Surface Engineering Processes for Reducing Friction and Wear

A special issue of Coatings (ISSN 2079-6412). This special issue belongs to the section "Corrosion, Wear and Erosion".

Deadline for manuscript submissions: 30 November 2024 | Viewed by 1595

Special Issue Editors

Interests: materials science; surface engineering; manufacturing processes; tribology; mechanical properties; corrosion and oxidation

Special Issues, Collections and Topics in MDPI journals

Interests: materials science; surface engineering; manufacturing processes; tribology; mechanical properties; corrosion and oxidation

Special Issue Information

Dear Colleagues,

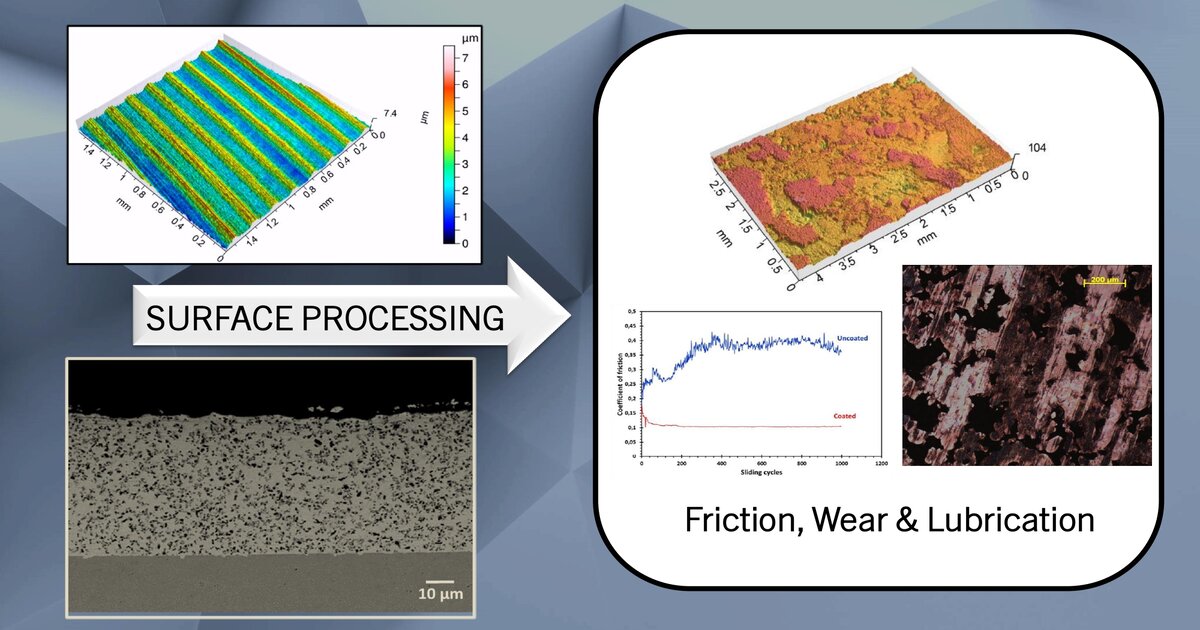

Surface engineering is considered as a critical area in industrial manufacturing as the quality of surfaces strongly affects the functionality, efficiency and durability of technological processes and products. One of the main goals for surface modification is to reduce the adverse effects of friction and wear in wide range of engineering applications, such as biomedical, electrical, energy, transport, etc. However, due to the variability and diversity of these applications, diverse contact conditions and environments are met. Thus, in order to select and apply the most appropriate surface treatment, testing under relevant to the application conditions is needed.

Having the above in mind, this Special Issue focuses on the utilization of surface engineering processes to minimize friction and wear phenomena in engineering applications. The topics of interest for this Special Issue, in particular, include (but are not restricted to):

- All existing surface processing technologies (e.g., coating deposition, laser treatments, ion implantation, etc.) for modifying materials;

- Novel surface treatments and coatings;

- Use of surface treatments to reduce wear and friction;

- New tribological methods to study industrial problems on the lab scale;

- Friction and wear mechanisms in surface modified systems;

- Tribo-corrosion of surfaces;

- Other aspects of tribological surfaces and coatings are also welcome.

Dr. Emmanuel P. Georgiou

Dr. Angelos Koutsomichalis

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Coatings is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- surface engineering

- coatings

- materials processing

- friction

- wear

- lubrication

- tribo-testing

- green tribology

- sustainability