTG, DECHEMA; EU: Luxembourg, 2019. [Google Scholar]

- Jian, J.; Xiangbin, Z.; Xianbo, H. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv. Ind. Eng. Polym. Res. 2020, 3, 19–26. [Google Scholar] [CrossRef]

- Winnacker, M.; Rieger, B. Biobased Polyamides: Recent Advances in Basic and Applied Research. Macromol. Rapid Commun. 2016, 37, 1391–1413. [Google Scholar] [CrossRef] [PubMed]

- Groot, W.; Krieken, J.; van Sliekersl, O.; de Vos, S. Production and Purification of Lactic Acid and Lactide. In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 3–18. [Google Scholar]

- Chahal, S.P.; Starr, J.N. Lactic Acid. In Ullmann’s Encyclopedia of Industrial Chemistry, 6th ed.; Wiley-VCH: Weinheim, Germany, 2002. [Google Scholar]

- Prasirtsak, B.; Thitiprasert, S.; Tolieng, V.; Assabumrungrat, S.; Tanasupawat, S.; Thongchul, N. D-Lactic acid fermentation per-formance and the enzyme activity of a novel bacterium Terrilactibacillus laevilacticus SK5–6. Ann. Microbiol. 2019, 69, 1537–1546. [Google Scholar] [CrossRef]

- Endres, H.J.; Siebert-Raths, A. Engineering Biopolymers: Markets, Manufacturing, Properties, and Applications, 1st ed.; Hanser Publishers: Cincinnati, OH, USA, 2010; 674p. [Google Scholar]

- Kühnert, I.; Spörer, Y.; Brünig, H.; Tran, N.H.A.; Rudolph, N. Processing of Poly(lactic Acid). In Industrial Applications of Poly(lactic acid), 1st ed.; Advances in Polymer Science; Di Lorenzo, M.L., Androsch, R., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–33. [Google Scholar] [CrossRef]

- Kim, L.T.; Cink, K.; Vanyo, T. Processing of Poly(Lactic Acid). In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications, 1st ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2010; pp. 191–216. [Google Scholar]

- Perego, G.; Cella, G.D. Mechanical Properties. In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 141–154. [Google Scholar]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable Polylactic Acid (PLA)-Based Sustainable Engineered Blends and Biocomposites: Recent Developments, Challenges, and Opportunities. ACS Eng. 2021, 1, 7–38. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Siengchin, S.; Salim, N.V.; George, J.J.; Poulose, A. Polylactic Acid-Based Nanocellulose and Cellulose Composites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2022; 338p. [Google Scholar]

- Zhao, X.; Hu, H.; Wang, X.; Yu, X.; Zhou, W.; Peng, S. Super tough poly(lactic acid) blends: A comprehensive review. RSC Adv. 2020, 10, 13316–13368. [Google Scholar] [CrossRef] [Green Version]

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef] [PubMed]

- Boey, J.Y.; Mohamad, L.; Khok, Y.S.; Tay, G.S.; Baidurah, S. A Review of the Applications and Biodegradation of Polyhydroxyalka-noates and Poly(lactic acid) and Its Composites. Polymers 2021, 13, 1544. [Google Scholar] [CrossRef] [PubMed]

- Auras, R.; Kim, L.T.; Selke, S.E.M.; Tsuji, H. Preface. In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. xvii–xix. [Google Scholar]

- Moskowitz, S.L. Advanced Materials Innovation: Managing Global Technology in the 21st Century, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; 487p. [Google Scholar]

- Bennett, S.J.; Pearson, P.J. From petrochemical complexes to biorefineries? The past and prospective co-evolution of liquid fuels and chemicals production in the UK. Chem. Eng. Res. Des. 2009, 87, 1120–1139. [Google Scholar] [CrossRef]

- Buehler, B. Biodegradable polymers: The opportunities and challenges for agriculture. In Agricultural Outlook Forum; U.S. Department of Agriculture, World Agricultural Outlook Board: Washington, DC, USA, 1995. [Google Scholar]

- Singhvi, M.S.; Zinjarde, S.S.; Gokhale, D.V. Polylactic acid: Synthesis and biomedical applications. J. Appl. Microbiol. 2019, 127, 1612–1626. [Google Scholar] [CrossRef] [Green Version]

- Susuki, S.; Ikada, Y. Medical Applications. In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, and Applications, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Lunt, J. Large-scale production, properties and commercial applications of polylactic acid polymers. Polym. Degrad. Stab. 1998, 59, 145–152. [Google Scholar] [CrossRef]

- U.S. Congress, Office of Technology Assessment. Biopolymers: Making Materials Nature’s Way; Background Paper; U.S. Congress: Washington, DC, USA, 1993. Available online: https://ota.fas.org/reports/9313.pdf (accessed on 4 July 2021).

- Bell, S. Process Economics Program Report 128C; Polypropylene Update; SRI Consulting: Menlo Park, CA, USA, 2001. [Google Scholar]

- Thayer, A.M. Solid Waste Concerns Spur Plastic Recycling Efforts. Chem. Eng. News 1989, 67, 7–15. [Google Scholar] [CrossRef]

- Japan BioPlastics Association. About. Japan BioPlastics Association. 2021. Available online: http://www.jbpaweb.net/english/ (accessed on 11 July 2021).

- Layman, P.L. Packaging Continues as Strong Growth Market for Plastics. Chem. Eng. News 1987, 65, 15–17. [Google Scholar] [CrossRef]

- Klöpffer, W. (Ed.) Background and Future Prospects in Life Cycle Assessment, 1st ed.; LCA Compendium—The Complete World of Life Cycle Assessment; Springer: Dordrecht, The Netherlands; Frankfurt am Main, Germany, 2014; Available online: www.springer.com/gp/book/9789401786966 (accessed on 15 November 2018).

- Tamoor, M.; Samak, N.A.; Yang, M.; Xing, J. The Cradle-to-Cradle Life Cycle Assessment of Polyethylene terephthalate: Environmental Perspective. Molecules 2022, 27, 1599. [Google Scholar] [CrossRef]

- Hakala, S.; Virtanen, Y.; Meinander, K.; Tanner, T. Life-Cycle Assessment, Comparison of Biopolymer and Traditional Diaper systems. 1997. Available online: https://www.vttresearch.com/sites/default/files/pdf/tiedotteet/1997/T1876.pdf (accessed on 15 August 2021).

- Patel, M.; Gerhard, A.; Crank, M.; Schleich, J.; Marcheider-Weidemann, F.; Wolf, O.; Hüsing, B. Techno-Economic Feasibility of Large-Scale Production of Bio-Based Polymers in Europe; Report No.: EUR22103EN; IPTS-EC: Seville, Spain, 2005. [Google Scholar]

- Schut, J.H. Extruding Biopolymers: Packaging Reaps Cost Benefit of Going Green. 2007. Available online: https://www.ptonline.com/articles/extruding-biopolymers-packaging-reaps-cost-benefit-of-going-’green’ (accessed on 26 October 2021).

- Thayer, A. Polylactic acid is basis of Dow, Cargill venture. Chem. Eng. News 1997, 75, 14–16. [Google Scholar] [CrossRef]

- C&EN. Concentrates—Du Pont, ConAgra in Polylactides Venture; Chemical & Engineering News: Washington, DC, USA, 1991; Available online: https://pubs.acs.org/doi/pdf/10.1021/cen-v069n024.p009 (accessed on 4 July 2021).

- Narayan, R. Overview and Case Studies of Biodegradable Plastic Technologies. Selected Papers from ICS—UNIDO International Workshop on Environmentally Degradable Polymers. 1999. Available online: https://open.unido.org/api/documents/4813694/downLoad/SELECTED%20PAPERS%20FROM%20ICS-UNIDO%20WORKSHOP%20ON%20ENVIRONMENTALLY%20DEGRADABLE%20POLYMERS%20-%20POLYMERIC%20MATERIALS%20AND%20THE%20ENVIRONMENT%20 (accessed on 4 July 2021).

- Detaille, S. ENTREPRISES Galactic Dans le Grand Bain de L’acide Lactique En cinq ans, Elle est Devenue Deuxième Producteur Mondial Un Plastique Biodégradable et 199 Autres Dérivés; Le Soir: Brussels, Belgium, 1999; Available online: https://www.lesoir.be/art/%25252Fentreprises-galactic-dans-le-grand-bain-de-l-acide-lact_t-19990305-Z0GG7R.html (accessed on 25 October 2021).

- Argonne National Laboratory. Research and Highlights; Argonne National Laboratory: Lemont, IL, USA, 1992; 184p. [Google Scholar]

- ICIS News. Mitsui Toatsu Starts on Lacea. ICIS Explore, 1995. Available online: https://www.icis.com/explore/resources/news/1995/12/11/4882/mitsui-toatsu-starts-on-lacea(accessed on 11 July 2021).

- Lenz, R.W. JTEC Monograph on Biodegradable Polymers and Plastics in Japan: Research, Development, and Applications; JTEC/WTEC Program; Distributed by National Technical Information Service; International Technology Research Institute: Baltimore, MD, USA; Springfield, VA, USA, 1995; 34p. Available online: https://ntrs.nasa.gov/api/citations/19950021273/downloads/19950021273.pdf (accessed on 11 July 2021).

- Ritter, S.K. Green Challenge—Presidential Awards Recognize Innovative Syntheses, Process Improvements, and New Products that Promote Pollution Prevention; Chemical & Engineering News: Washington, DC, USA, 2002; Available online: https://pubs.acs.org/doi/pdf/10.1021/cen-v080n026.p026 (accessed on 23 October 2021).

- Taylor, G. US Chronopol nears PLA Market Launch; ICIS Explore: London, UK, 1998; Available online: https://www.icis.com/explore/resources/news/1998/01/07/47769/us-chronopol-nears-pla-market-launch (accessed on 4 July 2021).

- Mitsui. PLGATM, PLGA- Poly(DL-Lactide-co-Glycolide); Business and Products: Rye Brook, NY, USA, 2022; Available online: https://us.mitsuichemicals.com/service/product/plga.htm (accessed on 15 May 2022).

- Djukić-Vuković, A.; Mladenović, D.; Ivanović, J.; Pejin, J.; Mojović, L. Towards sustainability of lactic acid and polylactic acid polymers production. Renew. Sustain. Energy Rev. 2019, 108, 238–252. [Google Scholar] [CrossRef]

- Vink, E.T.H.; Davies, S. Life Cycle Inventory and Impact Assessment Data for 2014 IngeoTM Polylactide Production. Ind. Biotechnol. 2015, 11, 167–180. [Google Scholar] [CrossRef] [Green Version]

- De Oliveira, R.A.; Komesu, A.; Vaz Rossell, C.E.; Maciel Filho, R. Challenges and opportunities in lactic acid bioprocess design—From economic to production aspects. Biochem. Eng. J. 2018, 133, 219–239. [Google Scholar] [CrossRef]

- Komesu, A.; de Oliveira, J.A.R.; da Martinsm, L.H.S.; Maciel, M.R.W.; Filho, R.M. Lactic Acid Production to Purification: A Review. BioResources 2017, 12, 4364–4383. [Google Scholar] [CrossRef] [Green Version]

- Hartmann, M.H. High molecular Weight Polylactic acid Polymers. In Biopolymers from Renewable Resources; Springer: Berlin/Heidelberg, Germany, 1998; pp. 367–411. [Google Scholar]

- Chemical Online. Plastics from Corn? Dow and Cargill Will Investigate. News, 1997. Available online: https://www.chemicalonline.com/doc/plastics-from-corn-dow-and-cargill-will-inves-0001(accessed on 18 October 2021).

- Mitsui; Cargill Dow LLC; Mitsui Chemicals, Inc. Announce Collaboration on PLA Business Development; Press Releases: Tokyo, Japan, 2001; Available online: https://jp.mitsuichemicals.com/en/release/2001/pdf/010926e.pdf (accessed on 15 August 2021).

- McCoy, M. Milking A Market—Two Biobased Chemical Firms Tackle the Lactide Business with Different Approaches; Chemical & Engineering News: Washington, DC, USA, 2013; Available online: https://pubs.acs.org/doi/pdf/10.1021/cen-09147-bus1 (accessed on 31 October 2021).

- Naitove, M. Additives and Colorants Score Dramatic Advances. 2008. Available online: https://www.ptonline.com/articles/additives-and-colorants-score-dramatic-advances (accessed on 26 October 2021).

- Drumright, B.R.E.; Gruber, P.R.; Henton, D.E. Polylactic Acid Technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Ren, J. Biodegradable Poly (Lactic Acid): Synthesis, Modification, Processing and Applications, 1st ed.; Springer Science & Business Media: Beijing, China, 2011; 314p. [Google Scholar]

- Hongu, T.; Takigami, M.; Phillips, G.O. New Millennium Fibers, 1st ed.; Woodhead Publishing: Boca Raton, FL, USA, 2005; 435p. [Google Scholar]

- Bioplastics Magazine. FUTERRO Launches the First Fully Integrated PLA Plant in China. 2020. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20201022-FUTERRO-launches-the-first-fully-integrated-PLA-plant-in-China.php (accessed on 14 September 2021).

- Plasteurope.com. COFCO: First PLA Plant Using Thyssen Krupp Process Starts in China; Plasteurope: Bad Homburg, Germany, 2018; Available online: https://www.plasteurope.com/news/COFCO_t240963/ (accessed on 14 September 2021).

- Renewable Carbon News. Futerro Starts Up Its PLA Demo Unit in Belgium; Renewable Carbon News: Hürth, Germany, 2009; Available online: https://renewable-carbon.eu/news/futerro-starts-up-its-pla-demo-unit-in-belgium/ (accessed on 14 September 2021).

- Jiangxi Keyuan Bio-Material Co. Ltd. Profile. Company. 2021. Available online: http://www.keyuanbio.com/en/about-us/ (accessed on 14 September 2021).

- Bioplastics Magazine. LG Chem, ADM Partner on PLA Project; News: Mönchengladbach, Germany, 2021; Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20210914-LG-Chem-to-produce-100-Bioplastic-with-a-Global-Major-Grain-Processing-Company.php (accessed on 1 November 2021).

- NatureWorks. NatureWorks Passes Final Authorization Milestone for New Fully Integrated Ingeo PLA Manufacturing Plant in Thailand; News: Minnetonka, NY, USA, 2021; Available online: https://www.natureworksllc.com/News-and-Events/Press-Releases/2021/2021-08-09-NatureWorks-Final-Authorization-Ingeo-PLA-Plant-Thailand (accessed on 4 October 2021).

- Capaldo, F. Uhde Inventa-Fischer Starts Up Polylactic Acid Plant in Germany. ICIS Explore, 2010. Available online: https://www.icis.com/explore/resources/news/2010/12/01/9415832/uhde-inventa-fischer-starts-up-polylactic-acid-plant-in-germany(accessed on 14 September 2021).

- Sulzer. Sulzer Polylactides (PLA). The Bio-Based Alternative to Modern Thermoplastics. 2021. Available online: https://www.sulzer.com/-/media/files/products/polymer_production_technology/brochures/fact_sheet_polylactides.ashx#:~:text=Sulzer%20operates%20a%20fully%20continuous,on%20Sulzer’s%20PLA%20plant%20technology (accessed on 14 September 2021).

- SuPla Bioplastics. Home. 2021. Available online: http://www.supla-bioplastics.cn/en/Channel/erjifenlei.html (accessed on 14 September 2021).

- Guzman, D.D. NatureWorks Expands PLA Capacity; Green Chemicals Blog: Surrey, UK, 2012; Available online: https://greenchemicalsblog.com/2012/09/06/natureworks-expands-pla-capacity/ (accessed on 14 September 2021).

- Total Corbion PLA. PLA: Becoming a Market Leader in Bioplastics. TotalEnergies.com. 2021. Available online: https://totalenergies.com/energy-expertise/projects/bioenergies/pla-bioplastic (accessed on 14 September 2021).

- Total Corbion PLA. Total Corbion PLA Enters Engineering Stage for New 100 kTpa PLA Plant in Grandpuits, France. News. 2021. Available online: https://www.total-corbion.com/news/total-corbion-pla-enters-engineering-stage-for-new-100-ktpa-pla-plant-in-grandpuits-france/ (accessed on 14 September 2021).

- Tullo, A.H. Cargill Buying Dow’s Stake in Partnership; Chemical & Engineering News: Washington, DC, USA, 2005; Available online: https://pubs.acs.org/doi/pdf/10.1021/cen-v083n005.p011a (accessed on 23 October 2021).

- Tullo, A. Polylactic Acid Redux; Chemical & Engineering News: Washington, DC, USA, 2005; Available online: https://pubs.acs.org/doi/pdf/10.1021/cen-v083n009.p026 (accessed on 23 October 2021).

- NatureWorks. Cargill Acquires Full NatureWorks Ownership From Teijin. 2009. Available online: https://www.natureworksllc.com/news-and-events/press-releases/2009/07-01-09-ownership-change.aspx (accessed on 24 October 2021).

- Plastics Today. UPDATED: PTT Chemical Plans $150 Million Investment in Bioplastics Supplier Nature Works. 2011. Available online: https://www.plasticstoday.com/updated-ptt-chemical-plans-150-million-investment-bioplastics-supplier-natureworks (accessed on 31 October 2021).

- CSM. CSM Annual Report. 2007. Available online: https://docplayer.net/143547650-Csm-annual-report-2006.html (accessed on 25 October 2021).

- Haan, R. Unique Purac Lactides for Improved PLA Production and Properties—PLA Technology Developed with Sulzer Chemtech. 2009. Available online: https://www.soci.org/-/media/Files/Conference-Downloads/2009/Bioplastic-Processing-Apr-09/Haan.ashx?la=en (accessed on 25 October 2021).

- Bioplastics Magazine. Grand Opening of Total Corbion PLA’s 75,000 Tons per Year Bioplastics Plant. News. 2019. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20190910_Total_Corbion_Grand_Opening.php (accessed on 1 November 2021).

- Lopez, J. Total to Produce Sugar-Based PLA at Grandpuits, to Quit Crude Refining in Q1; ICIS Explore: London, UK, 2020; Available online: https://www.icis.com/explore/resources/news/2020/09/24/10556568/total-to-produce-sugar-based-pla-at-grandpuits-to-quit-crude-refining-in-q1 (accessed on 1 November 2021).

- Packaging Insights. Total Petrochemicals and Galactic Venture into Bioplastics Production. 2007. Available online: https://pi.cnsmedia.com/a/nfqM7wWFWuo= (accessed on 25 October 2021).

- Food Ingredients First. New PLA Bioplastics Plant Inaugurated by Galactic Joint Venture. 2010. Available online: https://www.foodingredientsfirst.com/news/new-pla-bioplastics-plant-inaugurated-by-galactic-joint-venture.html (accessed on 25 October 2021).

- Finasucre. Annual Report—2015/2016. 2016. Available online: https://www.finasucre.com/medias/upload/files/Rapports/ra_finasucre_2016_en.pdf (accessed on 1 November 2021).

- Sulzer. Build a Planet with Sustainable Bioplastics. 2018. Available online: https://www.sulzer.com/en/shared/news/build-a-planet-for-sustainable-bioplastics (accessed on 1 November 2021).

- Tullo, A.H. PHA: A Biopolymer Whose Time Has Finally Come; Chemical & Engineering News: Washington, DC, USA, 2019; Available online: https://cen.acs.org/business/biobased-chemicals/PHA-biopolymer-whose-time-finally/97/i35 (accessed on 27 January 2021).

- Jilin Province. 45,000-Ton/Year Polylactic Acid Coated Paper Project of Jilin City. Business. 2021. Available online: http://english.jl.gov.cn/ztzl/qyfwzt/english/syhg/202104/t20210401_7985509.html (accessed on 14 September 2021).

- Yamada, S.; Fukumoto, Y. China Aims to Go as Big in Bioplastics as It Did in Solar Panels; Nikkei Asia: Tokyo, Japan, 2021; Available online: https://asia.nikkei.com/Spotlight/Environment/China-aims-to-go-as-big-in-bioplastics-as-it-did-in-solar-panels (accessed on 14 September 2021).

- Leaversuch, R. Renewable PLA Polymer Gets “Green Light” for Packaging Uses; Plastics Technology: Cincinnati, OH, USA, 2002; Available online: https://www.thefreelibrary.com/Renewable+PLA+polymer+gets+%27green+light%27+for+packaging+uses-a084270504 (accessed on 23 October 2021).

- Tullo, A.H. Breaking The Bank with New Polymers. Chem. Eng. News 2002, 80, 13–19. [Google Scholar] [CrossRef]

- Befort, N. The promises of drop-in vs. functional innovations: The case of bioplastics. Ecol. Econ. 2020, 181, 106886. [Google Scholar] [CrossRef]

- Plastics Technology. NatureWorks to Boost Production of Ingeo PLA; Plastics Technology: Cincinnati, OH, USA, 2020; Available online: https://www.ptonline.com/news/natureworks-to-boost-production-of-ingeo-pla (accessed on 3 November 2021).

- C&EN. Natureworks Ups Pla Capacity. Chem. Eng. News 2009, 87, 16–17. [Google Scholar] [CrossRef]

- Nexant. Lactic Acid/Polylactic Acid; PERP Program; Report No. PERP 2013S7; Nexant: San Francisco, CA, USA, 2013. [Google Scholar]

- European Bioplastics. Bioplastics Market Data 2016; European Bioplastics, Nova Institute: Berlin, Germany, 2016. [Google Scholar]

- European Bioplastics. Bioplastics Market Data 2017; European Bioplastics, Nova Institute: Berlin, Germany, 2017. [Google Scholar]

- European Bioplastics. Bioplastics Market Data 2018; European Bioplastics, Nova Institute: Berlin, Germany, 2018. [Google Scholar]

- European Bioplastics. Bioplastics Market Data 2019; European Bioplastics, Nova Institute: Berlin, Germany, 2019. [Google Scholar]

- European Bioplastics. Bioplastics Market Data 2020; European Bioplastics, Nova Institute: Berlin, Germany, 2020. [Google Scholar]

- European Bioplastics. Bioplastics Market Development Update 2021; European Bioplastics, Nova Institute: Berlin, Germany, 2022; Available online: https://docs.european-bioplastics.org/publications/market_data/Report_Bioplastics_Market_Data_2021_short_version.pdf (accessed on 8 May 2022).

- Hackett, M. Biodegradable Polymers: Contributing to a Sustainable Future. IHS Markit. 2021. Available online: https://ihsmarkit.com/research-analysis/biodegradable-polymers-contributing-to-a-sustainable-future.html (accessed on 13 November 2021).

- Government of Japan. Roadmap for Bioplastics Introduction. 2021. Available online: http://www.env.go.jp/recycle/mat21030210_1.pdf (accessed on 9 November 2021).

- Research and Markets. Europe Polylactic Acid (PLA) Market Report and Forecast 2021–2026. Report. 2021. Available online: https://www.researchandmarkets.com/reports/5401681/europe-polylactic-acid-pla-market-report-and (accessed on 9 November 2021).

- Ahmed, E. Wal-Mart Signals Move to Natural Packaging. Bakeryandsnacks. 2005. Available online: https://www.bakeryandsnacks.com/Article/2005/10/27/Wal-Mart-signals-move-to-natural-packaging (accessed on 9 November 2021).

- Grand View Research. Global Polylactic Acid Market Size Report, 2022—2030. Reports. 2022. Available online: https://www.grandviewresearch.com/industry-analysis/polylactic-acid-pla-market (accessed on 8 January 2023).

- Döhler, N.; Wellenreuther, C.; Wolf, A. Market Dynamics of Biodegradable Bio-Based Plastics: Projections and Linkages to European policies. HWWI Res. 2020, 193, 4–28. Available online: https://bioplasticseurope.eu/media/pages/downloads/scientific-publications/27c6775164-1604264924/hwwi_researchpaper_193.pdf (accessed on 13 November 2021). [CrossRef]

- Sherman, L.M. Enhancing Biopolymers: Additives Are Needed for Toughness, Heat Resistance & Processability. 2008. Available online: https://www.ptonline.com/articles/enhancing-biopolymers-additives-are-needed-for-toughness-heat-resistance-processability (accessed on 2 November 2021).

- Ahmad, A.; Banat, F.; Taher, H. A review on the lactic acid fermentation from low-cost renewable materials: Recent developments and challenges. Environ. Technol. Innov. 2020, 20, 101138. [Google Scholar] [CrossRef]

- Cunha, B.L.C.; Bahú, J.O.; Xavier, L.F.; Crivellin, S.; de Souza, S.D.A.; Lodi, L.; Jardini, A.L.; Filho, R.M.; Schiavon, M.I.R.B.; Concha, V.O.C.; et al. Lactide: Production Routes, Properties, and Applications. Bioengineering 2022, 9, 164. [Google Scholar] [CrossRef]

- Dubey, S.P.; Abhyankar, H.A.; Marchante, V.; Brighton, J.L.; Blackburn, K. Chronological Review of the Catalytic Progress of Polylactic Acid Formation through Ring Opening Polymerization. Int. Res. J. Pure Appl. Chem. 2016, 12, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Eş, I.; Khaneghah, A.M.; Barba, F.J.; Saraiva, J.A.; Sant’Ana, A.S.; Hashemi, S.M.B. Recent advancements in lactic acid production—A review. Food Res. Int. 2018, 107, 763–770. [Google Scholar] [CrossRef] [PubMed]

- Rawoof, S.A.A.; Kumar, P.S.; Vo, D.-V.N.; Devaraj, K.; Mani, Y.; Devaraj, T.; Subramanian, S. Production of optically pure lactic acid by microbial fermentation: A review. Environ. Chem. Lett. 2020, 19, 539–556. [Google Scholar] [CrossRef]

- Van Wouwe, P.; Dusselier, M.; Vanleeuw, E.; Sels, B. Lactide Synthesis and Chirality Control for Polylactic acid Production. ChemSusChem 2016, 9, 907–921. [Google Scholar] [CrossRef]

- Naitove, M. It’s All Relative. Plastics Technology. 2008. Available online: https://www.ptonline.com/articles/its-all-relative (accessed on 2 November 2021).

- Tullo, A. A biodegradable polymer hits the big time. CEN Glob. Enterp. 2021, 99, 26–27. [Google Scholar]

- Trade Map. About Trade Map. About Trade Map. 2022. Available online: https://trademap.org/stAbout_tradeMap.aspx?nvpm=1%7c%7c%7c%7c%7c%7c%7c%7c%7c%7c%7c%7c%7c%7c%7c%7c (accessed on 20 February 2023).

- Elvers, D.; Song, C.H.; Steinbüchel, A.; Leker, J. Technology Trends in Biodegradable Polymers: Evidence from Patent Analysis. Polym. Rev. 2016, 56, 584–606. [Google Scholar] [CrossRef]

- European Bioplastics. NatureWorks Opens Lab to Turn Methane into PLA; European Bioplastics: Beilin, Germany, 2016; Available online: https://www.european-bioplastics.org/natureworks-opens-lab-to-turn-methane-into-pla/ (accessed on 1 November 2021).

- Thayer, A.M. BIOCATALYSIS—Chemical and Pharmaceutical Makers Seek more Efficient and Often Cleaner Routes to Making Old and New Products; Chemical & Engineering News: Washington, DC, USA, 2010; Available online: https://pubs.acs.org/doi/pdf/10.1021/cen-v079n021.p027 (accessed on 22 October 2021).

- Anderson, K.S.; Hillmyer, M.A. Melt preparation and nucleation efficiency of polylactide stereocomplex crystallites. Polymer 2006, 47, 2030–2035. [Google Scholar] [CrossRef]

- Plastics. Latest generation of PLA. Plastics. 2013. Available online: https://www.plastics.gl/exhibit/latest-generation-of-pla/ (accessed on 14 September 2021).

- Total Corbion PLA. High Heat PLA. 2015. Available online: http://www.corbion.com/media/77166/corbion-purac-pla-high-heat-themesheet.pdf (accessed on 14 September 2021).

- Södergård, A.; Stolt, M. Properties of lactic acid based polymers and their correlation with composition. Prog. Polym. Sci. 2002, 27, 1123–1163. [Google Scholar] [CrossRef]

- Tsuji, H.; Ikada, Y. Stereocomplex formation between enantiomeric poly(lactic acid)s. XI. Mechanical properties and morphology of solution-cast films. Polymer 1999, 40, 6699–6708. [Google Scholar] [CrossRef]

- BASF. Compostable Polymer. Products. 2021. Available online: https://www.basf.com/global/en/who-we-are/innovation/our-innovations/compostable-polymer.html (accessed on 17 September 2021).

- Laird, K. Green Matter: PMMA/PLA Alloy’s Sum is Greater than Its Parts. Plastics Today. 2012. Available online: https://www.plasticstoday.com/green-matter-pmmapla-alloys-sum-greater-its-parts (accessed on 2 November 2021).

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Jung, J.-W.; Kim, S.-H.; Kim, S.-H.; Park, J.-K.; Lee, W.-I. Research on the development of the properties of PLA composites for automotive interior parts. J. Korean Soc. Compos. Mater. 2011, 24, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Nehls, G. Lanxess Launches Renewable, Biocomposite Material. 2021. Available online: https://www.compositesworld.com/products/lanxess-launches-renewable-biocomposite-material (accessed on 22 February 2023).

- FKuR. Fibrolon® S 7530 Is a Biodegradable Compound. Fibrolon. 2023. Available online: https://fkur.com/en/bioplastics/fibrolon/fibrolon-s-7530/ (accessed on 22 February 2023).

- Li, N.; Li, Y.; Liu, S. Rapid prototyping of continuous carbon fiber reinforced polylactic acid composites by 3D printing. J. Mater. Process. Technol. 2016, 238, 218–225. [Google Scholar] [CrossRef]

- Malnati, P. CFRTP Enables Better, Greener Smartphones. Composites World. 2022. Available online: https://www.compositesworld.com/articles/cfrtp-enables-carbon-mobile-to-build-better-greener-smartphones- (accessed on 22 February 2023).

- Sin, L.T.; Tueen, B.S. Polylactic Acid: A Practical Guide for the Processing, Manufacturing, and Applications of PLA; William Andrew: Norwich, NY, USA, 2019; 423p. [Google Scholar]

- Fiori, S. CHAPTER 13: Industrial Uses of PLA. In Poly(lactic Acid) Science and Technology, 1st ed.; Ben Zhong Tang: Cambridge, UK, 2014; pp. 315–333. Available online: https://pubs.rsc.org/en/content/chapter/bk9781849738798-00315/978-1-84973-879-8 (accessed on 28 November 2022).

- Naitove, M. On-Site: Green Business Is Good Business for Fabri-Kal. 2009. Available online: https://www.ptonline.com/articles/on-site-green-business-is-good-business-for-fabri-kal (accessed on 2 November 2021).

- Lim, L.-T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Bomtempo, J.V. Innovation et Organisation: Le Cas de L’industrie des Polymères; Ecole Nationale Supérieure des Mines de Paris: Paris, France, 1994. [Google Scholar]

- Jeremic, S.; Milovanovic, J.; Mojicevic, M.; Skaro-Bogojevic, S.; Nikodinovic-Runic, J. Understanding bioplastic materials—Current state and trends. J. Serb. Chem. Soc. 2020, 85, 1507–1538. [Google Scholar] [CrossRef]

- Conn, R.E.; Kolstad, J.J.; Borzelleca, J.F.; Dixler, D.S.; Filer, L.J., Jr.; Ladu, B.N., Jr.; Pariza, M.W. Safety assessment of polylactide (PLA) for use as a food-contact polymer. Food Chem. Toxicol. 1995, 33, 273–283. [Google Scholar] [CrossRef]

- NatureWorks. Ingeo In Use. NatureWorks. 2022. Available online: https://www.natureworksllc.com/Ingeo-in-Use (accessed on 28 November 2022).

- Malinconico, M.; Vink, E.T.H.; Cain, A. Applications of Poly(lactic Acid) in Commodities and Specialties. In Industrial Applications of Poly(Lactic Acid), 1st ed.; Advances in Polymer Science; Di Lorenzo, M.L., Androsch, R., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 35–50. [Google Scholar] [CrossRef]

- Sari, N.H.; Suteja, S.; Sapuan, S.M.; Ilyas, R.A. Properties and Food Packaging Application of Poly-(Lactic) Acid. In Bio-based Packaging; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; pp. 245–263. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9781119381228.ch14 (accessed on 22 February 2023).

- Ahmed, J.; Varshney, S. Polylactides—Chemistry, Properties and Green Packaging Technology: A Review. Int. J. Food Prop. 2011, 14, 37–58. [Google Scholar] [CrossRef]

- Obuchi, S.; Ogawa, S. Packaging and Other Commercial Applications. In Poly(Lactic Acid), 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 457–467. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9780470649848.ch28 (accessed on 22 February 2023).

- Yang, Y.; Zhang, M.; Ju, Z.; Tam, P.Y.; Hua, T.; Younas, M.W.; Kamrul, H.; Hu, H. Poly(lactic acid) fibers, yarns and fabrics: Manufacturing, properties and applications. Text. Res. J. 2020, 91, 1641–1669. [Google Scholar] [CrossRef]

- Mochizuki, M. Textile Applications. In Poly(Lactic Acid), 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 469–476. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/9780470649848.ch29 (accessed on 22 February 2023).

- Dharmalingam, S.; Hayes, D.G.; Wadsworth, L.C.; Dunlap, R.N.; DeBruyn, J.M.; Lee, J.; Wszelaki, A.L. Soil Degradation of Polylactic Ac-id/Polyhydroxyalkanoate-Based Nonwoven Mulches. J. Polym. Environ. 2015, 23, 302–315. [Google Scholar] [CrossRef]

- Danimer Scientific. Form 10-K. SEC Fillings. 2021. Available online: https://ir.danimerscientific.com/sec-filings/all-sec-filings/content/0000950170-22-003031/dnmr-20211231.htm (accessed on 21 December 2022).

- Géczy, A.; Csiszar, A.; Rozs, E.; Hajdu, I.; Medgyes, B.; Krammer, O.; Straubinger, D.; Gál, L. Novel PLA/Flax Based Biodegradable Printed Circuit Boards. In Proceedings of the 2022 45th International Spring Seminar on Electronics Technology (ISSE), Vienna, Austria, 11–15 May 2022; pp. 1–6. [Google Scholar]

- Mohan, A.M. Farmers Lend an Ear. Packaging Digest. 2002. Available online: https://www.packagingdigest.com/print/1240 (accessed on 22 October 2021).

- NatureWorks. Eco-Profile. Why it Matters? 2021. Available online: https://www.natureworksllc.com/What-is-Ingeo/Why-it-Matters/Eco-Profile (accessed on 19 September 2021).

- Morão, A.; de Bie, F. Life Cycle Impact Assessment of Polylactic Acid (PLA) Produced from Sugarcane in Thailand. J. Polym. Environ. 2019, 27, 2523–2539. [Google Scholar] [CrossRef] [Green Version]

- Rezvani Ghomi, E.; Khosravi, F.; Saedi Ardahaei, A.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers 2021, 13, 1854. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Bhatt, A.; Tao, L.; Benavides, P.T. Life cycle analysis of polylactic acids from different wet waste feedstocks. J. Clean. Prod. 2022, 380, 135110. [Google Scholar] [CrossRef]

- Walker, S.; Rothman, R. Life cycle assessment of bio-based and fossil-based plastic: A review. J. Clean. Prod. 2020, 261, 121158. [Google Scholar] [CrossRef]

- PlastEurope. Follow-Up: End to Legal Dispute over Advertisement of PLA Yogurt Tub/Compromise Reached with German environmental Group. DANONE: 2011. Available online: https://www.plasteurope.com/news/DANONE_t220875/ (accessed on 15 November 2018).

- Brockhaus, S.; Petersen, M.; Kersten, W. A crossroads for bioplastics: Exploring product developers’ challenges to move beyond petroleum-based plastics. J. Clean. Prod. 2016, 127, 84–95. [Google Scholar] [CrossRef]

- NatureWorks. NatureWorks Announces 100 Percent Third-Party Certified Sustainable Feedstock by 2020. 2019. Available online: https://www.natureworksllc.com/News-and-Events/Press-Releases/2019/2019-02-14-100-Percent-Sustainable-Feedstock-by-2020 (accessed on 19 September 2021).

- Sharma, S.; Majumdar, A.; Butola, B.S. Tailoring the biodegradability of polylactic acid (PLA) based films and ramie-PLA green composites by using selective additives. Int. J. Biol. Macromol. 2021, 181, 1092–1103. [Google Scholar] [CrossRef]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef] [Green Version]

- Kawashima, N.; Yagi, T.; Kojima, K. Pilot-Scale Composting Test of Polylactic Acid for Social Implementation. Sustainability 2021, 13, 1654. [Google Scholar] [CrossRef]

- Taufik, D.; Reinders, M.J.; Molenveld, K.; Onwezen, M.C. The paradox between the environmental appeal of bio-based plastic packaging for consumers and their disposal behaviour. Sci. Total. Environ. 2019, 705, 135820. [Google Scholar] [CrossRef]

- European Environment Agency. Biodegradable and Compostable Plastics—Challenges and Opportunities. 2020. Available online: https://www.eea.europa.eu/publications/biodegradable-and-compostable-plastics/biodegradable-and-compostable-plastics-challenges (accessed on 13 November 2021).

- Alaerts, L.; Augustinus, M.; Van Acker, K. Impact of Bio-Based Plastics on Current Recycling of Plastics. Sustainability 2018, 10, 1487. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Kroell, N.; Li, K.; Feil, A.; Pretz, T. Influences of bioplastic polylactic acid on near-infrared-based sorting of conventional plastic. Waste Manag. Res. J. Sustain. Circ. Econ. 2021, 39, 1210–1213. [Google Scholar] [CrossRef]

- Feller, L. Plant-Based Polymers Pollute Recycled Plastic Stream—Group; ICIS Explore: London, UK, 2009; Available online: https://www.icis.com/explore/resources/news/2009/08/05/9237745/polylactic-acid-advantages-outweigh-risks-natureworks/Articles/2009/07/27/9235373/plant-based-polymers-pollute-recycled-plastic-stream-group.html (accessed on 1 November 2021).

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Use of Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- Badia, J.; Ribes-Greus, A. Mechanical recycling of polylactide, upgrading trends and combination of valorization techniques. Eur. Polym. J. 2016, 84, 22–39. [Google Scholar] [CrossRef] [Green Version]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Coszach, P.; Bogaert, J.C.; Willocq, J. Chemical Recycling of Pla by Hydrolysis. U.S. Patent US20120142958A1, 7 June 2012. Available online: https://patents.google.com/patent/US20120142958A1/en#citedBy (accessed on 11 December 2022).

- Sherwood, J. Closed-Loop Recycling of Polymers Using Solvents: Remaking plastics for a circular economy. Johns. Matthey Technol. Rev. 2020, 64, 4–15. [Google Scholar] [CrossRef]

- Packaging Europe. PLA with ‘20% Recycled Content’ Unveiled by Total Corbion. News. 2021. Available online: https://packagingeurope.com/api/content/4efd664a-3738-11ec-b00d-12f1225286c6/ (accessed on 10 November 2021).

- Hajighasemi, M.; Nocek, B.P.; Tchigvintsev, A.; Brown, G.; Flick, R.; Xu, X.; Cui, H.; Hai, T.; Joachimiak, A.; Golyshin, P.N.; et al. Biochemical and Structural Insights into Enzymatic Depolymerization of Polylactic Acid and Other Polyesters by Microbial Carboxylesterases. Biomacromolecules 2016, 17, 2027–2039. [Google Scholar] [CrossRef]

- Carbios. Carbios Strengthens Its Position in Polymer Biodegradation Technologies with the Acquisition of the SPI Fund’s Entire Stake of Carbiolice Capital. Press Releases. 2021. Available online: https://www.carbios.com/en/carbios-strengthens-its-position-in-polymer-biodegradation-technologies-with-the-acquisition-of-the-spi-funds-entire-stake-of-carbiolice-capital/ (accessed on 11 December 2022).

- Payne, J.; Jones, M.D. The Chemical Recycling of Polyesters for a Circular Plastics Economy: Challenges and Emerging Opportunities. ChemSusChem 2021, 14, 4041–4070. [Google Scholar] [CrossRef]

- Sherman, L.M. Biodegradable Plastics Volume to Increase More than 50 Percent. Plastics Technology. 2018. Available online: https://www.ptonline.com/blog/post/biodegradable-plastics-volume-to-increase-more-than-50-percent- (accessed on 3 November 2021).

- European Commission. Rolling Out Bioplastics in Europe. Eco-innovation Action Plan—European Commission. 2011. Available online: https://ec.europa.eu/environment/ecoap/about-eco-innovation/experts-interviews/671_en (accessed on 9 November 2021).

- Cherel-Bonnemaison, C.; Feber, D.; Leger, S.; Letoffe, A.; Nordigården, D. Sustainability in Packaging: Global Regulatory Development across 30 Countries; McKinsey: Paris, France; Detroit, MI, USA; Toronto, ON, Canada, 2022; Available online: https://www.mckinsey.com/industries/paper-forest-products-and-packaging/our-insights/sustainability-in-packaging-global-regulato-ry-development-across-30-countries?cid=other-eml-alt-mip-mck&hdpid=198399fb-3014-48bd-a421-65901ad600e8&hctky=12154637&hlkid=275bd902e60341a0a8cbcf5e08002dfc (accessed on 20 February 2022).

- Feber, D.; Granskog, A.; Grünewald, F.; Lingqvist, O.; Nordigården, D. Investable Themes for Participating in Sustainable Packaging; McKinsey: Detroit, MI, USA; Helsinki, Finland; Zurich, Switzerland; Stockholm, Sweden, 2021; Available online: https://www.mckinsey.com/industries/paper-forest-products-and-packaging/our-insights/sustainability-in-packaging-investable-themes (accessed on 2 February 2022).

- Laville, S. Coca-Cola Admits it Produces 3m Tonnes of Plastic Packaging a Year. The Guardian. 14 March 2019. Available online: https://www.theguardian.com/business/2019/mar/14/coca-cola-admits-it-produces-3m-tonnes-of-plastic-packaging-a-year (accessed on 21 September 2021).

- Choi, A. The Business Case for Investing in Sustainable Plastics; World Economic Forum: Cologny, Switzerland, 2020; Available online: https://www.weforum.org/agenda/2020/01/the-business-case-for-investing-in-sustainable-plastics/ (accessed on 18 December 2022).

- Palmeiro-Sánchez, T.; O’Flaherty, V.; Lens, P.N. Polyhydroxyalkanoate bio-production and its rise as biomaterial of the future. J. Biotechnol. 2022, 348, 10–25. [Google Scholar] [CrossRef]

- E4tech. From the Sugar Platform to Biofuels and Biochemicals; Apr. Report No.: EN-ER/C2/423-2012/SI2.673791; E4tech: London, UK, 2015. [Google Scholar]

- Shen, L.; Haufe, J.; Patel, M. Product Overview and Market Projection of Emerging Bio-based Plastics; Report No.: PRO-BIP-2009; Utrecht University: Utrecht, The Netherlands, 2009; Available online: http://news.bio-based.eu/media/news-images/20091108-02/Product_overview_and_market_projection_of_emerging_bio-based_plastics,_PRO-BIP_2009.pdf (accessed on 18 December 2018).

- Bauer, F.; Nielsen, T.D.; Nilsson, L.J.; Palm, E.; Ericsson, K.; Fråne, A.; Cullen, J. Plastics and climate change—Breaking carbon lock-ins through three mitigation pathways. One Earth 2022, 5, 361–376. [Google Scholar] [CrossRef]

- McMillan, F.M. The Chain Straighteners: Fruitful Innovation: The Discovery of Linear and Stereoregular Synthetic Polymers; Springer: Berlin/Heidelberg, Germany, 1979; 226p. [Google Scholar]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. Express Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef]

- Martin, H. Polymers, Patents, Profits: A Classic Case Study for Patent Infighting; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2007; 297p. [Google Scholar]

- Packaging Europe. Rethinking Polymers: The Challenges of Commercializing Biobased Materials. Features. 2022. Available online: https://packagingeurope.com/features/rethinking-polymers-the-challenges-of-commercializing-biobased-materials/7901.article (accessed on 20 December 2022).

- Van den Oever, M.; Molenveld, K.; van der Zee, M.; Bos, H. Bio-based and biodegradable plastics—Facts and Figures. In Focus on Food Packaging in The Netherlands; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2017. [Google Scholar]

- I’MTech. Bioplastics: “Still a Long Road to Higher Performance”. 2016. Available online: https://imtech.imt.fr/en/2016/10/20/bioplastics-long-road-performance/ (accessed on 24 December 2022).

- Rhein, F.E. The Dynamics of Green Innovation in B2B Industries: A Systems Approach to Explain the Diffusion of Bioplastics; Springer Nature: Bensheim, Germany, 2020. [Google Scholar]

- Sherman, L.M. Thin-Walled Biobased Packaging That’s Injection-Moldable and Commercially Viable. Plastics Technology. 2017. Available online: https://www.ptonline.com/blog/post/thin-walled-biobased-packaging-thats-injection-moldable-and-commercially-viable (accessed on 3 November 2021).

- Theinsathid, P.; Chandrachai, A.; Suwannathep, S.; Keeratipibul, S. Lead Users and Early Adoptors of Bioplastics: A Market-Led Approach to Innovative Food Packaging Films. J. Biobased Mater. Bioenergy 2011, 5, 17–29. [Google Scholar] [CrossRef]

- Notaro, S.; Lovera, E.; Paletto, A. Consumers’ preferences for bioplastic products: A discrete choice experiment with a focus on purchase drivers. J. Clean. Prod. 2021, 330, 129870. [Google Scholar] [CrossRef]

- Meyer, A. Does education increase pro-environmental behavior? Evidence from Europe. Ecol. Econ. 2015, 116, 108–121. [Google Scholar] [CrossRef] [Green Version]

- Vicente-Molina, M.; Fernández-Sainz, A.; Izagirre-Olaizola, J. Does gender make a difference in pro-environmental behavior? The case of the Basque Country University students. J. Clean. Prod. 2018, 176, 89–98. [Google Scholar] [CrossRef]

- Ruf, J.; Emberger-Klein, A.; Menrad, K. Consumer response to bio-based products—A systematic review. Sustain. Prod. Consum. 2022, 34, 353–370. [Google Scholar] [CrossRef]

- Zwicker, M.V.; Brick, C.; Gruter, G.-J.M.; van Harreveld, F. Consumer attitudes and willingness to pay for novel bio-based products using hypothetical bottle choice. Sustain. Prod. Consum. 2023, 35, 173–183. [Google Scholar] [CrossRef]

- Murphy, W.J. Outlook for Polymer Chemistry. Chem. Eng. News 1958, 36, 7. [Google Scholar] [CrossRef] [Green Version]

- Smith, J.K.; Spitz, P.H. Petrochemicals: The Rise of an Industry. Technol. Cult. 1989, 30, 710. [Google Scholar] [CrossRef]

- U.S. Tariff Commission. Synthetic Organic Chemicals; U.S. Tariff Commission: Washington, DC, USA, 1966.

- Van Rooij, A. The Company that Changed Itself: R&D and the Transformations of DSM, 1st ed.; Amsterdam University Press: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Verespej, M.; Mirel, P.H. A Production under Way in IOWA. Plastics News. 2010. Available online: https://www.plasticsnews.com/article/20100315/NEWS/303159957/mirel-pha-production-under-way-in-iowa (accessed on 21 December 2022).

- ADM. ADM to End Commercial Alliance with Metabolix. News. 2012. Available online: https://www.adm.com/en-us/news/news-releases/2012/1/adm-to-end-commercial-alliance-with-metabolix/ (accessed on 21 December 2022).

- Bioplastics Magazine. CJ BIO Inaugurates 5000 Tonne PHA Facility. News. 2022. Available online: https://www.bioplasticsmagazine.com/en/news/meldungen/20220502-PHA.php (accessed on 21 December 2022).

- McCoy, M. Succinic Acid, Once a Biobased Chemical Star, Is Barely Being Made. Chemical & Engineering News. 2019. Available online: https://cen.acs.org/business/biobased-chemicals/Succinic-acid-once-biobased-chemical/97/i12 (accessed on 21 December 2022).

- FNR. Processing of Bioplastics—A Guideline; FNR: Hannover, Germany, 2016; Available online: https://www.ifbb-hannover.de/files/IfBB/downloads/EV_Processing-of-Bioplastics-2016.pdf (accessed on 20 December 2022).

- IfBB—Institute for Bioplastics and Biocomposites. Databases. Information on Bioplastics. 2022. Available online: https://www.ifbb-hannover.de/en/databases.html (accessed on 20 December 2022).

- Adsale Plastics Network. CJ Biomaterials Enters Partnership to Promote PHA Technology. News. 2022. Available online: https://www.adsalecprj.com/en/news_show-79306.html (accessed on 23 December 2022).

- Ali, S.S.; Elsamahy, T.; Abdelkarim, E.A.; Al-Tohamy, R.; Kornaros, M.; Ruiz, H.A.; Zhao, T.; Li, F.; Sun, J. Biowastes for biodegradable bioplastics pro-duction and end-of-life scenarios in circular bioeconomy and biorefinery concept. Bioresour. Technol. 2022, 363, 127869. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N. Environmental performance comparison of bioplastics and petrochemical plastics: A review of life cycle assessment (LCA) methodological decisions. Resour. Conserv. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Escobar, N.; Britz, W. Metrics on the sustainability of region-specific bioplastics production, considering global land use change effects. Resour. Conserv. Recycl. 2021, 167, 105345. [Google Scholar] [CrossRef]

- Lovett, J.; de Bie, F.; Visser, D. Sustainable Sourcing of Feedstocks for Bioplastics. 2016. Available online: https://www.corbion.com/base/DownloadHelper/DownloadFile/11180 (accessed on 10 November 2021).

- Van Roijen, E.C.; Miller, S.A. A review of bioplastics at end-of-life: Linking experimental biodegradation studies and life cycle impact assessments. Resour. Conserv. Recycl. 2022, 181, 106236. [Google Scholar] [CrossRef]

- Lamberti, F.M.; Román-Ramírez, L.A.; Wood, J. Recycling of Bioplastics: Routes and Benefits. J. Polym. Environ. 2020, 28, 2551–2571. [Google Scholar] [CrossRef]

- Kawashima, N.; Yagi, T.; Kojima, K. How Do Bioplastics and Fossil-Based Plastics Play in a Circular Economy? Macromol. Mater. Eng. 2019, 304, 1900383. [Google Scholar] [CrossRef]

- Lopez, F.J.D.; Lavallée, M.V.; Renaud, G.; Saes, L. Circular Plastics in France; Netherlands Enterprise Agency: Hague, The Netherlands, 2021. [Google Scholar]

- Williams, J. Infographic: The Trouble with Bioplastic. The Earthbound Report. 2020. Available online: https://earthbound.report/2020/08/04/infographic-the-trouble-with-bioplastic/ (accessed on 22 February 2023).

- Huarachi, D.A.R.; Piekarski, C.M.; Puglieri, F.N.; de Francisco, A.C. Past and future of Social Life Cycle Assessment: Historical evolution and research trends. J. Clean. Prod. 2020, 264, 121506. [Google Scholar] [CrossRef]

- Spierling, S.; Knüpffer, E.; Behnsen, H.; Mudersbach, M.; Krieg, H.; Springer, S.; Albrecht, S.; Herrmann, C.; Endres, H.-J. Bio-based plastics—A review of environmental, social and economic impact assessments. J. Clean. Prod. 2018, 185, 476–491. [Google Scholar] [CrossRef]

- Staffas, L.; Gustavsson, M.; McCormick, K. Strategies and Policies for the Bioeconomy and Bio-Based Economy: An Analysis of Official National Approaches. Sustainability 2013, 5, 2751–2769. [Google Scholar] [CrossRef] [Green Version]

- The Pew Charitable Trusts. System IQ. Breaking the Plastic Wave. (A Comprehensive Assessment of Pathways Towards Stopping Ocean Plastic Pollution). 2020. Available online: https://www.pewtrusts.org/-/media/assets/2020/10/breakingtheplasticwave_mainreport.pdf (accessed on 23 December 2022).

- De Oroski, F.A. Modelos de Negócio e Transição de Sistemas Tecnológicos: O caso dos Bioplásticos. Ph.D. Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Maturana, M. Dilemas Estratégicos na Difusão de Inovações em Bioprodutos. Master’s Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2019. Available online: http://epqb.eq.ufrj.br/wp-content/uploads/2021/04/19_39.pdf (accessed on 20 January 2023).

- Bennett, S.J. The Socio-Technical Dynamics of Chemical Feedstock Transitions: The Case of Renewable Raw Materials in the UK; Imperial College London: London, UK, 2009; Available online: http://spiral.imperial.ac.uk/handle/10044/1/5596 (accessed on 4 December 2018).

| Group | Polymer | Direct Raw Material(s) | Capacity in 2022 (tons) | Capacity in 2027 (Forecast, tons) |

|---|---|---|---|---|

| Bio-based, non-biodegradable | PA (polyamides) | Dicarboxylic acids + Diamines OR Amino acids OR Cyclic amides | 246,420 | 1,178,100 |

| PE | Ethylene | 328,560 | 743,400 | |

| PP (polypropylene) | Propylene | 86,580 | 378,000 | |

| PTT | 1,3-Propanediol + Terephthalic acid | 295,260 | 296,100 | |

| PET | Ethylene glycol + Terephthalic acid | 93,240 | 113,400 | |

| PEF | Hydroxymethylfurfural + 2,5-Furandicarboxylic acid | 0 | 6300 | |

| Other | - | 24,420 | 25,200 | |

| Bio-based, biodegradable | PLA | Lactic acid | 459,540 | 2,387,700 |

| PHA | Fermentable sugars | 86,580 | 560,700 | |

| Starch blends | Starchy materials | 397,380 | 396,900 | |

| Regenerated cellulose films | Cellulose | 79,920 | 94,500 | |

| PBS | Succinic acid + 1,4-Butanediol | 19,980 | 18,900 | |

| Fossil-based, biodegradable | PBAT | 1,4-Butanediol + Adipic acid + Terephthalic acid | 99,900 | 100,800 |

| Company | Capacity (kta) | Location | Remarks | References |

|---|---|---|---|---|

| Cargill Dow LLC | 4 (to be doubled by late 1998) | Savage, Minnesota, USA | Primary global producer at the time | [31,66,67] |

| EcoPol (jv between Chronopol and EcoChem) | 1 | Johnstown, Colorado, USA | EcoChem was a JV between DuPont and ConAgra that ceased operations in 1994 | [67,68,69] |

| Galactic (Brussels Biotech) | Tens of tons | Escanaffles, Belgium | - | [70] |

| Hycail | - | The Netherlands | - | [69] |

| Kyowa Hakko | - | USA | Entered a non-exclusive license with Argonne National Laboratory (USA) of its BioLac process | [71] |

| Mitsui | 0.5 | Japan | Already a producer of PLA and copolymer for medical applications | [72,73] |

| Neste OY | - | Finland | No significant production, but had some application development efforts | [69] |

| Shimadzu | 0.1 | Japan | Production in collaboration with Mitsubishi Plastics | [73] |

| Company | Capacity (kta) | Location | References |

|---|---|---|---|

| B&F PLA (BBCA + Futerro) | 30 | Bengbu, China | [89] |

| COFCO | 10 | Changchun, China | [90] |

| Futerro (Galactic) | 1.5 | Escanaffles, Belgium (demonstration) | [91] |

| Hengtian | 10 | China | [21] |

| Hisun | 45 | China | [21] |

| Jiangxi KeYuan | 1 | Jiujiang, China | [92] |

| LG Chem + ADM | 75 (due to 2025) | USA | [93] |

| NatureWorks (Cargill + PTT Global) | 150 | Blair, Nevada, USA | [17] |

| 75 (due to 2024) | Nakhon Sawan, Thailand | [94] | |

| Uhde Inventa-Fischer | 0.5 | Guben, Germany (pilot) | [95] |

| Sulzer | <1 | Winterthur, Switzerland | [96] |

| SuPLA | 10 | Suqian, China | [97] |

| Synbra (purchased by BEWi Group in 2018) | 5 | Allschwil, Switzerland | [98] |

| TianRen | 3 | China | [21] |

| Tong-Jie-Liang Biomaterials | 10 | China | [21] |

| Total Corbion PLA | 75 | Rayong, Thailand | [99] |

| 100 (due to 2024) | Grandpuits, France | [100] |

| Stylized Fact | Main Trends Identified | Implications |

|---|---|---|

| 1. The Prevalence of Petrochemical Plastics Restricted the Bioplastic Capabilities |

|

|

| 2. Plastics Generally Present Property Issues When They Were Introduced |

|

|

| 3. Plastic Pollution Was a Key Trigger of Bioplastics Diffusion |

|

|

| 4. Bioplastics Experienced Lower-than-expected Market Growth, which Compromised Corporate Commitment |

|

|

| 5. Co-operation is Key to Promoting Bioplastics |

|

|

| 6. Sustainability Scrutiny Simultaneously Propel and Hinders Bioplastics |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teixeira, L.V.; Bomtempo, J.V.; Oroski, F.d.A.; Coutinho, P.L.d.A. The Diffusion of Bioplastics: What Can We Learn from Poly(Lactic Acid)? Sustainability 2023, 15, 4699. https://doi.org/10.3390/su15064699

Teixeira LV, Bomtempo JV, Oroski FdA, Coutinho PLdA. The Diffusion of Bioplastics: What Can We Learn from Poly(Lactic Acid)? Sustainability. 2023; 15(6):4699. https://doi.org/10.3390/su15064699

Chicago/Turabian StyleTeixeira, Leonardo Vieira, José Vitor Bomtempo, Fábio de Almeida Oroski, and Paulo Luiz de Andrade Coutinho. 2023. "The Diffusion of Bioplastics: What Can We Learn from Poly(Lactic Acid)?" Sustainability 15, no. 6: 4699. https://doi.org/10.3390/su15064699

APA StyleTeixeira, L. V., Bomtempo, J. V., Oroski, F. d. A., & Coutinho, P. L. d. A. (2023). The Diffusion of Bioplastics: What Can We Learn from Poly(Lactic Acid)? Sustainability, 15(6), 4699. https://doi.org/10.3390/su15064699