Understanding the Microstructure Evolution of 8Cr4Mo4V Steel under High-Dose-Rate Ion Implantation

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

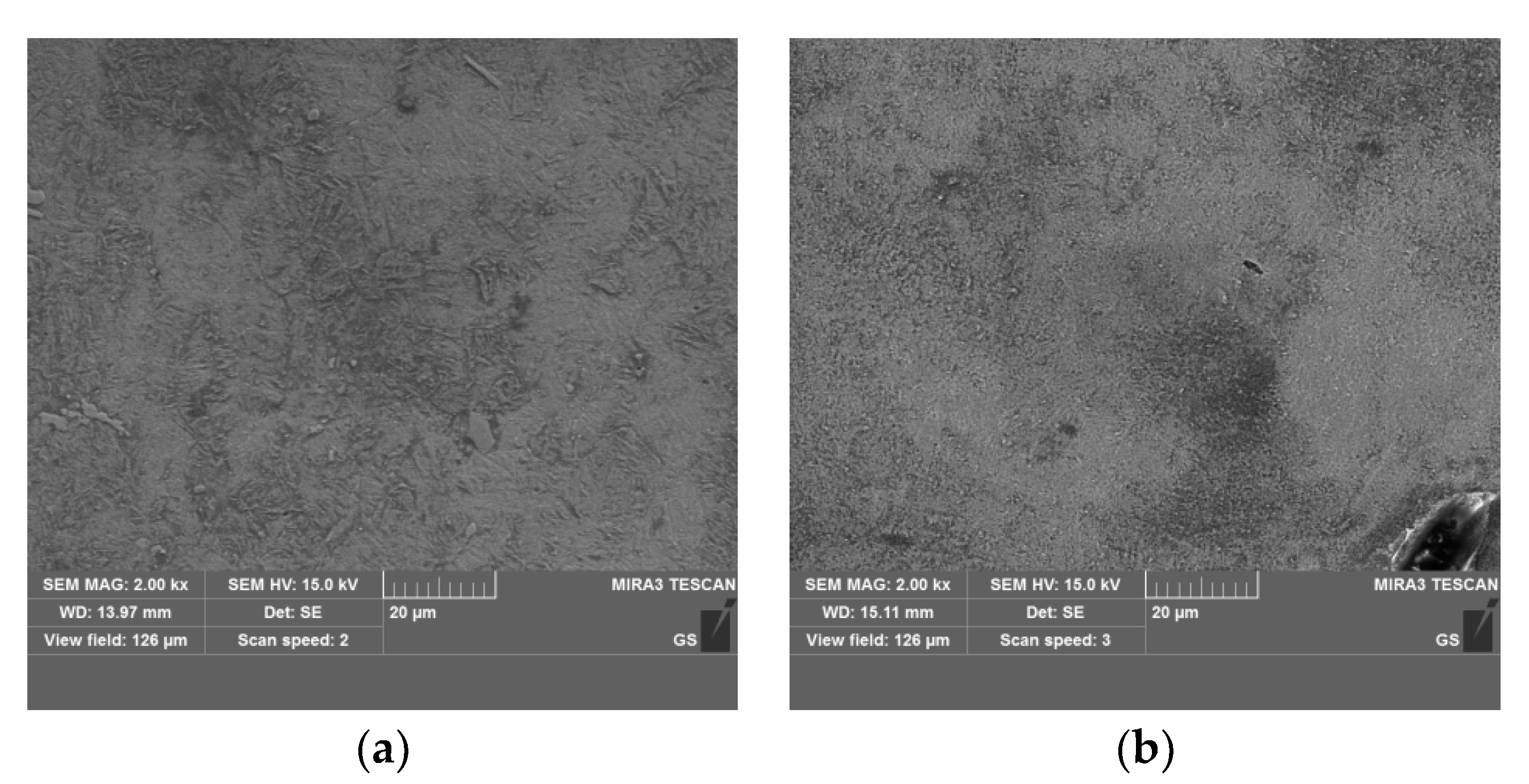

3.1. SEM Images of the Modified Layer by High-Dose-Rate Ion Implantation

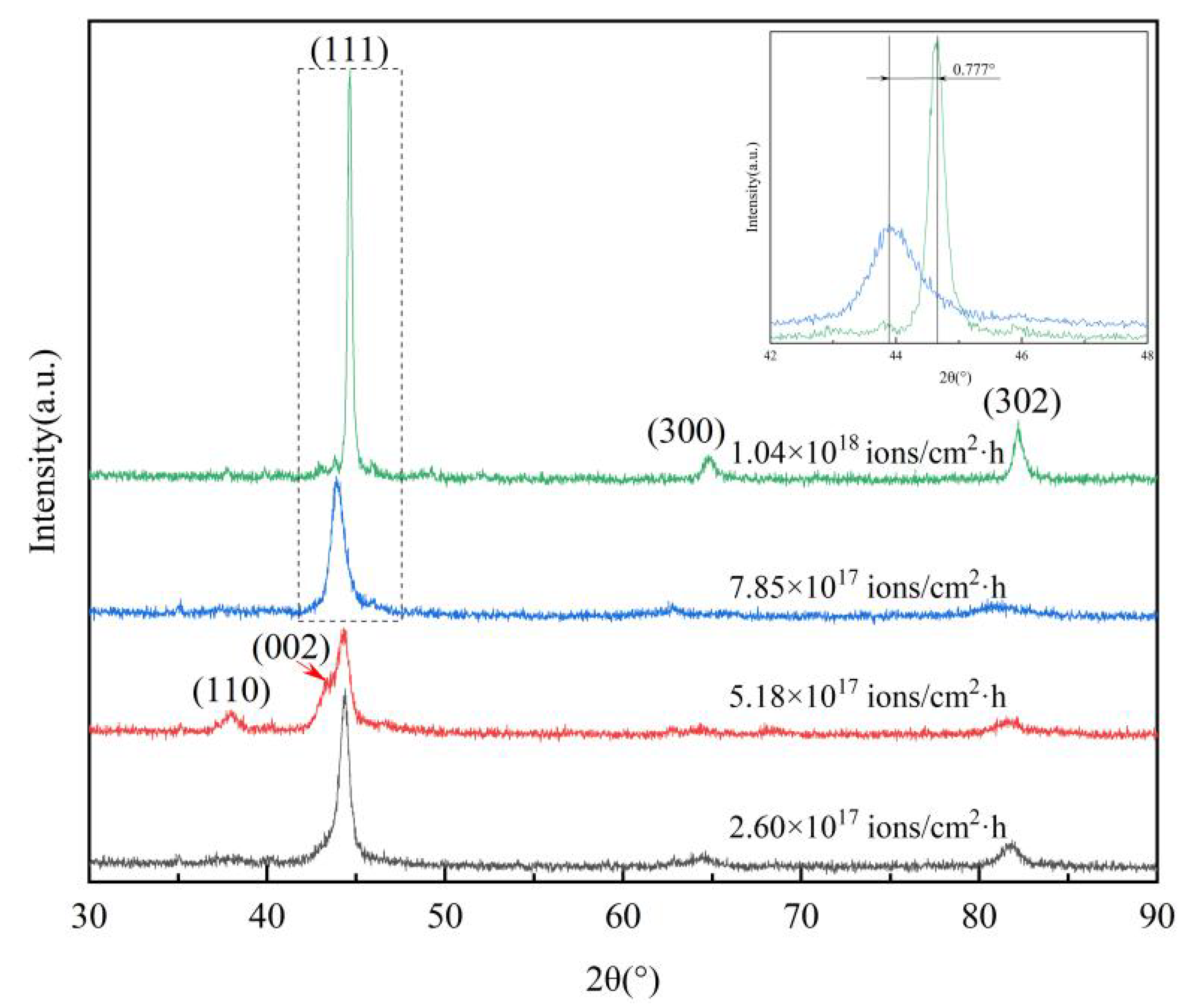

3.2. XRD Analysis of the Modified Layer by High-Dose-Rate Ion Implantation

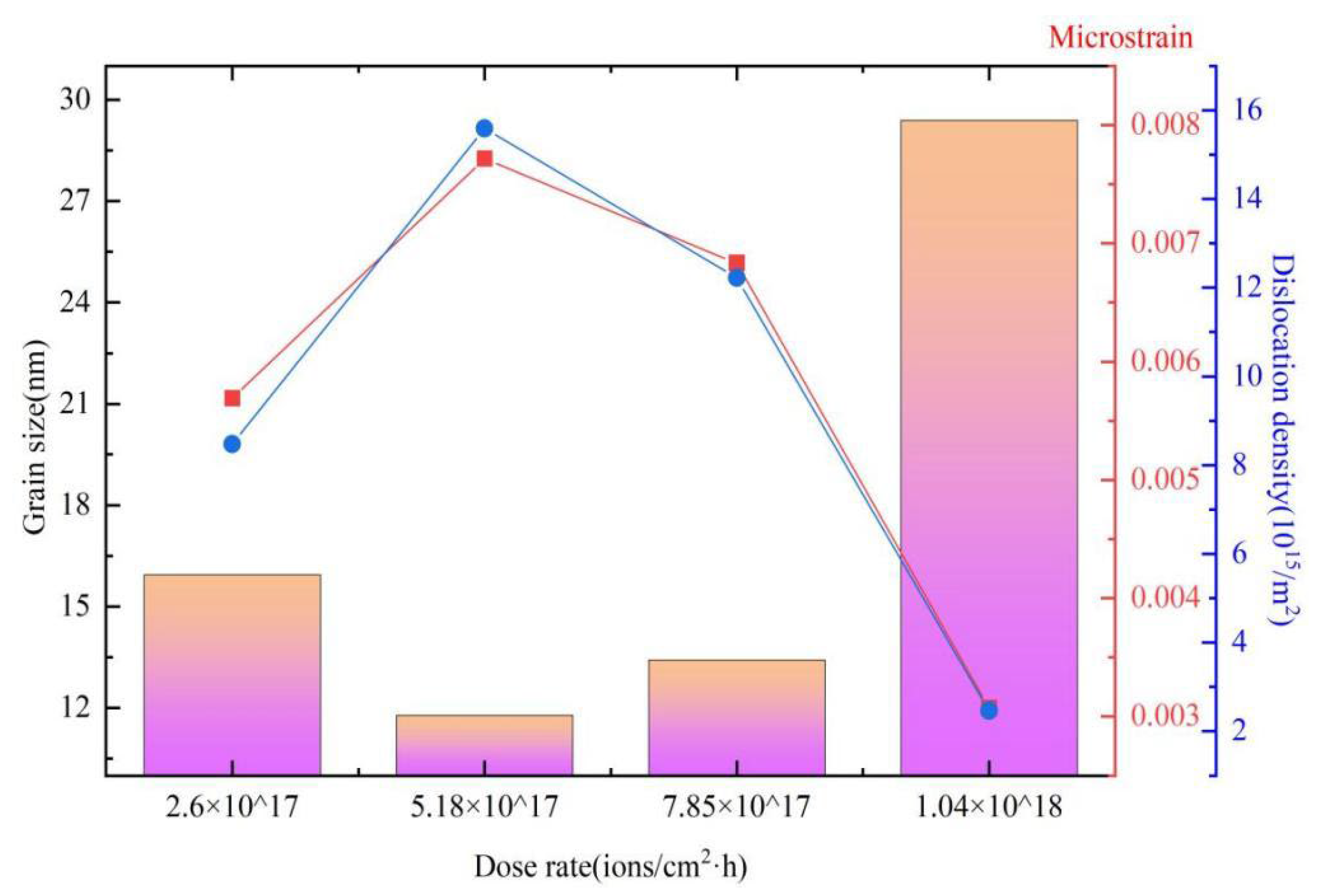

3.3. Determination of Crystallite Size by Scherrer Analysis

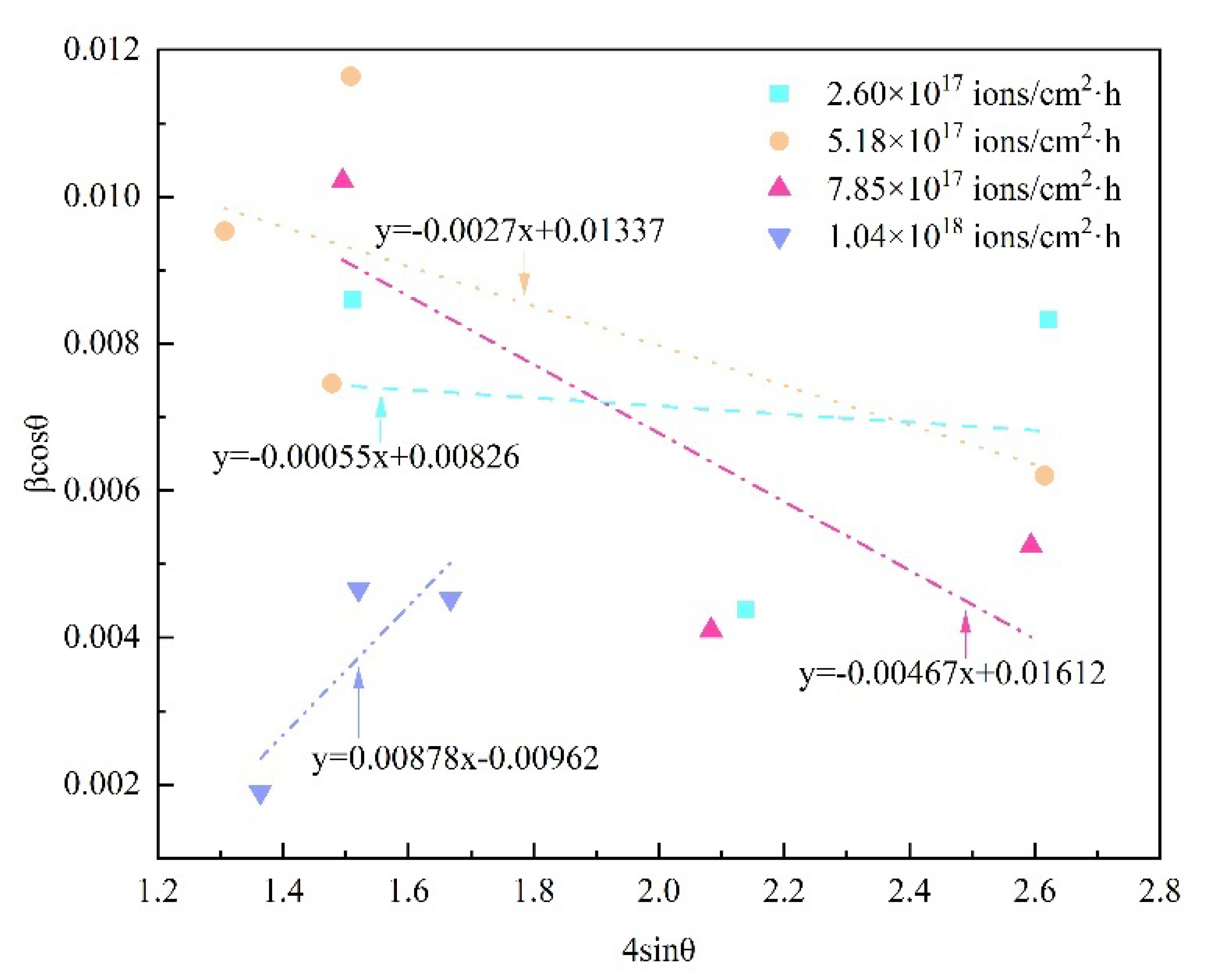

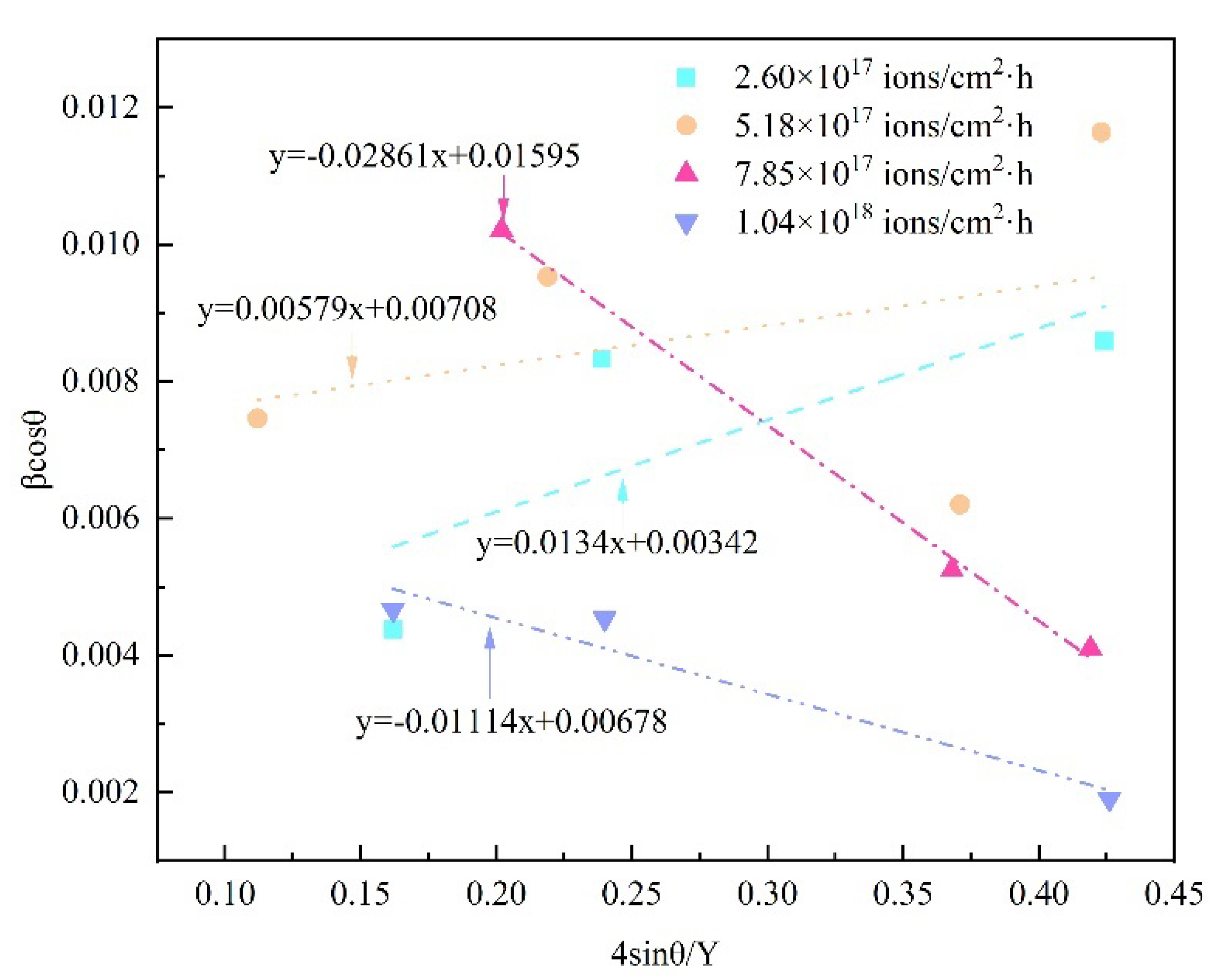

3.4. Estimation of Crystallite Size and Microstrain by Uniform Deformation Model (UDM)

3.5. Estimation of Crystallite Size and Lattice Deformation Stress by Uniform Stress Deformation Model (USDM)

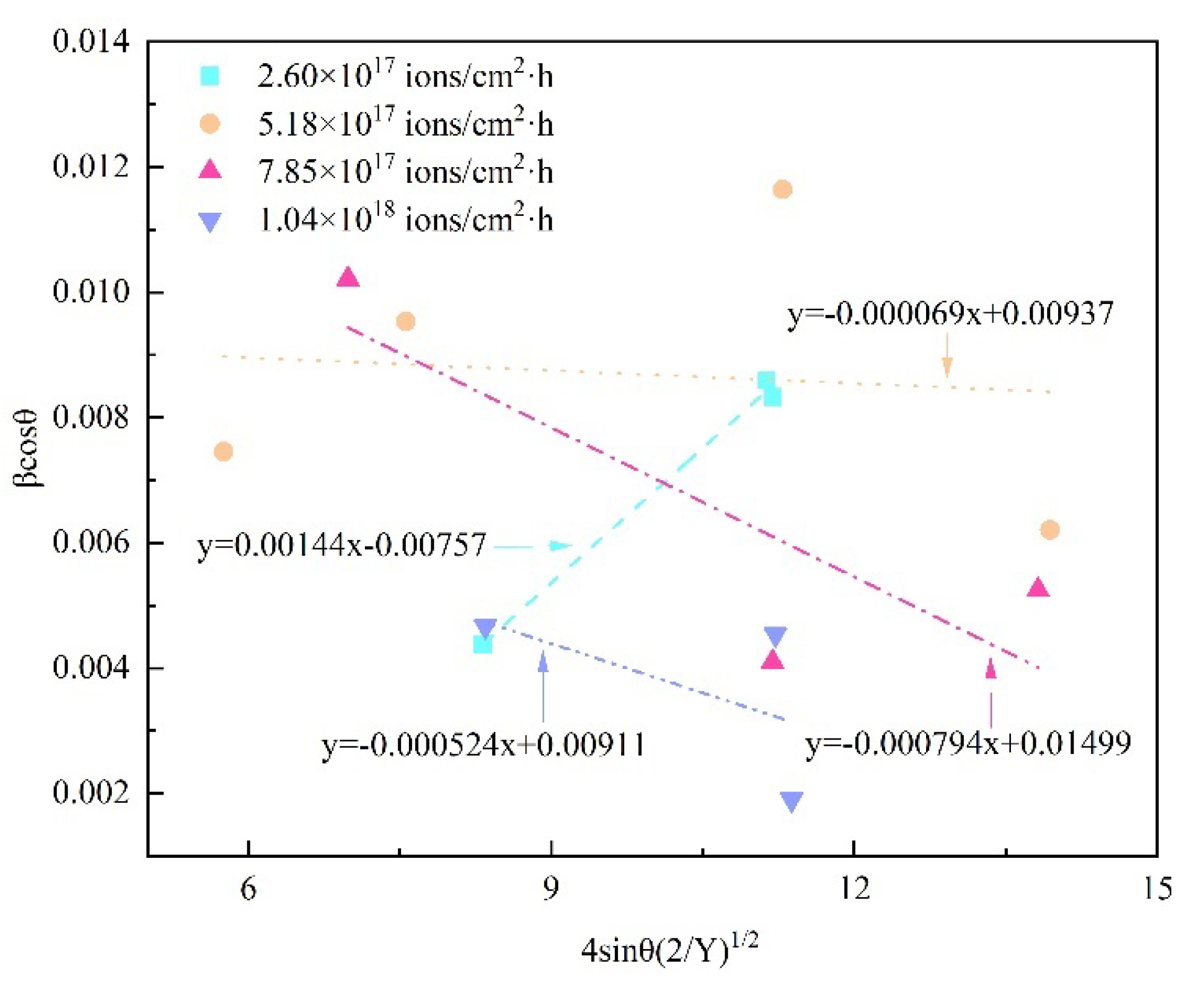

3.6. Estimation of Deformation Energy Density by Uniform Deformation Energy Density Model (UDEDM)

4. Conclusions

- (1)

- X-ray diffraction analysis suggests that the peaks corresponding to the implanted samples with a dose rate from 2.60 × 1017 to 7.85 × 1017 ions/cm2·h broadened and slightly shift to left by 0.777° towards, when compared with that of the implanted samples with a dose rate of 1.04 × 1018 ions/cm2·h.

- (2)

- The crystallite size initially decreased and then tended to increase; the microstrain and dislocation density initially increased and then tended to decrease with the increasing of dose rate. The microstrain and dislocation density reached the highest level of 7.716 × 10−3 and 1.559 × 1015 /m2, respectively, at the dose rate of 5.18 × 1017 ions/cm2·h.

- (3)

- In all of the Williamson–Hall graphs, the slope of the line reveals the different angle and values, which implies that the higher the increase in the slope of the approximating straight line, the sharper the increase in the magnitude of the microdistortions.

- (4)

- Williamson–Hall methods reveal that there exist a negative and positive slope in various orientations, indicating a compressive and tensile strain induced in 8Cr4Mo4V steel by various high dose rates during plasma immersion ion implantation.

- (5)

- The Williamson–Hall methods in this work demonstrate the feasibility of calculating lattice parameters and provide a further application for different materials to estimate the crystallite size, microstrain and dislocation density.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, D.; Liu, D.; Zhang, X.; He, G.; Ma, A.; Wu, G. Plain fatigue and fretting fatigue behaviors of 17-4PH steel subjected to ultrasonic surface rolling process: A comparative study. Surf. Coat. Technol. 2020, 399, 126196. [Google Scholar] [CrossRef]

- Bhadeshia, H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Zaretsky, E.V. Rolling bearing steels—A technical and historical perspective. Mater. Sci. Technol. 2013, 28, 58–69. [Google Scholar] [CrossRef]

- Wei, Y.; Yu, X.; Su, Y.; Shen, X.; Xia, Y.; Yang, W. Effect of residual stress and microstructure evolution on size stability of M50 bearing steel. J. Mater. Res. Technol. 2021, 10, 651–661. [Google Scholar] [CrossRef]

- Li, Z.; Li, K.; Qian, C.; Wang, D.; Ji, W.; Wu, Y.; Cai, Z.; Liu, Q. Effect of pulsed magnetic field on retained austenite of quenched 8Cr4Mo4V steel under cryogenic condition. J. Mater. Res. Technol. 2023, 23, 5004–5015. [Google Scholar] [CrossRef]

- Su, Y.; Li, P.; Wang, S.; Yang, S.; Wu, J.; Yu, X.; Liu, H. Influence of vacuum graded austempering treatment on microstructure and mechanical properties of M50 steel. J. Mater. Res. Technol. 2022, 21, 2721–2729. [Google Scholar] [CrossRef]

- Niu, J.; Zhang, X.; Ma, X.; Liu, Y.; Wang, L.; Wu, T. Characterization of vein-like structures formed in nitrided layers during plasma nitriding of 8Cr4Mo4V steel. Materialia 2022, 22, 101378. [Google Scholar] [CrossRef]

- Niu, J.; Qureshi, M.W.; Ding, Z.; Ma, X.; He, Y. Effect of nitriding on the transformation of alloy carbides (VC and Mo2C) in 8Cr4Mo4V steel. Appl. Surf. Sci. 2023, 610, 155561. [Google Scholar] [CrossRef]

- Miao, B.; Zhang, X.; Ma, X.X. Effects of microstructure and nanohardness of the 8Cr4Mo4V steel under high-dose-rate N-PIII. Trans. IMF 2023, in press. [Google Scholar] [CrossRef]

- Jiang, H.; Shan, D.; Guo, B.; Zong, Y. Effect of fibrous macrostructure on mechanical properties, anisotropy and fracture mechanism of roller bearing ring. Mat. Sci. Eng. A. 2021, 816, 141311. [Google Scholar] [CrossRef]

- Jiang, H.; Song, Y.; Wu, Y.; Shan, D.; Zong, Y. Macrostructure, microstructure and mechanical properties evolution during 8Cr4Mo4V steel roller bearing inner ring forging process. Mater. Sci. Eng. A 2020, 798, 140196. [Google Scholar] [CrossRef]

- Haolin, L.; Huiqin, S.; Chen, M.; Qifa, Y.; Qiu, X.; Deguang, X.; Tianyou, Z. Effects of B, N, Cr and Mo ion implantation on the corrosion resistance of pure iron and its alloys (GCr15 and Cr4Mo4V). Vacuum 1989, 39, 187–189. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, C.; Zheng, L.; Zhang, H. Corrosion resistance of carbon ion-implanted M50NiL aerospace bearing steel. Prog. Nat. Sci. 2017, 27, 615–621. [Google Scholar] [CrossRef]

- Yu, X.; Wei, Y.; Zheng, D.; Shen, X.; Su, Y.; Xia, Y.; Liu, Y. Effect of nano-bainite microstructure and residual stress on friction properties of M50 bearing steel. Tribol. Int. 2022, 165, 107285. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, Q. Bearing failure impulse enhancement method using multiple resonance band centre positioning and envelope integration. Measurement 2022, 200, 111623. [Google Scholar] [CrossRef]

- Qian, D.; Liu, Y.; Ren, H.; Wang, F.; Wu, M.; Deng, S. Microstructure and mechanical properties evolution of aviation M50 steel fabricated by the multiple electro-assisted rolling. J. Mater. Res. Technol. 2022, 20, 496–507. [Google Scholar] [CrossRef]

- Yue, X.; Hu, S.; Wang, X.; Liu, Y.; Yin, F.; Hua, L. Understanding the nanostructure evolution and the mechanical strengthening of the M50 bearing steel during ultrasonic shot peening. Mater. Sci. Eng. A 2022, 836, 142721. [Google Scholar] [CrossRef]

- Hou, X.-Q.; Zhang, Z.; Liu, C.-K.; Tao, C.-H. Formation mechanism and influence of white etching area on contact fatigue spalling of M50 bearing steel. Eng. Fail. Anal. 2022, 139, 106273. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.; Gu, L.; Bi, M.; Hou, P.; Zheng, D.; Wang, L. Analysis on surface damage of M50 steel at impact-sliding contacts. Tribol. Int. 2020, 150, 106384. [Google Scholar] [CrossRef]

- Xie, X.; Chen, C.; Luo, J.; Xu, J. The microstructure and tribological properties of M50 steel surface after titanium ion implantation. Appl. Surf. Sci. 2021, 564, 150349. [Google Scholar] [CrossRef]

- Dodd, A.; Kinder, J.; Torp, B.; Nielsen, B.; Rangel, C.; da Silva, M. The effect of ion implantation on the fatigue life and corrosion resistance of M50 steel bearings. Surf. Coatings Technol. 1995, 74–75, 754–759. [Google Scholar] [CrossRef]

- Rangel, C.; Simplicio, M.; Consiglieri, A.; Nielsen, B.; Torp, B.; Teixeira, N.; Alves, J.; Silva, M.; Soares, J.; Dodd, A.; et al. The effect of the angle of incidence on the aqueous corrosion of ion implanted M50 steel substrates. Surf. Coat. Technol. 1992, 51, 483–488. [Google Scholar] [CrossRef]

- Du, N.; Liu, H.; Cao, Y.; Fu, P.; Sun, C.; Liu, H.; Li, D. In situ investigation of the fracture of primary carbides and its mechanism in M50 steel. Mater. Charact. 2022, 186, 111822. [Google Scholar] [CrossRef]

- Wang, F.; Qian, D.; Hua, L.; Mao, H.; Xie, L.; Song, X.; Dong, Z. Effect of high magnetic field on the microstructure evolution and mechanical properties of M50 bearing steel during tempering. Mater. Sci. Eng. A 2020, 771, 138623. [Google Scholar] [CrossRef]

- Wang, F.; Qian, D.; Hua, L.; Lu, X. The effect of prior cold rolling on the carbide dissolution, precipitation and dry wear behaviors of M50 bearing steel. Tribol. Int. 2019, 132, 253–264. [Google Scholar] [CrossRef]

- Wang, Y.; Clayton, C.; Hubler, G.; Lucke, W.; Hirvonen, J. Applications of ion implantation for the improvement of localized corrosion resistance of M50 bearing steel. Thin Solid Films 1979, 63, 11–18. [Google Scholar] [CrossRef]

- Kang, Q.; Wei, K.; Fan, H.; Liu, X.; Hu, J. Ultra-high efficient novel plasma aluminum-nitriding methodology and performances analysis. Scr. Mater. 2022, 220, 114902. [Google Scholar] [CrossRef]

- Yang, L.; Xue, W.; Gao, S.; Liu, H.; Cao, Y.; Duan, D.; Li, D.; Li, S. Study on sliding friction and wear behavior of M50 bearing steel with rare earth addition. Tribol. Int. 2022, 174, 107725. [Google Scholar] [CrossRef]

- Ma, H.; Wei, K.; Zhao, X.; Liu, X.; Hu, J. Performance enhancement by novel plasma boron-nitriding for 42CrMo4 steel. Mater. Lett. 2021, 304, 130709. [Google Scholar] [CrossRef]

- Daroonparvar, M.; Bakhsheshi-Rad, H.R.; Saberi, A.; Razzaghi, M.; Kasar, A.K.; Ramakrishna, S.; Menezes, P.L.; Misra, M.; Ismail, A.F.; Sharif, S.; et al. Surface modification of magnesium alloys using thermal and solid-state cold spray processes: Challenges and latest progresses. J. Magnes. Alloy. 2022, 10, 2025–2061. [Google Scholar] [CrossRef]

- Cisternas, M.; Bhuyan, H.; Retamal, M.; Casanova-Morales, N.; Favre, M.; Volkmann, U.; Saikia, P.; Diaz-Droguett, D.; Mändl, S.; Manova, D.; et al. Study of nitrogen implantation in Ti surface using plasma immersion ion implantation & deposition technique as biocompatible substrate for artificial membranes. Mater. Sci. Eng. C 2020, 113, 111002. [Google Scholar] [CrossRef]

- Chu, P.K. Progress in direct-current plasma immersion ion implantation and recent applications of plasma immersion ion implantation and deposition. Surf. Coat. Technol. 2013, 229, 2–11. [Google Scholar] [CrossRef]

- Anders, A. Metal plasma immersion ion implantation and deposition: A review. Surf. Coat. Technol. 1997, 93, 158–167. [Google Scholar] [CrossRef]

- Shanaghi, A.; Chu, P.K. Enhancement of mechanical properties and corrosion resistance of NiTi alloy by carbon plasma immersion ion implantation. Surf. Coat. Technol. 2019, 365, 52–57. [Google Scholar] [CrossRef]

- Xu, C.; Wang, X.; Zhang, B.; Luo, X.; Tang, Z.; Dai, S. Effect of the Pre-Shot Peening and Nitrogen Ion Implantation Combined Surface Treatments on the Surface Structure and Properties of Gear Steel 16Cr3NiWMoVNbE. Metals 2022, 12, 1509. [Google Scholar] [CrossRef]

- Chiu, S.; Lee, S.; Wang, C.; Tai, F.; Chu, C.; Gan, D. Electrical and mechanical properties of DLC coatings modified by plasma immersion ion implantation. J. Alloy. Compd. 2008, 449, 379–383. [Google Scholar] [CrossRef]

- Ziegler, J.F. Ion Implantation Science and Technology; Yorktown Heights: New York, NY, USA, 1988. [Google Scholar] [CrossRef]

- Fernandes, B.; Mändl, S.; Oliveira, R.; Ueda, M. Mechanical properties of nitrogen-rich surface layers on SS304 treated by plasma immersion ion implantation. Appl. Surf. Sci. 2014, 310, 278–283. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, X.; Wang, Z.; Gong, C.; Yang, S.; Fu, R.K.; Chu, P.K. Uniformity enhancement of incident dose on concave surface in plasma immersion ion implantation assisted by beam-line ion source. Surf. Coat. Technol. 2011, 206, 2021–2024. [Google Scholar] [CrossRef]

- Rajkumar, R.; Kumar, M.; George, P.; Mukherjee, S.; Chari, K. Dose- and energy-dependent behaviour of silicon nitride films produced by plasma immersion ion implantation. Surf. Coat. Technol. 2002, 156, 272–275. [Google Scholar] [CrossRef]

- Koval, N.; Ryabchikov, A.; Sivin, D.; Lopatin, I.; Krysina, O.; Akhmadeev, Y.; Ignatov, D. Low-energy high-current plasma immersion implantation of nitrogen ions in plasma of non-self-sustained arc discharge with thermionic and hollow cathodes. Surf. Coat. Technol. 2018, 340, 152–158. [Google Scholar] [CrossRef]

- Ueda, M.; Reuther, H.; Gunzel, R.; Beloto, A.; Abramof, E.; Berni, L. High dose nitrogen and carbon shallow implantation in Si by plasma immersion ion implantation. Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2001, 175–177, 715–720. [Google Scholar] [CrossRef]

- Nikmah, A.; Rudyardjo, D.I.; Ady, J.; Taufiq, A. Studies on Density, Corrosion Rate and Hardness Characteristics of Stainless Steel Implanted by Nitrogen Ion. IOP Conf. Ser. Mater. Sci. Eng. 2019, 515, 012018. Available online: https://iopscience.iop.org/article/10.1088/1757-899X/515/1/012018 (accessed on 1 April 2019). [CrossRef]

- Yan, X.; Meng, J.; Gao, K.; Pang, X.; Volinsky, A.A. Tribo-corrosion and Albumin Attachment of Nitrogen Ion-Implanted CoCrMo Alloy During Friction Onset. J. Mater. Eng. Perform. 2019, 28, 363–371. [Google Scholar] [CrossRef]

- Jin, J.; Wang, W.; Chen, X. Microstructure and Mechanical Properties of Ti + N Ion Implanted Cronidur30 Steel. Materials 2019, 12, 427. [Google Scholar] [CrossRef] [PubMed]

- Bouras, M.; Boumaiza, A.; Ji, V.; Rouag, N. XRD peak broadening characterization of deformed microstructures and heterogeneous behavior of carbon steel. Theor. Appl. Fract. Mech. 2012, 61, 51–56. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.; Yuan, L.; Wei, Z.; Zhang, H.; Zhang, W. Quantitative phase analysis of Ti-3Al-5Mo-4.5 V dual phase titanium alloy by XRD whole pattern fitting method. Mater. Charact. 2022, 187, 111854. [Google Scholar] [CrossRef]

- Nakamura, Y.; Oguro, K.; Uehara, I.; Akiba, E. X-ray diffraction peak broadening and lattice strain in LaNi5-based alloys. J. Alloy. Compd. 2000, 298, 138–145. [Google Scholar] [CrossRef]

- Venkateswarlu, K.; Bose, A.C.; Rameshbabu, N. X-ray peak broadening studies of nanocrystalline hydroxyapatite by Williamson–Hall analysis. Phys. B Condens. Matter 2010, 405, 4256–4261. [Google Scholar] [CrossRef]

- Basak, M.; Rahman, L.; Ahmed, F.; Biswas, B.; Sharmin, N. The use of X-ray diffraction peak profile analysis to determine the structural parameters of cobalt ferrite nanoparticles using Debye-Scherrer, Williamson-Hall, Halder-Wagner and Size-strain plot: Different precipitating agent approach. J. Alloy. Compd. 2021, 895, 162694. [Google Scholar] [CrossRef]

- Khoshkhoo, M.S.; Scudino, S.; Thomas, J.; Surreddi, K.; Eckert, J. Grain and crystallite size evaluation of cryomilled pure copper. J. Alloy. Compd. 2011, 509, S343–S347. [Google Scholar] [CrossRef]

- Gürakar, S.; Serin, T. Comprehensive structural analysis and electrical properties of (Cu, Al and In)-doped SnO2 thin films. Mater. Sci. Eng. B 2019, 251, 114445. [Google Scholar] [CrossRef]

- Sivakami, R.; Dhanuskodi, S.; Karvembu, R. Estimation of lattice strain in nanocrystalline RuO2 by Williamson–Hall and size–strain plot methods. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 152, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Aly, K.A.; Khalil, N.; Algamal, Y.; Saleem, Q.M. Lattice strain estimation for CoAl2O4 nano particles using Williamson-Hall analysis. J. Alloy. Compd. 2016, 676, 606–612. [Google Scholar] [CrossRef]

- Brandstetter, S.; Derlet, P.; Van Petegem, S.; Van Swygenhoven, H. Williamson–Hall anisotropy in nanocrystalline metals: X-ray diffraction experiments and atomistic simulations. Acta Mater. 2008, 56, 165–176. [Google Scholar] [CrossRef]

- Borbély, A. The modified Williamson-Hall plot and dislocation density evaluation from diffraction peaks. Scr. Mater. 2022, 217, 114768. [Google Scholar] [CrossRef]

- Kibasomba, P.M.; Dhlamini, S.; Maaza, M.; Liu, C.-P.; Rashad, M.M.; Rayan, D.A.; Mwakikunga, B.W. Strain and grain size of TiO2 nanoparticles from TEM, Raman spectroscopy and XRD: The revisiting of the Williamson-Hall plot method. Results Phys. 2018, 9, 628–635. [Google Scholar] [CrossRef]

- Das Bakshi, S.; Sinha, D.; Chowdhury, S.G. Anisotropic broadening of XRD peaks of α′-Fe: Williamson-Hall and Warren-Averbach analysis using full width at half maximum (FWHM) and integral breadth (IB). Mater. Charact. 2018, 142, 144–153. [Google Scholar] [CrossRef]

- Ma, X.; Jiang, S.; Sun, Y.; Tang, G.; Sun, M. Elevated temperature nitrogen plasma immersion ion implantation of AISI 302 austenitic stainless steel. Surf. Coat. Technol. 2007, 201, 6695–6698. [Google Scholar] [CrossRef]

- Irshad, M.; Kousar, N.; Hanif, M.B.; Tabish, A.N.; Ghaffar, A.; Rafique, M.; Siraj, K.; Aslam, Z.; Assiri, M.A.; Imran, M.; et al. Investigating the microstructural and electrochemical performance of novel La0.3Ba0.7Zr0.5X0.3Y0.2 (X = Gd, Mn, Ce) electrolytes at intermediate temperature SOFCs. Sustain. Energy Fuels 2022, 6, 5384–5391. [Google Scholar] [CrossRef]

- Francis, M.; Kuruvilla, A.; Lakshmi, M. Effect of annealing on chemically deposited Cu2Se thin films. Mater. Chem. Phys. 2022, 292, 126845. [Google Scholar] [CrossRef]

- Rogers, K.; Daniels, P. An X-ray diffraction study of the effects of heat treatment on bone mineral microstructure. Biomaterials 2002, 23, 2577–2585. [Google Scholar] [CrossRef] [PubMed]

- Akl, A.A.; Mahmoud, S.A.; Al-Shomar, S.; Hassanien, A. Improving microstructural properties and minimizing crystal imperfections of nanocrystalline Cu2O thin films of different solution molarities for solar cell applications. Mater. Sci. Semicond. Process. 2018, 74, 183–192. [Google Scholar] [CrossRef]

- Hull, D.; Bacon, D.J. Introduction to Dislocations; Butterworth–Heinemann: Oxford, UK, 2011. [Google Scholar] [CrossRef]

- Lim, D.J.; Marks, N.A.; Rowles, M.R. Universal Scherrer equation for graphene fragments. Carbon 2020, 162, 475–480. [Google Scholar] [CrossRef]

- Pandya, S.G.; Corbett, J.P.; Jadwisienczak, W.M.; Kordesch, M.E. Structural characterization and X-ray analysis by Williamson–Hall method for Erbium doped Aluminum Nitride nanoparticles, synthesized using inert gas condensation technique. Phys. E Low-Dimens. Syst. Nanostructures 2016, 79, 98–102. [Google Scholar] [CrossRef]

- Nath, D.; Singh, F.; Das, R. X-ray diffraction analysis by Williamson-Hall, Halder-Wagner and size-strain plot methods of CdSe nanoparticles- a comparative study. Mater. Chem. Phys. 2019, 239, 122021. [Google Scholar] [CrossRef]

- Gupta, T.R.; Sidhu, S.S.; Katiyar, J.K.; Payal, H. Measurements of lattice strain in cold-rolled CR4 steel sheets using X-ray diffraction. Mater. Sci. Eng. B 2020, 264, 114930. [Google Scholar] [CrossRef]

- Panchal, S.; Chauhan, R. Krypton ion implantation effect on selenium nanowires. Phys. Lett. A 2017, 381, 2636–2642. [Google Scholar] [CrossRef]

- Khatter, J.; Chauhan, R. Impact of argon ion implantation on CdS nanorod mesh. Mater. Lett. 2022, 307, 131082. [Google Scholar] [CrossRef]

- Burton, A.W.; Ong, K.; Rea, T.; Chan, I.Y. On the estimation of average crystallite size of zeolites from the Scherrer equation: A critical evaluation of its application to zeolites with one-dimensional pore systems. Microporous Mesoporous Mater. 2009, 117, 75–90. [Google Scholar] [CrossRef]

- Bensouyad, H.; Sedrati, H.; Dehdouh, H.; Brahimi, M.; Abbas, F.; Akkari, H.; Bensaha, R. Structural, thermal and optical characterization of TiO2:ZrO2 thin films prepared by sol–gel method. Thin Solid Films 2010, 519, 96–100. [Google Scholar] [CrossRef]

- Adachi, S. Handbook on Physical Properties of Semiconductors; Springer: New York, NY, USA, 2004. [Google Scholar] [CrossRef]

- Zhang, J.-M.; Zhang, Y.; Xu, K.-W.; Ji, V. General compliance transformation relation and applications for anisotropic hexagonal metals. Solid State Commun. 2006, 139, 87–91. [Google Scholar] [CrossRef]

- Shahmoradi, Y.; Souri, D. Growth of silver nanoparticles within the tellurovanadate amorphous matrix: Optical band gap and band tailing properties, beside the Williamson-Hall estimation of crystallite size and lattice strain. Ceram. Int. 2019, 45, 7857–7864. [Google Scholar] [CrossRef]

- Huang, J.; Zou, S.; Xiao, W.; Liu, X.; Tang, D. Sputtering parameters effect on microstructural parameters of TiN coating via the Williamson-Hall analysis. Mater. Res. Express 2020, 7, 106402. [Google Scholar] [CrossRef]

- Senthilkumar, V.; Vickraman, P.; Jayachandran, M.; Sanjeeviraja, C. Structural and electrical studies of nano structured Sn1−x Sbx O2 (x = 0.0, 1, 2.5, 4.5 and 7 at%) prepared by co-precipitation method. J. Mater. Sci. Mater. Electron. 2010, 21, 343–348. [Google Scholar] [CrossRef]

| C | Cr | Mo | V | Ni | Mn | Si | Co | W | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.8~0.85 | 4.0~4.25 | 4.0~4.5 | 0.9~1.1 | ≤0.15 | 0.15~0.35 | ≤0.25 | ≤0.25 | ≤0.25 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, B.; Zhang, J.; Guo, J.; Ma, X.; Wang, L.; Zhang, X. Understanding the Microstructure Evolution of 8Cr4Mo4V Steel under High-Dose-Rate Ion Implantation. Materials 2023, 16, 5876. https://doi.org/10.3390/ma16175876

Miao B, Zhang J, Guo J, Ma X, Wang L, Zhang X. Understanding the Microstructure Evolution of 8Cr4Mo4V Steel under High-Dose-Rate Ion Implantation. Materials. 2023; 16(17):5876. https://doi.org/10.3390/ma16175876

Chicago/Turabian StyleMiao, Bin, Jinming Zhang, Jiaxu Guo, Xinxin Ma, Liqin Wang, and Xinghong Zhang. 2023. "Understanding the Microstructure Evolution of 8Cr4Mo4V Steel under High-Dose-Rate Ion Implantation" Materials 16, no. 17: 5876. https://doi.org/10.3390/ma16175876