1. Introduction

Vanilla (from

Vanilla planifolia Andrews) is one of the most popular sweet spices in the World, and is now produced throughout tropical and subtropical areas. Due to its attractive sweet flavor, vanilla is widely used or consumed in a variety of products, including herbal cigarettes, alcoholic beverages, foodstuffs and cosmetics [

1]. The major flavor constituent of vanilla extract is vanillin (4-hydroxy-3-methoxybenzaldehyde) [

2]. Although vanillin extraction has been studied for over 60 years, enzymatic extraction of vanilla tincture has rarely been reported.

Interest in the use of naturally-occurring flavors has increased dramatically in recent years, but since these natural flavorings belong to several different chemical classes, various extraction techniques must be used in order to obtain them [

3]. Many botanical raw materials are rich in important fats, flavorings and coloring compounds, but these are often difficult to separate as they are sequestered by plant fiber, in particular cellulose which has a compact structure [

4]. The use of enzymes to partially destroy the structure of the cell wall renders these intracellular compounds more readily available for separation and solvent extraction. Delgado-Vargas and Paredes-López [

5] have reported that greater quantities of pigment could be extracted from fresh marigolds treated with cellulolytic enzymes than from untreated marigolds, with the highest yield of carotenoids obtained using econase-CEP, a commercially-available cellulase enzyme. Traditional methods of extraction use large quantities of organic solvent applied for prolonged periods of time, but nonetheless often yield a low extraction rate. A newer approach involves the use of enzymatic processing as a pretreatment step before extraction with an organic solvent; this method is simpler, uses less organic solvent and is more effective than the traditional method [

6]. This technique thus shows genuine promise as an improved method for extracting components from plants.

Response surface methodology (RSM) is a collection of statistical and mathematical techniques useful for the improvement and optimization of complex processes. The main advantage of RSM is its ability to reduce the number of experimental trials needed to evaluate multiple parameters and their interactions, in order to provide sufficient information for statistically acceptable results [

7,

8]. It has been successfully demonstrated that this technique can be used for optimizing process variables [

9,

10].

Based on our preliminary experiments using this enzymatic technique, we have identified heating time, enzyme quantity and temperature to be key factors influencing extraction of vanillin. The overall objective of the present study was to investigate the effects of heating time, enzyme quantity and temperature on vanillin extraction, and to optimize the processing conditions using RSM to obtain high levels of vanillin.

2. Results and Discussion

2.1 Statistical Analysis

The experiments were carried out in a random order. The experimental plan was determined according to the quadratic regression rotation combination design. Values obtained from the extraction process are presented in

Table 1, while characteristics of the model for extraction yield are shown in

Table 2 and

Table 3. ANOVA confirmed the adequacy of the statistical models, since their

p values were less than 0.05, and they were statistically significant at the 95% confidence level. The models produced high determination coefficients (

R2 = 0.95) and low coefficients of variation (

CV = 1.02%). These results indicate that the experiments carried out had good precision and reliability. The significance of each coefficient was determined by the t value and the

p value, and these are listed in

Table 2. The smaller the magnitude of the

p value, the more significant is the corresponding coefficient. The fitted model equation was as follows (Equation 1):

Table 1.

Design program and experimental results of RSM.

Table 1.

Design program and experimental results of RSM.

| Exp. number | Heating Time | Enzyme quantity | Temperature | Extraction yield |

|---|

| /X1(h) | /X2 (mL) | /X3(°C) | /(mg/g) |

|---|

| 1 | 7.78 | 43.31 | 77.8 | 6.96 |

| 2 | 7.78 | 43.31 | 42.16 | 6.94 |

| 3 | 7.78 | 23.69 | 77.8 | 7.17 |

| 4 | 7.78 | 23.69 | 42.16 | 7.25 |

| 5 | 4.22 | 43.31 | 77.8 | 7.08 |

| 6 | 4.22 | 43.31 | 42.16 | 7.04 |

| 7 | 4.22 | 23.69 | 77.8 | 7.01 |

| 8 | 4.22 | 23.69 | 42.16 | 7.19 |

| 9 | 9 | 33.5 | 60 | 7.11 |

| 10 | 3 | 33.5 | 60 | 7.01 |

| 11 | 6 | 50 | 60 | 7.13 |

| 12 | 6 | 17 | 60 | 7.31 |

| 13 | 6 | 33.5 | 90 | 7.27 |

| 14 | 6 | 33.5 | 30 | 7.41 |

| 15 | 6 | 33.5 | 60 | 7.63 |

| 16 | 6 | 33.5 | 60 | 7.53 |

| 17 | 6 | 33.5 | 60 | 7.59 |

| 18 | 6 | 33.5 | 60 | 7.65 |

| 19 | 6 | 33.5 | 60 | 7.57 |

| 20 | 6 | 33.5 | 60 | 7.67 |

| R2 | | | | 0.95 |

| CV (%) | | | | 1.02 |

Table 2.

Variance analysis of extraction yield.

Table 3.

Variance analysis of the second-order regression model on extraction yield.

Table 3.

Variance analysis of the second-order regression model on extraction yield.

| Regression | DF | Sum of Squares | R-Square | F Value | p-value |

|---|

| Pr > F |

|---|

| Linear | 3 | 0.75522 | 0.0626 | 4.55 | 0.0295 |

| Quadratic | 3 | 1.036994 | 0.8601 | 62.44 | <.0001 |

| Cross product | 3 | 0.037809 | 0.0314 | 2.28 | 0.142 |

| Total Model | 9 | 1.150324 | 0.9541 | 23.09 | <.0001 |

2.3. Optimization

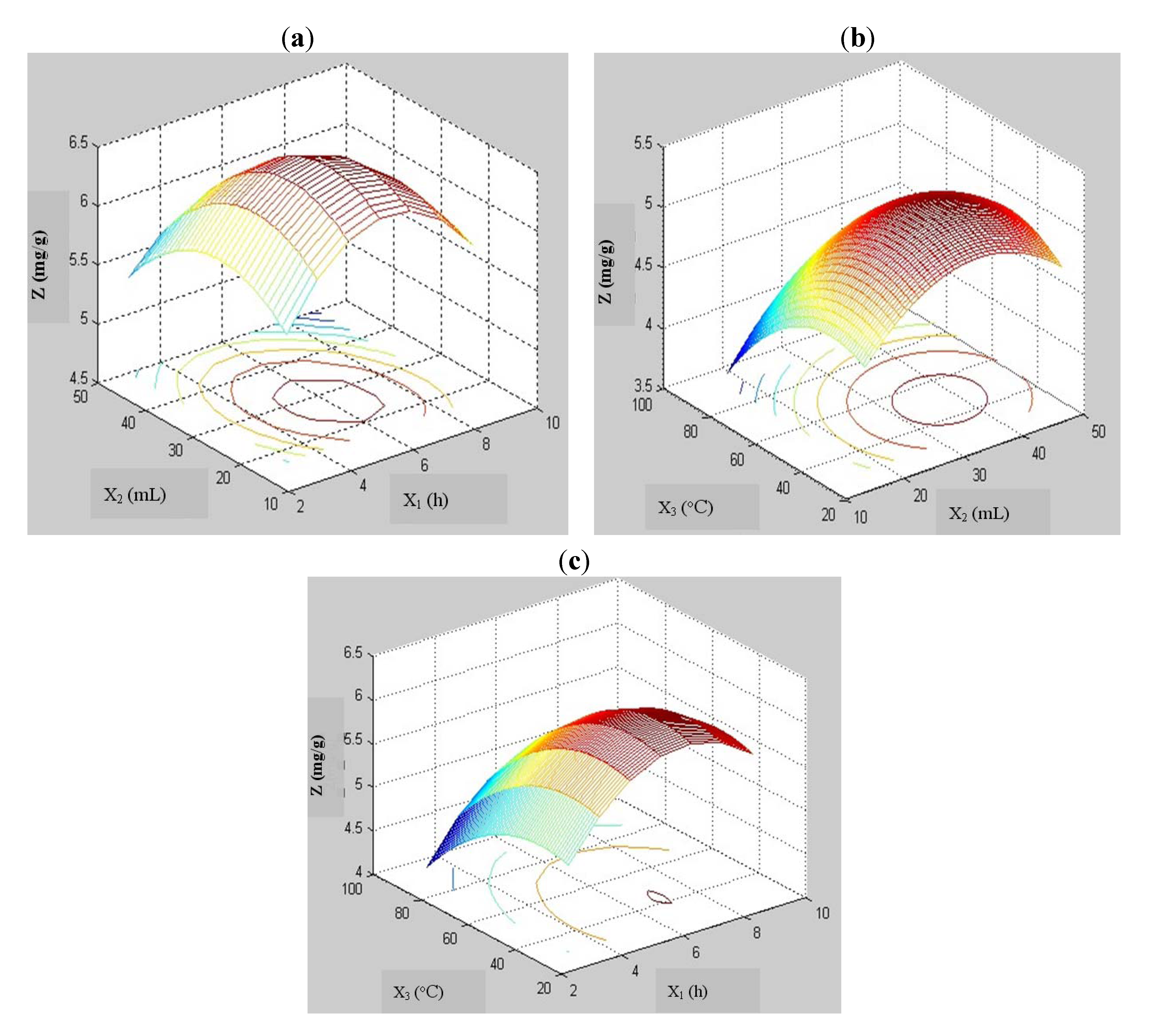

The optimal processing parameters were determined in order to maximize the vanillin extraction yield. The extraction yield may be optimized from the figures (

Figure 1a–c ). The zone of optimization depicts heating time to be in the range of 5.0–7.0 h, enzyme quantity to be in the range of 30–45 mL, and temperature to be in the range of 40–62 °C. The model describes the optimal conditions for extraction yield as: Heating time of 6 h; enzyme quantity of 33.5 mL; and temperature of 60 °C. The response (Z) calculated from the final polynomial function was an extraction yield of 7.62 mg/g.

The suitability of the model equation for predicting the optimum response values was tested using the recommended optimum conditions. This set of conditions was determined to be optimum by a RSM optimization approach, which was also used to experimentally validate and predict the value of the responses using model equations. The experimental values were found to be in agreement with the predicted ones. The optimal extraction yield of vanillin in this experiment was less than 8.06 mg/g, as has been described previously [

12]. This may be due to the different solvent, extraction time and pretreatment used; in the aforementioned study, the higher polarity of the solvent used may have facilitated the solubilization of vanillin (particularly glucovanillin), and use of heat pretreatment may also have improved vanillin extraction. In our study, pretreatment with enzyme dramatically reduced the time required for vanillin extraction from vanilla beans. The extraction time was far shorter than that of conventional methods, and RSM was shown to be effective for estimating the effects of processing variables [

13].

3. Experimental

3.1 Materials

Vanilla beans (from cured vanilla pods of

Vanilla planifolia Andrews) were obtained from the Spice and Beverage Research Institute (Hainan, China); the water and vanillin contents were 12.4% and 8.06 mg/g, respectively, determined using a method described previously [

6]. Cellulase (15 U/mg) was purchased from Shanghai Bioscience and Technology Co., Ltd (Shanghai, China). Standard vanillin was purchased from Sigma Chemical Company (St. Louis, MO, USA). Methanol (HPLC grade) and other chemicals (analytical grade) were sourced from Shanghai Chemical Reagent Co., Ltd. (Shanghai, China).

3.2. Hydrolysis and Vanillin Extraction

Vanilla beans were ground in a centrifugal grinding mill (type ZM-1) fitted with a 1 mm stainless steel sieve (Retsch, Haan, Germany). 10 g vanilla powder was mixed with 50 mL acetic acid buffer (pH 4.8) and cellulase in a 250 mL Erlenmeyer flask. The flask was sealed and placed in a water bath, and the process of enzymatic hydrolysis was allowed to proceed with stirring using a magnetic stirrer (IKA Works Inc., Wilmington, NC, USA). Heating time, cellulase quantity and water bath temperature were varied to allow their effects on vanillin liberation to be studied. After hydrolysis, the reaction was stopped by 10 min immersion in boiling water, and the mixture was allowed to cool. 200 mL ethanol was then added, and the mixture stirred at 50 rpm for 12 h at 35 °C. Following this, the mixture was centrifuged with a Z36 HK Super Speed Centrifuge (Labnet, USA) at 10,000 × g for 30 min at 20 °C, to separate the solid and liquid phases. 1 mL of liquid phase was removed for vanillin quantification using HPLC. The yield of vanillin extraction was expressed using Equation 2.

3.3. Determination of Vanillin by HPLC

Vanillin levels were quantified using a slight modification of methods described previously [

4,

6]. The HPLC system used was an Agilent 1260 series HPLC (Agilent Technologies, USA); separations were performed with a Zorbax Eclipse Plus C

18 (4.6 mm × 100 mm, 3.5 μm) analytical column (Agilent Technologies) operating at 30 °C. A wavelength of 280 nm was considered the most appropriate for vanillin quantification, as maximal vanillin absorbance was found at this wavelength, and no interference was observed from other compounds present in the ethanol extract. A methanol/water (pH 4, acidified with acetic acid) mobile phase gradient was used, as follows: 0.8 mL/min of 60%/40% acidified water/methanol for 3 min; 1 mL/min of 65%/35% acidified water/methanol for 9 min; 0.8 mL/min of 60%/40% acidified water/methanol. The injection volume was 3.0 μL.

3.4. Experimental Design

According to our previous experimental findings, the most influential factors affecting extraction yield were heating time, enzyme quantity and temperature. In order to evaluate the effects and interactions of these three factors, RSM was used in designing the experiment. SAS software (version 9.0, SAS Institute Inc., USA) was used to generate the quadratic regression rotation combination design. The independent variables were heating time (X

1), enzyme quantity (X

2) and temperature (X

3). Each independent variable had coded levels of −1.682, −1, 0, 1 and +1.682. This design was constructed based on a three-factor and a five-level Box–Wilson central composite design (CCD), leading to 20 sets of experiments, allowing each experimental response to be optimized. The experimental designs with regard to the coded (X) and actual heating times, enzyme quantities and temperature levels are shown in

Table 4. The response (Z) was the extraction yield (mg/g). The response function Z was related to the coded variables (Xi, i = 1, 2, 3) by a second-degree polynomial equation using the method of least squares (Equation 3):

where Z is the response value calculated by the model; X1, X2 and X3 are coded variables, corresponding to heating time, enzyme quantity and temperature, respectively. a1, a2 and a3 are the linear; a11, a22 and a33 are the quadratic; and a12, a13 and a23 are the cross-product effects of the X1, X2 and X3 factors on the response.

Analysis of variance (ANOVA) was performed, ANOVA tables generated, and the effects and regression coefficients of individual linear, quadratic and interaction terms were determined. The statistical significance of the regression coefficients was determined using a T-test, and the applicability of the model was assessed using coefficient of determination (R2) and coefficient of variation (CV) values. The optimal processing conditions were obtained using graphical and numerical analyses, based on the criterion of desirability.

Table 4.

Experimental design for the optimization of vanillin extraction.

Table 4.

Experimental design for the optimization of vanillin extraction.

| Code levels | Variables |

|---|

| X1/Heating time (h) | X2/Enzyme quantity (mL) | X3/Temperature (°C) |

|---|

| r = +1.682 | 9 | 50 | 90 |

| 1 | 7.78 | 43.31 | 77.8 |

| 0 | 6 | 33.5 | 60 |

| −1 | 4.22 | 23.69 | 42.2 |

| −r = −1.682 | 3 | 17 | 30 |

| △j | 1.78 | 9.81 | 17.8 |

4. Conclusions

Response surface methodology is a useful tool to investigate the optimal conditions with regard to heating time, enzyme quantity and temperature, for extracting vanillin from vanilla beans. The coefficient of determination (R2) values for all parameters showed a good fit between the model and the experimental data, at the 95% confidence level. Analysis of the different conditions (heating time, enzyme quantity and temperature) for vanillin extraction revealed that heating time and enzyme quantity had a significant effect on extraction yield, while other variables showed an optimal zone for vanillin extraction. These results fitted well with the experimental data, and the models obtained can be used to optimize the values of the variables.