High-Pressure Induced Phase Transitions in High-Entropy Alloys: A Review

Abstract

:1. Introduction

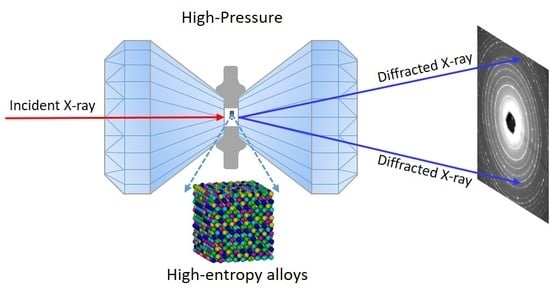

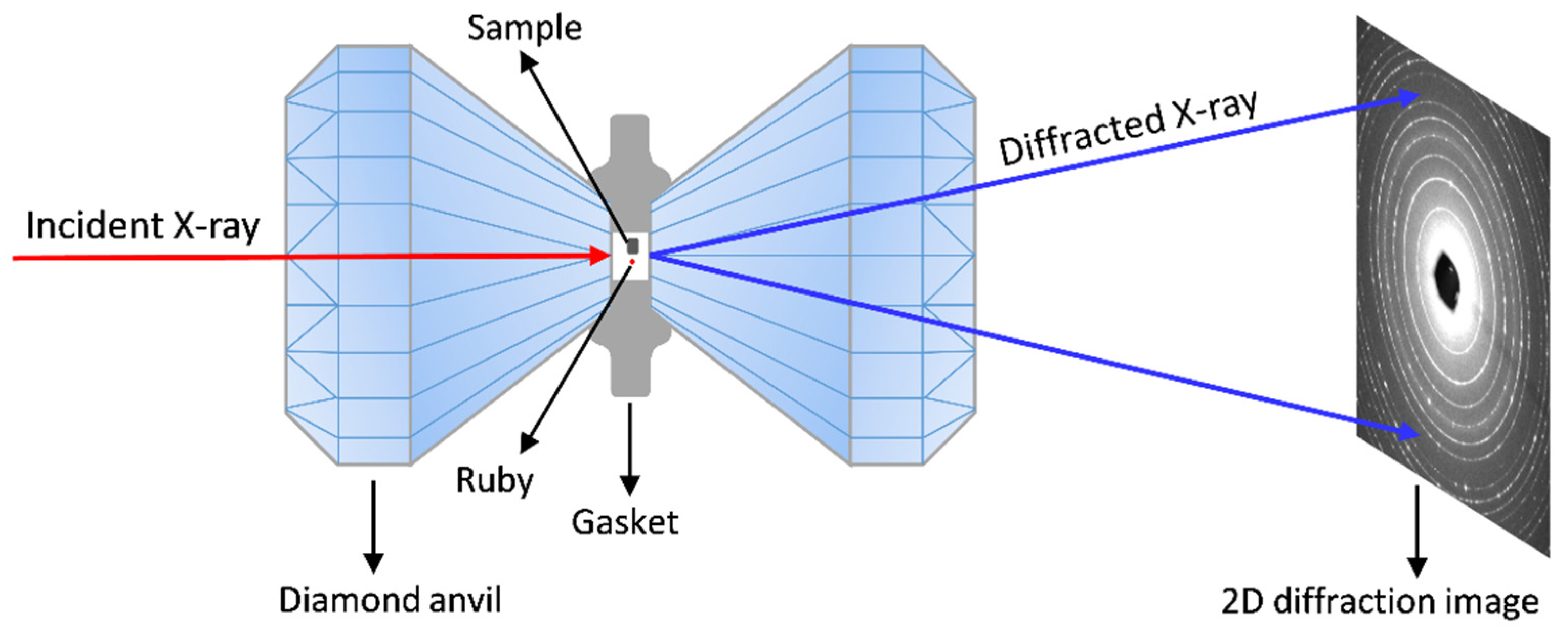

2. Experimental Methods

3. Structural Stability and Evolution of HEAs under High Pressure

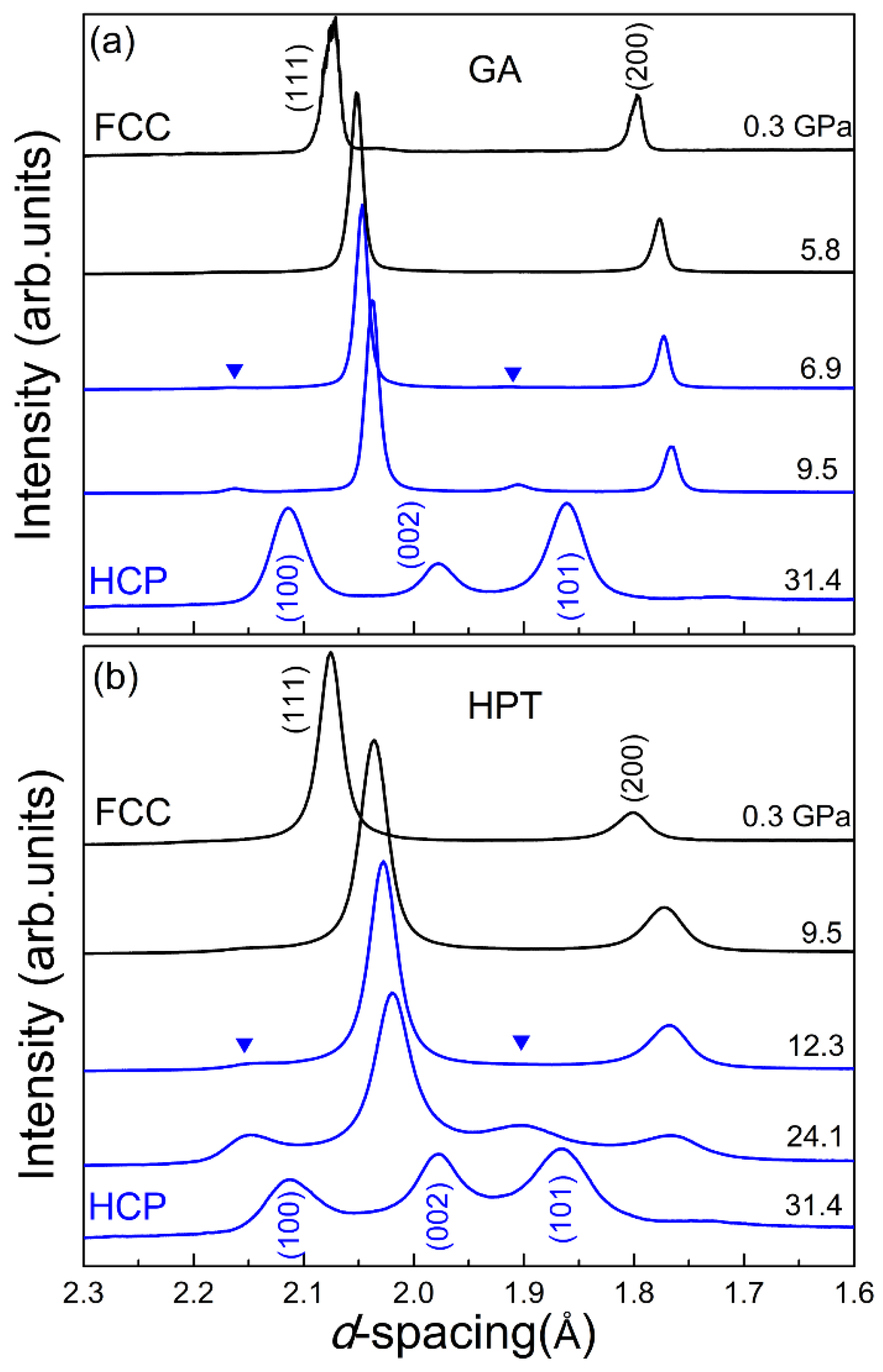

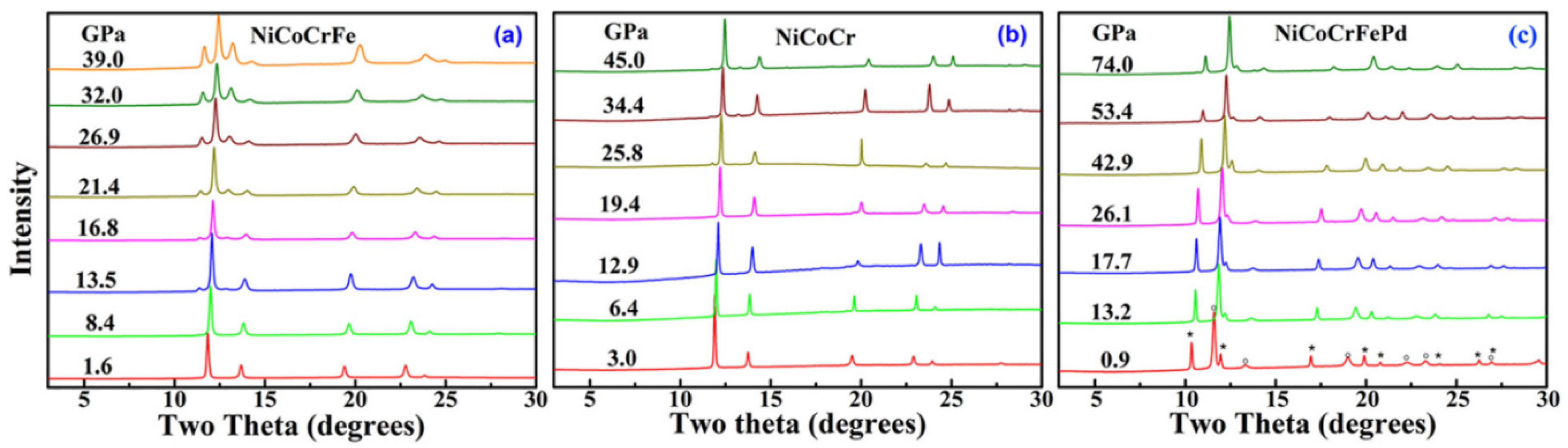

3.1. Fcc-Structured HEAs

3.2. Bcc-Structured HEAs

3.3. Hcp-Structured HEAs

4. Conclusions and Outlooks

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Lu, Z.P.; Wang, H.; Chen, M.W.; Baker, I.; Yeh, J.W.; Liu, C.T.; Nieh, T.G. An assessment on the future development of high-entropy alloys: Summary from a recent workshop. Intermetallics 2015, 66, 67–76. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.R.; Liaw, P.K.; Zhang, Y. Science and technology in high-entropy alloys. Sci. China Mater. 2018, 61, 2–22. [Google Scholar] [CrossRef] [Green Version]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Gao, M.C.; Alman, D.E. Searching for Next Single-Phase High-Entropy Alloy Compositions. Entropy 2013, 15, 4504–4519. [Google Scholar] [CrossRef] [Green Version]

- Takeuchi, A.; Amiya, K.; Wada, T.; Yubuta, K.; Zhang, W. High-Entropy Alloys with a Hexagonal Close-Packed Structure Designed by Equi-Atomic Alloy Strategy and Binary Phase Diagrams. JOM 2014, 66, 1984–1992. [Google Scholar] [CrossRef]

- Feuerbacher, M.; Heidelmann, M.; Thomas, C. Hexagonal High-entropy Alloys. Mater. Res. Lett. 2015, 3, 1–6. [Google Scholar] [CrossRef]

- Gao, M.C.; Zhang, B.; Guo, S.M.; Qiao, J.W.; Hawk, J.A. High-Entropy Alloys in Hexagonal Close-Packed Structure. Metall. Mater. Trans. A 2016, 47, 3322–3332. [Google Scholar] [CrossRef]

- Qiao, J.W.; Bao, M.L.; Zhao, Y.J.; Yang, H.J.; Wu, Y.C.; Zhang, Y.; Hawk, J.A.; Gao, M.C. Rare-earth high entropy alloys with hexagonal close-packed structure. J. Appl. Phys. 2018, 124, 195101. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.; Wu, Y.; He, J.; Wang, H.; Liu, X.; An, K.; Wu, W.; Lu, Z. Phase-Transformation Ductilization of Brittle High-Entropy Alloys via Metastability Engineering. Adv. Mater. 2017, 29, 1701678. [Google Scholar] [CrossRef] [PubMed]

- Praveen, S.; Kim, H.S. High-Entropy Alloys: Potential Candidates for High-Temperature Applications—An Overview. Adv. Eng. Mater. 2017, 20, 1700645. [Google Scholar] [CrossRef]

- Liang, Y.-J.; Wang, L.; Wen, Y.; Cheng, B.; Wu, Q.; Cao, T.; Xiao, Q.; Xue, Y.; Sha, G.; Wang, Y.; et al. High-content ductile coherent nanoprecipitates achieve ultrastrong high-entropy alloys. Nat. Commun. 2018, 9, 4063. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Niu, L.; Chen, N.; Jin, K.; Yang, T.; Xiu, P.; Zhang, Y.; Gao, F.; Bei, H.; Shi, S.; et al. Enhancing radiation tolerance by controlling defect mobility and migration pathways in multicomponent single-phase alloys. Nat. Commun. 2016, 7, 13564. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zou, Y.; Ma, H.; Spolenak, R. Ultrastrong ductile and stable high-entropy alloys at small scales. Nat. Commun. 2015, 6, 7748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chuang, M.-H.; Tsai, M.-H.; Wang, W.-R.; Lin, S.-J.; Yeh, J.-W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Yeh, J.-W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef] [Green Version]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Tonkov, E.Y.; Ponyatovsky, E.G. Phase Transformations of Elements Under High Pressure; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Mao, H.K.; Bassett, W.A.; Takahashi, T. Effect of Pressure on Crystal Structure and Lattice Parameters of Iron up to 300 kbar. J. Appl. Phys. 1967, 38, 272–276. [Google Scholar] [CrossRef]

- Bassett, W.A.; Huang, E. Mechanism of the Body-Centered Cubic—Hexagonal Close-Packed Phase Transition in Iron. Science 1987, 238, 780–783. [Google Scholar] [CrossRef] [PubMed]

- Yoo, C.S.; Akella, J.; Campbell, A.J.; Mao, H.K.; Hemley, R.J. Phase Diagram of Iron by in Situ X-ray Diffraction: Implications for Earth’s Core. Science 1995, 270, 1473–1475. [Google Scholar] [CrossRef]

- Miracle, D.B. High-Entropy Alloys: A Current Evaluation of Founding Ideas and Core Effects and Exploring “Nonlinear Alloys”. JOM 2017, 69, 2130–2136. [Google Scholar] [CrossRef] [Green Version]

- Otto, F.; Dlouhy, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef] [Green Version]

- Schneeweiss, O.; Friák, M.; Dudová, M.; Holec, D.; Šob, M.; Kriegner, D.; Holý, V.; Beran, P.; George, E.P.; Neugebauer, J.; et al. Magnetic properties of the CrMnFeCoNi high-entropy alloy. Phys. Rev. B 2017, 96, 014437. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.; Ng, C.; Lu, J.; Liu, C.T. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef] [Green Version]

- Ming, L.C.; Manghnani, M.H.; Katahara, K.W. Investigation of a→w transformation in the Zr-Hf system to 42 GPa. J. Appl. Phys. 1981, 52, 1332–1335. [Google Scholar] [CrossRef]

- Smith, D.; Joris, O.P.J.; Sankaran, A.; Weekes, H.E.; Bull, D.J.; Prior, T.J.; Dye, D.; Errandonea, D.; Proctor, J.E. On the high-pressure phase stability and elastic properties of β -titanium alloys. J. Phys. Condens. Matter 2017, 29, 155401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mao, W.L.; Campbell, A.J.; Heinz, D.L.; Shen, G. Phase relations of Fe–Ni alloys at high pressure and temperature. Phys. Earth Planet. Interiors 2006, 155, 146–151. [Google Scholar] [CrossRef]

- Velisavljevic, N.; Chesnut, G.N. Direct hcp→bcc structural phase transition observed in titanium alloy at high pressure. Appl. Phys. Lett. 2007, 91, 101906. [Google Scholar] [CrossRef]

- Ahart, M.; DeVreugd, C.; Li, J.; Viehland, D.; Gehring, P.M.; Hemley, R.J. X-ray diffraction study of the pressure-induced bcc-to-hcp phase transition in the highly magnetostrictive Fe0.81Ga0.19 alloy. Phys. Rev. B 2013, 88, 184102. [Google Scholar] [CrossRef]

- Sakai, T.; Takahashi, S.; Nishitani, N.; Mashino, I.; Ohtani, E.; Hirao, N. Equation of state of pure iron and Fe0.9Ni0.1 alloy up to 3Mbar. Phys. Earth Planet. Interiors 2014, 228, 114–126. [Google Scholar] [CrossRef]

- Zeng, Q.S.; Ding, Y.; Mao, W.L.; Luo, W.; Blomqvist, A.; Ahuja, R.; Yang, W.; Shu, J.; Sinogeikin, S.V.; Meng, Y.; et al. Substitutional alloy of Ce and Al. Proc. Nat. Acad. Sci. USA 2009, 106, 2515–2518. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dubrovinsky, L.S.; Saxena, S.K.; Lazor, P.; Ahuja, R.; Eriksson, O.; Wills, J.M.; Johansson, B. Experimental and theoretical identification of a new high-pressure phase of silica. Nature 1997, 388, 362. [Google Scholar] [CrossRef]

- Hemley, R.J.; Jephcoat, A.P.; Mao, H.K.; Ming, L.C.; Manghnani, M.H. Pressure-induced amorphization of crystalline silica. Nature 1988, 334, 52. [Google Scholar] [CrossRef]

- Bai, L.; Li, Q.; Corr, S.A.; Meng, Y.; Park, C.; Sinogeikin, S.V.; Ko, C.; Wu, J.; Shen, G. Pressure-induced phase transitions and metallization in VO2. Phys. Rev. B 2015, 91, 104110. [Google Scholar] [CrossRef]

- Cheng, B.; Li, Q.; Zhang, H.; Liu, R.; Liu, B.; Yao, Z.; Cui, T.; Liu, J.; Liu, Z.; Sundqvist, B.; et al. Pressure-induced metallization and amorphization in VO2 nanorods. Phys. Rev. B 2016, 93, 184109. [Google Scholar] [CrossRef]

- Sheng, H.W.; Liu, H.Z.; Cheng, Y.Q.; Wen, J.; Lee, P.L.; Luo, W.K.; Shastri, S.D.; Ma, E. Polyamorphism in a metallic glass. Nat. Mater. 2007, 6, 192–197. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.-S.; Ding, Y.; Mao, W.L.; Yang, W.; Sinogeikin, S.V.; Shu, J.; Mao, H.-K.; Jiang, J.Z. Origin of Pressure-Induced Polyamorphism in Ce75Al25 Metallic Glass. Phys. Rev. Lett. 2010, 104, 105702. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Sheng, H.; Ding, Y.; Wang, L.; Yang, W.; Jiang, J.-Z.; Mao, W.L.; Mao, H.-K. Long-Range Topological Order in Metallic Glass. Science 2011, 332, 1404–1406. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; He, F.; Tasan, C.C. Metastability in high-entropy alloys: A review. J. Mater. Res. 2018, 33, 2924–2937. [Google Scholar] [CrossRef]

- Tracy, C.L.; Park, S.; Rittman, D.R.; Zinkle, S.J.; Bei, H.B.; Lang, M.; Ewing, R.C.; Mao, W.L. High pressure synthesis of a hexagonal close-packed phase of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2017, 8, 15634. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, F.; Wu, Y.; Lou, H.B.; Zeng, Z.D.; Prakapenka, V.B.; Greenberg, E.; Ren, Y.; Yan, J.Y.; Okasinski, J.S.; Liu, X.J.; et al. Polymorphism in a high-entropy alloy. Nat. Commun. 2017, 8, 15687. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, F.; Lou, H.; Chen, S.; Chen, X.; Zeng, Z.; Yan, J.; Zhao, W.; Wu, Y.; Lu, Z.; Zeng, Q. Effects of non-hydrostaticity and grain size on the pressure-induced phase transition of the CoCrFeMnNi high-entropy alloy. J. Appl. Phys. 2018, 124, 115901. [Google Scholar] [CrossRef]

- Huang, E.W.; Lin, C.M.; Jain, J.; Shieh, S.R.; Wang, C.P.; Chuang, Y.C.; Liao, Y.-F.; Zhang, D.Z.; Huang, T.; Lam, T.N.; et al. Irreversible phase transformation in a CoCrFeMnNi high entropy alloy under hydrostatic compression. Mater. Today Commun. 2018, 14, 10–14. [Google Scholar] [CrossRef]

- Ahmad, A.S.; Su, Y.; Liu, S.Y.; Ståhl, K.; Wu, Y.D.; Hui, X.D.; Ruett, U.; Gutowski, O.; Glazyrin, K.; Liermann, H.P.; et al. Structural stability of high entropy alloys under pressure and temperature. J. Appl. Phys. 2017, 121, 235901. [Google Scholar] [CrossRef] [Green Version]

- Yu, P.F.; Zhang, L.J.; Cheng, H.; Zhang, H.; Ma, M.Z.; Li, Y.C.; Li, G.; Liaw, P.K.; Liu, R.P. The high-entropy alloys with high hardness and soft magnetic property prepared by mechanical alloying and high-pressure sintering. Intermetallics 2016, 70, 82–87. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.X.; Zhao, S.J.; Jin, K.; Bei, H.B.; Popov, D.; Park, C.Y.; Neuefeind, J.C.; Weber, W.J.; Zhang, Y.W. Pressure-induced fcc to hcp phase transition in Ni-based high entropy solid solution alloys. Appl. Phys. Lett. 2017, 110, 011902. [Google Scholar] [CrossRef]

- Ma, Y.; Fan, J.; Zhang, L.; Zhang, M.; Cui, P.; Dong, W.; Yu, P.; Li, Y.; Liaw, P.K.; Li, G. Pressure-induced ordering phase transition in high-entropy alloy. Intermetallics 2018, 103, 63–66. [Google Scholar] [CrossRef]

- Yusenko, K.V.; Riva, S.; Crichton, W.A.; Spektor, K.; Bykova, E.; Pakhomova, A.; Tudball, A.; Kupenko, I.; Rohrbach, A.; Klemme, S.; et al. High-pressure high-temperature tailoring of High Entropy Alloys for extreme environments. J. Alloys Compd. 2018, 738, 491–500. [Google Scholar] [CrossRef]

- Li, G.; Xiao, D.; Yu, P.; Zhang, L.; Liaw, P.K.; Li, Y.; Liu, R. Equation of State of an AlCoCrCuFeNi High-Entropy Alloy. JOM 2015, 67, 2310–2313. [Google Scholar] [CrossRef]

- Cheng, B.; Zhang, F.; Lou, H.; Chen, X.; Liaw, P.K.; Yan, J.; Zeng, Z.; Ding, Y.; Zeng, Q. Pressure-induced phase transition in the AlCoCrFeNi high-entropy alloy. Scr. Mater. 2019, 161, 88–92. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, F.; Nie, Z.; Wang, L.; Wang, F.; Wang, B.; Zhou, S.; Xue, Y.; Cheng, B.; Lou, H.; et al. Abundant polymorphic transitions in the Al0.6CoCrFeNi high-entropy alloy. Mater. Today Phys. 2019, 8, 1–9. [Google Scholar] [CrossRef]

- Guo, J.; Wang, H.; von Rohr, F.; Wang, Z.; Cai, S.; Zhou, Y.; Yang, K.; Li, A.; Jiang, S.; Wu, Q.; et al. Robust zero resistance in a superconducting high-entropy alloy at pressures up to 190 GPa. Proc. Natl. Acad. Sci. USA 2017, 114, 13144–13147. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yusenko, K.V.; Riva, S.; Carvalho, P.A.; Yusenko, M.V.; Arnaboldi, S.; Sukhikh, A.S.; Hanfland, M.; Gromilov, S.A. First hexagonal close packed high-entropy alloy with outstanding stability under extreme conditions and electrocatalytic activity for methanol oxidation. Scr. Mater. 2017, 138, 22–27. [Google Scholar] [CrossRef]

- Yu, P.F.; Zhang, L.J.; Ning, J.L.; Ma, M.Z.; Zhang, X.Y.; Li, Y.C.; Liaw, P.K.; Li, G.; Liu, R.P. Pressure-induced phase transitions in HoDyYGdTb high-entropy alloy. Mater. Lett. 2017, 196, 137–140. [Google Scholar] [CrossRef]

- Mao, H.-K.; Chen, B.; Chen, J.; Li, K.; Lin, J.-F.; Yang, W.; Zheng, H. Recent advances in high-pressure science and technology. Matter Radiat. Extremes 2016, 1, 59–75. [Google Scholar] [CrossRef]

- Shen, G.Y.; Mao, H.-K. High-pressure studies with x-rays using diamond anvil cells. Rep. Prog. Phys. 2017, 80, 016101. [Google Scholar] [CrossRef] [PubMed]

- Mao, H.-K.; Chen, X.-J.; Ding, Y.; Li, B.; Wang, L. Solids, liquids, and gases under high pressure. Rev. Mod. Phys. 2018, 90, 015007. [Google Scholar] [CrossRef]

- Mao, H.K.; Xu, J.; Bell, P.M. Calibration of the ruby pressure gauge to 800 kbar under quasi-hydrostatic conditions. J. Geophys. Res. 1986, 91, 4673. [Google Scholar] [CrossRef]

- Ma, D.; Grabowski, B.; Körmann, F.; Neugebauer, J.; Raabe, D. Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: Importance of entropy contributions beyond the configurational one. Acta Mater. 2015, 100, 90–97. [Google Scholar] [CrossRef]

- Tian, F.; Varga, L.K.; Shen, J.; Vitos, L. Calculating elastic constants in high-entropy alloys using the coherent potential approximation: Current issues and errors. Comput. Mater. Sci. 2016, 111, 350–358. [Google Scholar] [CrossRef]

- Wang, W.R.; Wang, W.L.; Wang, S.C.; Tsai, Y.C.; Lai, C.H.; Yeh, J.W. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 2012, 26, 44–51. [Google Scholar] [CrossRef]

- Yamazaki, D.; Ito, E.; Yoshino, T.; Tsujino, N.; Yoneda, A.; Guo, X.; Xu, F.; Higo, Y.; Funakoshi, K. Over 1Mbar generation in the Kawai-type multianvil apparatus and its application to compression of (Mg0.92Fe0.08)SiO3 perovskite and stishovite. Phys. Earth Planet. Interiors 2014, 228, 262–267. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, L.; Cheng, H.; Tang, H.; Fan, J.; Liaw, P.K.; Li, G.; Liu, R. Formation, reverse transformation, and properties of ε-martensite phase in the CoCrFeMnNi high-entropy alloy under high-pressure. J. Alloys Compd. 2019, 779, 1–6. [Google Scholar] [CrossRef]

- Tian, F. A Review of Solid-Solution Models of High-Entropy Alloys Based on Ab Initio Calculations. Front. Mater. 2017, 4, 36. [Google Scholar] [CrossRef]

- Winkler, B.; Milman, V. Density functional theory based calculations for high pressure research. Cryst. Mater. 2014, 229, 112–122. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, Y. Perspective: Crystal structure prediction at high pressures. J. Chem. Phys. 2014, 140, 040901. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Wang, Y.; Lv, J.; Ma, Y. Materials discovery at high pressures. Nat. Rev. Mater. 2017, 2, 17005. [Google Scholar] [CrossRef]

| Composition | Initial Structure | Synthesis Method | Grain Size (μm) | Pressure Medium | Max. P (GPa) | Transition P (GPa) | Phase Transition | Ref. |

|---|---|---|---|---|---|---|---|---|

| CoCrFeMnNi | fcc | Homogenization | / | Silicone oil | 54.1 | 14.7 | fcc-hcp | [51] |

| CoCrFeMnNi | fcc | Gas-atomization | ~ 5 | Helium | 22.1 | 41.1 | fcc-hcp | [52] |

| CoCrFeMnNi | fcc | Gas-atomization | ~ 5 | Silicone oil | 6.9 | 31.4 | fcc-hcp | [53] |

| CoCrFeMnNi | fcc | Gas-atomization | ~ 5 | Amorphous boron | 2.2–6.6 | 36.6 | fcc-hcp | [53] |

| CoCrFeMnNi | fcc | High pressure tortion | ~ 0.01 | Silicone oil | 12.3 | 31.4 | fcc-hcp | [53] |

| CoCrFeMnNi | fcc | Cold rolled | ~ 100 | Neon | 7.1 | 20 | fcc-hcp | [54] |

| CoCrFeMnNi | fcc | / | / | Neon | / | 48.9 | no | [55] |

| CoCrFeMnNi | fcc | High pressure sintered | ~ 0.1 | Silicone oil | / | 31 | no | [56] |

| CoCrFeCuNi | fcc | High pressure sintered | ~ 0.1 | Silicone oil | / | 31 | no | [56] |

| NiCoCrFe | fcc | Homogenization | / | ME | 13.5 | 39 | fcc-hcp | [57] |

| NiCoCr | fcc | Homogenization | / | ME | 45 | 45 | fcc-hcp | [57] |

| NiCoCrFePd | fcc | Homogenization | / | Neon | / | 74 | no | [57] |

| CoCrCuFeNiPr | dual fcc | Milled powder | / | Silicone oil | / | 106.4 | disordered-ordered fcc | [58] |

| Al0.3CoCrFeNi | fcc | Annealed | ~ 100 | Neon | / | 61 | no | [59] |

| AlCoCrCuFeNi | fcc+bcc | As-cast | / | MEW | / | 24 | no | [60] |

| AlCoCrFeNi | bcc | Melt-spun ribbon | / | Silicone oil | /17.6 | 42 | b2–distorted bcc | [61] |

| Al0.6CoCrFeNi | bcc | Gas-atomization | ~ 10 | Silicone oil/Helium | 10.6 | 40 | bcc-orthorhombic-bct | [62] |

| Al0.6CoCrFeNi | fcc | Gas-atomization + Annealed | ~ 5 | Silicone oil/Helium | 17.5 | 40 | fcc-hcp | [62] |

| TiZrHfNb | bcc | / | / | Neon | / | 50.8 | no | [55] |

| Al2CoCrFeNi | bcc | Annealed | ~ 100 | Neon | / | 61 | no | [59] |

| (TaNb)0.67(HfZrTi)0.33 | bcc | As-cast | / | / | / | 96 | no | [63] |

| ReRuCoFe | hcp | / | / | Neon | / | 80.4 | no | [55] |

| Ir0.19Os0.22Re0.21Rh0.20Ru0.19 | hcp | / | / | / | / | 45 | no | [64] |

| HoDyYGdTb | hcp | As-cast | / | Silicone oil | / | 60.1 | hcp→Sm-type→dhcp→dfcc | [65] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Lou, H.; Cheng, B.; Zeng, Z.; Zeng, Q. High-Pressure Induced Phase Transitions in High-Entropy Alloys: A Review. Entropy 2019, 21, 239. https://doi.org/10.3390/e21030239

Zhang F, Lou H, Cheng B, Zeng Z, Zeng Q. High-Pressure Induced Phase Transitions in High-Entropy Alloys: A Review. Entropy. 2019; 21(3):239. https://doi.org/10.3390/e21030239

Chicago/Turabian StyleZhang, Fei, Hongbo Lou, Benyuan Cheng, Zhidan Zeng, and Qiaoshi Zeng. 2019. "High-Pressure Induced Phase Transitions in High-Entropy Alloys: A Review" Entropy 21, no. 3: 239. https://doi.org/10.3390/e21030239