Effects of Styrene-Acrylic Sizing on the Mechanical Properties of Carbon Fiber Thermoplastic Towpregs and Their Composites

Abstract

1. Introduction

2. Results and Discussion

2.1. Thermal Stability and Sizing Content

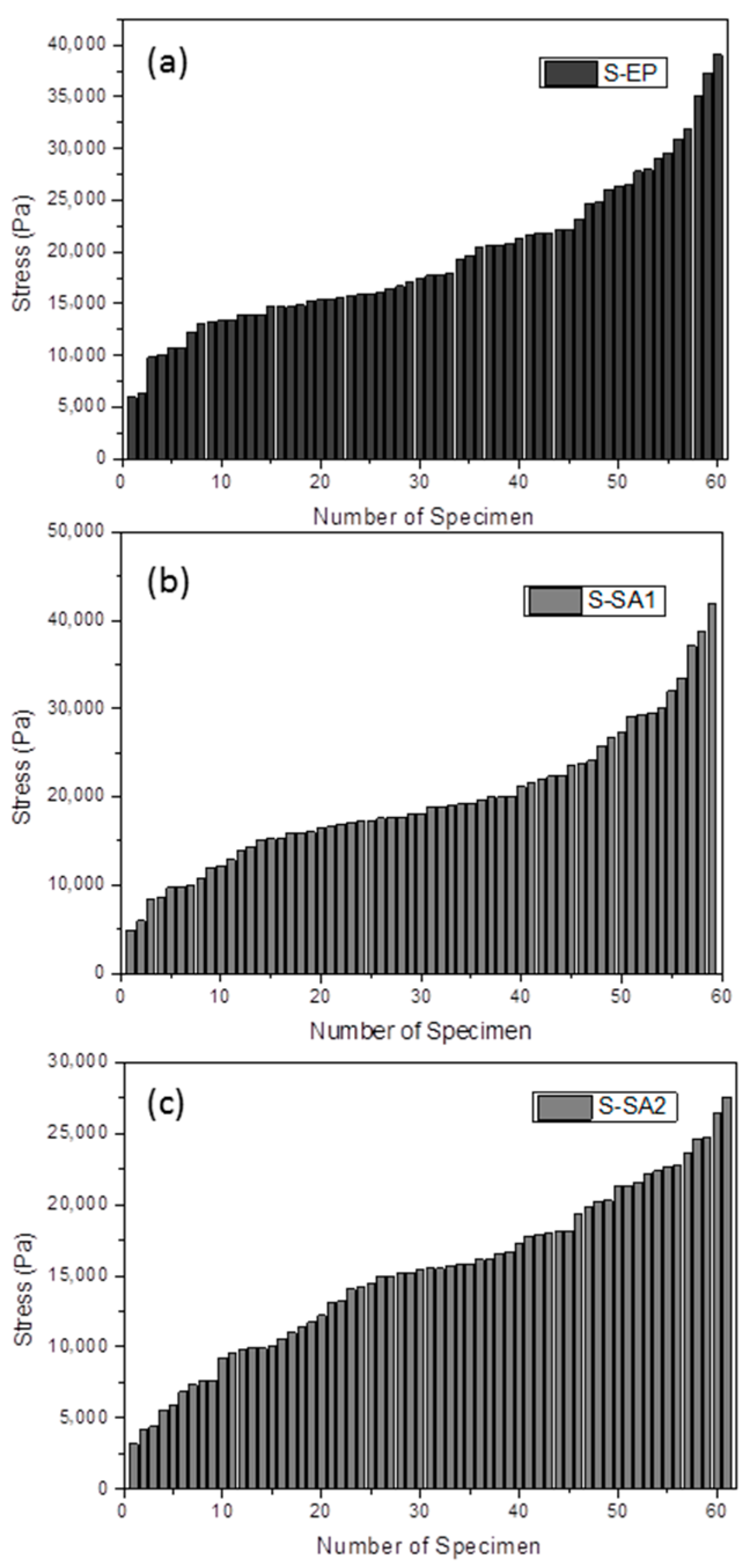

2.2. Protective Effects of Different Sizing Agents

2.3. Bending Rigidity of Carbon-Fiber Tows

2.4. Evaluation of the Towpregs

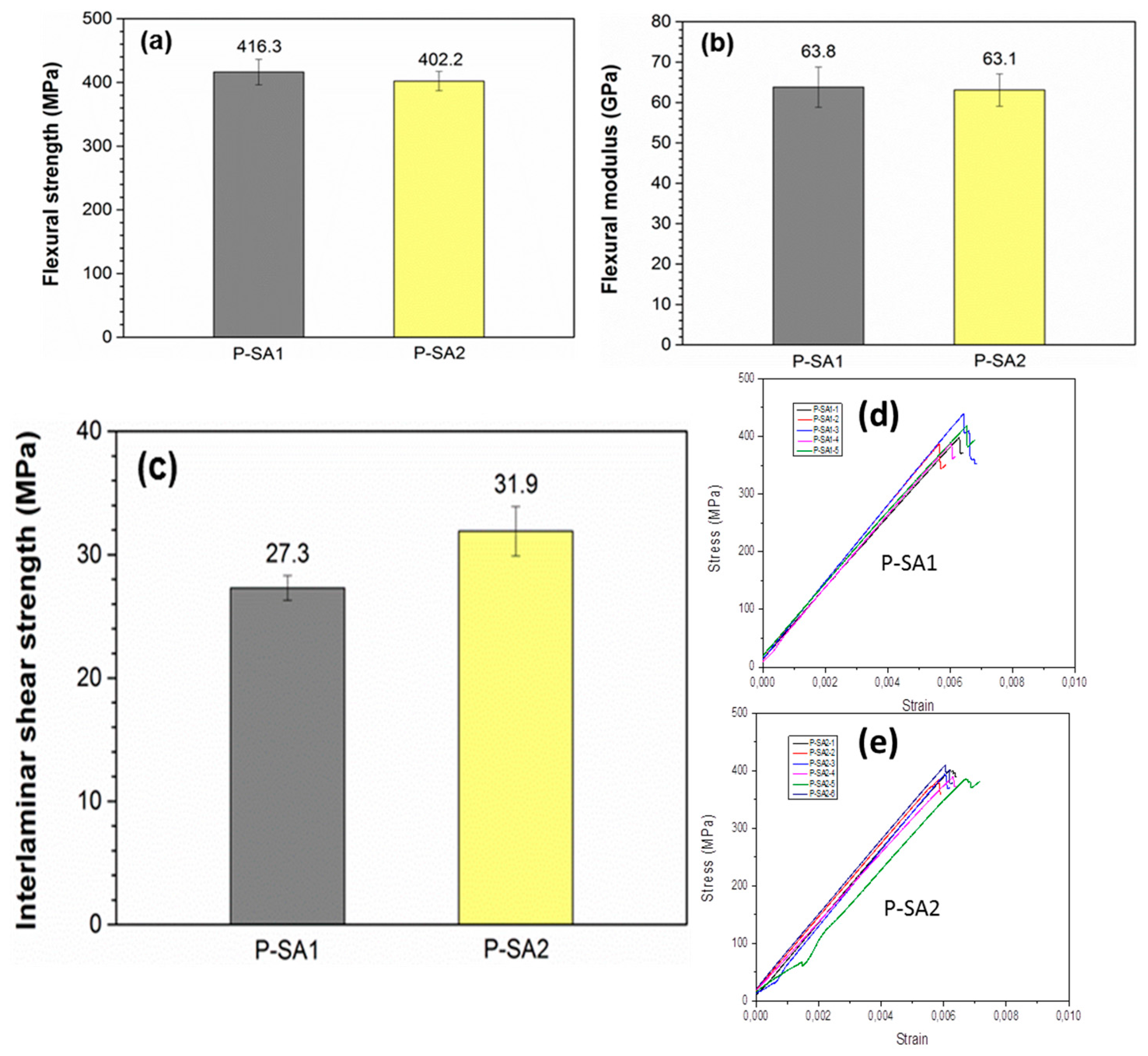

2.5. Mechanical Performances of Composite Panel

3. Materials and Methods

3.1. Materials

3.2. Sizing Process and Fabrication of Towpregs and Composite Panels

3.3. Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Martensson, P.; Zenkert, D.; Akermo, M. Method for the cost-efficient and weight-efficient material diversity and partitioning of a carbon fibre composite body structure. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015. [CrossRef]

- Dang, B.; Chen, Y.; Shen, X.; Chen, B.; Sun, Q.; Jin, C. Fabrication of a Nano-ZnO/Polyethylene/Wood-Fiber Composite with Enhanced Microwave Absorption and Photocatalytic Activity via a Facile Hot-Press Method. Materials 2017, 10, 1267. [Google Scholar] [CrossRef] [PubMed]

- Nair, S.N.; Dasari, A.; Yue, C.Y.; Narasimalu, S. Failure Behavior of Unidirectional Composites under Compression Loading: Effect of Fiber Waviness. Materials 2017, 10, 909. [Google Scholar] [CrossRef] [PubMed]

- Domun, N.; Paton, K.R.; Hadavinia, H.; Sainsbury, T.; Zhang, T.; Mohamud, H. Enhancement of Fracture Toughness of Epoxy Nanocomposites by Combining Nanotubes and Nanosheets as Fillers. Materials 2017, 10, 1179. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-W.; Park, S.-J.; Kim, Y.-H. Improvement of Interfacial Adhesion of Incorporated Halloysite-Nanotubes in Fiber-Reinforced Epoxy-Based Composites. Appl. Sci. 2017, 7, 441. [Google Scholar] [CrossRef]

- Sidorenko, D.; Loginov, P.; Mishnaevsky, L.; Levashov, E. Nanocomposites for Machining Tools. Materials 2017, 10, 1171. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.; Lou, C.-W.; Lin, J.-H. The Effects of Thermoplastic Polyurethane on the Structure and Mechanical Properties of Modified Polypropylene Blends. Appl. Sci. 2017, 7, 1254. [Google Scholar] [CrossRef]

- Ang, L.; Tran, L.; Phillips, S.; Koh, Y.; Lee, H. Low-Frequency Noise Reduction by Earmuffs with Coir and Coir/Carbon Fibre-Reinforced Polypropylene Ear Cups. Appl. Sci. 2017, 7, 1121. [Google Scholar] [CrossRef]

- Huang, C.-L.; Lou, C.-W.; Liu, C.-F.; Huang, C.-H.; Song, X.-M.; Lin, J.-H. Polypropylene/Graphene and Polypropylene/Carbon Fiber Conductive Composites: Mechanical, Crystallization and Electromagnetic Properties. Appl. Sci. 2015, 5, 1196–1210. [Google Scholar] [CrossRef]

- Martynenko, V.G.; Lvov, G.I. Numerical prediction of temperature-dependent anisotropic viscoelastic properties of fiber reinforced composite. J. Reinf. Plast. Compos. 2017, 36, 1790–1801. [Google Scholar] [CrossRef]

- Fang, X.; Shen, C.; Dai, G. Mechanical properties of unidirectional continuous fiber tapes reinforced long fiber thermoplastics and their manufacturing. J. Reinf. Plast. Compos. 2015, 35, 408–420. [Google Scholar] [CrossRef]

- Yamashita, S.; Hashimoto, K.; Suganuma, H.; Takahashi, J. Experimental characterization of the tensile failure mode of ultra-thin chopped carbon fiber tape-reinforced thermoplastics. J. Reinf. Plast. Compos. 2016, 35, 1342–1352. [Google Scholar] [CrossRef]

- Senthilvelan, S.; Gnanamoorthy, R. Selective Carbon Fiber Reinforced Nylon 66 Spur Gears: Development and Performance. Appl. Compos. Mater. 2005, 13, 43–56. [Google Scholar] [CrossRef]

- Smith, P.A. Carbon Fiber Reinforced Plastics-Properties. In Comprehensive Composite Materials II; Zweben, C.H., Beaumont, P.W.R., Eds.; Oliver Walter: Exeter, UK, 2000; pp. 342–359. [Google Scholar]

- Kagan, V.A.; Pinho, G.P. Laser Transmission Welding of Semicrystalline Thermoplastics—Part II: Analysis of Mechanical Performance of Welded Nylon. J. Reinf. Plast. Compos. 2016, 23, 95–107. [Google Scholar] [CrossRef]

- Drzal, L.T.; Iyer, S.R. Manufacture of Powder-impregnated Thermoplastics Composites. J. Thermoplast. Compos. Mater. 1990, 3, 325–355. [Google Scholar]

- Silva, J.F.; Nunes, J.P.; Velosa, J.C.; Bernardo, C.A.; Marques, A.T. Thermoplastic matrix towpreg production. Adv. Polym. Technol. 2010, 29, 80–85. [Google Scholar] [CrossRef]

- Nairn, J.A. Analysis of stress Transfer from the Matrix to the fiber Through an imperfect Interface: Application to Raman Data And the Single-Fiber Fragmentation test. ASTM STP 1290 1996. [CrossRef]

- Pitkethly, M.J. The use of Interfacial Test Methods in Composite Materials Development. ASTM STP 1290 1996. [CrossRef]

- Szczurek, A.; Barcikowski, M.; Leluk, K.; Babiarczuk, B.; Kaleta, J.; Krzak, J. Improvement of Interaction in a Composite Structure by Using a Sol-Gel Functional Coating on Carbon Fibers. Materials 2017, 10, 990. [Google Scholar] [CrossRef] [PubMed]

- Dai, Z.; Shi, F.; Zhang, B.; Li, M.; Zhang, Z. Effect of sizing on carbon fiber surface properties and fibers/epoxy interfacial adhesion. Appl. Surf. Sci. 2011, 257, 6980–6985. [Google Scholar] [CrossRef]

- Giraud, I.; Franceschi-Messant, S.; Perez, E.; Lacabanne, C.; Dantras, E. Preparation of aqueous dispersion of thermoplastic sizing agent for carbon fiber by emulsion/solvent evaporation. Appl. Surf. Sci. 2013, 266, 94–99. [Google Scholar] [CrossRef]

- Subramanian, S.; Lesko, J.J.; Reifsnider, K.L.; Stinchcomb, W.W. Damage Mechanisms and Failure Modes in Cross-Ply Laminates Under Monotonic Tensile Loading: The Influence of Fiber Sizing. Appl. Compos Mater. 1994, 1, 283–300. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Kabalnova, L. Effect of Sizing and Loading Levels on the Cure Kinetics of Carbon Fiber Vinylester Composites. J. Reinf. Plast. Compos. 2001, 20, 90–104. [Google Scholar] [CrossRef]

- Karahan, M.; Godara, A. Influence of carbon nanotubes grown on the fibres on damage progression in woven carbon-epoxy composites. J. Reinf. Plast. Compos. 2013, 32, 515–524. [Google Scholar] [CrossRef]

- Qian, X.; Wang, X.; OuYang, Q.; Chen, Y.; Yan, Q. Surface structural evolvement in electrochemical oxidation and sizing and its effect on carbon fiber/epoxy composites properties. J. Reinf. Plast. Compos. 2012, 31, 999–1008. [Google Scholar] [CrossRef]

- Zhang, H.; Li, W. Synergia effect of grafting polymer and coating on carbon fibers surface and interface of its composites. J. Reinf. Plast. Compos. 2014, 33, 1520–1528. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A.; Deniz, V. Effects of initial fiber length and fiber length distribution on the properties of carbon-fiber-reinforced-polypropylene composites. J. Reinf. Plast. Compos. 2012, 31, 1053–1060. [Google Scholar] [CrossRef]

- Thomason, J.L.; Adzima, L.J. Sizing up the interphase: an insider’s guide to the science of sizing. Compos. Part A Appl. Sci. Manuf. 2001, 32, 313–321. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, S.; Lu, C.; He, S.; An, F. Improved interfacial adhesion in carbon fiber/polyether sulfone composites through an organic solvent-free polyamic acid sizing. Appl. Surf. Sci. 2013, 279, 279–284. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, S.; Lu, C. Surface modification of carbon fibers by a polyether sulfone emulsion sizing for increased interfacial adhesion with polyether sulfone. Appl. Surf. Sci. 2014, 317, 737–744. [Google Scholar] [CrossRef]

- Gamze Karsli, N.; Ozkan, C.; Aytac, A.; Deniz, V. Characterization of poly(butylene terephthalate) composites prepared by using various types of sized carbon fibers. Mater. Des. 2015, 87, 318–323. [Google Scholar] [CrossRef]

- Cao, J.; Chung, D.D.L. Carbon fiber reinforced cement mortar improved by using acrylic dispersion as an admixture. Cem. Concr. Res. 2001, 31, 1633–1637. [Google Scholar] [CrossRef]

- Zhong, Z.; Yu, Q.; Yao, H.; Wu, W.; Feng, W.; Yu, L.; Xu, Z. Study of the styrene–acrylic emulsion modified by hydroxyl-phosphate ester and its stoving varnish. Prog. Org. Coat. 2013, 76, 858–862. [Google Scholar] [CrossRef]

- Yang, X.; Li, W. Some viscous behaviors of styrene-acrylic emulsion thickened with konjac glucomannan. Prog. Org. Coat. 2013, 76, 1396–1401. [Google Scholar] [CrossRef]

- Wypych, G. PA-6 polyamide-6. In Handbook of Polymers, 2nd ed.; ChemTec Publishing: Toronto, ON, Canada, 2016; pp. 215–220. [Google Scholar]

- Weibull, W. A Statistical Distribution Function of Wide Applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar]

- Park, J.P.; Park, C.; Cho, J.; Bahn, C.B. Effects of Cracking Test Conditions on Estimation Uncertainty for Weibull Parameters Considering Time-Dependent Censoring Interval. Materials 2016, 10, 3. [Google Scholar] [CrossRef] [PubMed]

- Bru, T.; Hellstrom, P.; Gutkin, R.; Ramantani, D.; Peterson, G. Characterisation of the mechanical and fracture properties of a uni-weave carbon fibre/epoxy non-crimp fabric composite. Data Brief 2016, 6, 680–695. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Chen, X.; Zhou, Y. Advanced weaving technologies for high-performance fabrics. High-Perform. Appar. 2018, 75–112. [Google Scholar] [CrossRef]

- Velosa, J.C.; Nunes, J.P.; Silva, A.F.; Bernardo, C.A.; Marques, A.T. Production of Thermoplastic Towpregs. Mater. Sci. Forum 2010, 636, 220–225. [Google Scholar] [CrossRef]

- Ho, H.; Drzal, L.T. Evaluation of interfacial mechanical properties of fiber reinforced composites using the microindentation method. Compos. Part A Appl. Sci. Manuf. 1996, 27, 961–971. [Google Scholar] [CrossRef]

- Drzal, L.T.; Herrera-Franco, P.J.; Ho, H. 5.05—Fiber–Matrix Interface Tests A2—Zweben, Anthony KellyCarl. In Comprehensive Composite Materials; Pergamon: Oxford, UK, 2000; pp. 71–111. [Google Scholar]

- Herrera-Franco, P.J.; Drzal, L.T. Comparison of methods for the measurement of fibre/matrix adhesion in composites. Composites 1992, 23, 2–27. [Google Scholar] [CrossRef]

- Ma, Y.; Ueda, M.; Yokozeki, T.; Sugahara, T.; Yang, Y.; Hamada, H. A comparative study of the mechanical properties and failure behavior of carbon fiber/epoxy and carbon fiber/polyamide 6 unidirectional composites. Compos. Struct. 2017, 160, 89–99. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds mentioned are not available from the authors. |

| Sized Fiber | S-SA1 | S-SA2 | S-EP |

|---|---|---|---|

| Max Stress (MPa) | 41.9 | 27.6 | 39.1 |

| Mean value (MPa) | 19.6 | 15.1 | 19.3 |

| P1 (%) | 13 | 10 | 3 |

| P2 (%) | 54 | 26 | 53 |

| P3 (%) | 25 | 44 | 33 |

| P4 (%) | 8 | 20 | 11 |

| Tow | Spec | Tensile Strength (GPa) | Tensile Modulus (GPa) | Elongation (%) | Linear Density (g/km) | Density (g/cm3) | Diameter (μm) |

|---|---|---|---|---|---|---|---|

| SYT 45 Carbon Fiber | 12k | 4.5 | 240 | 1.9 | 800 | 1.80 | 7 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bowman, S.; Jiang, Q.; Memon, H.; Qiu, Y.; Liu, W.; Wei, Y. Effects of Styrene-Acrylic Sizing on the Mechanical Properties of Carbon Fiber Thermoplastic Towpregs and Their Composites. Molecules 2018, 23, 547. https://doi.org/10.3390/molecules23030547

Bowman S, Jiang Q, Memon H, Qiu Y, Liu W, Wei Y. Effects of Styrene-Acrylic Sizing on the Mechanical Properties of Carbon Fiber Thermoplastic Towpregs and Their Composites. Molecules. 2018; 23(3):547. https://doi.org/10.3390/molecules23030547

Chicago/Turabian StyleBowman, Sean, Qiuran Jiang, Hafeezullah Memon, Yiping Qiu, Wanshuang Liu, and Yi Wei. 2018. "Effects of Styrene-Acrylic Sizing on the Mechanical Properties of Carbon Fiber Thermoplastic Towpregs and Their Composites" Molecules 23, no. 3: 547. https://doi.org/10.3390/molecules23030547

APA StyleBowman, S., Jiang, Q., Memon, H., Qiu, Y., Liu, W., & Wei, Y. (2018). Effects of Styrene-Acrylic Sizing on the Mechanical Properties of Carbon Fiber Thermoplastic Towpregs and Their Composites. Molecules, 23(3), 547. https://doi.org/10.3390/molecules23030547