Low Cycle Fatigue Life Prediction Using Unified Mechanics Theory in Ti-6Al-4V Alloys

Abstract

1. Introduction

2. Unified Mechanics Theory-Based Life Prediction Model

2.1. Unified Mechanics Theory

2.1.1. Second Law of Unified Mechanics Theory

2.1.2. Third Law of Unified Mechanics Theory

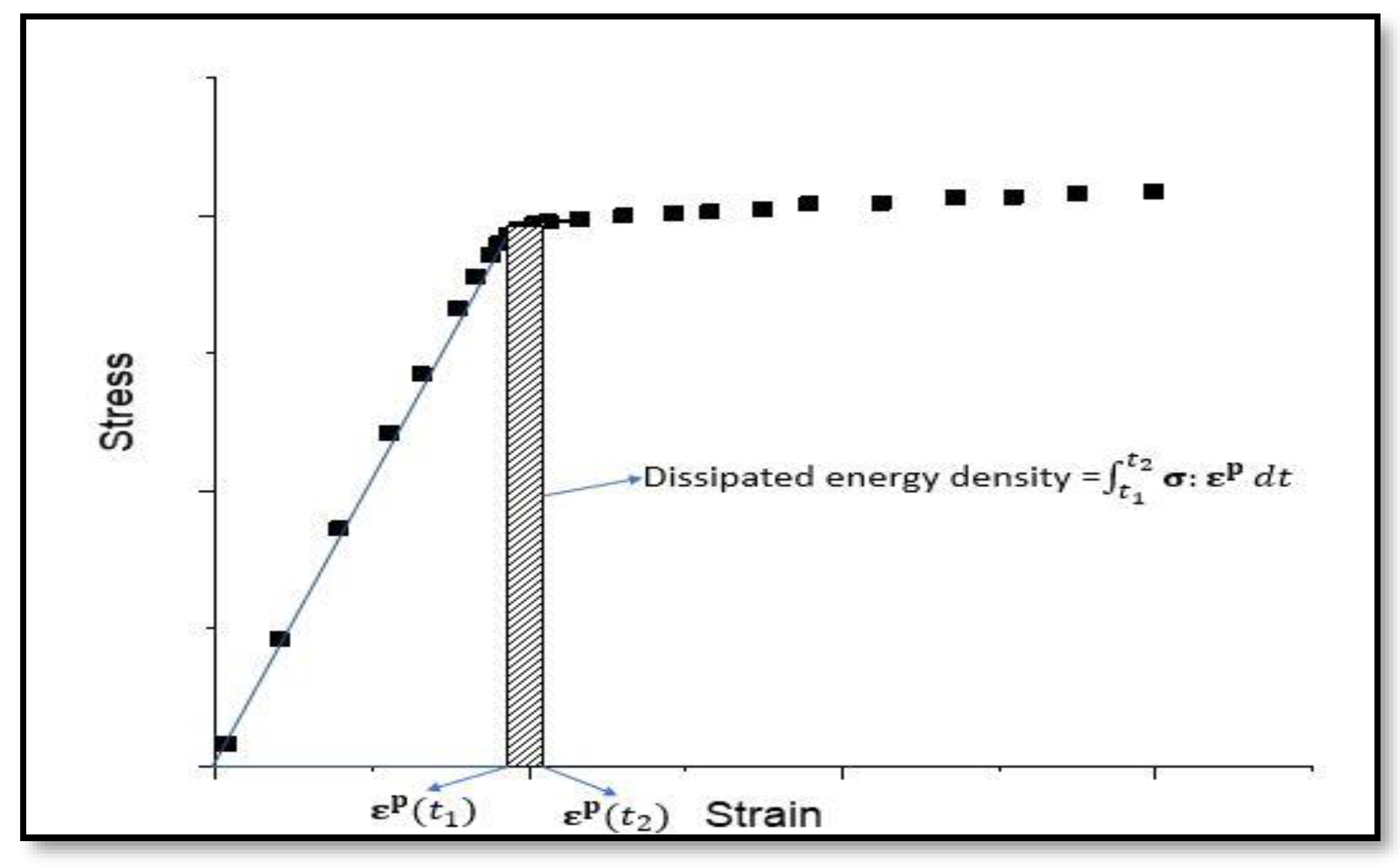

2.1.3. Thermodynamic State Index (TSI) for Damage in Low Cycle Fatigue of Materials

2.2. Analytical Approach for the Prediction of Damage and Fatigue Life

2.3. Computational 3-D Model for the Prediction of Damage

2.3.1. Derivation of the Computational Model

2.3.2. Algorithm for the Computational Model

3. Validation of the Computational Model for Monotonic Loading

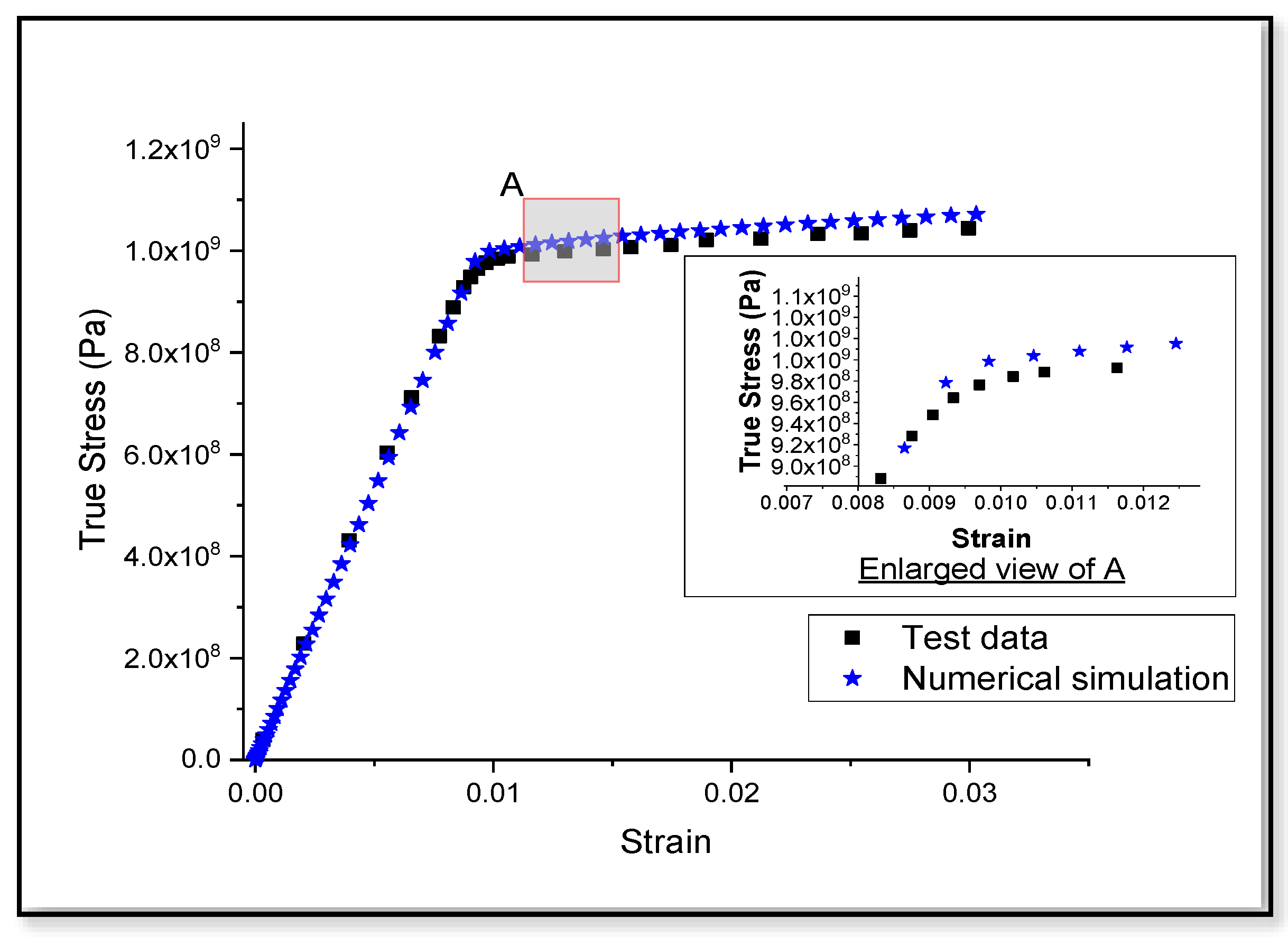

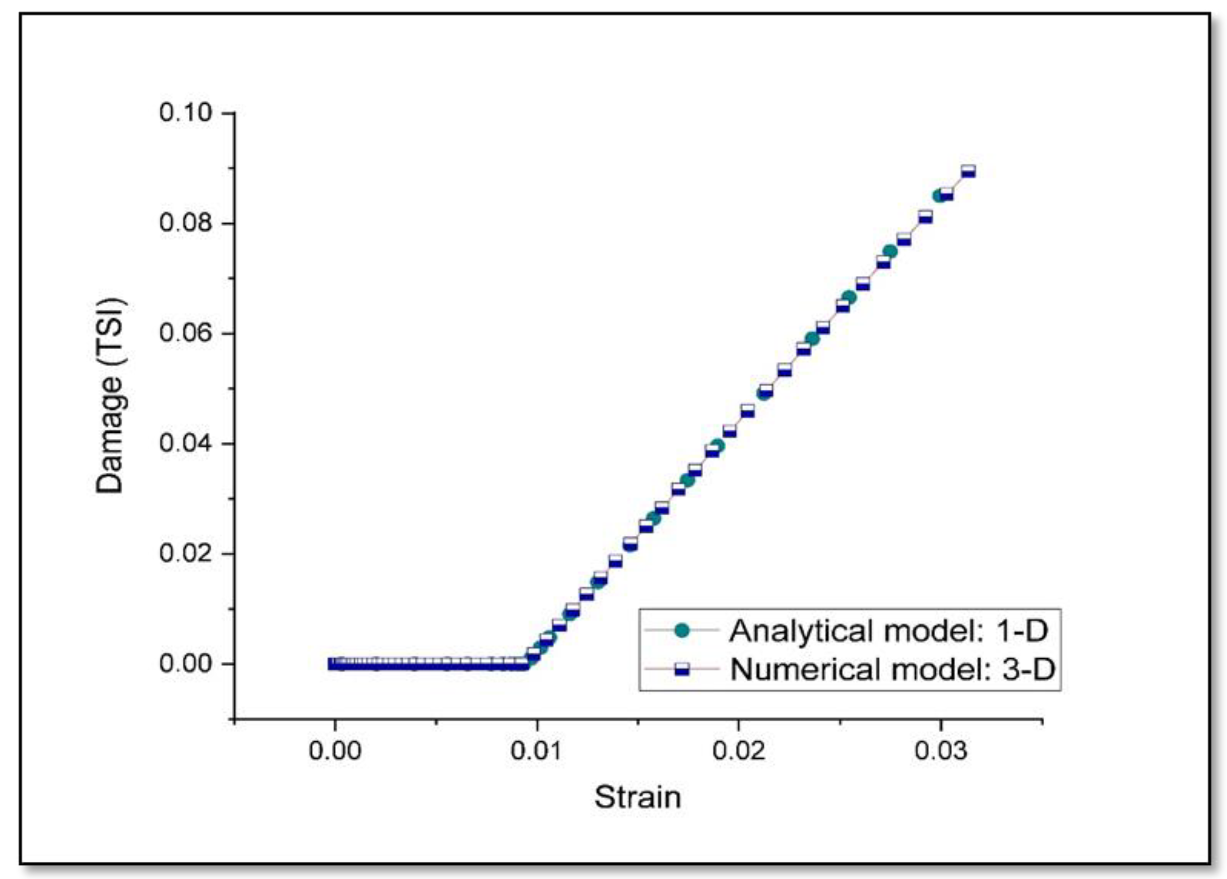

3.1. Validation of the Numerical Model for Monotonic Tensile Loading

3.2. Validation of the 3-D Numerical Model for Monotonic Compressive Loading

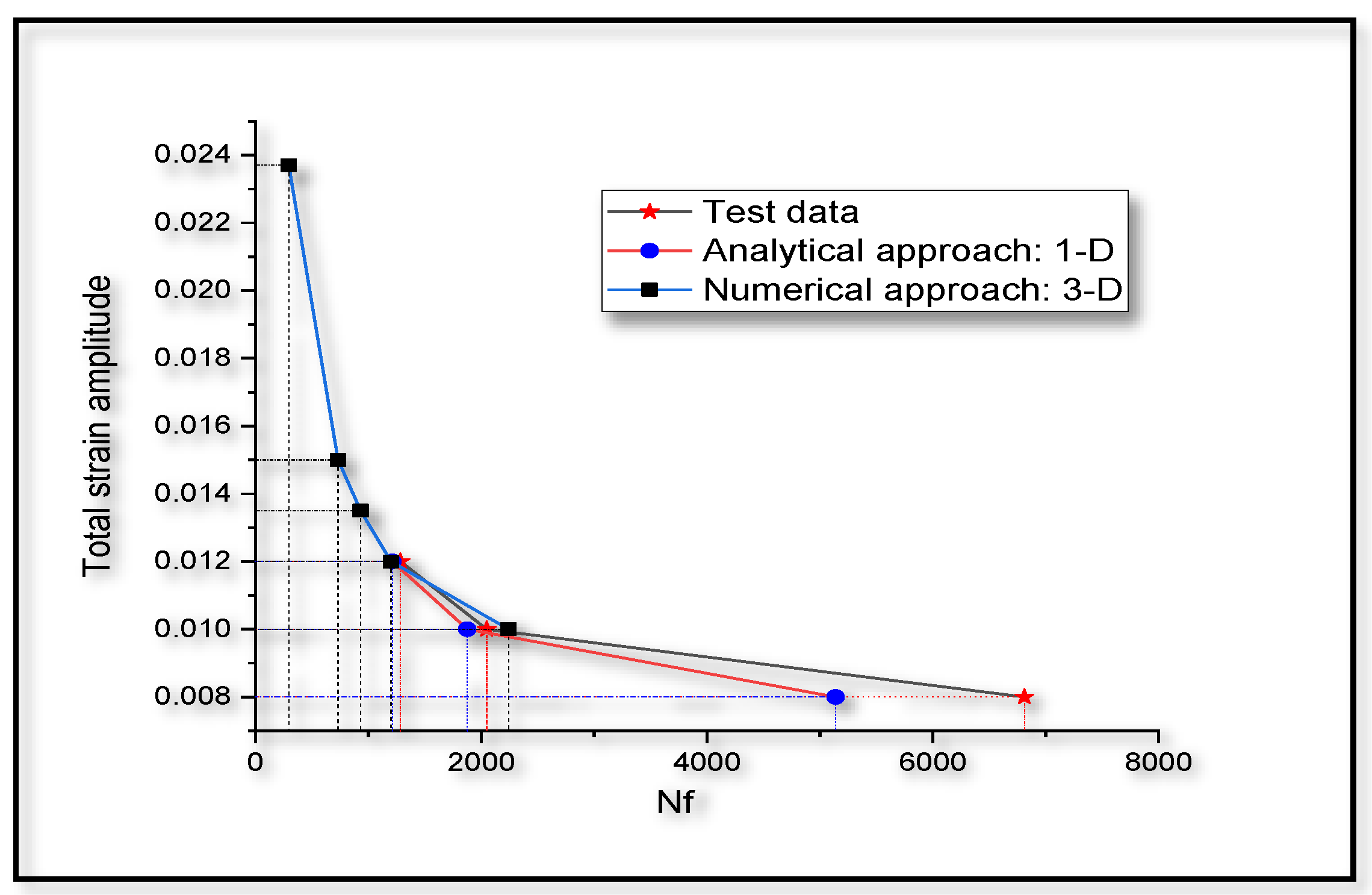

4. Model Predictions for Low Cycle Fatigue Life

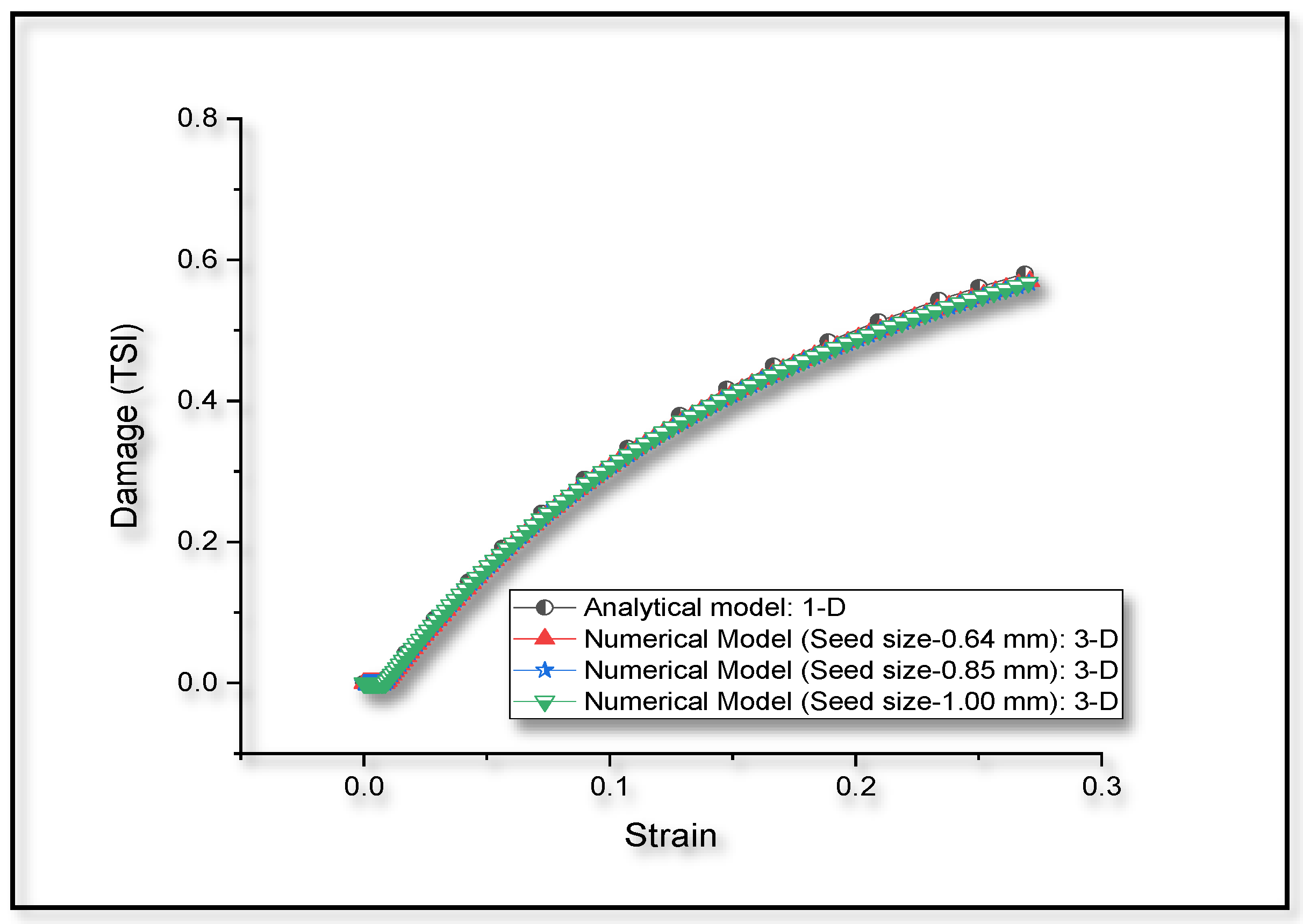

4.1. Analytical Approach for Fatigue Life Prediction

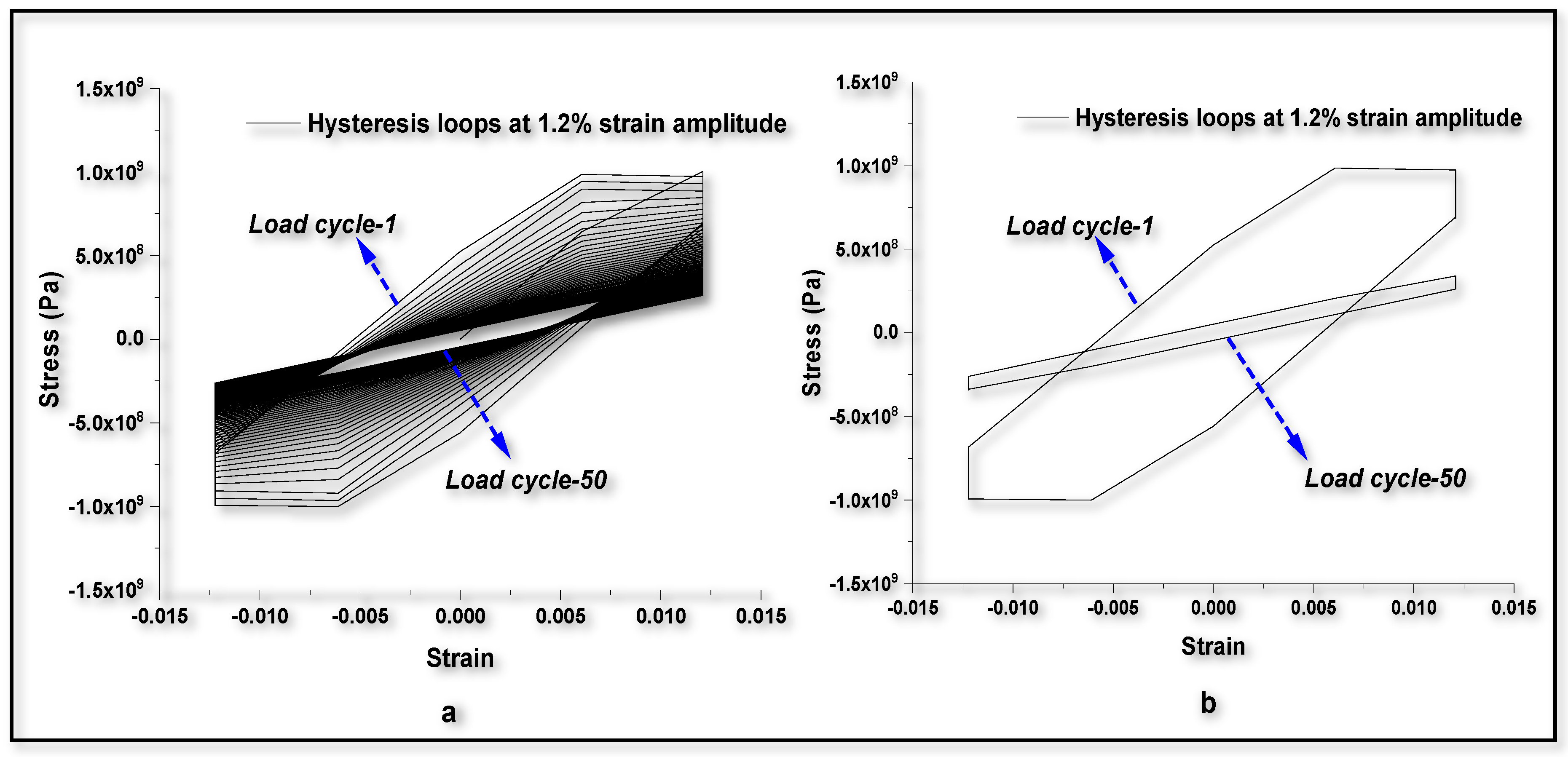

4.2. Computational Procedure for Fatigue Life Prediction

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mouritz, A.P. Introduction to Aerospace Materials; Woodhead Publishing Limited: Cambridge, UK, 2012; ISBN 9781845695323. [Google Scholar]

- Biswas, N.; Ding, J.L.; Balla, V.K.; Field, D.P.; Bandyopadhyay, A. Deformation and fracture behavior of laser processed dense and porous Ti6Al4V alloy under static and dynamic loading. Mater. Sci. Eng. A 2012, 549, 213–221. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Altenberger, I.; Nalla, R.K.; Sano, Y.; Wagner, L.; Ritchie, R.O. On the effect of deep-rolling and laser-peening on the stress-controlled low- and high-cycle fatigue behavior of Ti-6Al-4V at elevated temperatures up to 550 °C. Int. J. Fatigue 2012, 44, 292–302. [Google Scholar] [CrossRef]

- CHENG, A.S.; LAIRD, C. Fatigue Life Behavior of Copper Single Crystals. Part I: Observations of Crack Nucleation. Fatigue Fract. Eng. Mater. Struct. 1981, 4, 331–341. [Google Scholar] [CrossRef]

- Ren, Y.M.; Lin, X.; Guo, P.F.; Yang, H.O.; Tan, H.; Chen, J.; Li, J.; Zhang, Y.Y.; Huang, W.D. Low cycle fatigue properties of Ti-6Al-4V alloy fabricated by high-power laser directed energy deposition: Experimental and prediction. Int. J. Fatigue 2019, 127, 58–73. [Google Scholar] [CrossRef]

- Tanaka, K.; Mura, T. Dislocation Model for Fatigue Crack Initiation. Am. Soc. Mech. Eng. 1981, 48, 97–103. [Google Scholar] [CrossRef]

- Guo, Q.; Zaïri, F.; Guo, X. An intrinsic dissipation model for high-cycle fatigue life prediction. Int. J. Mech. Sci. 2018, 140, 163–171. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Senko, V.I. Tribo-fatigue. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Tribology, Orlando, FL, USA, 5–11 November 2005; pp. 141–148. [Google Scholar]

- Wang, T.; Samal, S.K.; Lim, S.K.; Shi, Y. Entropy Production-Based Full-Chip Fatigue Analysis: From Theory to Mobile Applications. IEEE Trans. Comput. Des. Integr. Circuits Syst. 2019, 38, 84–95. [Google Scholar] [CrossRef]

- Hashin, Z. A Relnterpretation of the Palmgren- miner Rule for Fatigue Life. J. Appl. Mech. 2016, 47, 324–328. [Google Scholar] [CrossRef]

- Smith, K.N.; Topper, T.H.; Watson, P. A stress–strain function for the fatigue of metals (stress-strain function for metal fatigue including mean stress effect). J. Mater. 1970, 5, 767–778. [Google Scholar]

- Lemaitre, J.; Desmorat, R. Engineering damage mechanics: ductile, creep, fatigue and brittle failures; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2005; ISBN 3540215034. [Google Scholar]

- Bhattacharya, B.; Ellingwood, B. Continuum damage mechanics analysis of fatigue crack initiation. Int. J. Fatigue 1998, 20, 631–639. [Google Scholar] [CrossRef]

- Ontiveros, V.; Amiri, M.; Kahirdeh, A.; Modarres, M. Thermodynamic entropy generation in the course of the fatigue crack initiation. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 423–434. [Google Scholar] [CrossRef]

- Harvey, S.E.; Marsh, P.G.; Gerberich, W.W. Atomic force microscopy and modeling of fatigue crack initiation in metals. Acta Metall. Mater. 1994, 42, 3493–3502. [Google Scholar] [CrossRef]

- Kumar, J.; Sundara Raman, S.G.; Kumar, V. Analysis and Modeling of Thermal Signatures for Fatigue Damage Characterization in Ti–6Al–4V Titanium Alloy. J. Nondestruct. Eval. 2016, 35, 1–10. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Sherbakov, S.S. Mechanothermodynamic entropy and analysis of damage state of complex systems. Entropy 2016, 18, 268. [Google Scholar] [CrossRef]

- Kahirdeh, A.; Khonsari, M.M. Energy dissipation in the course of the fatigue degradation: Mathematical derivation and experimental quantification. Int. J. Solids Struct. 2015, 77, 74–85. [Google Scholar] [CrossRef]

- Amiri, M.; Naderi, M.; Khonsari, M.M. An experimental approach to evaluate the critical damage. Int. J. Damage Mech. 2011, 20, 89–112. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Sherbakov, S.S. Mechanothermodynamical system and its behavior. Contin. Mech. Thermodyn. 2012, 24, 239–256. [Google Scholar] [CrossRef]

- Zhang, M.H.; Shen, X.H.; He, L.; Zhang, K.-S. Application of Differential Entropy in Characterizing the Deformation Inhomogeneity and Life Prediction of Low-Cycle Fatigue of Metals. Materials 2018, 11, 1917. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Sherbakov, S.S. A Model of Mechanothermodynamic Entropy in Tribology. Entropy 2017, 19, 115. [Google Scholar] [CrossRef]

- Sosnovskiy, L.; Sherbakov, S. Mechanothermodynamics; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-319-24979-7. [Google Scholar]

- Young, C.; Subbarayan, G. Maximum Entropy Models for Fatigue Damage in Metals with Application to Low-Cycle Fatigue of Aluminum 2024-T351. Entropy 2019, 21, 967. [Google Scholar] [CrossRef]

- Santecchia, E.; Hamouda, A.M.S.; Musharavati, F.; Zalnezhad, E.; Cabibbo, M.; El Mehtedi, M.; Spigarelli, S. A Review on Fatigue Life Prediction Methods for Metals. Adv. Mater. Sci. Eng. 2016, 2016, 9573524. [Google Scholar] [CrossRef]

- Haddad, W.M. Thermodynamics: The unique universal science. Entropy 2017, 19, 621. [Google Scholar] [CrossRef]

- Haddad, W.M.; Chellabonia, V.; Nersesov, S.G. Thermodynamics: A Dynamical Systems Approach; Princeton University Press: Princeton, NJ, USA, 2005; ISBN 0-691-12327-6. [Google Scholar]

- Basaran, C.; Yan, C.Y. A thermodynamic framework for damage mechanics of solder joints. J. Electron. Packag. Trans. ASME 1998, 120, 379–384. [Google Scholar] [CrossRef]

- Basaran, C.; Nie, S. An irreversible thermodynamics theory for damage mechanics of solids. Int. J. Damage Mech. 2004, 13, 205–223. [Google Scholar] [CrossRef]

- Basaran, C.; Tang, H. Implementation of a thermodynamic framework for damage mechanics of solder interconnect in microelectronic packaging. ASME Int. Mech. Eng. Congr. Expo. Proc. 2002, 11, 61–68. [Google Scholar]

- Basaran, C.; Lin, M.; Ye, H. A thermodynamic model for electrical current induced damage. Int. J. Solids Struct. 2003, 40, 1738–1745. [Google Scholar] [CrossRef]

- Gomez, J.; Basaran, C. A thermodynamics based damage mechanics constitutive model for low cycle fatigue analysis of microelectronics solder joints incorporating size effects. Int. J. Solids Struct. 2005, 42, 3744–3772. [Google Scholar] [CrossRef]

- Gomez, J.; Basaran, C. Damage mechanics constitutive model for Pb/Sn solder joints incorporating nonlinear kinematic hardening and rate dependent effects using a return mapping integration algorithm. Mech. Mater. 2006, 38, 585–598. [Google Scholar] [CrossRef]

- Tang, H.; Basaran, C. A damage mechanics-based fatigue life prediction model for solder joints. J. Electron. Packag. Trans. ASME 2003, 125, 120–125. [Google Scholar] [CrossRef]

- Temfack, T.; Basaran, C. Experimental verification of thermodynamic fatigue life prediction model using entropy as damage metric. Mater. Sci. Technol. 2015, 31, 1627–1632. [Google Scholar] [CrossRef]

- Wang, J.; Yao, Y. An entropy based low-cycle fatigue life prediction model for solder materials. Entropy 2017, 19, 503. [Google Scholar]

- Basaran, C.; Zhao, Y.; Tang, H.; Gomez, J. A damage-mechanics-based constitutive model for solder joints. J. Electron. Packag. Trans. ASME 2005, 127, 208–214. [Google Scholar] [CrossRef]

- Basaran, C.; Chandaroy, R. Thermomechanical analysis of solder joints under thermal and vibration loading. J. Electron. Packag. Trans. ASME 2002, 124, 60–66. [Google Scholar] [CrossRef]

- Basaran, C.; Li, S.; Abdulhamid, M.F. Thermomigration induced degradation in solder alloys. J. Appl. Phys. 2008, 103, 123520-1–123520-9. [Google Scholar] [CrossRef]

- Basaran, C.; Lin, M. Damage mechanics of electromigration induced failure. Mech. Mater. 2008, 40, 66–79. [Google Scholar] [CrossRef]

- Basaran, C.; Lin, M. Damage mechanics of electromigration in microelectronics copper interconnects. Int. J. Mater. Struct. Integr. 2007, 1, 16–39. [Google Scholar] [CrossRef]

- Basaran, C.; Nie, S. Time dependent behavior of a particle filled composite PMMA/ATH at elevated temperatures. J. Compos. Mater. 2008, 42, 2003–2025. [Google Scholar] [CrossRef]

- Basaran, C.; Nie, S. A thermodynamics based damage mechanics model for particulate composites. Int. J. Solids Struct. 2007, 44, 1099–1114. [Google Scholar] [CrossRef]

- Li, S.; Basaran, C. A computational damage mechanics model for thermomigration. Mech. Mater. 2009, 41, 271–278. [Google Scholar] [CrossRef]

- Lin, M.; Basaran, C. Electromigration induced stress analysis using fully coupled mechanical-diffusion equations with nonlinear material properties. Comput. Mater. Sci. 2005, 34, 82–98. [Google Scholar] [CrossRef]

- Shidong, L.; Abdulhamid, M.F.; Basaran, C. Simulating Damage Mechanics of Electromigration and Thermomigration. Simulation 2008, 84, 391–401. [Google Scholar] [CrossRef]

- Yao, W.; Basaran, C. Electromigration damage mechanics of lead-free solder joints under pulsed DC: A computational model. Comput. Mater. Sci. 2013, 71, 76–88. [Google Scholar] [CrossRef]

- Yao, W.; Basaran, C. Computational damage mechanics of electromigration and thermomigration. J. Appl. Phys. 2013, 114, 103708. [Google Scholar] [CrossRef]

- Cuadras, A.; Crisóstomo, J.; Ovejas, V.J.; Quilez, M. Irreversible entropy model for damage diagnosis in resistors. J. Appl. Phys. 2015, 118, 165103-1–165103-8. [Google Scholar] [CrossRef]

- Cuadras, A.; Romero, R.; Ovejas, V.J. Entropy characterisation of overstressed capacitors for lifetime prediction. J. Power Sources 2016, 336, 272–278. [Google Scholar] [CrossRef]

- Cuadras, A.; Yao, J.; Quilez, M. Determination of LEDs degradation with entropy generation rate. J. Appl. Phys. 2017, 122, 145702-1–145702-7. [Google Scholar] [CrossRef]

- Imanian, A.; Modarres, M. A thermodynamic entropy approach to reliability assessment with applications to corrosion fatigue. Entropy 2015, 17, 6995–7020. [Google Scholar] [CrossRef]

- Imanian, A.; Modarres, M. A thermodynamic entropy-based damage assessment with applications to prognostics and health management. Struct. Heal. Monit. 2018, 17, 1–15. [Google Scholar] [CrossRef]

- Jang, J.Y.; Khonsari, M.M. On the evaluation of fracture fatigue entropy. Theor. Appl. Fract. Mech. 2018, 96, 351–361. [Google Scholar] [CrossRef]

- Liakat, M.; Khonsari, M.M. Entropic characterization of metal fatigue with stress concentration. Int. J. Fatigue 2015, 70, 223–234. [Google Scholar] [CrossRef]

- Osara, J.A.; Bryant, M.D. A Thermodynamic Model for Lithium-Ion Battery Degradation: Application of the Degradation-Entropy Generation Theorem. Inventions 2019, 4, 23. [Google Scholar] [CrossRef]

- Osara, J.A.; Bryant, M.D. Thermodynamics of Fatigue: Degradation-Entropy Generation Methodology for System and Process Characterization and Failure Analysis. Entropy 2019, 21, 685. [Google Scholar] [CrossRef]

- Gomez, J.; Lin, M.; Basaran, C. Damage Mechanics Modeling of Concurrent Thermal and Vibration Loading on Electronics Packaging. Multidiscip. Model. Mater. Struct. 2006, 2, 309–326. [Google Scholar] [CrossRef]

- Amiri, M.; Khonsari, M.M. On the role of entropy generation in processes involving fatigue. Entropy 2012, 14, 24–31. [Google Scholar] [CrossRef]

- Wang, J.; Yao, Y. An entropy-based failure prediction model for the creep and fatigue of metallic materials. Entropy 2019, 21, 1104. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, W.; Wang, N.; Zhang, W. A copula entropy approach to dependence measurement for multiple degradation processes. Entropy 2019, 21, 724. [Google Scholar] [CrossRef]

- Yun, H.; Modarres, M. Measures of Entropy to Characterize Fatigue Damage in Metallic Materials. Entropy 2019, 21, 804. [Google Scholar] [CrossRef]

- Li, E.H.; Li, Y.Z.; Li, T.T.; Li, J.X.; Zhai, Z.Z.; Li, T. Intelligent analysis algorithm for satellite health under time-varying and extremely high thermal loads. Entropy 2019, 21, 983. [Google Scholar] [CrossRef]

- Sosnovskiy, L.A.; Sherbakov, S.S. On the Development of Mechanothermodynamics as a New Branch of Physics. Entropy 2019, 21, 1188. [Google Scholar] [CrossRef]

- Gunel, E.M.; Basaran, C. Damage characterization in non-isothermal stretching of acrylics. Part I: Theory. Mech. Mater. 2011, 43, 979–991. [Google Scholar] [CrossRef]

- Naderi, M.; Amiri, M.; Khonsari, M.M. On the thermodynamic entropy of fatigue fracture. Proc. R. Soc. A Math. Phys. Eng. Sci. 2010, 466, 423–438. [Google Scholar] [CrossRef]

- Naderi, M.; Khonsari, M.M. An experimental approach to low-cycle fatigue damage based on thermodynamic entropy. Int. J. Solids Struct. 2010, 47, 875–880. [Google Scholar] [CrossRef]

- Abdulhamid, M.F.; Basaran, C. Influence of thermomigration on lead-free solder joint mechanical properties. J. Electron. Packag. Trans. ASME 2009, 131, 011002. [Google Scholar] [CrossRef]

- Boltzmann, L. Ableitung des Stefan’schen Gesetzes, betreffend die Abhängigkeit der Wärmestrahlung von der Temperatur aus der electromagnetischen Lichttheorie. Ann. Phys. 1884, 258, 291–294. [Google Scholar] [CrossRef]

- Sharp, K.; Matschinsky, F. Translation of Ludwig Boltzmann’s paper “on the relationship between the second fundamental theorem of the mechanical theory of heat and probability calculations regarding the conditions for thermal equilibrium” Sitzungberichte der kaiserlichen akademie d. Entropy 2015, 17, 1971–2009. [Google Scholar] [CrossRef]

- Planck, M. On the Law of Distribution of Energy in the Normal Spectrum. Ann. Phys. 1901, 4, 553. [Google Scholar] [CrossRef]

- Lemaitre, J.; Chaboche, J.-L. Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1990; ISBN 0-521-32853-5. [Google Scholar]

- Voyiadjis, G.Z.; Faghihi, D. Thermo-mechanical strain gradient plasticity with energetic and dissipative length scales. Int. J. Plast. 2012, 30–31, 218–247. [Google Scholar] [CrossRef]

- Murakami, S. Continuum Damage Mechanics; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 9789400726659. [Google Scholar]

- Carrion, P.E.; Shamsaei, N.; Daniewicz, S.R.; Moser, R.D. Fatigue behavior of Ti-6Al-4V ELI including mean stress effects. Int. J. Fatigue 2017, 99, 87–100. [Google Scholar] [CrossRef]

- Murakami, S. Mechanical modeling of material damage. J. Appl. Mech. Trans. ASME 1988, 55, 280–286. [Google Scholar] [CrossRef]

- Spitzig, W.A.; Sober, R.J.; Richmond, O. Pressure dependence of yielding and associated volume expansion in tempered martensite. Acta Metall. 1975, 23, 885–893. [Google Scholar] [CrossRef]

- Mahnken, R. Strength difference in compression and tension and pressure dependence of yielding in elasto-plasticity. Comput. Methods Appl. Mech. Eng. 2001, 190, 5057–5080. [Google Scholar] [CrossRef]

| Material Parameter | Value | Unit |

|---|---|---|

| Young’s modulus, E | 106 | GPa |

| Poisson’s ratio, ν | 0.31 | |

| Density, | 4540 | kg/m3 |

| Critical TSI, | 1 | |

| Hardening parameter, | 968.00 | MPa |

| Hardening exponent, | 0.64 | |

| Yield strength, | 992.00 | MPa |

| Molar mass, | 0.047867 | kg/mol |

| Reference temperature, T | 298 | K |

| Material Parameter | Value | Unit |

|---|---|---|

| Young’s modulus, E | 118 | GPa |

| Poisson’s ratio, ν | 0.31 | |

| Density, | 4540 | kg/m3 |

| Critical TSI, | 1 | |

| Hardening parameter, | 550.00 | MPa |

| Hardening exponent, | 0.65 | |

| Yield strength, | 1047.00 | MPa |

| Molar mass, | 0.047867 | kg/mol |

| Reference temperature, T | 298 | K |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bin Jamal M, N.; Kumar, A.; Lakshmana Rao, C.; Basaran, C. Low Cycle Fatigue Life Prediction Using Unified Mechanics Theory in Ti-6Al-4V Alloys. Entropy 2020, 22, 24. https://doi.org/10.3390/e22010024

Bin Jamal M N, Kumar A, Lakshmana Rao C, Basaran C. Low Cycle Fatigue Life Prediction Using Unified Mechanics Theory in Ti-6Al-4V Alloys. Entropy. 2020; 22(1):24. https://doi.org/10.3390/e22010024

Chicago/Turabian StyleBin Jamal M, Noushad, Aman Kumar, Chebolu Lakshmana Rao, and Cemal Basaran. 2020. "Low Cycle Fatigue Life Prediction Using Unified Mechanics Theory in Ti-6Al-4V Alloys" Entropy 22, no. 1: 24. https://doi.org/10.3390/e22010024

APA StyleBin Jamal M, N., Kumar, A., Lakshmana Rao, C., & Basaran, C. (2020). Low Cycle Fatigue Life Prediction Using Unified Mechanics Theory in Ti-6Al-4V Alloys. Entropy, 22(1), 24. https://doi.org/10.3390/e22010024