Fluid Interfaces in Colloidal Systems: Aerosols, Foams, and Emulsions

A special issue of Coatings (ISSN 2079-6412). This special issue belongs to the section "Liquid–Fluid Coatings, Surfaces and Interfaces".

Deadline for manuscript submissions: closed (31 December 2022) | Viewed by 5315

Special Issue Editors

Interests: biointerfaces; biophysical transport; interfacial fluid mechanics; stability of fluid interfaces; interfacial rheology

Special Issue Information

Dear Colleagues,

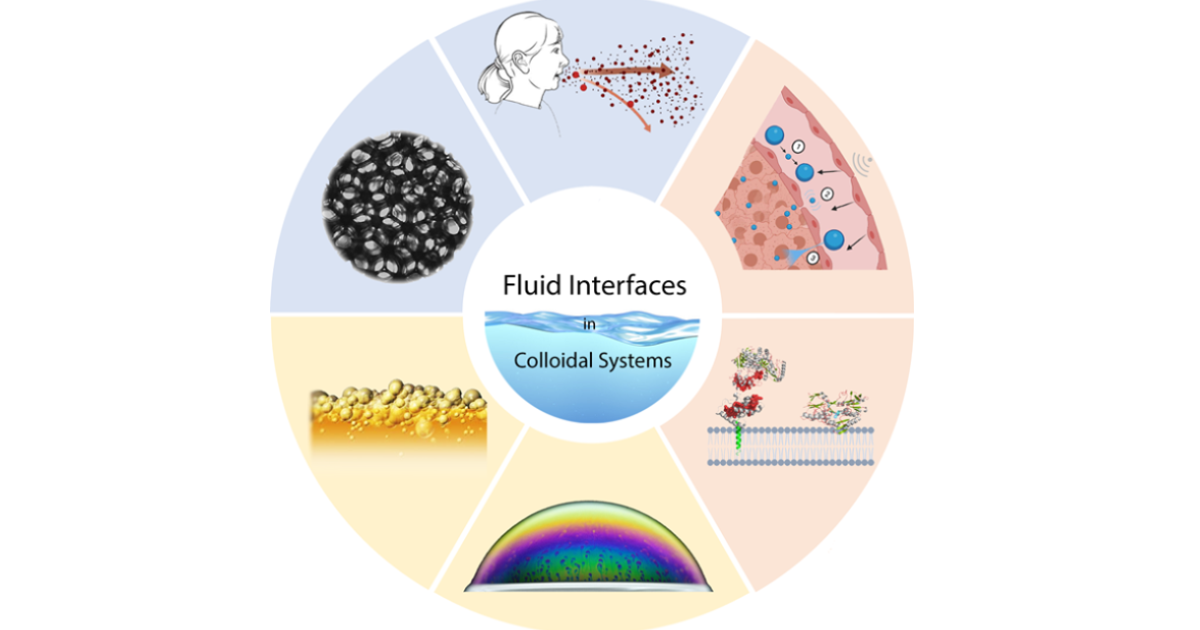

Recent years have seen significant advances in the science of fluid interfaces in colloidal systems spurred by modern demands from industrial-scale machinery, sophisticated manufacturing techniques, human health and precision theranostics. Theoretical, computational and experimental advances have vastly improved our understanding of many important aspects, including aerosol generation during respiratory illnesses, the interfacial rheology of fluid interfaces with biomolecules, the rupture mechanics of polymeric films, terminal drainage characteristics of aqueous foam films and the stability of non-aqueous foams and emulsions. This Special Issue serves to document these advances and support future research in this area by compiling relevant articles and reviews on this topic.

The scope of this Special Issue includes but is not limited to the following concepts:

- Theoretical, computational and experimental research on the role of aerosol generation and stability, particularly in the context of communicable diseases such as COVID-19.

- Advances in the interfacial physics of microbubbles and emulsions used for theranostics, such as the stability and dynamics of ultrasound contrast agents.

- Developments in the understanding of non-aqueous foam stabilization and destabilization mechanisms.

- Theoretical and experimental research on the terminal film-thinning dynamics of foams and emulsion films, particularly under the influence of structural forces.

- Drainage, stability and interfacial rheology of biointerfaces such as protein- and lipid-laden fluid interfaces.

- Stability and rupture mechanics of polymeric foams and emulsion films.

Dr. Vineeth ‘Vinny’ Chandran Suja

Prof. Dr. Ernesto Di Maio

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Coatings is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- respiratory aerosols

- biointerfaces

- polymeric foams

- theranostic microbubbles

- non-aqueous foams and emulsions

- antifoaming