Advances in 3D Printed Reinforced Materials/Electronics: Processes, Properties and Applications

A special issue of Materials (ISSN 1996-1944). This special issue belongs to the section "Manufacturing Processes and Systems".

Deadline for manuscript submissions: closed (20 March 2024) | Viewed by 1637

Special Issue Editors

Interests: additive manufacturing; mechanics; fatigue; carbon fiber composites; metallic materials

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

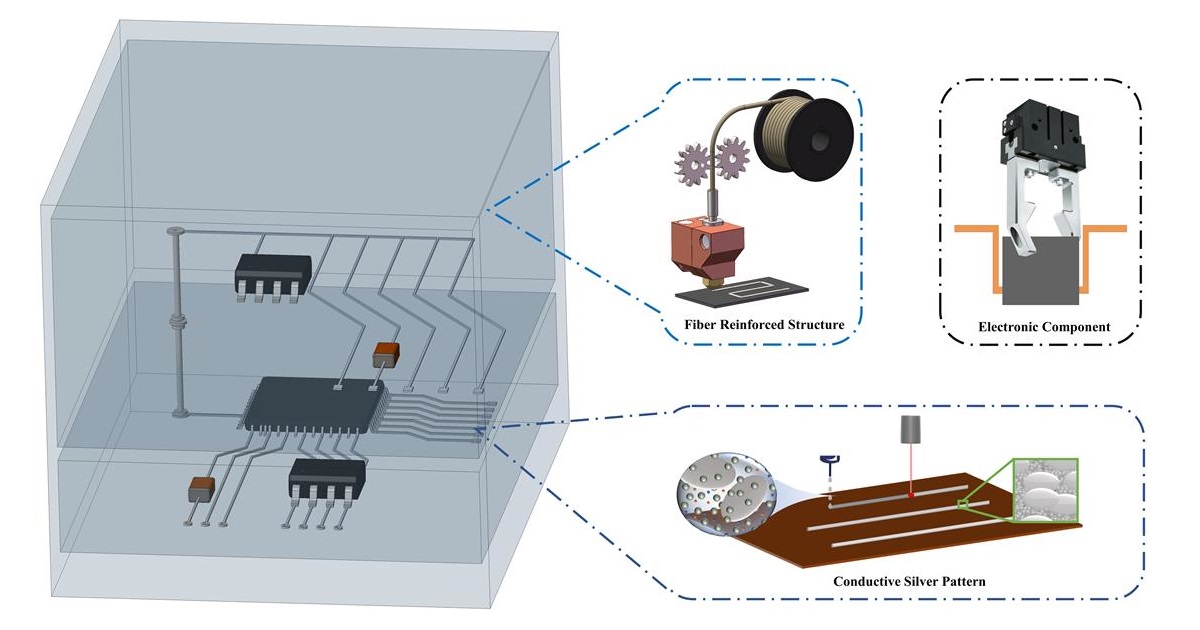

Additive manufacturing (AM) shows prominent advantages in the modern industry owing to the almost unlimited design freedom to produce components with complex 3D shapes without the need for tooling. In order to fabricate the real-world applications with high performance or multiple functions, reinforcements or conductive elements are introduced in the latest AM techniques. The methodology and mechanism of AM with multi-functionality are meaningful to the further development.

The scope of this Special Issue is to present the latest developments in the field of AM of structures or components with reinforcements or conductive elements. Topics addressed include new computational models and approaches predicting the fabrication process and mechanical properties of complex structures and components, and new additive manufacturing technologies covering various families of material extrusion, material lamination, material jetting, direct ink writing, selective laser sintering, curing and sintering, etc. New composite systems containing either fiber reinforcement or conductive elements, are covered. The applications of AM of integrated structures in other fields, e.g., robot design and bio-inspired structure design, are also welcome.

Dr. Haibin Tang

Dr. Xingzhi Xiao

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- 3D printed electronic

- additive manufacturing

- advanced functional materials

- fiber reinforced composites

- computational modeling

- manufacturing process and performance