Electroheat Models and Analysis of Metallic Materials

A special issue of Metals (ISSN 2075-4701). This special issue belongs to the section "Computation and Simulation on Metals".

Deadline for manuscript submissions: closed (31 March 2022) | Viewed by 6122

Special Issue Editor

Interests: numerical modeling of physical fields; coupled problems rooting in electromagnetics; forward and backward tasks; electroheating and related processes.

Special Issue Information

Dear Colleagues,

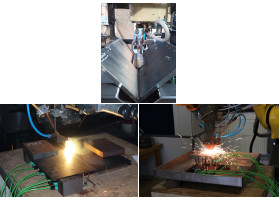

Presently, electroheating of metals belongs to a group of industrial technologies used for the manufacturing of a wide spectrum of products. Their direct or indirect heating is typically an integral part of more sophisticated processes such as hardening, casting, annealing, brazing, welding or cladding. In order to reach the required parameters of the final products, the relevant devices and lines must be designed very carefully, with respect to all accompanying physical phenomena.

Knowledge of these phenomena can be obtained either by measurements or by their computer simulation. However, experiments in this domain are rather expensive and, in recent times, have been increasingly replaced by numerical modeling, which has become much cheaper. That is why the simulation-based or modeling-based approach is presently preferred all over the world. Moreover, this approach has another significant advantage consisting in the fact that the designs can also be optimized.

The existing models of particular physical fields playing important roles in the above processes (electromagnetic fields, temperature fields, fields of mechanical displacements, residual stresses or flow) are well known and describe the physical reality with a good accuracy. Nevertheless, issues may appear in the physical properties—and their temperature dependencies—of materials, mainly alloys (specific heat, thermal conductivity, and viscosity of melt), which are often known only partially or even unknown. Problems of another kind are typical for triply or quadruply coupled tasks; unacceptably long computing times and the necessity of a vast memory in the case of 3D arrangements, poor convergence of the iterative processes, etc. However, all of these issues related to the forward solutions are being gradually solved in many scientific workshops worldwide.

On the other hand, the optimization and solution of the backward problems is, at present, still at the earliest stages. The principal reason is the scope of such tasks. The use of classical optimization methods often fails here and, therefore, novel approaches must be sought. Some of them seem to be prospective; for example, those based on surrogate models (that still have to be sufficiently accurate) and supplemented with carefully selected algorithms for searching the space and design of experiments.

We cordially invite the authors that are able to contribute to the mentioned topics to send us a paper describing their recent research in the field. We do hope that the Special Issue will bring a lot of useful information into the domain, with novel methods and algorithms that substantially accelerate the computation processes, and also lead to new theoretical knowledge.

Prof. Ivo Doležel

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Metals is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- electroheating processes

- forward and backward problems

- numerical analysis

- optimization

- physical fields

- electromagnetic field

- temperature field

- direct heating

- induction heating

- hardening