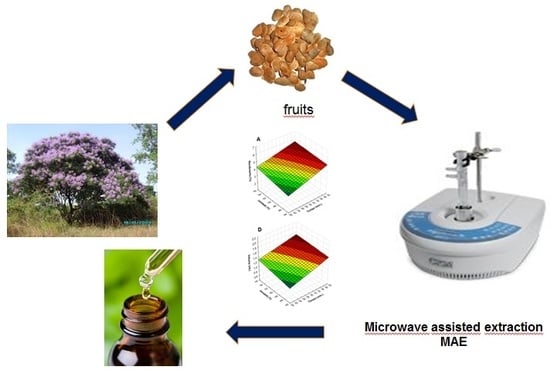

A Green Protocol for Microwave-Assisted Extraction of Volatile Oil Terpenes from Pterodon emarginatus Vogel. (Fabaceae)

Abstract

1. Introduction

2. Results

2.1. Optimisation of Microwave-Assisted Extraction of Volatile Oil

2.2. Volatile Oil Extraction

2.3. Analysis of the Chemical Composition by Gas Chromatography Mass Spectrometry (GC/MS)

3. Discussion

4. Materials and Methods

4.1. Botanical Material

4.2. Conventional Extraction (CE)

4.3. Microwave-assisted Extraction, Experimental Design (MAE) and Statistical Analysis

4.4. Yield of Volatile Oil

4.5. Characterisation of the Chemical Composition of Volatile Oils by Gas Chromatography/Mass Spectrometry (GC/MS)

4.6. Calculation of Energy Consumption

4.7. Calculation of Analytical Eco-Scale

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Polhill, R.M.; Raven, P.H. Advances in Legume Systematics, 1st ed.; Royal Botanic Gardens: Kew, UK, 1981; pp. 1–26. ISBN 0947643 540.

- Judd, W.S.; Campbell, C.S.; Kellogg, E.A.; Stevens, P.F. Plant Systematics: A Phylogenetic Approach; Sinauer Associates: Sunderlan, MA, USA, 1999; pp. 1–576. ISBN 0878934030. [Google Scholar]

- Souza, V.C.; Lorenzi, H. Botânica Sistemática: Guia Ilustrado para Identificação das Famílias de Angiospermas da Flora Brasileira, Baseado em APG II; Plantarum: Nova Odessa, Brazil, 2005; ISBN 8586714216 9788586714214. [Google Scholar]

- Ratter, J.A.; Ribeiro, J.F.; Briggewater, S. The Brazilian Cerrado vegetation and threats to its biodiversity. Ann. Bot. 1997, 80, 223–230. [Google Scholar] [CrossRef]

- Mendonça, R.C.; Felfili, J.M.; Walter, B.M.T.; Silva, M.C.; Rezende, A.V.; Filgueiras, A.V.; Nogueira, P.E. Flora Vascular do Cerrado. In Cerrado: Ambiente e Flora; Sano, S.M., de Almeida, S.P., Eds.; Planaltina: Brasilia, Brazil, 1998; pp. 289–556. ISBN 8570750080. [Google Scholar]

- Solereder, H. Systematic Anatomy of the Dicotyledons: A Handbook for Laboratories of Pure and Applied Botany; Clarendon Press: Oxford, UK, 1908; pp. 253–301. [Google Scholar]

- Almeida, M.E.; Gottlieb, O.R. Further isoflavones from Pterodon apparicioi. Phytochemistry 1975, 14, 2716–2720. [Google Scholar] [CrossRef]

- Moraes, W.F. Estudo Fitoquímico e Avaliação das Atividades Analgésica e Anti-Inflamatória do Extrato Etanólico, Frações e Substância Isolada da Casca do Caule de Pterodon Emarginatus Vog. (Sucupira). Master’s Thesis, Universidade Federal de Goiás, Goiânia, Brazil, 2007. Available online: http://livros01.livrosgratis.com.br/cp065661.pdf (accessed on 2 December 2017).

- Bustamante, K.G.L.; Figueiredo, A.D.L.; Soares, M.L.; Bara, M.T.F.; Ferreira, H.D.; Rezende, M.H.; Pimenta, F.C.; Paula, J.R. Avaliação da atividade antimicrobiana do extrato etanólico bruto da casca da sucupira branca (Pterodon emarginatus Vogel)—Fabaceae. Rev. Bras. Plant. Med. 2010, 2, 3. [Google Scholar] [CrossRef]

- Santos, A.P.; Zatta, D.T.; Moraes, W.F.; Bara, M.T.; Ferri, P.; Silva, M.R.; Paula, J.R. Composição química, atividade antimicrobiana do óleo essencial e ocorrência de esteróides nas folhas de Pterodon emarginatus Vogel, Fabaceae. Rev. Bras. Farmacogn. 2010, 20, 891–896. [Google Scholar] [CrossRef]

- Mors, W.B.; Santos, M.F.; Monteiro, H.J.; Gilbert, B.; Pellegrino, J. Chemoprophylactic agent in schistosomiasis: 14, 15-epoxygeranylgeraniol. Science 1967, 157, 950–951. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, J.C.T.; Sertié, J.A.A.; Barbosa, M.V.J.; Patricio, K.C.M.; Caputo, L.R.G.; Sarti, S.J.; Ferreira, L.P.; Bastos, J.K. Anti-inflamatory activity of the crude extract from the fruits of Pterodon emarginatus Vog. J. Ethnopharmacol. 1999, 64, 127–133. [Google Scholar] [CrossRef]

- Paula, F.B.A.; Gouvêa, C.M.C.P.; Alfredo, P.P.; Salgado, I. Protective action of a hexane crude extract of Pterodon emarginatus fruits against oxidative and nitrosative stress induced by acute exercise in rats. BMC Complement. Altern. Med. 2005, 5, 17. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, D.F. Estudo Químico e Avaliação Biológica de Attalea 11xcels Mart. Ex Spreng. (Urucuri) e Pterodon Emarginatus Vog. (Sucupira-Branca) em Aedes aegypti. Master’s Thesis, Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 2003. [Google Scholar]

- Ganzler, K.; Bati, J.; Valko, K. A new method for the extraction and high-performance liquid chromatographic determination of vicine and convicine in faba beans. Chromatography 1986, 84, 435–442. [Google Scholar]

- Campos, A.M.; Craveiro, A.A.; Teixeira, T.C. Óleo Essencial das Sementes de Pterodon polygalaeflorus Benth. In Resumos da 13a Reunião da Sociedade Brasileira de Química; PN-004; Comunicado Técnico: Caxambú, Brazil, 1990. [Google Scholar]

- Collin, G.J.; Lord, D.; Allaire, J.; Gagnon, D. Essential oil and microwave extracts. Parfums Cosmèt. Aromes 1991, 97, 105–112. [Google Scholar]

- Chen, S.S.; Spiro, M. Study of microwave extraction of essential oil constituents from plant materials. J. Microw. Power Electromagn. Energy 1994, 29, 231–241. [Google Scholar] [CrossRef]

- Lucchesi, M.E.; Chemat, F.; Smadja, J. Solvent-free microwave extraction: An innovative tool for rapid extraction of essential oil from aromatic herbs and spices. J. Microw. Power Electromagn. Energy 2004, 39, 135–139. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.W.; Liu, Y.Q.; Wei, S.L.; Yan, Z.J.; Lu, K. Comparison of microwave-assisted and conventional hydrodistillation in the extraction of essential oils from mango (Mangifera indica L.) flowers. Molecules 2010, 15, 7715–7723. [Google Scholar] [CrossRef] [PubMed]

- Kahriman, N.; Yayh, B.; Yücel, M.; Karaoglu, S.A.; Yayh, N. Chemical constituents and antimicrobial activity of the essential oil from Vicia dadianorum extracted by hydro and microwave distillations. Rec. Nat. Prod. 2012, 6, 49–56, ISSN 1307-6167. [Google Scholar]

- Phutdhawong, W.; Kawaree, R.; Sanjaiya, S.; Sengpracha, W.; Buddhasukh, D. Microwave-assisted isolation of essential oil of Cinnamomum iners Reinw. ex Bl.: Comparison with conventional hydrodistillation. Molecules 2007, 12, 868–877. [Google Scholar] [CrossRef] [PubMed]

- Abraham, W.R. Bioactive sesquiterpenes produced by fungi are they useful for humans as well? Curr. Med. Chem. 2001, 8, 583–606. [Google Scholar] [CrossRef] [PubMed]

- Vian, M.A.; Fernandez, X.; Visinoni, F.; Chemat, F. Microwave hydrodiffusion and gravity, a new technique for extraction of essential oils. J. Chromatogr. A. 2008, 1190, 14–17. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Zhang, Y.; Jiang, B. Comparison of microwave-assisted hydrodistillation with the traditional hydrodistillation method in the extraction of essential oils from dwarfed Cinnamomum camphora var. Linaolifera fujita leaves and twigs. Adv. J. Food Sci. Technol. 2013, 5, 1436–1442. [Google Scholar] [CrossRef]

- Gobbo-Neto, L.; Lopes, N.P. Plantas medicinais: Fatores de influência no conteúdo de metabólitos secundários. Quím. Nova 2007, 30, 374–381. [Google Scholar] [CrossRef]

- Santos, A.S.; Alves, S.D.M.; Figueirêdo, F.J.C.; da Rocha Neto, O.G. Descrição de Sistema e de Métodos de Extração de Óleos Essenciais e Determinação de Umidade de Biomassa em Laboratório, Embrapa Amazônia Oriental; Comunicado Técnico: Belém, Brazil, 2004. [Google Scholar]

- Velasco, C.A. Microwave Extraction of Peppermint Oil in Comparison to Current Practice Steam Extraction. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2007. [Google Scholar]

- Figueirêdo, F.J.C.; Alves, S.D.M.; Santos, A.S.; da Rocha Neto, O.G. Rendimento e Qualidade Físico-Química de Óleo Essencial Extraído de Diferentes Composições da Biomassa Área de Pimenta Longa; Boletim de Pesquisa e Desenvolvimento; Embrapa Amazônia Oriental: Belém, Brazil, 2004; Available online: https://ainfo.cnptia.embrapa.br/digital/bitstream/item/48556/1/Boletim-PD-33-AMAZ-ORIENTAL.pdf (accessed on 25 February 2018).

- Adams, R.P. Identification of Essential Oil Components by Gas Chromatography/Mass Spectroscopy; Allured Publishing Corporation; Carol Stream: New York, NY, USA, 2007; pp. 1–804. ISBN 9781932633214. [Google Scholar]

- Riese, J.; Grunewald, M.; Lier, S. Utilization of renewably generated power in the chemical process industry. Energ. Sustain. Soc. 2014, 4, 1–10. [Google Scholar] [CrossRef]

- Van Den Doll, H.; Kratz, P.D.J.A. Generalization of the retention index system including linear temperature programmed gas-liquid partition chromatography. J. Chromatogr. 1963, 11, 463–471. [Google Scholar] [CrossRef]

- Gałuszka, A.; Konieczka, P.; Migaszewski, Z.M.; Namie’snik, J. Analytical Eco-Scale for assessing the greenness of analytical procedures. Trends Anal. Chem. 2012, 37, 61–72. [Google Scholar] [CrossRef]

Sample Availability: Samples of the volatile oil extract from MAE and CE are available from the authors. |

| Run | Time (min)(X1) | Moisture (%)(X2) | Power (W)(X3) | Yield (% v/w) | Vol. (mL) |

|---|---|---|---|---|---|

| 1 | 21(−1) | 44(−1) | 220(−1) | 1.6 | 0.5 |

| 2 | 21(−1) | 44(−1) | 280(+1) | 5.3 | 1.6 |

| 3 | 21(−1) | 56(+1) | 220(−1) | 3.3 | 1.0 |

| 4 | 21(−1) | 56(+1) | 280(+1) | 5.3 | 1.6 |

| 5 | 39(+1) | 44 (−1) | 220(−1) | 3.3 | 1.0 |

| 6 | 39(+1) | 44 (−1) | 280(+1) | 6.6 | 2.0 |

| 7 | 39(+1) | 56(+1) | 220(−1) | 5.0 | 1.5 |

| 8 | 39(+1) | 56(+1) | 280(+1) | 6.0 | 1.8 |

| 9 | 30(0) | 50(0) | 250(0) | 3.6 | 1.1 |

| 10 | 30(0) | 50(0) | 250(0) | 3.6 | 1.1 |

| 11 | 30(0) | 50(0) | 250(0) | 3.3 | 1.0 |

| 12 | 30(0) | 50(0) | 250(0) | 3.6 | 1.1 |

| 13 | 30(0) | 50(0) | 250(0) | 3.6 | 1.1 |

| Source of Variation a | Sum of Square | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| X1 | 3.65 | 1 | 3.65 | 202.50 | 0.00014 b |

| X12 | 3.14 | 1 | 3.14 | 174.38 | 0.00019 b |

| X2 | 0.98 | 1 | 0.98 | 54.44 | 0.00180 b |

| X3 | 12.50 | 1 | 12.50 | 694.44 | 0.00001 b |

| X1X2 | 0.04 | 1 | 0.04 | 2.50 | 0.18900 d |

| X1X3 | 0.25 | 1 | 0.25 | 13.61 | 0.02103 c |

| X2X3 | 2.00 | 1 | 2.00 | 111.11 | 0.00046 b |

| Lack of fit | 0.04 | 1 | 0.04 | 2.50 | 0.18900 d |

| Pure error | 0.07 | 4 | 0.02 | ||

| Total sum of squares | 22.67 | 12 | |||

| R2adj | 0.9876 |

| Extraction | Medium Volume and Medium Yield | |

|---|---|---|

| Volume (mL) | Yield (% v/w) | |

| MAE | 1.73 | 5.76 |

| CE* | 1.80 | 3.60 |

| CE** | 0.22 | 0.44 |

| Methods | Conventional | PPs | Microwave | PPs |

|---|---|---|---|---|

| Reagents | Biomass Sample: 50 g | 2 | Biomass Sample: 30 g | 2 |

| H2O: 500 mL | 3 | H2O: 13.2 mL | 2 | |

| Instruments | Hot plate (2.6 kW/h) | 2 | Microwave | 0 |

| GC/MS | 2 | GC/MS | 2 | |

| Occupation hazard | 0 | Occupation hazard | 0 | |

| Waste | 5 | Waste | 5 | |

| Total Penalty Points | 14 | 11 | ||

| Analytical Eco-Scale Score | 86 | 89 | ||

| RI | Compound | MAE (%) | CE (%) | Chemical Properties |

|---|---|---|---|---|

| 1436 | γ-Elemene | 1.16 | 7.02 | Molecular formula C15H24 CAS 5951-67-7 Molecular weight 204.352 Boiling point 125 °C at 8 mmHg Relative density 0.8782 at 20 °C Refraction index 1.5130 at 26 °C Soluble in benzene and acetone |

| 1376 | α-Copaene | 3.54 | 1.05 | Molecular formula C15H24 CAS-3856-25-5 Molecular weight 204.352 Boiling point 248 °C at 760 mmHg and 124 °C at 15 mmHg Relative density 0.8996 at 20 °C Refraction index 1.4894 at 20 °C Soluble in ethanol acetone, acetic acid e ligroin |

| 1494 | E-Caryophyllene | 25.65 | 6.75 | Molecular formula C15H24 CAS 87-44-5 Molecular weight 204.352 Boiling point 262–264 °C at 760 mmHg, 122 °C at 13.5 mmHg and 118–119 °C at 9.7 mmHg Relative density 0.9075 at 20 °C Refraction index 1.4986 at 20 °C Very soluble in benzene |

| 1454 | α-Humulene | 4.92 | 2.49 | Molecular formula C15H24 CAS 6753-98- 6Molecular weight 204.352 Boiling point 166–168 °C at 760 mmHg and 123 °C at 10 mmHg Relative density 0.8905 at 20 °C Refraction index 1.5038 at 20 °C |

| 1531 | trans-α-Bisabolol | 6.24 | -- | Molecular formula C15H24 CAS 17627-44-0 Molecular weight 222.36 Boiling point 153 °C at 12 mmHg mmHg and 123 °C at 10 mmHg Relative density 0.9211 at 20 °C Refraction index 1.493–1.497 at 20 °C Soluble in ethanol, isopropanol and parafin |

| 1469 | allo-Aromadendrene | 1.31 | 0.92 | Molecular formula C15H24 CAS 25246-27-9 Molecular weight 222.36 Boiling point 265–267 °C at 760 mmHg Relative density 0.923 at 20 °C Refraction index 1.501 at 20 °C |

| 1523 | cis-Sesquisabinene | 1.23 | 0.70 | Molecular formula C15H24 Molecular weight 204.352 Boiling point 286 °C at 760 mmHg (predictive value). |

| 1479 | γ-Muurolene | 48.03 | 47.31 | Molecular formula C15H24 Molecular weight 204.352 Boiling point 126 °C at 12 mmHg Relative density 0.9182 at 20 °C Refraction index 1.3166 at 20 °C |

| Variables | Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| X1 | 21 | 30 | 39 |

| X2 | 44 | 50 | 56 |

| X3 | 220 | 250 | 280 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vila Verde, G.M.; Barros, D.A.; Oliveira, M.S.; Aquino, G.L.B.; M. Santos, D.; De Paula, J.R.; Dias, L.D.; Piñeiro, M.; M. Pereira, M. A Green Protocol for Microwave-Assisted Extraction of Volatile Oil Terpenes from Pterodon emarginatus Vogel. (Fabaceae). Molecules 2018, 23, 651. https://doi.org/10.3390/molecules23030651

Vila Verde GM, Barros DA, Oliveira MS, Aquino GLB, M. Santos D, De Paula JR, Dias LD, Piñeiro M, M. Pereira M. A Green Protocol for Microwave-Assisted Extraction of Volatile Oil Terpenes from Pterodon emarginatus Vogel. (Fabaceae). Molecules. 2018; 23(3):651. https://doi.org/10.3390/molecules23030651

Chicago/Turabian StyleVila Verde, Giuliana M., Diogo A. Barros, Marilene Silva Oliveira, Gilberto L.B. Aquino, Danilo M. Santos, José Realino De Paula, Lucas D. Dias, Marta Piñeiro, and Mariette M. Pereira. 2018. "A Green Protocol for Microwave-Assisted Extraction of Volatile Oil Terpenes from Pterodon emarginatus Vogel. (Fabaceae)" Molecules 23, no. 3: 651. https://doi.org/10.3390/molecules23030651

APA StyleVila Verde, G. M., Barros, D. A., Oliveira, M. S., Aquino, G. L. B., M. Santos, D., De Paula, J. R., Dias, L. D., Piñeiro, M., & M. Pereira, M. (2018). A Green Protocol for Microwave-Assisted Extraction of Volatile Oil Terpenes from Pterodon emarginatus Vogel. (Fabaceae). Molecules, 23(3), 651. https://doi.org/10.3390/molecules23030651