1. Introduction

Locating new and versatile platform chemicals and biofuels from sustainable resources to replace those derived from petrochemicals is a central ongoing and urgent task prompted by depleting fossil fuel reserves and growing global warming concerns [

1,

2,

3,

4]. Alternative fine chemicals and biofuels that have been suggested to address some of these issues are butanol [

5], ethanol [

5], dimethylfuran [

1], 5-ethoxymethylfurfural [

2], γ-valerolactone, and alkanes produced from biomass [

6,

7]. Many of these alternatives rely on the efficient conversion of biomass carbohydrates into furfural derivatives. This is because biomass carbohydrates constitute 75% of the World’s renewable biomass and cellulose [

4] and as such, they represent a promising alternative energy and sustainable chemical feedstock. In this regard, 5-halomethyfurfurals such as 5-chloromethylfurfural (CMF) and 5-bromomethylfurfural (BMF) has received significant attention as platform chemicals for synthesizing a broad range of chemicals and liquid transportation fuels [

8,

9].

CMF and BMF are extremely reactive [

9] so that when subjected to further chemistries the provide a variety of important compounds for fine chemicals, pharmaceuticals, furan-based polymers and biofuels. These compounds include hydroxymethylfurfural (HMF) [

9,

10], 2,5-dimethylfuran (DMF) [

1], and 5-ethoxymethylfurfural (EMF) [

2], and some biologically active compounds [

11]. Among them, DMF and EMF stand out since they possess excellent properties, including high energy density, high boiling point and water stability. For these reasons, they have been promoted as novel biofuels. In particular, EMF has been the subject of considerable attention since it possesses an energy density of 8.7 kWhL

−1, substantially higher than that of ethanol (6.1 kWhL

−1), and comparable to that of standard gasoline (8.8 kWhL

−1) and diesel fuel (9.7 kWhL

−1) [

12]. Although, CMF and BMF themselves are not biofuels, they could readily be converted into EMF biofuels in ethanol in nearly quantitative yields.

The conventional synthesis of CMF involves the treatment of HMF or cellulose with dry hydrogen halide. More specifically, the hydroxyl group in HMF undergoes a facile halogen substitution reaction. Examples in the literature include those of Sanda

et al. who obtained CMF from the reaction of ethereal gaseous hydrogen chloride with HMF [

13]. Furthermore, while the conversion of cellulose into CMF was low (12%) [

14,

15], a substantially higher yield (48%) was obtained for the preparation of BMF when dry HBr was employed [

16]. Considering the importance of these compounds, Mascal

et al. recently reported the synthesis of CMF from cellulose treated by HCl-LiCl and successive continuous extraction [

2]. Unfortunately, 5-(chloromethyl)furfural, 2-(2-hydroxyacetyl)furan, 5-(hydroxylmethyl), furfural and levulinic acid were also produced with this system. More recently, Kumari

et al. reported the preparation of BMF from cellulose by a modified procedure using HBr-LiBr involving continuous extraction [

17]. Despite the numerous efforts aimed at these transformations, each of them suffers from at least one of the following limitations: diverse by-products in significant yields that reduce the selectivity of the reaction and its economics, low conversions and yields, harsh reaction conditions (dry hydrogen halide, relative high temperature), requirements for large amounts of costly reagents (LiCl, LiBr), prolonged reaction times and tedious operations with complex set ups (continuous extraction) [

18]. These drawbacks seriously hamper their potential industrial applications. Consequently, as part of our program aimed at developing new biofuels and fine chemicals based on biomass, we embarked our research for the development of efficient and economical methods aimed at converting carbohydrates to CMF under mild reaction conditions.

In this communication we demonstrate the use of the biphasic mixture HCl-H

3PO

4/CHCl

3 for the one-pot conversion of carbohydrates into CMF. The rational for the use of this biphasic approach is based on the thinking that as CMF is generated from HMF it is immediately transported and extracted from the aqueous acidic phase into the organic phase significantly minimizing by-product yields [

9].

2. Results and Discussion

Initial efforts using the biphasic treatment (HCl(37%)-H

3PO

4(85%)/CHCl

3) of the monosaccharide D-fructose at 45 °C for 20 h, offered a CMF yield of 35.8%. we then attempted to further optimize this result by systematically varying the volume ratio of HCl and H

3PO

4 (

Table 1), the nature of the non-aqueous solvent, the reaction time and temperature. This is due to the fact that

Table 1 deals only with the volume ratio of HCl and H

3PO

4. The effects of changing other variables are reported in Tables elsewhere.

Table 1.

The effect various reaction variables on CMF yields from D-fructose a.

Table 1.

The effect various reaction variables on CMF yields from D-fructose a.

| Entry | HCl/H3PO4 (v/v) | Temperature (°C) | Time (h) | Yields (mol%) b |

|---|

| 1 | 1/0 | 45 | 20 | 28.4 |

| 2 | 2/1 | 45 | 20 | 36.9 |

| 3 | 3/1 | 45 | 20 | 42.1 |

| 4 | 4/1 | 45 | 20 | 46.8 |

| 5 | 5/1 | 45 | 20 | 45.5 |

The data of

Table 1 indicates that the amount of hydrochloric acid in the biphasic medium plays an important role in this transformation. Increasing the amount of HCl in the system seemed to concomitantly increase the yield of CMF (

Table 1, entries 1–5). Even at lower volume ratios of HCl/H

3PO

4 such as 2:1, the yield of CMF was seen to increase by 8.5%, compared with the reaction with just hydrochloric acid (

Table 1, entries 1,2). H

3PO

4 offered enough hydrogen ions to promote the fructose selective conversion to CMF. The D-fructose molecule needs catalytic hydrogen ions to form fructofuranosyl intermediates, and the acid-induced elimination of three moles of water from this intermediate leads to the conversion to 5-hydroxymethyl-2-furaldehyde (HMF) [

19,

20]. As hydrochloric acid existed in the system, HMF could easily be transformed to 5-chloromethylfurfural (CMF). Increasing the mixed acid ratio (HCl/H

3PO

4) to 3:1 offered a CMF yield of 42.1% (

Table 1, entry 3). Further increases in the mixed acid ratio (HCl/H

3PO

4) offered only marginal yield increases in the CMF yield (

Table 1, entries 4,5). Therefore, in the dehydration reaction to produce CMF from fructose, HCl performed as a good mineral acid catalyst and provided the essential chloride for the production of CMF. Román-Leshkov

et al. also observed various acid catalysts used to implement the dehydration reaction, while HCl showed the highest catalytic ability amongst common mineral acids [

21].

The effect of reaction temperature was examined in detail by conducting CMF yield studies at 35, 45, and 55 °C at different ratios of HCl/ H

3PO

4 (

Table 2).

Table 2.

Effect of reaction temperature on the yields of CMF at different ratios of HCl/H3PO4a.

Table 2.

Effect of reaction temperature on the yields of CMF at different ratios of HCl/H3PO4a.

| Entry | HCl/H3PO4 (v/v) | Temperature (°C) | Time (h) | CMF Yield (mol %) b |

|---|

| 1 | 3/1 | 35 | 20 | 38.5 |

| 2 | 3/1 | 45 | 20 | 42.1 |

| 3 | 3/1 | 55 c | 20 | 38.8 |

| 4 | 4/1 | 35 | 20 | 43.9 |

| 5 | 4/1 | 45 | 20 | 46.8 |

| 6 | 4/1 | 55 | 20 | 42.8 |

| 7 | 5/1 | 35 | 20 | 43.2 |

| 8 | 5/1 | 45 | 20 | 45.5 |

| 9 | 5/1 | 55 | 20 | 40.2 |

Upon increasing the temperature from 35 to 45 °C, the yields of CMF were seen to increase, when the mixed acid ratio of HCl/H

3PO

4 was varied from 3:1, 4:1 and 5:1 (

Table 2, entries 1–9). At the temperature of 55 °C, however, all the CMF yields decreased somewhat compared to 45 °C (

Table 2, entries 1–9). This could be rationalized on the basis of different energies of activation for the different side-reactions being more pronounced at the slightly higher temperatures.

In the presence of acid catalysts, fructose could dehydrate to produce CMF and various by-products. Increasing temperatures improved the yields of by-products. The cyclic fructofuransyl intermediate pathway degraded by means of secondary reactions, such as fragmentation, condensation or other dehydration reactions. In this respect our data was consistent with similar research by Moreau

et al. [

22] and Antal

et al. [

23] that dealt with the D-fructose dehydration mechanism and the formation of HMF. Overall, at lower reaction temperatures, the mixed acids did not offer their catalytic role, and the yield of CMF was not high.

CMF yields obtained from the acid ratio (HCl/H

3PO

4) of 4:1 at different temperatures were seen to be higher than when the acid ratio was 3:1 or 5:1 (

Table 2, entries 1–9). As such the acid volume ratio and the reaction temperature were established to be 4:1 and 45 °C, respectively, for this transformation.

The immiscible organic solvent plays an important role in extracting the products formed during the acidic aqueous phase reaction, thud significantly reducing side reactions. The nature of the extraction solvent was thus further explored and it was verified that indeed chloroform (

Table 3, entry 1) was the extraction solvent of choice amongst all screened solvents. For example, 1, 2-dichlororethane (

Table 3, entry 2) and 1-chlorobutane (

Table 3, entry 3) were not able to extract all the CMF from the acidic aqueous phase, while toluene promoted a multitude of side reactions manifesting themselves in the complexity of the isolated product mixture. Unlike toluene, chloroform showed an excellent selectivity for extracting CMF from the acidic aqueous phase, simultaneously promoting reaction uniformity and reducing by-product diversity. Overall, this makes the work-up with chloroform and purification steps convenient with potential practical applications.

Table 3.

Effect of extraction solvent on reaction yields a.

Table 3.

Effect of extraction solvent on reaction yields a.

| Entry | Extraction Solvent | Temperature (°C) | Time (h) | CMF Yield (mol%) b |

|---|

| 1 | Chloroform | 45 | 20 | 46.8 |

| 2 | 1,2-Dichloroethane | 45 | 20 | 28.8 |

| 3 | 1-Chlorobutane | 45 | 20 | 22.6 |

| 4 | Toluene | 45 | 20 | --- c |

Finally the effect of reaction time was investigated using the optimized reaction conditions determined so far. A 10 h reaction time offered a CMF yield of only 34.6% (

Table 4, entry 1). Extending the reaction time to 20 h, dramatically increased the CMF yield by 12.2% (

Table 4, entries 1,2). Further extension of the reaction time did not offer additional CMF yield improvements (

Table 4, entries 3,4).

Table 4.

Effect of reaction time on reaction yields a.

Table 4.

Effect of reaction time on reaction yields a.

| Entry | HCl/H3PO4 (v/v) | Extractant | Temperature (°C) | Time (h) | CMF Yield (mol%) b |

|---|

| 1 | 4:1 | CHCl3 | 45 | 10 | 34.6 |

| 2 | 4:1 | CHCl3 | 45 | 20 | 46.8 |

| 3 | 4:1 | CHCl3 | 45 | 30 | 44.9 |

| 4 | 4:1 | CHCl3 | 45 | 40 | 45.2 |

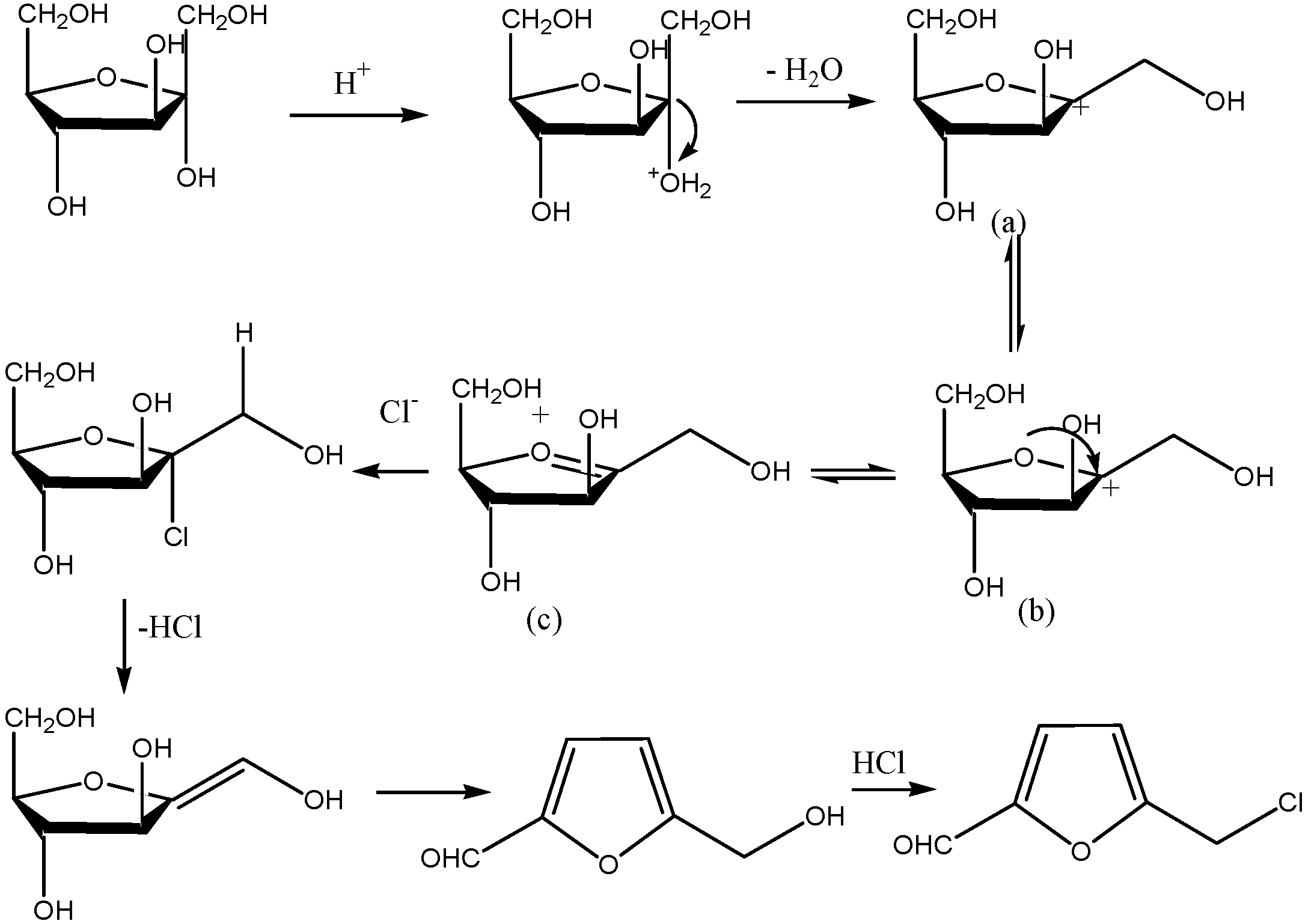

From the above analysis, a possible route of the fructose dehydration to form CMF as illustrated in

Scheme 1 can be suggested.

Scheme 1.

Possible route depicting the fructose dehydration to form CMF. Structures (a), (b) and (c) are fructofuransyl intermediates referred to in the text.

Scheme 1.

Possible route depicting the fructose dehydration to form CMF. Structures (a), (b) and (c) are fructofuransyl intermediates referred to in the text.

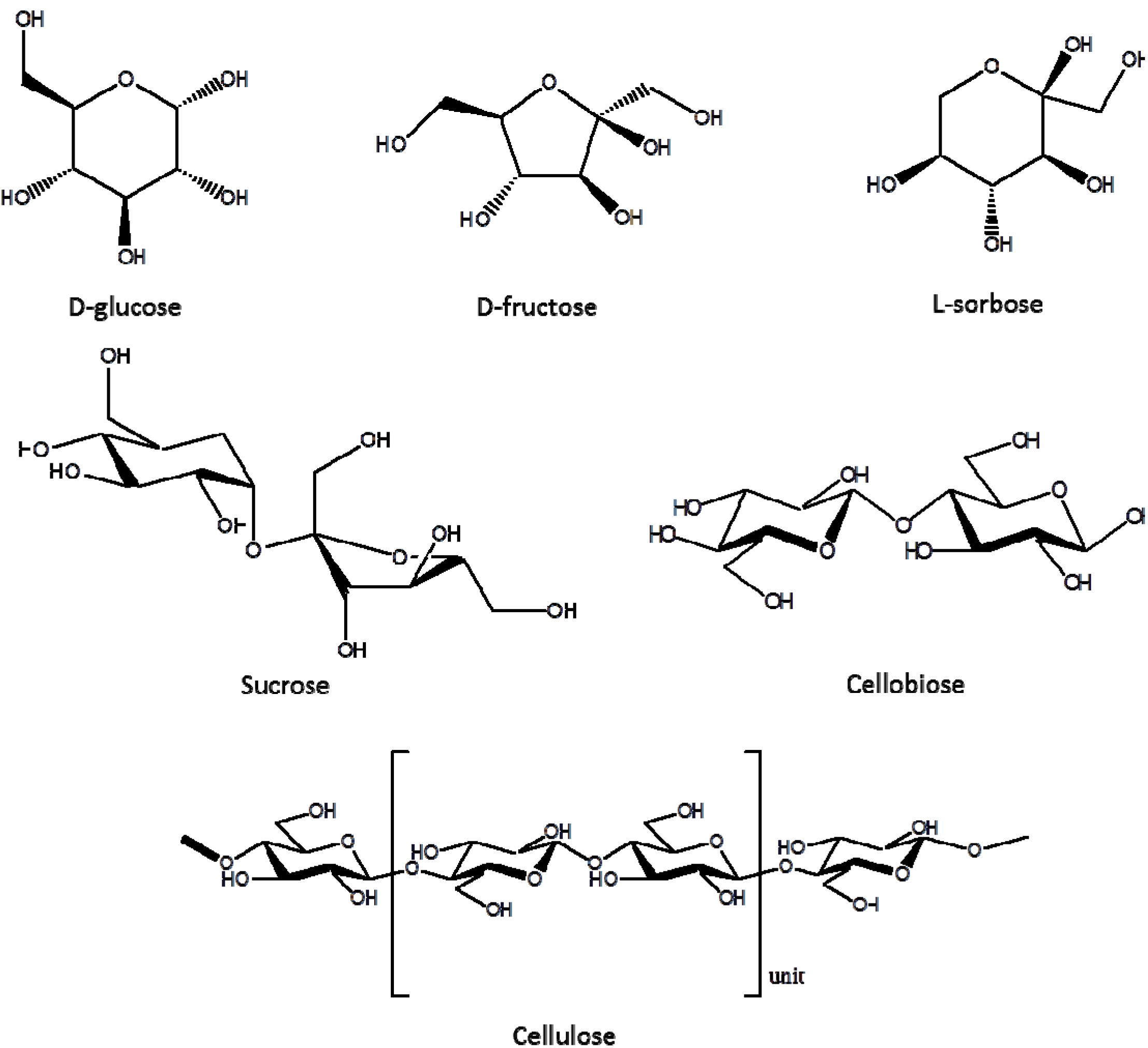

In an effort to further understand and chart the selectivity and general applicability of the proposed methodology a series of mono-saccharine, two disaccharides and a poly-saccharide were examined.

The data of

Table 5 showed that fructose offered the highest yields of CMF (

Table 5, entry 1), while glucose and cellulose the lowest (

Table 5, entries 2–6). Interestingly D-fructose and D-glucose, while they are chemically very similar (

Scheme 2), they produced significantly different yields of CMF (

Table 5, entries 1,2). This is most likely because with the ketohexose (D-fructose) was easier to form the fructofuransyl intermediate than with the aldohexose (D-glucose), due to the higher reactivity of ketohexoses. It is likely that D-glucose could not dehydrate directly and transform into fructofuransyl intermediates under our conditions. The glucose to fructose isomerization reaction seems to be a pre-requisite for the formed fructose to dehydrate and yield CMF under the mixed acid catalytic system we propose. Our contention is supported by Rosatella

et al. who proposed two methods to form the fructofuransyl intermediates, and the main one was the glucose to fructose isomerization reaction [

24]. Furthermore, Zhao

et al. [

25] and Huang

et al. [

26] observed that in order to obtain high HMF yields from glucose the selective

in situ isomerization of fructose was essential.

Table 5.

Effect of different carbohydrate substrate on CMF yields a.

Table 5.

Effect of different carbohydrate substrate on CMF yields a.

| Entry | Carbohydrate | CMF Yield (mol %) b |

|---|

| 1 | Fructose | 46.8 |

| 2 | Glucose | 7.3 |

| 3 | Sorbose | 16.4 |

| 4 | Sucrose | 43.1 |

| 5 | Cellobiose | 19.3 |

| 6 | Cellulose | 7.8 |

Scheme 2.

Structures of carbohydrates used and discussed in this work.

Scheme 2.

Structures of carbohydrates used and discussed in this work.

The monosaccharide sorbose offered a better CMF yield than D-glucose (

Table 5, entry 3), since it is a ketohexose. Although sorbose is one of the epimers (C-2 and C-3) of D-fructose (

Scheme 2), it had similar reactivity to D-glucose. Our data is further supported by that of Khajavi

et al. who has also documented that sorbose and glucose showed almost the same ability to produce HMF, but much lower than fructose [

27].

The disaccharide sucrose (

Scheme 2) comprised of linked fructose and glucose units afforded CMF yields similar to fructose (

Table 5, entry 4, 43.1 mol%). In the mixed acid aqueous medium, the sucrose molecule was quickly hydrolyzed into fructose and glucose. Almost all of the fructose could be selectively converted into CMF in the biphasic system, due to the higher CMF yield from sucrose. Literature data also reports that 90% fructose solutions (obtained from sucrose hydrolysis) can be converted into fructofuransyl intermediates, while the glucose residue remains nearly unchanged [

28]. Therefore, the overall activating nature of the carbonyl group in the C-2 position of the sugar seems to be apparent. Its absence (glucose and cellulose) dramatically reduces the reaction yields toward the production of CMF.

Cellobiose consists of two glucose molecules joined by equatorial C1-C4 glycosidic bonds (

Scheme 2). In an aqueous mixed acid solution, cellobiose was easily hydrolyzed to glucose molecules and as such it showed a somewhat higher CMF yield of 19.3% (

Table 5, entry 5), while the polysaccharide cellulose only showed similar yields as glucose (

Table 5, entry 6). The possible explanation for this observation was that cellulose is a high molecular weight linear polysaccharide, and its degradation involves the breaking of bonds between glucose units within the chain. As such the mixed acidic aqueous system might produce many random chain scissions, leading to many secondary reactions. Similar data have also been addressed in the literature by Emsley

et al. [

29] and Scheiding

et al. [

30].

Finally we examined various pulps and a wood powder for their potential to prepare CMF with the proposed methodology. Hardwood kraft pulp with the highest total sugar content (

Table 6), containing mostly cellulose and hemicellulose, (which can hydrolyze into glucose and xylose) offered a yield of CMF of 21.3 mol% (based on the glucose of the pulp). This was a much higher than either glucose or cellulose could offer by themselves (

Table 7, entry 1;

Table 5, entries 2,6). The softwood (Norway spruce) thermomechanical pulp offered CMF yields of 22.8% while the hardwood powdered wood gave a CMF yield of 31.4% (both figures based on total sugar contents of these samples) (

Table 7). These yields may be explained on the basis that mannose and other hexoses present in wood may also convert to fructofuransyl intermediates besides glucose. This data is supported by earlier efforts, where it was shown that mannose and glucose was of similar reactivity transforming to fructofuransyl intermediates producing hydroxymethylfurfural (HMF) [

27]. Overall, our data with the complete lignocellulosic substrate is encouraging since all wood components were present during the reaction (cellulose, lignin and hemicelluloses). Under these circumstances, we believe that the obtained yields of CMF were encouraging. Efforts in our laboratory are continuing to further promote these yields in the presence of selective catalysts in the system [

31].

Table 6.

Sugar contents present in the examined lignocellulosic materials.

Table 6.

Sugar contents present in the examined lignocellulosic materials.

| Lignocellulose Sample | Rhamnose(%) | Arabinose(%) | Galactose(%) | Glucose(%) | Xylose(%) | Mannose(%) | Total Sugars (%) |

|---|

| Eucalyptus Kraft pulp | 0.0 | 0.0 | 0.0 | 75.9 | 20.8 | 0.0 | 85.7 |

| Norway SpruceSoftwood TMP | 0.0 | 0.0 | 1.8 | 44.2 | 6.3 | 11.8 | 64.1 |

| Eucalyptus Hardwood | 0.0 | 0.0 | 1.3 | 45.0 | 17.5 | 0.9 | 64.7 |

Table 7.

Preparation of CMF with wood pulp and wood powder a.

Table 7.

Preparation of CMF with wood pulp and wood powder a.

| Entry | Lignocellulose Sample | CMF Yield (mol %) b | CMF Yield (mol %) c |

|---|

| 1 | Eucalyptus Kraft pulp | 21.3 | 16.0 |

| 2 | Norway Spruce softwood TMP | 33.7 | 22.8 |

| 3 | Eucalyptus hardwood | 47.4 | 31.4 |